Revised (Final) Supporting Statement Attachment 2A and H 08012008

SupportingStatement_2A_H_Survey_Version2_080108.doc

Information Collection Effort for Facilities with Combustion Units

Revised (Final) Supporting Statement Attachment 2A and H 08012008

OMB: 2060-0616

ICR No. 2286.01

OMB Control No. TBD

Expiration Date: XX/XXXX

Questionnaire for Boilers, Process Heaters, Incinerators and Other Combustion Units

Survey Overview

You will use this document to guide you through the question sequence. You will not enter your responses in this document. The responses will be entered in a series of seven answer key spreadsheets. These spreadsheets match the question sequence in this document and provide a specific area to record your response in each of the seven spreadsheets.

If you have not already downloaded a copy of the main answer key, it can be downloaded here: http://survey.erg.com/ss/wsb.dll/s/7g8d/answerkey.xls. The answer key contains macros in order to provide user-friendly drop down menus and check boxes for some answers. In order to run the macros correctly, please refer to the instructions in Appendix B1 of this document.

After you have reviewed your responses, you will attach a series of Excel spreadsheets containing your completed responses and e-mail them to [email protected] by the specified response deadline in the Section 114 letter. If your attachments are greater than 10 megabytes or too large for attaching to your internal e-mail system, you may upload the completed spreadsheets to a FTP site ftp://combustionsurvey:[email protected] (see Appendix B2 for instructions on uploading files to the FTP site) or mail a CD-rom containing the completed spreadsheets to EPA at the address specified in the Section 114 letter.

Please ensure that you clearly and consistently label your facility name and combustion unit ID on each spreadsheet you submit. You may select combustion unit IDs for each unit (or each group of similar small gas-fired boilers or process heaters), but please use a consistent unit ID across all spreadsheets that refer to the same unit (or group of similar units).

This survey is divided into four parts:

Part I – Facility Level Data

Please answer these questions for the facility listed in the Section 114 letter you received in the mail. If you received more than one Section 114 letter for multiple facilities, you must create a separate survey response for each facility.

Part II – Data From Each Relevant Boiler, Process Heater or Other Combustion Unit*

II.A Design, Operating, Air Pollution Control Device, and Emission Data for Small Gas-fired* Boilers or Process Heaters*

Please fill out Section II.A for all operational small gas-fired*. boilers or process heaters

II.B Unit Design, Operation, and Air Pollution Control Data for All Other Operational boilers*, process heaters*, or other combustion units* (excluding small gas-fired* boilers or process heaters and incinerators)

II.C. Fuels/Materials burned in Operational Boilers*, Process Heaters* or Other Combustion Units* (excluding small gas-fired* boilers or process heaters and incinerators)

Please fill out Sections II.B-II.C for each operational boiler, process heater, or other combustion unit that does not qualify under section II.A or PART IV. Sections II.B-II.C have been designed to request answers about a particular combustion unit before moving on to other combustion units at the facility.

To identify the appropriate fuel category to enter in your survey responses, please refer to the fuel category reference table in Appendix C of this document.

II.D. Emission Data

Section II.D will collect available emissions test data, CEM data, and Permitted and Regulatory emission limits from all operational combustion units that were not eligible to complete Section II.A or PART IV. All facilities that complete sections II.B and II.C must complete this section.

To identify the appropriate fuel category to enter in your survey responses, please refer to the fuel category reference table in Appendix C of this document.

Part III – Fuel/Materials Analysis Data

Please fill out Part III for any fuel/material used in an operational boiler, process heater or other combustion unit at the facility other than natural gas, propane, liquefied petroleum gas, and refinery gas. All facilities using any fuel/material other than natural gas, propane, liquefied petroleum gas, and refinery gas in a boiler, process heater or other combustion unit must complete this section.

To identify the appropriate fuel category to enter in your survey responses, please refer to the fuel category reference table in Appendix C of this document.

Part IV – Data from Each Incinerator Unit*

Please fill out Part IV if you have any operational incinerators* at your facility. Otherwise you may skip this part.

_______________________________________________________________________________________________

Part I: Facility Data

1. Name of facility: ______________________________

2. Complete street address of facility (physical location):

a. Address _____________

b. City _____________

c. State _____________

d. Zip _____________

e. County _____________

3. Facility contact

a. Name (First Name, Last Name): _________________________

b. Title: _____________________________

c. Telephone number: (____) ______________________ ext. ___

d. Fax number: (____) ______________________

e. E-mail: _________________________

4. If not the same as question #1, provide legal name of the owner of this facility: _____________________

5. Is the owner of this facility a private enterprise, not-for-profit, or a public sector entity? (select one)

() private enterprise

() not-for-profit

() public sector

6.. Is your facility a major source* of HAP? (Y/N)

7. Size of entity

a. If private company owns facility:

a1. Please enter the approximate number of employees of the business enterprise that owns this facility, including where applicable, the parent company and all subsidiaries, branches, and unrelated establishments owned by the parent company:

(select from list)

a2 Please enter the number of facility employees: (select from list)

b. If public sector owns facility:

b1. What is the population of the local government entity (city, county, town, school district, special district) that owns the facility? ________________

8. Is the legal owner a small entity* as defined by the Regulatory Flexibility Act? (select one)

___ Yes

___No

___Don’t know

9. Select facility’s primary NAICS. The primary NAICS code represents the line of business that generates the most income for the facility: (select from list of 3-digit NAICS codes)

II.A Design, Operation, Air Pollution Control Device, and Emission Data for Small Gas-Fired* Boilers or Process Heaters

Facility Name: (name of facility will automatically be linked to the name you provided in Part I)

Please provide a brief inventory of each similar group of small gas fired boilers:

Enter the number of gas fired boilers less than or equal to 10 million Btu/hr (mmBtu/hr) heat input design capacity _____

Please classify any tune-up practices performed on this group of boilers along with the corresponding frequency (i.e., daily, monthly, quarterly, semiannually, annually, every two years, every five years or longer). Tune-up practices include activities that involve checking the unit’s combustion processes and adjusting as needed:

() using the scheduled tune-up and procedures provided by the boiler manufacturer

() Inspection and cleaning, as necessary, of fireside and water-side surfaces.

() Inspecting, cleaning and/or reconditioning of fuel systems.

() Checking all electrical and combustion control systems.

() Testing of exhaust gases (CO, O2, other) as necessary to calculate combustion efficiency and make necessary adjustments to the combustion system. If this option is checked, indicate what level the CO is adjusted to: _______________

() Inspection and repair of all valves (relief, safety, hydraulic, pneumatic, etc.).

() Inspection and repair of refractories.

() Cleaning and inspecting fan housing, blades, and inlet screens.

() Cleaning/reconditioning and inspecting the feedwater system.

Please classify any good combustion practices performed on this group of boilers, along with the corresponding frequency (i.e., daily, monthly, quarterly, semiannually, annually, every two years, every five years or longer) of each practice:

() Using up to date operating procedures, training, recordkeeping

() Maintenance knowledge (including training on applicable equipment and procedures)

() Maintenance practices including maintenance procedures and recordkeeping

() Fuel/air ratio periodic checks

() Automatic O2/CO trim control systems

() Monitoring furnace residence time and temperature

() Fuel quality and proper fuel handling (including monitoring quality, periodic sampling and analysis, fuel supplier certification, if used)

() Proper fuel distribution in the combustion zone

() Combustion air distribution based on observations with periodic or continuous adjustments

() Low NOx burners

If any of these boilers are subject to a CO limit, please provide the numerical limit with units.

CO numerical limit with units_________(e.g., 400 ppm at 3% O2 dry, lb/mmBtu heat input, other-please specify)

Fuel associated with numerical limit (select from list)_ _______

Corresponding Averaging Time (i.e., 30-day rolling average, hourly, other) for CO limit: ______

Please provide a brief inventory of each similar group of small gas fired process heaters:

Enter the number of small gas fired process heaters less than or equal to 10 million Btu/hr (mmBtu/hr) heat input design capacity _____

Please classify any tune-up practices performed on this group of process heaters along with the corresponding frequency (i.e., daily, monthly, quarterly, semiannually, annually, every two years, every five years or longer). Tune-up practices include activities that involve checking the unit’s combustion processes and adjusting as needed:

() using the scheduled tune-up and procedures provided by the boiler manufacturer

() Inspection and cleaning, as necessary, of fireside and process material-side surfaces.

