Guidelines for Designating Biobased Products for Federal Procurement

Guidelines for Designating Biobased Products for Federal Procurement

BEES Please for USDA--User Guide_OMBtoFeb2011 (2)

Guidelines for Designating Biobased Products for Federal Procurement

OMB: 0503-0011

User Guide

Remi Coulon

PricewaterhouseCoopers

Ecobalance, Inc.

Barbara Lippiatt

U.S. Department of Commerce

National Institute of Standards and Technology

With Support From:

U.S. Environmental Protection Agency

NOTE: This survey contains collection of information requirements subject to the Paperwork Reduction Act. Notwithstanding any other provisions of the law, no person is required to respond to, nor shall any person be subject to penalty for failure to comply with, a collection of information subject to the requirements of the Paperwork Reduction Act. The estimate response time for this survey is 62.5 hours. The response time includes the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information. Send Comments regarding this estimate or any other aspects of this collection of information, including suggestions for reducing the length of this questionnaire, to the National Institute of Standards and Technology, Attn., Barbara Lippiatt, NIST, 100 Bureau Drive, Stop 8603, Gaithersburg, MD 20899. The OMB number for this survey is 0693-0036, expiring on February 28, 2011.

CONTENTS

Foreword

SECTION I - Basic concepts

1 Definition of the System Boundaries 3

2 Allocation Rules 3

SECTION II - Understanding the questionnaire

3 Site Questionnaire 5

3.1 Information Requested 5

3.2 Possible Sources of On-site Information 6

3.3 Principles Applicable to the Site Questionnaire 6

3.3.1 Principle 1: Some Flows may be Neglected 6

3.3.2 Principle 2: General Site Operations are Excluded 6

3.3.3 Principle 3: Only Flows that Cross the Site Boundaries are Recorded 7

3.3.4 Principle 4: Input/Output Reporting Rules 8

3.4 General Organization of the Site Questionnaire 8

4 Use Phase Questionnaire 9

SECTION III - COMPLETING THE questionnaire

5 Site Questionnaire 10

5.1 Column C: Units 11

5.2 Column D: Quantity 11

5.3 Columns E, F and G : Data Quality 11

5.3.1 Column E: Data Source 12

5.3.2 Column F: Data Type 12

5.3.3 Column G: Collection Date 12

5.3.4 Data Quality Summary 12

5.4 Column H: On-Site Utility Quantities 13

5.5 Columns I, J and K: Data Quality 13

5.6 Column X and Y: Transport of Materials to Site 14

6 Use Phase Questionnaire 14

6.1 General Questions 14

6.2 Installation and Maintenance Data 15

Foreword

The National Institute of Standards and Technology (NIST) is gathering data to develop environmental profiles of biobased products. The goal is to support section 9002 of the 2002 Farm Security and Rural Investment Act (Public Law 107-171) and Executive Order 13101, “Greening the Government through Waste Prevention, Recycling, and Federal Acquisition” by applying metrics enabling consideration of the life-cycle performance of biobased products in Federal purchase decisions. Spending $200 billion/year on goods and services, the Federal Government’s procurement practices set a strong example for others to follow. Under sponsorship of the U.S. EPA Environmentally Preferable Purchasing Program, the U.S. Department of Agriculture, and NIST, BEES supports these initiatives encouraging Federal agencies to purchase environmentally-preferable, cost-effective products. We need information on your products so that Federal personnel may consider them in their environmentally-preferable purchase decisions.

Please return your completed questionnaire to [email protected]. If email is not possible, please copy the completed questionnaire to a blank diskette and mail to:

Barbara C. Lippiatt

100 Bureau Drive, Stop 8603

National Institute of Standards and Technology

Gaithersburg, MD 20899-8603

For assistance in completing the questionnaire, contact Barbara Lippiatt at [email protected] or (301) 975-6133.

