Private Sector

Questionnaire for Steam Electric Power Generating Effluent Guidelines (New)

Part B _022210.xls

Private Sector

OMB: 2040-0281

Document [xlsx]

Download: xlsx | pdf

Part B Instructions

Part B Section 1

Part B Section 2

Part B Section 3

Part B Section 4

Part B Section 4 Tables

Part B Section 5

Part B Section 6

Part B Section 6 Table

Part B Section 7

Part B Section 8

Part B Section 8 Tables

Part B Comments

Code Tables

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Overview

Part B Table of ContentsPart B Instructions

Part B Section 1

Part B Section 2

Part B Section 3

Part B Section 4

Part B Section 4 Tables

Part B Section 5

Part B Section 6

Part B Section 6 Table

Part B Section 7

Part B Section 8

Part B Section 8 Tables

Part B Comments

Code Tables

Sheet 1: Part B Table of Contents

| ICR Number XXXX.XX | Plant ID: | Insert Plant ID | |||||

| OMB Control Number: XXXX-XXXX | Plant Name: | Insert Plant Name | |||||

| Expiration Date: mm/dd/yyyy | |||||||

|

|||||||

| Steam Electric Questionnaire | |||||||

| Second FRN Version Draft | |||||||

| PART B - FLUE GAS DESULFURIZATION (FGD) SYSTEMS | |||||||

| Table of Contents | |||||||

| Section Title | Tab Name | ||||||

| Part B Instructions | Part B Instructions | ||||||

| General FGD System Information | Part B Section 1 | ||||||

| Planned FGD System Information | Part B Section 2 | ||||||

| FGD Additive Information | Part B Section 3 | ||||||

| Wet FGD System Information | Part B Section 4 | ||||||

| FGD Solids Disposition and Marketing for Wet FGD Systems | Part B Section 4 Tables | ||||||

| FGD Wastewater Generation | Part B Section 5 | ||||||

| FGD Monitoring Data Instructions | Part B Section 6 | ||||||

| FGD Monitoring Data | Part B Section 6 Table | ||||||

| FGD Wastewater Treatment | Part B Section 7 | ||||||

| Dry FGD System Information | Part B Section 8 | ||||||

| FGD Solids Disposition and Marketing for Dry FGD systems | Part B Section 8 Tables | ||||||

| Part B Comments | Part B Comments | ||||||

| Steam Electric Questionnaire Code Tables | Code Tables | ||||||

Sheet 2: Part B Instructions

| Steam Electric Questionnaire | Part B. Instructions | ||||||

| Plant ID: | Insert Plant ID | ||||||

| Plant Name: | Insert Plant Name | ||||||

| PART B. FLUE GAS DESULFURIZATION (FGD) SYSTEMS | |||||||

| INSTRUCTIONS | |||||||

| Part B requests information about flue gas desulfurization (FGD) systems that are located at the plant or are planned to be located at the plant. Complete Part B if you operate one or more FGD systems, or if you are currently constructing/installing or planning to construct/install one or more FGD systems by December 31, 2020. | |||||||

| Throughout Part B, information is requested on FGD systems that are under construction/installation or planned to be constructed/installed by December 31, 2020. Provide design information, or best engineering estimates as necessary, for these planned systems. | |||||||

| As you are completing the electronic form, note the following: When you enter your plant name and plant ID on the Part B Table of Contents tab, all name and ID fields throughout Part B will automatically populate. Refer to the overall questionnaire instructions, the glossary, and the acronym list for assistance with completing Part B. | |||||||

| Please provide all free response answers in the highlighted yellow areas. Throughout Part B, you may need to make copies of certain sections/questions for multiple FGD systems. Instructions are provided throughout Part B regarding making copies. Note that system ID fields must be populated on the copied tab or section, located in the upper right corner under "Plant ID" and "Plant Name", in order to correlate the requested information with the correct system. | |||||||

| Use the Part B Comments tab to do the following: provide additional information as requested in certain questions within Part B; indicate atypical data (e.g., if 2009 information is not representative of normal operations); and note methods used to make best engineering estimates in the event that exact data are not available. | |||||||