() Inspecting, cleaning and/or reconditioning of fuel systems.

() Checking all electrical and combustion control systems.

() Testing of exhaust gases (CO, O2, other) as necessary to calculate combustion efficiency and make necessary adjustments to the combustion system. If this option is checked, indicate what level the CO is adjusted to: _______________

() Inspection and repair of all valves (relief, safety, hydraulic, pneumatic, etc.).

() Inspection and repair of refractories.

() Cleaning and inspecting fan housing, blades, and inlet screens.

Please classify any good combustion practices performed on this group of process heaters, along with the corresponding frequency (i.e., daily, monthly, quarterly, semiannually, annually, every two years, every five years or longer) of each practice:

() Using up to date operating procedures, training, recordkeeping

() Maintenance knowledge (including training on applicable equipment and procedures)

() Maintenance practices including maintenance procedures and recordkeeping

() Fuel/air ratio periodic checks

() Automatic O2/CO trim control systems

() Monitoring furnace residence time and temperature

() Fuel quality and proper fuel handling (including monitoring quality, periodic sampling and analysis, fuel supplier certification, if used)

() Proper fuel distribution in the combustion zone

() Combustion air distribution based on observations with periodic or continuous adjustments

() Low NOx burners

If any of these process heaters are subject to a CO limit, please provide the numerical limit with units.

CO numerical limit with units_________(e.g., 400 ppm at 3% O2 dry, lb/mmBtu heat input, other-please specify)

Fuel associated with numerical limit (select from list_ _______

Corresponding Averaging Time (i.e., 30-day rolling average, hourly, other) for CO limit: ______

3. For each small gas-fired* boiler or process heater, provide the results of the most recent stack test data for each of the pollutants listed in the emission test spreadsheet by completing the spreadsheet linked below. EPA is not requesting actual test reports at this time; however we reserve the right to request actual copies in the future. EPA will also accept other supporting emission test data to document any earlier emission tests on the unit with similar controls and fuels. You may also submit a spreadsheet of any other information available relative to trials or tests of emission control methods or R&D efforts. The Agency is requesting these data only as they may already be available; no additional sampling or analyses are required to provide these data. The answer key for providing emission test data from small gas-fired* boilers or process heaters is available at this Web-Site: http://survey.erg.com/ss/data/BSF/Small_Gas_Emissions_Data_030308.xls

4. For each small gas-fired* boiler or process heater provide the daily averages of continuous emissions monitor (CEM) data for CO and appropriate adjustments for O2 or other diluent gas. EPA is also requesting corresponding CEM data for NOx in order to evaluate the relationship of low NOx units and CO emissions., If available these data are requested for the most recent 30 days of operation, and the highest single daily average for CO emissions within the most recent calendar year of CEM data. You should exclude data from the averages if they are from periods of start-up, shutdown, or malfunctions. The answer key for providing CEM data is available at this Web-site: http://survey.erg.com/ss/data/BSF/Small%20Gas_CEM_data_022608.xls

5. Do you have any boilers, process heaters, incinerators, or other combustion units at your facility (excluding small gas-fired boilers or process heaters)? Y/N

If no, you are done with the survey. Please review your answers and submit your response to EPA by the deadline listed in the Section 114 letter.

Part II.B Unit Design, Operation, and Air Pollution Control Data for All Other Operational boilers*, process heaters*, or other combustion units* (excluding small gas-fired* boilers or process heaters and incinerators)

Facility Name: (name of facility will automatically be linked to the name you provided in Part I)

1. General Information

Combustion device ID:_____

Year built: _______

Design capacity (heat input) value: _______

Fuel type associated with design capacity (heat input) value (select from list): _____

Design capacity units (select from list):

Furnace heat release rate (Btu/ ft3): ________

Is unit subject to NSPS? Yes/No

If you indicated yes to question g, indicate the year of NSPS (select from list)::

Primary combustion device use (check all that apply):

() steam generation

() space heat

() process heat

() electricity generation

() waste incineration

() cogeneration

() Other (please explain): _______________________

j. Additional combustion device uses (check all that apply):

() steam generation

() space heat

() process heat

() electricity generation

() waste incineration

() cogeneration

() Other (please explain): _______________________

k. For boilers only, check all that apply (several may apply to your unit):

k.1 Erection Design

() Package (shop erected)

() Field Erected

() Modular (part shop erected and part field erected)

k.2 Unit Design

() Water tube

() Fire tube

() Hybrid (if hybrid is selected, check the appropriate subtype)

() main combustion zone design is watertube

() main combustion zone design is firetube

k.3 Suspension Firing

() tangential

() wall-fired

() combination of suspension firing and grate firing (i.e., oil and bark)

() other (please explain)

l. For solid-fuel* boilers only, check all that apply (several may apply to your unit)

( ) Stoker

() spreader

() mass feed

() manual feed

() other (please specify): _________

() Fluidized Bed

() circulating

() bubbling

() Pulverized Coal

() Cyclone

() Other

() fuel cells

() suspension burners

() sloped-grate

() dutch oven

() gasifier

() other not listed (please specify): _________

m. For process heaters only, check all that apply:

Erection Design

() Package (shop erected)

() Field Erected

Unit Design

() Fire tube

() Water tube

()Thermal oil heaters

() Other (please explain): _____________

:

() Firing Mechanism

() fuel cells

() suspension burners

() sloped-grate

() dutch oven

() gasifier

() other not listed (please specify): _________

n. For other combustion units, check all that apply

Draft Configuration

() natural draft

() forced draft

Unit Type

() Dryer

() Heater

() Kiln

() Engine

() Other not listed (please specify): _________

2. Operating Parameters

a. Hours of Operation (hr/yr) (excluding periods of start-up, shutdown, and malfunction)

Typical: _________

b. Duty Cycle: (select one)

() base-loaded

() load following

() stand-by

c. Is the operation seasonal*? Y/N

3. Air Pollution Control

Facility Name: (name of facility will automatically be linked to the name you provided in Part I)

You will first be asked to list all add-on control devices, in the order contacted by the exhaust, and then you will be asked to identify good combustion practices used, followed by combustion controls. Specify the control device type using the descriptions provided in the drop-down menus. Your responses should include information on devices considered integral to your combustion unit (such as mechanical collectors) as well as add-on control devices.

a1. Control device currently installed (select from list)

a2. Year control device installed:

a3. Has an upgrade/modification been made to the control device since it was installed? Y/N

a4. Was an upgrade/modification/installation / replacement of the control device in a1 made to comply with the now vacated 40 CFR 63 Subpart DDDDD? Y/N (skip to a9 if no)

a5. If yes to a4, was the prior control device removed or added to the current control device?

() removed

() added to

() modified

a6. If yes to a4, what was the control device prior to the upgrade/modification/installation/replacement made in preparation of compliance with 40 CFR 63 Subpart DDDDD? (select from list)

a7. If yes to question a4 above, please provide the month and year that the upgrade/modification/replacement to the control device was made (mm/yyyy): ______

a8. If yes to a4, provide the date when the control device selected in a6 was installed or last upgraded/modified (whichever date is most recent)? (year)____

a9. Is the control device used as a common control device for more than one combustion unit?

() Not common

() Common, list names of units affected by this control in comments section below: ___________

a10. What, if any, Continuous Parameter Monitoring Systems (CPMS)* are installed for this control device? (check all that apply)

() none installed

() pressure drop

() flow rate entering or exiting the control device

() Voltage and secondary current (or total power input) to the control device

() Other (please specify):

Below is an example table from the answer key for how one might answer questions a1-a10 on the control devices installed on a particular combustion unit. In this case, mechanical collector was installed in 1987; a wet scrubber was removed and replaced with an ESP to comply with the vacated DDDDD standard.