SECTION I

Basic Concepts

BEES quantifies environmental performance using the increasingly popular, multi-disciplinary approach known as life-cycle assessment (LCA). LCA is a “cradle-to-grave,” systems approach for measuring environmental performance currently being standardized by the International Standards Organization (ISO).1 The approach is based on the belief that all stages in the life of a product generate environmental impacts and must therefore be analyzed, including raw materials acquisition, product manufacture, transportation, installation, operation and maintenance, and ultimately recycling and waste management. An analysis that excludes any of these stages is limited because it ignores the full range of upstream and downstream impacts of stage-specific processes.

The strength of environmental life-cycle assessment is its comprehensive, multi-dimensional scope. Many green claims and strategies are now based on a single life-cycle stage or a single environmental impact. A product is claimed to be green simply because it has recycled content, or claimed not to be green because it emits volatile organic compounds (VOCs) during its installation and use. These single-attribute claims may be misleading because they ignore the possibility that other life-cycle stages, or other environmental impacts, may yield offsetting impacts. For example, the recycled content product may have a high embodied energy content, leading to resource depletion, global warming, and acid rain impacts during the raw materials acquisition, manufacturing, and transportation life-cycle stages. LCA thus broadens the environmental discussion by accounting for shifts of environmental problems from one life-cycle stage to another, or one environmental medium (land, air, water) to another. The benefit of the LCA approach is in implementing a trade-off analysis to achieve a genuine reduction in overall environmental impact, rather than a simple shift of impact.

The general LCA methodology involves four steps.2 The goal and scope definition step spells out the purpose of the study and its breadth and depth. The inventory analysis step identifies and quantifies the environmental inputs and outputs associated with a product over its entire life-cycle. Environmental inputs include water, energy, and other resources; outputs include releases to air, land, and water. However, it is not these inputs and outputs, or inventory flows, that are of direct interest. We are most interested in their consequences, or impacts on the environment. Thus, the next LCA step, impact assessment, characterizes these inventory flows in relation to a set of environmental impacts. For example, the impact assessment step might relate carbon dioxide emissions, a flow, to global warming, an impact. Finally, the interpretation step combines the environmental impacts in accordance with the goals of the LCA study.

We need you help with the second LCA step, inventory analysis. During this step, a life cycle inventory is compiled which records material and energy flows into and out of a product system. Based on your completed questionnaire, NIST will compile a life-cycle inventory for your product and integrate it into BEES, which conducts a life-cycle impact assessment to estimate the impacts of your inventory flows. BEES also facilitates the LCA interpretation step synthesizing impact scores into an aggregate environmental performance score for your product.

This section defines the scope of the BEES LCA to give context to our request for your help with inventory analysis.

1Definition of the System Boundaries

Life-cycle assessment evaluates environmental impacts across all stages in the life of a product: raw materials acquisition, product manufacture, transportation, use, and end of life. Since you are not likely to have detailed environmental performance data for the extraction and production of the raw materials you consume, we are not asking for these data. Rather, this questionnaire includes data mainly on the product manufacturing step you control, from raw materials entering your plant to the finished products ready to be shipped from your plant. The questionnaire also contains optional questions on the use phase of your product (including product installation and maintenance), as well as questions on its disposition at the end of its useful life (including recyclability and product density for solid waste concerns).

The final life-cycle inventory NIST will compile for your product will include all life-cycle stages, with raw material acquisition data collected from standard databases, and any missing use and end-of-life stage data based on published sources and industry interviews.

2Allocation Rules

We are asking for data related to the environmental inputs and outputs of your product’s manufacturing process. It is understood that a process may produce two or more products at the same time (co-products). If so, the inputs and outputs for the process need to be split, or allocated, to indicate the flows specific to the product in question. This allocation will be done by NIST once your completed questionnaire is received. Therefore, report information for the entire production process, including the product in question and any other products produced by the same process.

Your manufacturing process may use some on-site utilities that are shared by the entire plant and, therefore, by other products that the plant may produce. Examples of on-site utilities include:

a site power plant generating steam, electricity, compressed air, or hot water which is consumed by the whole site,

a general wastewater treatment plant which treats effluents coming from the entire site.