Sheet 3: Part B Section 1

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | |||||||||||||

| Plant ID: | Insert Plant ID | |||||||||||||

| Plant Name: | Insert Plant Name | |||||||||||||

| Part: | B | |||||||||||||

| Section Title: | 1. General FGD System Information | |||||||||||||

| Instructions: | Part B requests information about flue gas desulfurization (FGD) systems that are located at the plant or are planned to be located at the plant that are used to service fossil-fueled electric generating units. See Part A Section 8 for unit classifications. Complete Part B if you operate one or more FGD systems, or if you are currently constructing/installing or planning to begin constructing one or more FGD systems to service fossil-fueled electric generating units. | |||||||||||||

| CBI? |

B1-1. | Does the plant operate one or more flue gas desulfurization (FGD) systems that service fossil-fueled steam electric generating units, or is the plant currently constructing/installing or planning to construct/install one or more FGD systems to service fossil-fueled steam electric generating units by December 31, 2020? | ||||||||||||

| (Continue) | ||||||||||||||

| (Skip to next Questionnaire Part) | ||||||||||||||

| CBI? |

B1-2. | Complete Table B-1 for each FGD system that the plant operates that services fossil-fueled electric generating units, or is currently constructing/installing or planning to construct/install to service fossil-fueled electric generating units by December 31, 2020. Assign an FGD system ID to each FGD system using the drop down menu provided. Assign the FGD systems sequentially using the numbered IDs (e.g., FGD-1, FGD-2) for the systems currently operating. Assign the FGD systems sequentially using the lettered IDs (e.g., FGD-A, FGD-B) for the systems that are planned to operate. Enter the date the system initially began operation or is planned to begin operation. Identify each steam electric unit (currently operating or planned units) that is serviced by each FGD system using the codes EPA assigned to steam electric units in Table A-8 and/or Table A-9. Identify the type of oxidation performed in the FGD system for all wet FGD systems (Note: mark "Not Applicable" for dry FGD systems). Also provide the design sulfur dioxide removal efficiency for each FGD system. | ||||||||||||

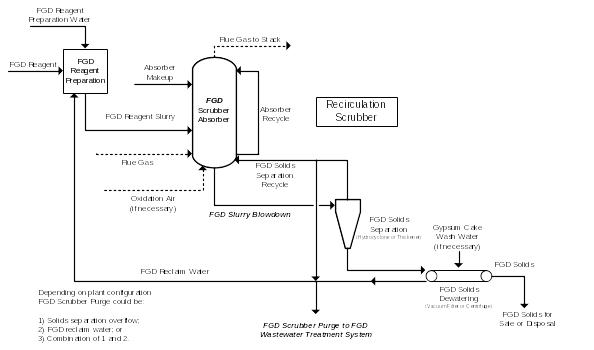

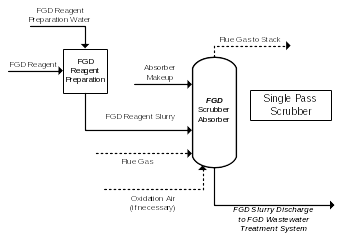

| Wet FGD systems capture sulfur dioxide from the flue gas using a wet slurry that generates a process wastewater that exits the scrubber absorber, shown as FGD slurry blowdown in Figure B-1 for recirculation scrubbers, or as FGD slurry discharge in Figure B-2 for single pass scrubbers. Indicate for each FGD system if FGD slurry blowdown (or FGD slurry discharge) is generated. | ||||||||||||||

| Use the drop down boxes to identify the type of FGD system and to specify the type(s) of sorbents used in the system. If a sorbent used is not provided in the drop down, identify "other" and provide the type(s) of sorbent in the yellow highlighted box to the right. | ||||||||||||||

|

||||||||||||||

| Figure B-1. Example Recirculation Wet FGD Scrubber System Diagram | ||||||||||||||

|

||||||||||||||

| Figure B-2. Example Single Pass Wet FGD Scrubber System Diagram | ||||||||||||||

| Table B-1. FGD Systems in Operation or Planning to be Operated by December 31, 2020 | ||||||||||||||

| FGD System ID | Date System Initially Brought On Line, or Planned to be Brought On Line (month/year) |