Example |

|

|

|

Answer Only if a4 was ‘Yes’ |

|

|

|||

a1.

|

a2.

|

a3.

|

a4. |

a5. |

a6. |

a7. |

a8. |

a9. |

a10. |

Mechanical Collector |

1987 |

N |

N |

|

|

|

|

Not Common |

|

ESP |

2008 |

N |

Y |

Removed |

Wet Scrubber |

07/2008 |

1987 |

Not Common |

Flow rate Voltage |

b. Is oxygen or carbon monoxide used for boiler/process heater combustion air trim control? (select one)

() oxygen

() carbon monoxide

() neither

Please classify any tune-up practices performed on this combustion unit along with the corresponding frequency (i.e., daily, monthly, quarterly, semiannually, annually, every two years, every five years or longer). Tune-up practices include activities that involve checking the unit’s combustion processes and adjusting as needed:

() using the scheduled tune-up and procedures provided by the boiler manufacturer

() Inspection and cleaning, as necessary, of fire-side and water-side surfaces.

() Inspecting, cleaning and/or reconditioning of fuel systems.

() Checking all electrical and combustion control systems.

() Testing of exhaust gases (CO, O2, other) as necessary to calculate combustion efficiency and make necessary adjustments to the combustion system. Indicate what level the CO is adjusted to: _______________

() Inspection and repair of all valves (relief, safety, hydraulic, pneumatic, etc.).

() Inspection and repair of refractories.

() Cleaning and inspecting fan housing, blades, and inlet screens.

() Cleaning/reconditioning and inspecting the feedwater system.

Please classify any good combustion practices performed on this combustion unit, along with the corresponding frequency (i.e., daily, monthly, quarterly, semiannually, annually, every two years, every five years or longer) of each practice:

() Using up to date operating procedures, training, recordkeeping

() Maintenance knowledge (including training on applicable equipment and procedures)

() Maintenance practices including maintenance procedures and recordkeeping

() Fuel/air ratio periodic checks

() Automatic O2/CO trim control systems

() Monitoring furnace residence time and temperature

() Fuel quality and proper fuel handling (including monitoring quality, periodic sampling and analysis, fuel supplier certification, if used)

() Proper liquid atomization

() Proper fuel distribution in the combustion zone

() Combustion air distribution based on observations with periodic or continuous adjustments

() fly ash reinjection

() combustion of drier fuel

() better fuel distribution in firebox

() co-firing

() low NOx burners

4. Stack

a. Does combustion unit emit through its own single stack*? (Y/N)

b. Does combustion unit emit through a common stack*? (Y/N) (If yes, answer question b1 below)

b1. List quantity and category of all other combustion units venting to this common stack: (example: 2 coal fired boilers venting to common stack) _____________________________________

c. Does combustion unit emit through multiple stacks*? (Y/N)

Part II.C Fuels/Materials burned in the Combustion Unit

You will be asked to enter each fuel/material combusted in the combustion unit in the following order:

Start-up* fuel/material

Individual and co-fired fuels/material combusted during normal operation

Additional Fuels/Materials that are not routinely combusted (including fuels that are fired on an intermittent basis)

Facility Name: (pass through facility name on each page) Combustor ID: (pass through combustor ID on each page)

1. If start-up* fuel is different than normal fuel, please answer question 1 parts a, b, and c, otherwise proceed to question 2:

a. Select fuel/material from drop-down menu (if other is selected on drop-down menu provide a space to explain other)

b. Number of start-ups per year ________

c. Typical length of time for start-up (hours) _______

2. Fuels/Materials Combusted During Normal Operation:

Please complete the table below in the answer key for each fuel or combination of fuels fired in the combustion unit. You will provide the name of the material, the minimum, maximum and annual or seasonal average heat input of the fuel used in the combustion unit.

In the example below, this boiler fires bituminous coal, and plant-based agricultural residue. The agricultural residue is fired seasonally.

Use the fuel categories from the dropdown menus to respond. Select the fuel category that is most specific to your fuel/material based on the table in Appendix C of this document. For example, "landfill gas (LFG)" is more useful than "waste-gas"; "bituminous coal" or "anthracite coal" is more useful than "coal". If you specific fuel type is not listed in Appendix C, then you should select “other solid”, “other liquid”, or “other gas” and provide a brief name for the specific fuel type.

Fuel/Material |

Is fuel/material fed directly to combustion unit (“B” for boiler, “P” for process heater, “O” for other combustion units” |

Is this fuel/material used seasonally (S*) or annually (A) |

Hours used per year

|

Heat Input (mmBtu/hr) |

Permitted Limit for Fuel Usage (not permitted emission limit) |

|||

Question 2a |

Question 2b |

Question 2c |

Question 2d |

Min 2e |

Max 2f |

Mean 2g |

Value 2h. |

Units 2i. |

Example |

|

|

|

|

|

|

|

|

Bituminous Coal |

B |

A |

8200 |

100 |

175 |

110 |

100 |

tons/day |

Plant-Based Agricultural Residue |

B |

S |

1000 |

25 |

50 |

32 |

Not Applicable |

|

3. Fuels/Materials NOT Routinely Combusted (including fuels that are fired on an intermittent basis)

Please complete the table below in the answer key. This table is similar to question 2 above, however it applies to fuels/materials NOT routinely fired in the combustion unit. An example response is shown below.

Fuel/Material |

Is fuel/material fed directly to combustion unit (“B” for boiler, “P” for process heater, “O” for other combustion units” |

Describe Conditions for fuel use |

Hours used per year

|

Heat Input (mmBtu/hr) |

Permitted Limit for Fuel Usage (not permitted emission limit) |

|||

Question 3a |

Question 3b |

Question 3c |

Question 3d |

Min 3e |

Max 3f |

Mean 3g |

Value 3h |

Units 3i |

Example |

|

|

|

|

|

|

|

|

Wood: Unadulterated Timber |

B |

Agricultural residue is unavailable during part of seasonal operation |

200 |

25 |

50 |

38 |

Not Applicable |

|

4a. Do you have an emission test report available for this unit? (EPA is not requesting actual test reports at this time; however we reserve the right to request actual copies in the future.) Y/N

4b. If yes to question 4a above, please list where the available test report occurred not the equipment arrangement:

() dedicated control device, single dedicated stack

() common control device, single stack

() dedicated control device, multiple stacks

() common control device, multiple stacks

() other (please explain) ______________

5a. Please select the exhaust gases for which you have continuous emission monitors (CEM)* installed on this unit:

() SO2

() NOx

() CO

() O2 (or other diluent gas)

() VOC or hydrocarbon monitor

() PM

5b. For each of the CEM monitors you have installed, was this monitor installed for regulatory purposes?

5c. For each of the CEM monitors you have installed, do you have the ability to record CEM data?

5d. For each of the CEM monitors you have installed, do you have the ability to save CEM data?

6. Do any boilers, process heaters or other combustion units at your facility fire any non-fossil or other* fuels/materials? (Y/N) If no skip questions 7 and 8.

7. If the unit were to stop burning non-fossil or other* material in your combustion unit(s), what would happen to the material? (Please answer questions 7 and 8 separately for each non-fossil fuel burned) Your answers provided in questions 7-9 below are non-binding.

(a) Select non-fossil fuel from list

(b) Check corresponding alternative method(s) for handling this non-fossil fuel or other material.

() Send to a landfill off-site

() Dispose on-site

() Dispose through local trash collection

() Vent to atmosphere

() Send to waste water treatment plant

() Contract for special disposal service

() Sell to a processor for making product

() Sell to off-site facility for use as a fuel

() Stop purchasing material from 3rd Party

() Don’t know

() No other alternative currently available

() Other: _________________________________________________

8. If the unit were to stop burning this non-fossil or other* fuel/material in your combustion unit(s), how would you compensate for the lost heating value?

(a) Select non-fossil fuel from list

(b) Check corresponding compensation for lost heating value.

() burn a fossil fuel such as coal, oil, or gas in the same units

() buy new equipment capable of burning another fuel

() not applicable, material has no heating value

() purchase steam from another nearby facility

() generate additional steam from other boiler(s) located at the same facility

() Unknown

(c) Would your combustion units likely stop combusting these non-fossil or other materials if continuing to burn these materials would result in the unit being subject to 129 instead of 112?

() Yes

() No

() Unknown

If you fire more than one type of non-fossil or other* fuel/material at your facility, repeat questions 7 and 8 for each non-fossil or other* fuel/material.