In an LCA study, since on-site utilities usually serve several processes, their input and output quantities are allocated among processes, as shown in Figure 1. You need to make this allocation. For example, suppose the on-site utility consumes 100 lb of coal per year and produces 50 kWh of electricity per year. Processing the product in question consumes 25 kWh of electricity per year, or half the production of the on-site utility. In this case, half the coal use, or 50 lb of coal, would be allocated to the specific product process per year. No allocation is necessary if there are no other production processes sharing these utilities.

Figure 1: Example of Data Required in Questionnaire

SECTION II

Understanding the Questionnaire

The questionnaire is divided into two main parts as described in the following sections:

Site Questionnaire

Use Phase Questionnaire (Optional)

3Site Questionnaire

3.1Information Requested

The site questionnaire asks for the following information:

Inflows

The quantities of raw materials or intermediary products consumed, including water, during the processing or manufacturing of the product. For recycled materials, specify the percentage of recycled content.

The quantities of purchased energy and purchased fuels, itemized by energy or fuel type (e.g., electricity, natural gas, fuel oil), consumed during the processing or manufacturing of the product.

The distances and modes of transport corresponding to the raw materials, intermediary products, and purchased fuels consumed.

Outflows

The product data we need to allocate on a per product basis all entered quantities. For example, if consumption of a raw material is reported in units of pounds per year, then the annual production of the product should be reported here. Production quantities for co-products must also be reported here.

The solid waste, recovered matter (e.g., cardboard, metals) air emissions, and water effluents resulting from the production process.

This questionnaire is meant to be exhaustive and some entries may not be relevant to the production of your product.

3.2Possible Sources of On-site Information

The following table identifies the business units most likely to have the information necessary to provide the data requested in this questionnaire.

Flow Category |

Business Unit |

Raw materials and energy On-site utilities (power plants, etc.) |

Purchasing Department, Production Department Energy Department for power plant Environmental Department for wastewater treatment plant |

Air emissions |

Environmental Department |

Water effluents |

Environmental Department |

Solid Waste

|

Environmental Department Production department |

Table 1: Possible Sources of On-Site Information

3.3Principles Applicable to the Site Questionnaire

3.3.1Principle 1: Some Flows may be Neglected

Inflows

It is impossible and of little use to try to record all the inflows to a product production process. Many inputs are consumed in such small quantities that their contribution to the final LCA results would be negligible. Decision rules have been established, as follows, to restrict data collection to significant inputs:

All energy inputs, including electricity, steam, and compressed air, must be recorded;

99.9 percent (by weight) of total production process inputs are recorded;

The omitted inputs are thought not to have an important environmental burden; and

Input flows are always recorded when data are available. Typical criteria for the importance of an environmental burden include: (a) the material contains a highly toxic compound such as cyanide, phenol, hexavalent chromium, or any other significant hazardous compounds, or (b) the cost is high, since this may indicate scarce resources or high energy consumption.

Solid Waste and Co-products

Solid waste or co-products for which the accumulated tonnage represents less than 1% (by weight) of the total waste or co-product tonnage for the production process need not be recorded, unless it contains highly toxic compounds.

3.3.2Principle 2: General Site Operations are Excluded

Flows that are not directly related to industrial activities are not taken into account, such as cafeteria inflows and waste, building heat, and restroom operations. These specific flows related to people and offices, for which data may be readily available, are not registered in the questionnaires because they are not unique to the product production process. In addition, flows attributable to people and offices which are difficult to separate from production process flows, such as electricity, are usually small in comparison to the production process flows, so may be left aggregated and allocated to the production process if necessary. The capital equipment associated with the site facility may also be excluded. Capital equipment is often found to be a minor contributor to environmental performance

3.3.3Principle 3: Only Flows that Cross the Site Boundaries are Recorded

Internal flows for a product production process should not be reported in the questionnaire. This principle applies to both inflows (materials and energy) and outflows. For example, as indicated by its depiction in red in Figure 2, the amount of steam energy entering the production process should not be reported because it is an internal flow subject to double counting. If the steam is produced in a boiler, its use is already accounted for through the allocated boiler inputs (e.g., heavy fuel oil) and emissions which are recorded in the questionnaire.