Steam Electric Units from Table A-8 and/or A-9 Serviced by This FGD System [check all boxes that apply] |

Does (or Will) the System Generate a FGD Slurry Blowdown (or Slurry Discharge) Stream (i.e., is it a wet system)? | Type of Oxidation (Forced, Natural, or Inhibited) | Type of FGD System | Type of Sorbent | Sulfur Dioxide Removal Efficiency (%) |

|||||||

| Example: | Primary: | |||||||||||||

| 01/1995 | Secondary: | 97.5 | ||||||||||||

| Tertiary: | ||||||||||||||

| Quaternary: | ||||||||||||||

| Primary: | ||||||||||||||

| Secondary: | ||||||||||||||

| Tertiary: | ||||||||||||||

| Quaternary: | ||||||||||||||

| Primary: | ||||||||||||||

| Secondary: | ||||||||||||||

| Tertiary: | ||||||||||||||

| Quaternary: | ||||||||||||||

| Primary: | ||||||||||||||

| Secondary: | ||||||||||||||

| Tertiary: | ||||||||||||||

| Quaternary: | ||||||||||||||

| Primary: | ||||||||||||||

| Secondary: | ||||||||||||||

| Tertiary: | ||||||||||||||

| Quaternary: | ||||||||||||||

| Primary: | ||||||||||||||

| Secondary: | ||||||||||||||

| Tertiary: | ||||||||||||||

| Quaternary: | ||||||||||||||

| Primary: | ||||||||||||||

| Secondary: | ||||||||||||||

| Tertiary: | ||||||||||||||

| Quaternary: | ||||||||||||||

| Primary: | ||||||||||||||

| Secondary: | ||||||||||||||

| Tertiary: | ||||||||||||||

| Quaternary: | ||||||||||||||

| Primary: | ||||||||||||||

| Secondary: | ||||||||||||||

| Tertiary: | ||||||||||||||

| Quaternary: | ||||||||||||||

Sheet 4: Part B Section 2

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | ||||||||||

| Plant ID: | Insert Plant ID | ||||||||||

| Plant Name: | Insert Plant Name | ||||||||||

| Part: | B | ||||||||||

| Section Title: | 2. Planned FGD System Information | ||||||||||

| Instructions: | Throughout this section, provide information for all FGD systems under construction/installation or planned to be constructed/installed by December 31, 2020 that are reported in Table B-1 and are expected to generate FGD slurry blowdown. Please provide all free response answers in the highlighted yellow areas. | ||||||||||

| CBI? |

B2-1. | Complete Table B-2 for each FGD system under construction/installation or planned to be constructed/installed by December 31, 2020 that is reported in Table B-1 and is expected to generate FGD slurry blowdown. Enter the planned method for handling solids generated, whether FGD scrubber purge (or slurry discharge) will be generated, the type of wastewater treatment system, the design maximum and 24-hour daily average flow rate for the treatment system, and the date the treatment system will be brought on line. Use codes from the Code Tables tab, as appropriate, and separate multiple entries with commas. If you do not know the type of wastewater treatment system that will be installed or the flow rate of the treatment system, enter "Unknown" into the appropriate columns in the table. | |||||||||

| Table B-2. FGD Systems Planned or Under Construction/Installation | |||||||||||

| FGD System ID | Planned Solids Handling for the FGD Slurry Blowdown (See Solids Handling Table in Code Tables Tab) a | Will System Generate FGD Scrubber Purge (or Slurry Discharge)? | Will FGD Scrubber Purge (or Slurry Discharge) be Treated by New or Existing Treatment System | Type of Wastewater Treatment System Planned to Treat FGD Scrubber Purge(or Slurry Discharge) (See Wastewater Treatment Units Table in Code Tables Tab) | Design Flow Rate for FGD Treatment System | Estimated Date the New FGD Treatment System Will be Brought On Line (or Date FGD Scrubber Purge (or Slurry Discharge) Will be Transferred to Existing System) (month/year) |

|||||

| Maximum (gpm) | 24-Hour Daily Average (gpm) | ||||||||||

| Example |

EQ-P, CP-1-1, CL-P-1, PH-1, FLT-S-1 | 1,200 | 1,000 | 06/2012 | |||||||

| a – This question refers to the blowdown solids handling, not the treatment system solids handling. | |||||||||||