9. What additional annualized costs would you incur for this unit to comply with Section 129 CISWI rule (40 CFR Part 60 Subpart CCCC or 40 CFR Part 63 Subpart DDDD) as compared to the vacated Boiler MACT? (Check appropriate cost range, and provide note on cost components evaluated).

a. () $0 to $50,000

() $50,001 to $100,000

() $100,001 to $500,000

() $500,001 to $1,000,000

() >$1,000,000

() Unknown

b. Indicate the cost components evaluated in your cost estimate above: __________________________________________________________________

10. Do you have another boiler, process heater, or other combustion unit you need to add to this survey? Y/N (If Yes, re-start at part II.B, otherwise proceed to part II.D)

Part II.D Emission Data from Combustion Device

1. Provide the results of the most recent stack test data for each of the pollutants listed in the emission test spreadsheet by completing and e-mailing the Excel spreadsheet linked below to [email protected]. EPA is not requesting actual test reports at this time; however we reserve the right to request actual copies in the future. EPA will also accept other supporting emission test data to document any earlier emission tests on the unit with similar controls and fuels. You may also submit a spreadsheet of any other information available relative to trials or tests of emission control methods or R&D efforts. The Agency is requesting these data only as they may already be available; no additional sampling or analyses are required to provide these data. The answer key for providing emission test data is available at this Web-site: http://survey.erg.com/ss/data/BSF/Emissions_Data_030308.xls

2. Provide the daily averages of continuous emissions monitor (CEM) data for NOx, SO2, CO, O2 (or other diluent gas), PM and 6-minute averages for opacity, if available for the most recent 30 days of operation, and the highest single daily average (higheset single 6-minute average for opacity) data point within the most recent calendar year of CEM data. You should exclude data from the averages if they are from periods of start-up, shutdown, or malfunctions. You can submit this data by completing the CEM data spreadsheet and e-mailing it to [email protected] The answer key for providing CEM data is available at this Web-site: .

http://survey.erg.com/ss/data/BSF/CEM_data_022608.xls

3. Provide a summary of permitted or regulatory emission limits, if applicable to your unit for each pollutant listed in the Permitted and Regulatory Emission Limit Worksheet. If the unit does not have a limit for a given unit, you may leave this entry blank. You can submit this data by completing the permitted and regulatory spreadsheet and e-mailing it to [email protected]. The answer key for providing permitted and regulatory limits is available at this Web-site: http://survey.erg.com/ss/data/BSF/Permitted_and_Regulatory_Limit.xls

Part III: Fuel/Material Data

Facility Name: (pass through facility name on each page)

1. Fuel/Material Description (select from list and be consistent with selections made in Section II.C. Question 2)

2. Where does fuel/material originate?

() On-site*

() Off-site

() Both (i.e., some bark from on-site combined with some bark generated off-site)

3. Is a fuel/material analysis provided by a fuel supplier or conducted on-site available? (Y/N)

If you have a fuel/material analysis available, provide the results of the most recent fuel/materials analysis for all fuels and materials (excluding natural gas, propane, liquefied petroleum gas, and refinery gas) combusted on-site in combustion units. Use the fuel categories from the list below, when available. Select the ‘other’ fuel description only if the fuel burned in the unit(s) is not on the list. If ‘other’ is selected please provide a brief name for this fuel. Select the most descriptive name as possible. For example, "landfill gas (LFG)" is more useful than "waste-gas"; "bituminous coal" or "anthracite coal" is more useful than "coal".

Please e-mail an electronic copy of the fuel analysis to [email protected]. The fuel analysis should be formatted according to the linked Excel spreadsheet below. Please identify the fuel name, facility name, and combustor ID consistently with how you answered Parts I and II. You may also provide a summary of any earlier fuel analyses, as long as these are representative of fuels/materials still used in the boiler/process heater. The answer key for providing fuel analysis data is available at this Web-site: http://survey.erg.com/ss/data/BSF/Fuel_Analysis.xls.

4. If any of your boilers, process heaters, or other combustion units other than small gas-fired boilers or process heaters covered under survey Part II.A or incinerators covered under survey part IV burn any other fuels you may copy and paste additional rows in the answer key to answer questions 1-3 about these fuels.

Part IV – Data from each Incinerator Unit*

Complete this section for each incinerator* at your facility that is not regulated by Section 3005 of RCRA. If you do not have any incinerators at your facility, you are done with the survey. Please review your answers and submit your response to EPA by the deadline listed in the Section 114 letter.

1. Unit-Data

a. Combustion device ID: ______

b. Unit Design Information (check all that apply): () single batch fed

() starved air

() fixed hearth

() rotary hearth

() intermittent batch fed

() excess air

() rotary kiln

() moving grate

() continuously fed

() single chamber

() multi-chamber/afterburner

() spreader stoker

() other:

c. Manufacturer: ____________________________________________________________

d. Model Number: ___________________________________________________________

e. Installation Date: _________________________________________________________

f. Dates/descriptions of major renovations: _______________________________________

g1. Design Capacity : __________________________________________

g2. Design Capacity Units: (tons waste per day, Other (please specify)

h1. Typical Hours Operated, Per Year: _________________

h2. Per day: ___________________

2. Air Pollution Control Device and Equipment Modifications Information

Repeat this section for each control device or equipment modification made to the incinerator.

(a) Is your incinerator equipped with an air pollution control device (e.g. wet scrubber, fabric filter, electrostatic precipitator)? If yes, please specify the type and provide any details as specified below for each control device:

a1. Type: ___________________________________________________________________

a2. Year Installed: ____________________________________________________________

a3. Manufacturer: _____________________________________________________________

a4. Model No.: _______________________________________________________________

a5. Percent of incinerator operating time that control device is operated: _________________ %

a6. Control device air flow capacity (typically in acfm): ______________________________

a7. Date control device(s) were last modified, repaired, or rebuilt: ______________________

a8. Annual hours of control device downtime for repairs and maintenance: _______________

a9. Is control device shared with other equipment? (Y/N) If yes, please identify the other equipment that is routed to the same control device: ___________________________________________________________________________

b1. What were the installed capital costs of the control device? ($, year)____________________

b2. What are the annual operating costs?($, year)___________________________________

(c) If your unit is equipped with a control device, please list the applicable operating parameters: c1. Wet scrubber pressure drop (in. H2O): ___________

c2. Fabric filter air-to-cloth ratio: __________________

c3. Other: _____________________________________

c. If you have made modifications to the incinerator(s) to reduce emissions:

c1. When were the modifications made?_______________________________________

c2. Briefly describe the type of modifications?_________________________________

c3. Do you have information on the costs of the modifications? Y/N _________

(If you answered “Yes”, please attach copy of cost information)

3. Waste Segregation or Recycling Practices

a. Does the facility currently employ waste segregation or recycling practices that reduce the volume of waste being incinerated? Y/N (if no, skip to question 4)

b. When were waste segregation practices begun? (month, year) ____________________________

c. What types of materials are segregated from the waste stream? (please check all that apply)

() paper/cardboard

() glass

() plastics

() batteries

() fluorescent light bulbs

() other metal containing materials (please list)

____________________________________

() other chlorine containing materials (please list)

__________________________________

() other (please list)

__________________________________

d. What is done with the materials that are segregated from the waste stream? __________________________________________________________________________

e. Estimate the current cost of your waste segregation/recycling program (please indicate whether cost estimate is on an annual basis, monthly basis, or other).

__________________________________________________________________________

f. Do you have any emissions test data that would show the effects of segregating materials from the waste stream (e.g., test data before and after waste segregation practices began)? Y/N

If yes, please attach complete copies of the test reports and any analyses of the impact of waste segregation on emissions.

4. Emission Test Data

a. Has emissions testing ever been conducted on this unit(s): Y/N _______

b. If so, please provide complete copies of the test reports that document all emission testing that has been conducted in the last 10 years. You may provide electronic versions of the test reports in lieu of attaching paper copies.

5. Do you have another incinerator unit you need to add to this survey? Y/N (If Yes, repeat part IV for another unit. Otherwise you are done with the survey. Please review your answers and submit your response to EPA by the deadline listed in the Section 114 letter).

Appendix A: Definitions for Questionnaire

Definitions:

1. For purposes of this survey, combustion units include the following devices:

Boiler means an enclosed device using controlled flame combustion and having the primary purpose of recovering thermal energy in the form of steam or hot water. Waste heat boilers, electric utility steam generating units (see definition), kraft recovery furnaces (see definition),and units required to have permit under Section 3005 of RCRA (e.g., hazardous waste waste incinerators) do not have to respond to this survey.