Figure 2: Example of Internal and External Flow (energy input)

An example of an internal outflow is shown in Figure 3. In this example, wastewater produced by the production process is sent to an on-site wastewater treatment plant. In this case, only the net water effluents, or treated effluents leaving the site, should be recorded, together with the allocated inputs to the wastewater treatment plant.

Figure 3: Example of Internal and External Flow (water effluents)

Another example of an internal flow that should not be reported is process water. Process water could be used and recycled within the plant; only record the amount of makeup water in the questionnaire.

3.3.4Principle 4: Input/Output Reporting Rules

Enter the chemical composition for reagents and other chemical consumables rather than their commercial names or their functions. The environmental burden of reagents and other chemical consumables (e.g. degreasing agents, solvents, etc.) is based on the chemical composition of the compound. Further, the chemical composition is necessary to connect upstream production data to the BEES system.

For example, assume 10 lb of a coagulating agent with a commercial name “CO-2000” is consumed in a wastewater treatment plant. The coagulating agent consists of, by weight, 60% ferric chloride, 30% water, and 10% other products (which can be neglected according to Principle 1). In this case, enter 6 lb of ferric chloride rather than 10lb of “CO-2000.”

When chemical composition is not available, enter the consumable under its function name followed by the term “unspecified” (e.g. coagulating agent: unspecified, anti-corroding agent: unspecified).

Chemical products are frequently supplied either diluted with water or in an amorphous material. Their consumption must be reported in pure terms, that is, 100% of weight, such as in the example of ferric chloride above.

3.4General Organization of the Site Questionnaire

Table 2 explains the significance of the color coding in the BEES questionnaire. All flows relevant for your product are not necessarily specified in the questionnaire. Each table contains white fields below a row of light gray cells entitled “please specify”. Enter your additional flows into these white fields.

Field Color |

Character Color |

Field Characteristics |

Protection (data entry prevented?) |

White |

Black |

Fields where the data should be entered directly |

No |

White |

Blue |

Fields where allocated data should be entered |

No |

Light Green |

Black/Blue |

Fields containing fixed information |

Yes |

Light Gray |

no characters |

Empty fields |

Yes |

Table 2: Questionnaire Color-Coding

Only fill the white fields. Additional columns or rows can be added if space is needed for more inputs, co-products, or additional on-site utilities. No rows should be added for air emissions or water effluents.

4Use Phase Questionnaire

The optional use phase questionnaire begins with general questions about the product:

The useful life of the product, for calculating the number of product replacements over the use phase of the product life cycle.

The weight of the product per functional unit, for calculating emissions and raw material use per functional unit.

The density of the product, for conversion of product weight to product volume for solid waste computations. Additionally, whether the product is considered recyclable, and if so, the percentage of the product currently being recycled at the end of its useful life.

Transportation distances and modes of transportation for transport of the finished product to the site of product consumption. The average load transported and the maximum capacity of the vehicle are also requested. For truck transportation these are important parameters used to calculate the fuel consumption of the truck.

The manufacturer’s suggested retail price is used for economic performance calculations.

The use phase questionnaire also asks about installation and maintenance practices for the product:

Any installation energy or other manufacturer-recommended installation materials (e.g., bonding agent for floor tiles, nails for roofing materials).

Product maintenance schedule and requirements (e.g., floor wax for quarterly waxing of floor coverings).

SECTION III

Completing the Questionnaire

The BEES questionnaire consists of three sections: “General Data”, “Site Data” and “Use Phase Data”. The General Data section gives basic information on your company, contact person, and product. Once NIST receives your completed questionnaire, our expert consultants will review your data for completeness, accuracy, and consistency, and may have questions for your contact person.

Detailed instructions for completing the “Site Data” and “Use Phase Data” sections follow.