Sheet 5: Part B Section 3

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | ||||||

| Plant ID: | Insert Plant ID | ||||||

| Plant Name: | Insert Plant Name | ||||||

| Part: | B | ||||||

| Section Title: | 3. FGD Additive Information | ||||||

| Instructions: | Throughout this section, provide information for all FGD Systems listed in Table B-1. Please provide all free response answers in the highlighted yellow areas. | ||||||

| CBI? |

B3-1. | In Table B-3, indicate the additive(s) used or planned to be used in each FGD system listed in Table B-1, and provide a description of its purpose. [Check all boxes that apply.] | |||||

| Table B-3. FGD Additive Information | |||||||

| Additive | FGD System(s) in which Additive is Used or is Planned to be Used | Purpose of Additive | |||||

| Adipic acid | |||||||

| Dibasic acid (DBA) | |||||||

| Elemental sulfur | |||||||

| Formic acid | |||||||

| Organosulfide | |||||||

| Sodium thiosulfate | |||||||

| Other (specify below): | |||||||

| Other (specify below): | |||||||

| None | |||||||

Sheet 6: Part B Section 4

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | ||||||||||||

| Plant ID: | Insert Plant ID | ||||||||||||

| Plant Name: | Insert Plant Name | ||||||||||||

| FGD System ID: | Insert System ID | ||||||||||||

| Part: | B | ||||||||||||

| Section Title: | 4. Wet FGD System Information | ||||||||||||

| Instructions: | Throughout this section, you will be required to provide information for each wet FGD system that the plant operates, reported in Table B-1. This section does not need to be completed for planned systems. Please provide all free response answers in the highlighted yellow areas. | ||||||||||||

| Make copies of Section 4 and the Section 4 tables for each wet FGD system previously defined in Table B-1 using the "Copy Section 4 and Section 4 Tables" button below. Please note that you will create two new tabs for these sections. You may delete unneeded tabs, if accidently created. Enter the FGD system ID in the space provided above (use FGD system IDs assigned in Table B-1). | |||||||||||||

| CBI? | B4-1. | Did you report use of a FGD system that generates FGD slurry blowdown (i.e., wet system) in Table B-1? | |||||||||||

| (Continue) | |||||||||||||

| (Skip to Section 8) | |||||||||||||

|

|||||||||||||

| CBI? | B4-2. | Provide the operating concentration range of chlorides within the FGD scrubber absorber. | |||||||||||

| Minimum operating concentration: | ppm | ||||||||||||

| Maximum operating concentration: | ppm | ||||||||||||

| CBI? |

B4-3. | Provide the maximum design chlorides concentration for the FGD system and indicate which specific equipment unit(s) of the FGD system determine this concentration (e.g., FGD scrubber absorber, piping). Also provide the materials of construction for the specific FGD equipment that determine the maximum design chlorides concentration. If multiple materials are used in the construction of the FGD equipment that determines the maximum design chlorides concentration, identify the component that is the most vulnerable to corrosion due to chlorides concentrations. If the material of construction is not provided in the drop down menu, select "other" and provide the name in the yellow box provided. | |||||||||||

| FGD system maximum design chlorides concentration: | ppm | ||||||||||||

| FGD equipment that determines maximum design concentration: | |||||||||||||

| FGD equipment that determines maximum design concentration: | |||||||||||||

| FGD equipment that determines maximum design concentration: | |||||||||||||

| FGD equipment that determines maximum design concentration: | |||||||||||||

| CBI? |

B4-4. | Indicate the FGD system parameter(s) that are used to determine when the FGD slurry is blown down from the FGD system. [Check all boxes that apply.] | |||||||||||