Process heater means an enclosed device using controlled flame, that is not a boiler, and the unit’s primary purpose is to transfer heat indirectly to a process material (liquid, gas, or solid) or to a heat transfer material for use in a process unit, instead of generating steam. Process heaters are devices in which the combustion gases do not directly come into contact with process materials. Process heaters do not include units used for comfort heat or space heat, food preparation for on-site consumption, or autoclaves.

Other combustion unit means any other unit firing a non-fossil liquid or solid fuel/material, other than unadulterated wood (see definition), whether covered under another MACT standard that is not a boiler, process heater, or incinerator. Units required to have a permit under Section 3005 of RCRA (e.g., hazardous waste incinerators) do not have to respond to this survey.

Incinerator refers to a combustion unit with the primary purpose of destroying matter and/or reducing the volume of the materials and is neither a boiler or process heater. Units required to have a permit under Section 3005 (e.g., hazardous waste incinerators) do not have to respond to this survey.

2. Electric utility steam generating unit means a fossil fuel-fired combustion unit of more than 25 megawatts that serves a generator that produces electricity for sale. A fossil fuel-fired unit that cogenerates steam and electricity and supplies more than one-third of its potential electric output capacity and more than 25 megawatts electrical output to any utility power distribution system for sale is considered an electric utility steam generating unit. Non-fossil fuel-fired electric utility steam generating units of any size must respond to this survey.

3. Kraft recovery furnace means a furnace (i.e., boiler) used to recover chemicals consisting primarily of sodium and sulfur compounds by burning black liquor which is spent cooking liquor that has been separated from the pulp produced by the kraft pulping process. Recovery furnaces that combust other non-fossil liquid or solid materials with the black liquor must respond to this survey.

4. Small gas-fired boilers or process heaters mean boilers or process heaters that have a heat input capacity less than 10 mmBtu/hr that: (1) burn natural gas, propane, liquefied petroleum gas (LPG), or refinery gas not combined with any other fuels; (2) if a unit burns distillate liquid fuel only during periods of gas curtailment, gas supply emergencies, or for periodic testing of liquid fuel and the periodic testing of liquid fuel does not to exceed a combined total of 48 hours during any calendar year, this unit is still a gas-fired boiler for the purpose of this survey.

5. On-site means the fuel/material generated from a process located at the facility. Off-site means either a raw material or other material generated from a process not located at the same facility as the combustion unit.

6. Major sources are those plant sites with the potential to emit 10 tons per year (tpy) of any one hazardous air pollutant (HAP) or 25 tpy of a combination of HAPs. Section 112(b) of the Clean Air Act Amendments contains the list of HAPs.

7. Small Entity is defined as follows:

(1) for Private Businesses it is determined for each NAICS of the owning entity based on number of employees and/or company revenue. Please see http://www.sba.gov/idc/groups/public/documents/sba_homepage/serv_sstd_tablepdf.pdf to evaluate the small entity status of your facility;

(2) for local government entities, such as a city, county, town, school district or special district with a population of less than 50,000; and

(3) for not-for-profits an organization that is independently owned and operated and is not dominant in its field.

8. Solid fuel fired units are any boilers, process heaters or other combustion units that fire solid fuel alone or in conjunction with other fuel types

9. Stack configurations are defined as follows:

A dedicated single stack configuration is where all flue gases from a combustion device are emitted through one stack.

A common stack configuration combines flue gases from more than one combustion device.

A multiple stack configuration represents a situation where a boiler vents to a dedicated control device, and the exhaust gases from the control device are emitted from more than one stack.

10. Seasonal operation indicates an operating pattern that varies heat input demand depending on time of year, but follows the same pattern annually.

11. Seasonal average is the mean value of number (emission rate or operating parameter) over an entire operating season. For example, if bagasse is fired 120 days per year, 24 hours per day, the seasonal average heat input rate would be the average of all the heat input rates during the 120 day period.

12. CEM (Continuous emission monitor) provides continuous measurement of pollutants emitted into the atmosphere in exhaust gases from combustion or industrial processes.

13. CPMS (Continuous Parameter Monitoring System) provides continuous measurement of operating parameters for control devices such as gas flow rate entering or exiting the control device, daily average voltage and secondary current (or total power input) to the control device, daily average pressure drop across the scrubber, or daily average liquid-to-gas ratio.

14. Start-up means the setting in operation of an affected combustion unit for any purpose. Start-up fuel does not apply to stabilization fuels. You should include stabilization fuels as part of your response to questions II.C.2 and II.C.3.

15. Unadulterated wood means wood that is not painted, varnished or treated with chemicals such as glues, resins, preservatives or adhesives. Any painted or varnished wood, wood containing glues or resins, or chemically treated wood (e.g., pressure treated wood, treated railroad ties) or wood containing glues or adhesives (e.g., plywood, particle board) is considered adulterated wood.

16. Non-fossil or other fuel/material is defined as any material that is not coal, oil, or natural gas, or derived from coal (e.g., coal refuse (culm, gob, coal tar), oil (e.g., petroleum coke), or natural gas. For illustrative purposes only, EPA has provided a detailed (though not extensive) list of non-fossil fuels. This definition or list does not represent or imply any regulatory definition of non-fossil fuel.

Non-Fossil Fuel/Material |

||

Acetone: New and Used Solvent |

Sewage gas |

Shredded cloth |

Agricultural Residue: Almond Shells |

Biogas (Excluding Sewage Sludge) |

Solid paraffin |

Agricultural Residue: Almond Tree Prunings |

Envirofuel pellets |

Solvents |

Agricultural Residue: Barley dust and chaff |

Filters |

Spent Coffee Grounds |

Agricultural Residue: Barley Needles |

Fuel cubes (paper diaper clippings/refuse) |

Spent Oxide |

Agricultural Residue: Corn Fiber |

Glycerol Distillation Byproduct |

Stripper condensate |

Agricultural Residue: Corn Gluten Feed |

Heavy Recycle |

Sulfur Free Organic Byproduct |

Agricultural Residue: Corn Mill Dryer Off-gas |

High Caustic Fuel |

Sunwax- Diatomaceous earth with sunflower oil wax |

Agricultural Residue: Corn Starch Residue |

Hog fuel: Hardwood |

Tall oil, tall oil derivatives |

Agricultural Residue: Corn Stover |

Hog fuel: Softwood |

Tar |

Agricultural Residue: Cotton And Corn |

Hog fuel: Urban |

Tire Chips |

Agricultural Residue: Cotton Gin Residue |

Lumber Refuse (hogged pallet boards/other non-treated scrap) |

Tire Derived Fuel (TDF) |

Agricultural Residue: Cotton Stalks |

Mixed wood residues |

Tires (whole) |

Agricultural Residue: Cottonseed Hulls |

Log Yard Cleanup |

Toluene |

Agricultural Residue: Fruit Pits |

Hydrogen |

Turkey brood woodwaste |

Agricultural Residue: Nut Shells |

Hydro pulper refuse |

Turpentine |

Agricultural Residue: Oat Hulls |

Industrial plastics |

Used Alcohol |

Agricultural Residue: Olive cake |

Ink Solvents |

Petroleum Refining Scrap Oil |

Agricultural Residue: Olive kernel |

Knots and Knotter Rejects |

Reprocessed oil |

Agricultural Residue: Orchard Prunings |

JP-8 Aviation Fuel |

Fuel oil solids (tank clean-out residue) |

Low carbonate corn fiber (LCCF) |

Landfill Gas |

Used #6 Oil |

Agricultural Residue: Pecan hulls |

Latex Paint Water |

Fume Filter Oil |

Agricultural Residue: Post harvest biomass residues |

Lightweight Asphalt |

Used Gear Oil |

Agricultural Residue: Rice Hulls |

Lignin |

Used Hydraulic Oil |

Agricultural Residue: Soybean Hulls |

Paunch Manure |

Used Lube Oil |

Agricultural Residue: Straw |

Manure |

Crankcase oil |

Agricultural Residue: Sunflower Hulls |

Manure, bedding & yard residues |

Used Motor Oil |

Agricultural Residue: Sunflower Husks |

Mechanical Pulp Mill Rejects |

Used Oil |

Agricultural Residue: Sunflower Pellets |

Mill trash |

Used Thermal Oil |

Agricultural Residue: Switchgrass |

Mixed liquid residues |

Off-spec used oil |

Agricultural Residue: Wheat fiber (WF) |

Neutralene |

On-spec used oil |

Agricultural Residue: Oil Seed (Rape, Canola, Corn, Beans) |

Virgin Lube oil |

Oil Residues/excesses/byproducts -- #6, asphalts |

Agricultural Residue: Palm oil plantation byproducts (palm kernel exfoliate, fiber, shell, EFB) |