5Site Questionnaire

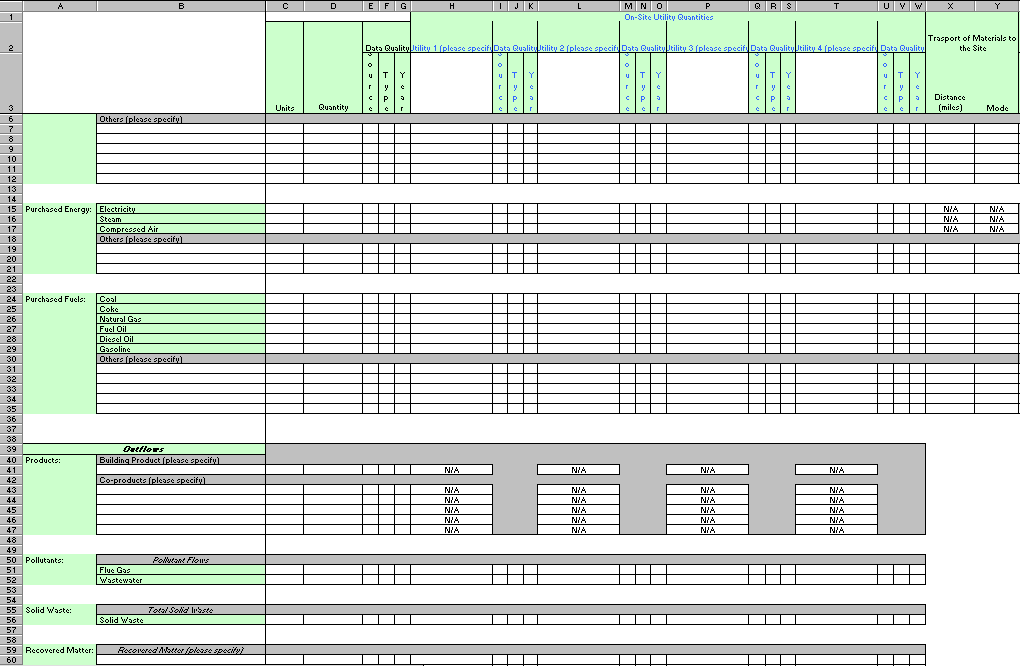

Figure 4 displays the structure of the Site Data Questionnaire. The columns for data input will be described in turn.

Column: C D E F G H I J K X Y

Figure 4: Site Data Questionnaire Structure

5.1Column C: Units

The “Units” column requests the units corresponding to the quantity reported in column D. It is important that units be used that permit conversion to inflow and outflow quantities per functional unit of product. For example, if consumption of a raw material is reported in pounds per year, then yearly production of the product should also be reported. If pollutants are reported as concentrations (e.g., SOx in ppmv), then the corresponding volume should also be indicated (a row for volume of flue gas and wastewater is included in the questionnaire).

For energy flows, please indicate if the quantity represents Net Caloric Value (NCV) or Gross Caloric Value (GCV)3.

5.2Column D: Quantity

Column D: Quantity needs to be filled with values corresponding to the product’s production process (see Figure 1). The white cells in column D must be filled for all listed air and water pollutant outflows even if no figure is available. There are three possible entry types:

The pollutant outflow is relevant and its quantity known.

The outflow is not applicable (“N/A”), that is, it cannot exist because the input it comes from is not consumed. For example, no SOx could be released to the air if the fuels that are combusted do not contain any sulfur compounds.

Ouflow quantity data are not available (“?”), that is, the flow may exist but has never been measured, or it cannot be calculated or assessed precisely.

In column D, enter the quantity (in the units specified in column C), “N/A,” or “?”. For the first possibility, a zero quantity may be valid if:

the flow has been measured but is under the detection limit,

the flow has been calculated and found equal to zero,

the flow is cited in a bibliographic reference as being equal to zero.

Some outflows are repeated because they contribute to more than one environmental impact. Fill all the cells, with repetitive values entered if applicable.

5.3Columns E, F and G : Data Quality

Columns E, F and G contain white cells which must be filled with coded information on data quality for each inflow and outflow for which a quantity has been entered in column D. When a flow is not applicable or its quantity not available, its data quality cells may be left blank. The data quality coding system is explained below.

5.3.1Column E: Data Source

Three types of sources are defined as:

Literature

Factory, i.e. site specific

Other, e.g. from other sites

In column E, enter either “L” for literature, “F” for factory, or “O” for other. Any character other than L, F or O is not permitted in column E.