| ppm | |||||||||||||

| and | % | ||||||||||||

| CBI? |

B4-5. | For water sources that may be used as a source of FGD reagent preparation water or absorber make-up water (e.g., fresh intake, recycled process water), indicate the maximum chlorides concentration and maximum solids percentage that is acceptable for the water to be used for those purposes. Identify any other criteria that the source water must meet. | |||||||||||

| ppm | |||||||||||||

| % | |||||||||||||

| CBI? | B4-6. | Provide the typical flow rate, duration, and frequency of the mist eliminator wash water for the FGD system for calendar year 2009. Provide 2010 data for systems that were not operating in 2009. | |||||||||||

| gpm | |||||||||||||

| hpd | |||||||||||||

| dpy | |||||||||||||

| CBI? | B4-7. | Provide the typical flow rate, duration, and frequency of the FGD reagent preparation water for the FGD system for calendar year 2009. Provide 2010 data for systems that were not operating in 2009. | |||||||||||

| gpm | |||||||||||||

| hpd | |||||||||||||

| dpy | |||||||||||||

| CBI? | B4-8. | Provide the typical flow rate, duration, and frequency of the FGD reagent slurry for the FGD system for calendar year 2009. Provide 2010 data for systems that were not operating in 2009. | |||||||||||

| gpm | |||||||||||||

| hpd | |||||||||||||

| dpy | |||||||||||||

| CBI? |

B4-9. | Provide the typical flow rate, duration, and frequency of the absorber make-up water for the FGD system for calendar year 2009. Provide 2010 data for systems that were not operating in 2009. | |||||||||||

| gpm | |||||||||||||

| hpd | |||||||||||||

| dpy | |||||||||||||

| CBI? |

B4-10. | Provide the source of the mist eliminator wash water used. [Check all boxes that apply.] If the source is a process wastewater not provided in the dropdown box, select other and provide in the yellow box the name of the process wastewater and a short description. | |||||||||||

| CBI? |

B4-11. | Provide the source of the FGD reagent preparation water used. [Check all boxes that apply.] If the source is a process wastewater not provided in the dropdown box, select other and provide in the yellow box the name of the process wastewater and a short description. | |||||||||||

| CBI? |

B4-12. | Provide the source of the absorber make-up water used. [Check all boxes that apply.] If the source is a process wastewater not provided in the dropdown box, select other and provide in the yellow box the name of the process wastewater and a short description. | |||||||||||

| CBI? |

B4-13. | Indicate the type of solids that are generated within the FGD scrubber system. Also provide the approximate percent of the total FGD solids generated within the FGD system for each type (e.g., 85% calcium sulfate, 15% calcium sulfite). | |||||||||||

| % FGD solids generated | |||||||||||||

| % FGD solids generated | |||||||||||||

| % FGD solids generated | |||||||||||||

| % FGD solids generated | |||||||||||||

| CBI? | B4-14. | Are the FGD solids combined with fly ash, bottom ash, or other material? | |||||||||||

| (Continue) | |||||||||||||

| (Skip to Question B4-16) | |||||||||||||

| CBI? | B4-15. | Is a cementitious/pozzolanic material produced with the FGD solids at the plant? | |||||||||||

| CBI? |

B4-16. | Indicate the methods of FGD solids separation used by the plant for FGD slurry blowdown (or slurry discharge). Refer to Figure B-1 for an example of a FGD solids separation system. Note that FGD solids separation and FGD solids dewatering are separate processes. [Check all boxes that apply.] | |||||||||||

| CBI? | B4-17. | Indicate the method of FGD solids dewatering used by the plant for the FGD solids. [Check all boxes that apply.] | |||||||||||

| CBI? |

B4-18. | Provide the typical, maximum, and minimum chlorides concentration of the FGD solids produced by the FGD system in calendar year 2009. The chlorides concentration should be given on a wet basis (i.e., analysis of the FGD with the moisture content included); however, if the chlorides concentration is not known on a wet basis, provide the dry-basis concentration and note that it is a dry-basis concentration in the comments. | |||||||||||