Vegetable Oil |

Oil Spill cleanup Residues |

Agricultural Residue: Distillers Dry Grains |

Yellow grease (used cooking oils- sold as commercial fuel) |

Waste Derived Liquid Fuel |

Agricultural Residue: Distillers grains (DG) |

Nonhazardous byproduct solvent |

Wax and cellophane wrapper and packaging trimmings |

Agricultural Residue: Distillers grains stillage (DGS) |

Noncondensable Gas (includes stripper offgas) |

Wood: Adulterated Coproduct: Other wood |

Agricultural Residue: Dried Distiller Grains with Solubles (DDGs) |

Nonhalogenated solvent |

Wood: Adulterated Coproduct: Plywood/particleboard/finished |

Agricultural Residue: Dry Distiller Grains (DDG) |

Oil Booms |

Wood: Adulterated Coproduct: Treated |

Agricultural Residue: Malt Sprouts |

Orimulsion |

Wood: Laminated |

Agricultural Residue: Post harvest biomass residues |

Oily rags |

Wood: Plywood trim |

Alcohol: Ethanol |

Old Corrugate Cardboard (OCC) scraps |

Medium Density Fiber Board Sander Dust |

Alcohol: Solvent |

Old corrugated container rejects |

Medium Density Fiber Board Trim (some with water based primer) |

Animal Fats |

Paint Rags |

Oriented strand board trim/dry residuals |

Liquefied Chicken Fat |

Paint residues |

Particle Board sander dust |

Tallow |

Paper |

Particle Board trim |

Ash pile char |

Compressed paper |

Hardboard Dust |

Bagasse |

Paper broke |

Wood: Balsa |

Bio liquids |

Paper Byproducts: knots and paper fines |

Wood: Bark |

Biomass |

Paper cores |

Wood: Briquettes |

Bitumen |

Paper - office waste |

Wood: Chips |

Black Liquor |

Paper wrapper and packaging trimmings |

Wood: chips- fines |

Blast Furnace Gas |

Pathological: Animal Remains |

Wood: chips- old |

Blond Fiber |

Pathological: Human Remains |

Wood: Dried milled lumber |

Boiler ash |

Peat |

Wood: engineered wood plant scrap |

Cardboard |

Petrochemical process gas |

Wood: Hardwood chipping and residues |

Carpet Scrap |

Petroleum Distillation Solvent |

Wood: Pine and cedar trees, chipping and residues |

Char |

Plastics |

Wood: Hardwood pellets (hammer-milled, dried, pelletized - sold as fuel) |

Clarifier residuals- primary |

Pine tar |

Wood: Hogged Bark |

Clarifier residuals- secondary |

Poultry litter |

Wood: Mixed |

Coating Sludge |

Process coproduct gas |

Wood: Pallets |

Dewatered sludge |

Process coproduct liquid |

Wood: Pellets |

Industrial wastewater sludge |

Process coproduct solid |

Woodex pellets |

Industrial sludge |

Process engineered fuels |

Wood: Pine and fir |

Sewage Sludge |

Process gas |

Wood: Redwood and fir |

Sludge |

Pulp liquor |

Wood: Shavings |

Sludge without water |

Pulp mill gas |

Wood: Silvicultural |

Wastewater Treatment Residuals |

Reclaimed Ink Solvent |

Wood: Timber: Little Bark |

CO gas |

Recovered Gaseous Butane |

Wood: Timber: Mostly Bark |

Composite Water |

Rectified methanol |

Wood: Timber: Whole Tree |

Conforming Waste Materials |

Red oil (steam stripper steam condensate, incl terpenes, terpenoids, methanol, TRS) |

Wood: unadulterated hardwood |

Construction/Demolition Derived Material |

Refuse |

Wood: unadulterated softwood |

Cyanide |

Refuse derived fuel (RDF) |

Wood: waste-clean |

Decorative laminate/cast polymer scrap |

Reinjection char |

Wood: Whole tree chips/harvest residue |

Deinking residuals |

Resin Solid |

Wood: Hardboard pellets (hammer-milled,dried, pelletized) |

Dewatered combustible residues |

Restaurant oils & greases |

Wood: Hardboard Residues |

Coating Residues |

Sander dust |

Wood: Engineered Wood Plant Scrap |

Foam Residues |

Sawdust |

Wood: Woodworking residuals (cabinet mfg) |

Diaper scraps |

Sawmill scrap |

Wood: Laminate Production Scrap Dust |

Diesel fuel |

Scrap X-Ray Film |

Wood: Lamination Finishing Plant Residue |

Digester Gas |

Screen rejects |

Wood: Lamination Plant Residue |

Other gas: please explain |

Other solid: please explain |

Wood: Railroad Ties |

Other liquid: please explain |

|

Wood: Railroad Ties Chipped |

Appendix B1: Directions for Enabling Macros in Microsoft Excel ©

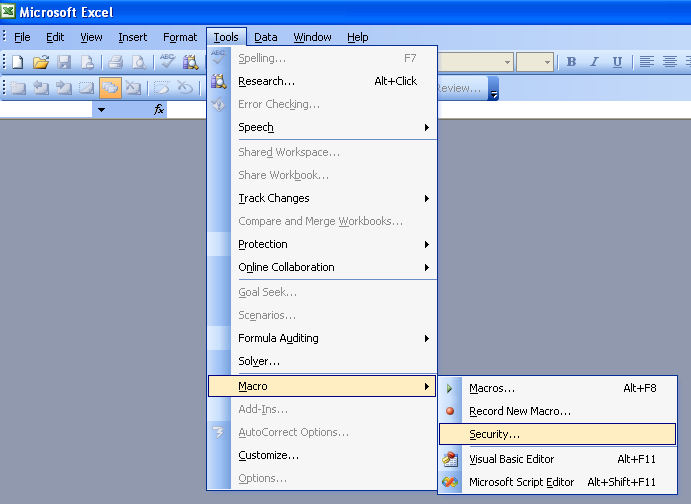

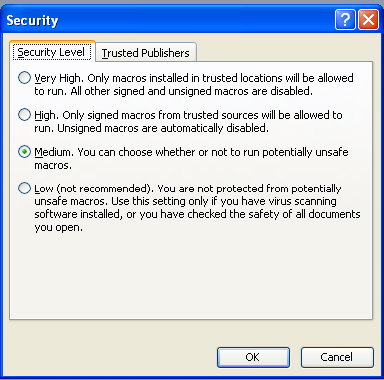

Step 1: Open Microsoft Excel © and select Tools>>Macro>>Security

Step 2: Set macro security to “medium”

Step 3: Open Survey Answer Key file and when prompted select “Enable Macros”

Appendix B2: Instructions for Uploading Survey Response Files to FTP Site

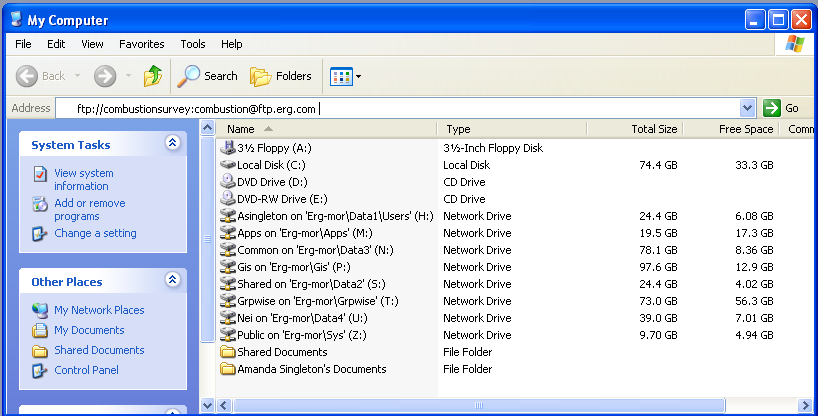

The maximum total size of all file attachments that [email protected] may receive is 10 megabytes per e-mail. If your file attachments exceed 10 megabytes, or exceed the file attachment size allowable on your computer system you may submit your response in one of two other ways: 1) Upload your response files to the Survey FTP site, or 2) mail an electronic copy of your response files to the EPA address shown in your Section 114 letter. The steps below outline how to upload files to the FTP site:

Step 1: Go to “My Computer” and enter ftp://combustionsurvey:[email protected] in the address bar. A window will open containing other files that have been uploaded to the ftp.