5.3.2Column F: Data Type

Five types of data are defined as:

Measured: the flow quantity is based on continuous measurement. For instance, electricity consumption is readily available from electric meters. Coal consumption is continuously measured with scales or other forms of stock accountability.

Calculated: the flow quantity has been calculated using emission factors, mass balance, or other indirect methods. For instance, SOx emissions may have been measured for several years, and an emission factor determined and used for subsequent years. Another example is CO2 air emissions calculated from the carbon balance.

Averaged Value: the flow quantity has been extrapolated from spot measurements. For instance, VOCs may be measured three times per year, one day each time; from these values the annual quantity may be calculated.

Estimated: the flow quantity has been established based on approximations. For instance, the transportation distance for a given raw material may be estimated due to lack of better information.

Unknown: This data type is only appropriate for data from the literature when the information provided is insufficient to classify the data as one of the previous types.

In column F, enter either “M” for measured, “C” for calculated, “A” for averaged, “E” for estimated, or “U” for unknown. Any character other than M, C, A, E or U is not valid in column F.

5.3.3Column G: Collection Date

The collection date is the year when the measurement, calculation, or estimation was actually made.

The collection date is identified by the last two digits of the year. Any characters other than two digits are not valid in column G. In principle, 2000 data are requested in this questionnaire.

5.3.4Data Quality Summary

Table 3 summarizes the data quality codes to be used in the three data quality columns.

Data Source, Column E |

Data Type, Column F |

Collection Date, Column G |

||

L |

Literature |

M |

Measured |

|

F |

Factory, site specific |

C |

Calculated |

last two digits |

O |

Other |

A |

Averaged |

of year |

|

|

E |

Estimated |

(e.g., 00 for 2000) |

|

|

U |

Unknown

|

|

Data quality indicators are one of the most important data elements in LCA studies since poor data quality seriously handicaps the validity and credibility of the results. The data quality information you record for each flow will permit NIST to qualify the use of the subsequent results. For example, NIST may report that:

80% of data were measured on site

10% were calculated from literature

10% were estimated

5.4Column H: On-Site Utility Quantities

Column H: On-Site Utility Quantities must be filled with allocated quantities from an on-site utility process if applicable (see Figure 1 and Section 2). The same rules outlined above for completing Column D apply to Column H. There are four columns available for inputting on-site utility data, and others may be added if necessary. As mentioned above, the outflow rows record flows crossing the site boundaries. Thus, for example, the reporting for an on-site wastewater treatment plant would include:

In the inflow rows, the allocated consumption of raw materials (e.g., reagents and energy) at the wastewater treatment plant.

In the water outflow rows, the water emissions released to nature. Only the flows allocated to the product production process are reported.

In the outflow rows, solid waste and by-products from the wastewater treatment plant, namely the sewage sludge and waste oils. Types of sewage sludges are not differentiated.

Both treated effluents and untreated effluents, i.e. effluents which are directly released to the environment without treatment, are recorded.

5.5Columns I, J and K: Data Quality

Columns I, J, and K seek information on data quality for the on-site utility data. The same rules as for completing columns E, F and G apply. The additional on-site utility columns also have corresponding data quality columns.

5.6Column X and Y: Transport of Materials to Site

Columns X and Y ask for information on transportation of the raw material and fuel inputs to the site, with corresponding data quality columns. The distance the material is transported and the mode of transportation are requested for each material transported to the site.

6Use Phase Questionnaire

6.1General Questions

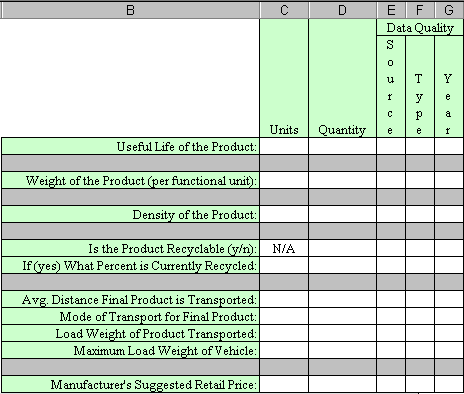

The Use Phase Questionnaire asks general questions regarding the use phase of the finished product as shown in Figure 5.

Column: B C D E F G

Figure 5: Use Phase Questionnaire: General Questions

Enter the “Units” (column C) and “Quantity” (Column D) for the items listed in Column B. These items are described in more detail in Section 4. Coded information on data quality is entered in columns E, F and G for each completed item. When an item is not relevant or its quantity not available, the data quality fields need not be completed. The data quality coding is explained in Section 5.3.

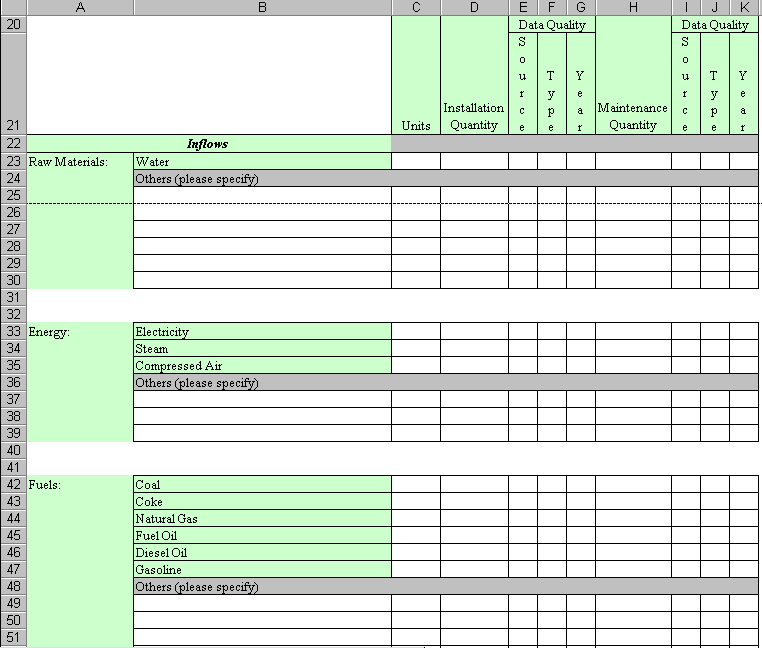

6.2Installation and Maintenance Data

The Use Phase Questionnaire also contains questions regarding the installation and maintenance of the final product as shown in Figure 5.

Column: B C D E F G H I J K

Figure 6: Use Phase Data Questionnaire: Installation and Maintenance

Enter the “Units” (column C) and “Quantity” (Columns D and H) for the items listed in column B. Coded information on data quality is entered in columns E, F, and G and I, J, and K for each completed item. When an item is not relevant or its quantity not available, the data quality fields need not be completed. The data quality coding is explained in Section 5.3.

1 International Standards Organization, Environmental Management--Life-Cycle Assessment--Principles and Framework, Draft International Standard 14040, 1996; ISO Environmental Management--Life-Cycle Assessment—Goal and Scope Definition and Inventory Anslysis, Committee Draft International Standard 14041.2, 1996; and ISO Environmental Management--Life-Cycle Assessment—Life Cycle Impact Assessment, Committee Draft International Standard 14042.1, 1997; and ISO Environmental Management--Life-Cycle Assessment—Life Cycle Interpretation, Committee Draft International Standard 14043.1, 1996.

2 International Standards Organization, Environmental Management--Life-Cycle Assessment--Principles and Framework, Draft International Standard 14040, 1996.

3NCV or Low Heat Value is the energy recoverable by the combustion of a unit quantity of fuel when the combustion product (the exhaust) is not brought back to the ambient temperature and pressure. GCV or High Heat Value is the total quantity of energy released by the combustion of a unit quantity of fuel, as measured by a bomb calorimeter. The difference between GCV and NCV is the vaporization latent heat of the water contained in the exhaust and the exhaust sensible heat.

| File Type | application/msword |

| File Title | BEES PLEASE |

| Author | Barbara C. Lippiatt |

| Last Modified By | usda |

| File Modified | 2008-03-13 |

| File Created | 2008-03-13 |

© 2026 OMB.report | Privacy Policy