Step 2: Create a folder containing all of your survey response files. You may name the folder as follows, without using any spaces in the folder name “StateAbbreviation_FacilityName_City” (e.g., NC_ NCStateUniversity_Raleigh). Copy and paste the entire folder from your computer to the window pointing to ftp://combustionsurvey:[email protected].

Step 3: To ensure that your files have been uploaded, please wait for the file transfer to complete before shutting the ftp window.

Step 4: Send an e-mail to [email protected] that lists the names of the folders you have uploaded to the ftp site.

Appendix C: Reference Sheet To Identify Appropriate Fuel Categories in Survey Dropdown Menus Based on Specific Fuel Type Combusted in the Unit

Instructions for Identifying Fuel Category: Use this table below to identify which fuel grouping from column D you should select from the fuel drop down menus in the survey questions. If your specific fuel type is not listed in columns B or C, please select the fuel category "Other gas" "Other liquid" or "Other solid" and explain what specific type of other fuel you are combusting.

All Fuels - Fossil and Non-Fossil |

Fuel

Category in Drop-Down Menus |

|

Acetone: New and Used Solvent |

|

Acetone: New and Used Solvent |

Agricultural Residue: Almond Shells |

Agricultural Residue: Pecan hulls |

Plant-based Agricultural Residue |

Agricultural Residue: Almond Tree Prunings |

Agricultural Residue: Post harvest biomass residues |

|

Agricultural Residue: Barley dust and chaff |

Agricultural Residue: Rice Hulls |

|

Agricultural Residue: Barley Needles |

Agricultural Residue: Soybean Hulls |

|

Agricultural Residue: Corn Fiber |

Agricultural Residue: Straw |

|

Agricultural Residue: Corn Gluten Feed |

Agricultural Residue: Sunflower Hulls |

|

Agricultural Residue: Corn Mill Dryer Off-gas |

Agricultural Residue: Sunflower Husks |

|

Agricultural Residue: Corn Starch Residue |

Agricultural Residue: Sunflower Pellets |

|

Agricultural Residue: Corn Stover |

Agricultural Residue: Switchgrass |

|

Agricultural Residue: Cotton And Corn |

Agricultural Residue: Wheat fiber (WF) |

|

Agricultural Residue: Cotton Gin Residue |

Agricultural Residue: Oil Seed (Rape, Canola, Corn, Beans) |

|

Agricultural Residue: Cotton Stalks |

Agricultural Residue: Palm oil plantation byproducts (palm kernel exfoliate, fiber, shell, EFB) |

|

Agricultural Residue: Cottonseed Hulls |

Agricultural Residue: Distillers Dry Grains |

|

Agricultural Residue: Fruit Pits |

Agricultural Residue: Distillers grains (DG) |

|

Agricultural Residue: Nut Shells |

Agricultural Residue: Distillers grains stillage (DGS) |

|

Agricultural Residue: Oat Hulls |

Agricultural Residue: Dried Distiller Grains with Solubles (DDGs) |

|

Agricultural Residue: Olive cake |

Agricultural Residue: Dry Distiller Grains (DDG) |

|

Agricultural Residue: Olive kernel |

Agricultural Residue: Malt Sprouts |

|

Agricultural Residue: Orchard Prunings |

Agricultural Residue: Post harvest biomass residues |

|

Low carbonate corn fiber (LCCF) |

|

|

Alcohol: Ethanol |

|

Alcohol: Ethanol |

Alcohol: Solvent |

|

Alcohol: Solvent |

Animal Fats |

|

Animal Fat/Oils/Tallow |

Liquefied Chicken Fat |

|

|

Tallow |

|

|

Ash pile char |

|

Ash pile char |

Bagasse |

|

Bagasse |

Bio liquids |

|

Bio liquids |

Biomass |

|

Biomass |

Bitumen |

|

Bitumen |

Black Liquor |

|

Black Liquor |

Blast Furnace Gas |

|

Blast Furnace Gas |

Blond Fiber |

|

Blond Fiber |

Boiler ash |

|

Boiler ash |

Cardboard |

|

Cardboard |

Carpet Scrap |

|

Carpet Scrap |

Char |

|

Char |

Clarifier residuals- primary |

|

Industrial Commercial or Municipal Sludge |

Clarifier residuals- secondary |

|

|

Coating Sludge |

|

|

Dewatered sludge |

|

|

Industrial wastewater sludge |

|

|

Industrial sludge |

|

|

Sewage Sludge |

|

|

Sludge |

|

|

Sludge without water |

|

|

Wastewater Treatment Residuals |

|

|

CO gas |

|

CO gas |

Coal: Anthracite |

|

Coal: Anthracite |

Coal: Bituminous |

|

Coal: Bituminous |

Coal: Lignite |

|

Coal: Lignite |

Coal: Sub-bituminous |

|

Coal: Sub-bituminous |

Coal refuse – anthracite (culm) |

|

Coal refuse |

Coal refuse – bituminous (gob) |

|

|

Coal tar oil |

|

Coal tar |

Coal tar plus soil |

|

|

Composite Water |

|

Composite Water |

Conforming Waste Materials |

|

Conforming Waste Materials |

Construction/Demolition Derived Material |

|

Construction/Demolition Derived Material |

Cyanide |

|

Cyanide |

Decorative laminate/cast polymer scrap |

|

Decorative laminate/cast polymer scrap |

Deinking residuals |

|

Deinking residuals |

Dewatered combustible residues |

|

Dewatered combustible residues |

Coating Residues |

|

Coating Residues |

Foam Residues |

|

Foam Residues |

Diaper scraps |

|

Diaper scraps |

Diesel fuel |

|

Diesel fuel |

Digester Gas |

|

Biogas |

Sewage gas |

|

|

Biogas (Excluding Sewage Sludge) |

|

|

Envirofuel pellets |

|

Envirofuel pellets |

Filters |

|

Filters |

Fuel cubes (paper diaper clippings/refuse) |

|

Fuel cubes (paper diaper clippings/refuse) |

Glycerol Distillation Byproduct |

|

Glycerol Distillation Byproduct |

Heavy Recycle |

|

Heavy Recycle |

High Caustic Fuel |

|

High Caustic Fuel |

Hog fuel: Hardwood |

|

Hog Fuel |

Hog fuel: Softwood |

|

|

Hog fuel: Urban |

|

|

Lumber Refuse (hogged pallet boards/other non-treated scrap) |

|

|

Mixed wood residues |

|

|

Log Yard Cleanup |

|

|

Hydrogen |

|

Hydrogen |

Hydro pulper refuse |

|

Hydro pulper refuse |

Industrial plastics |

|

Industrial plastics |

Ink Solvents |

|

Ink Solvents |

Knots and Knotter Rejects |

|

Knots and Knotter Rejects |

JP-8 Aviation Fuel |

|

JP-8 Aviation Fuel |

Landfill Gas |

|

Landfill Gas |

Latex Paint Water |

|

Latex Paint Water |

Lightweight Asphalt |

|

Lightweight Asphalt |

Lignin |

|

Lignin |

LPG |

|

LPG |

Paunch Manure |

|

Manure |

Manure |

|

|

Manure, bedding & yard residues |

|

|

Mechanical Pulp Mill Rejects |

|

Mechanical Pulp Mill Rejects |

Mill trash |

|

Trash |

Mixed liquid residues |

|

Mixed liquid residues |

Natural gas |

|

Natural gas |

Neutralene |

|

Neutralene |

No. 2 Distillate |

|

No. 2 Distillate |

No. 4 Fuel oil |

|

No. 4 Fuel oil |

No. 5 Fuel oil |

|

No. 5 Fuel oil |

No. 6 Residual oil |

|

No. 6 Residual oil |

Virgin Hydraulic Oil |

|

Other Petroleum-based Oils |

Lube oil (virgin) |

|

|

Virgin Gear Oil |

|

|

Vegetable Oil |

|

Vegetable Oil |

Yellow grease (used cooking oils- sold as commercial fuel) |

|

Yellow grease (used cooking oils- sold as commercial fuel) |

Nonhazardous byproduct solvent |

|

Nonhazardous byproduct solvent |

Noncondensable Gas (includes stripper offgas) |

|

Noncondensable Gas (includes stripper offgas) |

Nonhalogenated solvent |

|

Nonhalogenated solvent |

Oil Booms |

|

Oil Booms |

Orimulsion |

|

Orimulsion |

Oily rags |

|

Oily rags |

Old Corrugate Cardboard (OCC) scraps |

|

Corrugate Cardboard or Container Scraps |

Old corrugated container rejects |

|

|

Paint Rags |

|

Paint Rags/Residues |

Paint residues |

|

|

Paper |

|

Paper and Paper Residues |

Compressed paper |

|

|

Paper broke |

|

|

Paper Byproducts: knots and paper fines |

|

|

Paper cores |

|

|

Paper - office waste |

|

|

Paper wrapper and packaging trimmings |

|

|

Pathological: Animal Remains |

|

Pathological: Animal or Human Remains |

Pathological: Human Remains |

|

|

Peat |

|

Peat |

Petrochemical process gas |

|

Petrochemical process gas |

Petroleum coke |

|

Coke Oven Gas |

Coke Oven Gas |

|

|

Petroleum Distillation Solvent |

|

Petroleum Distillation Solvent |

Petroleum refining process gas |

|

Refinery gas |

Refinery gas |

|

|

Plastics |

|

Plastics |

Pine tar |

|

Pine tar |

Poultry litter |

|

Poultry litter |

Process coproduct gas |

|

Process coproduct gas |

Process coproduct liquid |

|

Process coproduct liquid |

Process coproduct solid |

|

Process coproduct solid |

Process engineered fuels |

|

Process engineered fuels |

Process gas |

|

Process gas |

Propane |

|

Propane |

Pulp liquor |

|

Pulp liquor |

Pulp mill gas |

|

Pulp mill gas |

Reclaimed Ink Solvent |

|

Reclaimed Ink Solvent |

Recovered Gaseous Butane |

|

Recovered Gaseous Butane |

Rectified methanol |

|

Rectified methanol |

Red oil (steam stripper steam condensate, incl terpenes, terpenoids, methanol, TRS) |

Red oil (steam stripper steam condensate, incl terpenes, terpenoids, methanol, TRS) |

|

Refuse |

|

Refuse |

Refuse derived fuel (RDF) |

|

Refuse derived fuel (RDF) |

Reinjection char |

|

Reinjection char |

Resin Solid |

|

Resin Solid |

Restaurant oils & greases |

|

Restaurant oils & greases |

Scrap X-Ray Film |

|

Scrap X-Ray Film |

Screen rejects |

|

Screen rejects |

Shredded cloth |

|

Shredded cloth |

Solid paraffin |

|

Solid paraffin |

Solvents |

|

Solvents |

Spent Coffee Grounds |

|

Spent Coffee Grounds |

Spent Oxide |

|

Spent Oxide |

Stripper condensate |

|

Stripper condensate |

Sulfur Free Organic Byproduct |

|

Sulfur Free Organic Byproduct |

Sunwax- Diatomaceous earth with sunflower oil wax |

|

Sunwax- Diatomaceous earth with sunflower oil wax |

Tall oil, tall oil derivatives |

|

Tall oil, tall oil derivatives |

Tar |

|

Tar |

Tire Chips |

|

Tire Derived Fuel (TDF) |

Tire Derived Fuel (TDF) |

|

|

Tires (whole) |

|

Tires (whole) |

Toluene |

|

Toluene |

Turkey brood woodwaste |

|

Turkey brood woodwaste |

Turpentine |

|

Turpentine |

Used Alcohol |

|

Used Alcohol |

Petroleum Refining Scrap Oil |

Used Oil |

Used Petroleum-based Oils |

Reprocessed oil |

Used Thermal Oil |

|

Fuel oil solids (tank clean-out residue) |

Off-spec used oil |

|

Used #6 Oil |

On-spec used oil |

|

Fume Filter Oil |

Oil Residues/excesses/byproducts -- #6, asphalts |

|

Used Gear Oil |

Oil Spill cleanup Residues |

|

Used Hydraulic Oil |

Used Lube Oil |

|

Used Lube Oil |

|

|

Crankcase oil |

|

|

Used Motor Oil |

|

|

Waste Derived Liquid Fuel |

|

Waste Derived Liquid Fuel |

Wax and cellophane wrapper and packaging trimmings |

|

Wax and cellophane wrapper and packaging trimmings |

Wood: Adulterated Coproduct: Other wood |

Hardboard Residues |

Wood: Treated OR Wood: Painted or Varnished OR Wood: plywood, particleboard (containing glues or resins)

|

Wood: Adulterated Coproduct: Plywood/particleboard/finished |

Engineered Wood Plant Scrap |

|

Wood: Adulterated Coproduct: Treated |

Woodworking residuals (cabinet mfg) |

|

Wood: Laminated |

Laminate Production Scrap Dust |

|

Wood: Plywood trim |

Lamination Finishing Plant Residue |

|

Medium Density Fiber Board Sander Dust |

Lamination Plant Residue |

|

Medium Density Fiber Board Trim (some with water based primer) |

Railroad Ties |

|

Oriented strand board trim/dry residuals |

Railroad Ties Chipped |

|

Particle Board sander dust |

Sawdust (from adulterated wood) |

|

Particle Board trim |

Sander Dust (from adulterated wood) |

|

Hardboard Dust |

|

|

Wood: Balsa |

Wood: Pine and fir |

Wood: Unadulterated Timber OR Wood: Unadulterated Lumber OR Wood: Bark |

Wood: Bark |

Wood: Redwood and fir |

|

Wood: Briquettes |

Wood: Shavings |

|

Wood: Chips |

Wood: Silvicultural |

|

Wood: chips- fines |

Wood: Timber: Little Bark |

|

Wood: chips- old |

Wood: Timber: Mostly Bark |

|

Wood: Dried milled lumber |

Wood: Timber: Whole Tree |

|

Wood: engineered wood plant scrap |

Wood: unadulterated hardwood |

|

Wood: Hardwood chipping and residues |

Wood: unadulterated softwood |

|

Wood: Pine and cedar trees, chipping and residues |

Wood: waste-clean |

|

Wood: Hardwood pellets (hammer-milled, dried, pelletized - sold as fuel) |

Wood: Whole tree chips/harvest residue |

|

Wood: Hogged Bark |

Hardboard pellets (hammer-milled,dried, pelletized) |

|

Wood: Mixed |

Sander Dust |

|

Wood: Pallets |

Sawdust |

|

Wood: Pellets |

Sawmill scrap |

|

Woodex pellets |

|

Woodex pellets |

Other gas: please explain |

|

Other gas: please explain |

Other liquid: please explain |

|

Other liquid: please explain |

Other solid: please explain |

|

Other solid: please explain |

The public reporting and recordkeeping burden for this collection of information is estimated to average 24.2 hours per response. Send comments on the Agency's need for this information, the accuracy of the provided burden estimates, and any suggested methods for minimizing respondent burden, including through the use of automated collection techniques to the Director, Collection Strategies Division, U.S. Environmental Protection Agency (2822T), 1200 Pennsylvania Ave., NW, Washington, D.C. 20460. Include the OMB control number in any correspondence. Do not send the completed survey to this address.

| File Type | application/msword |

| File Title | Draft Questionnaire Content for Public Comment |

| Author | Eastern Research Group |

| Last Modified By | Higgins_C |

| File Modified | 2008-08-01 |

| File Created | 2008-08-01 |

© 2026 OMB.report | Privacy Policy