| Typical concentration: | ppm | ||||||||||||

| Minimum concentration: | ppm | ||||||||||||

| Maximum concentration: | ppm | ||||||||||||

| CBI? | B4-19. | What parameters affect the ability of the FGD solids to be marketed, sold and/or given away? [Check all boxes that apply.] | |||||||||||

| ppm | |||||||||||||

| ppm | |||||||||||||

| ppm | |||||||||||||

Sheet 7: Part B Section 4 Tables

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | |||||||||

| Plant ID: | Insert Plant ID | |||||||||

| Plant Name: | Insert Plant Name | |||||||||

| FGD System ID: | Insert System ID | |||||||||

| Part: | B | |||||||||

| Section Title: | 4. FGD Solids Disposition and Marketing for Wet FGD Systems | |||||||||

| Instructions: | Throughout this section, you will be required to provide information on FGD solids disposition for each wet FGD system that the plant operates, reported in Table B-1. This section does not need to be completed for planned systems. Please provide all free response answers in the highlighted yellow areas. | |||||||||

| CBI? |

B4-20. | In Table B-4, indicate the ultimate destination of FGD solids from the FGD system and provide the tonnage for each type of storage/handling technique for calendar years 2005, 2007, and 2009. If the FGD solids are stored in an on-site landfill or pond/impoundment, including those located on non-adjoining property, provide the amount of FGD solids stored permanently and/or temporarily. For example, a plant may operate a gypsum stacking operation using a pond/impoundment, and some amount of FGD solids that are transferred to the pond/impoundment are dewatered and sold for use in wallboard manufacturing. In this case, the amount of FGD solids sold for wallboard manufacturing should be identified in BOTH the "Sent to Pond/Impoundment reported in Table A-4: Stored temporarily" category AND the "Marketed and Sold" category. In this same example, all the FGD solids that are transferred to the pond/impoundment and either left settling at the bottom of the pond/impoundment or used in increase the banks of the pond/impoundment should be identified as "Sent to Pond/Impoundment reported in Table A-4: Stored permanently." |

||||||||

| Table B-4. FGD Solids Disposition for 2005, 2007, and 2009 | ||||||||||

| Ultimate Destination of FGD Solids | Amount Disposed in 2005 (tons) | Amount Disposed in 2007 (tons) | Amount Disposed in 2009 (tons) | |||||||

| Sent to Landfills reported in Table A-6 | Stored permanently | |||||||||

| Stored temporarily (later hauled off-site/marketed) | ||||||||||

| Sent to Pond/Impoundment reported in Table A-4 | Stored permanently | |||||||||

| Stored temporarily (later hauled off-site/marketed) | ||||||||||

| Sent to Landfills not reported in Table A-6 | ||||||||||

| Sent to Pond/Impoundment not reported in Table A-4 | ||||||||||

| Marketed and sold | ||||||||||

| Given away | ||||||||||

| Other, explain: | ||||||||||

| Other, explain: | ||||||||||

| CBI? |

B4-21. | Complete Table B-5 if the plant markets, sells, and/or gives away the FGD solids from this FGD system. For each destination, provide the tons of FGD solids for which the FGD solids are marketed, sold, and/or given away. Also provide the gross revenue generated from marketing/selling the FGD solids for each destination. | ||||||||

| Table B-5. FGD Solids Marketed/Sold in 2005, 2007, and 2009 | ||||||||||

| Destination | 2005 | 2007 | 2009 | |||||||

| Tons | Gross Revenue Generated ($) | Tons | Gross Revenue Generated ($) | Tons | Gross Revenue Generated ($) | |||||

| CBI? |

B4-22. | In Table B-6, provide the total cost incurred to remove or dispose of FGD solids from 2005 to 2009 including the cost for labor, materials, transportation, and energy. Also provide the cost by component. Include other components not provided in the list of processes in the yellow box provided. | ||||||||

| Table B-6. Cost Incurred to Remove or Dispose of FGD Solids in 2005, 2007, and 2009 | ||||||||||

| Process | 2005 | 2007 | 2009 | |||||||

| Total Costs Incurred | Total Costs Incurred | Total Costs Incurred | ||||||||

| Solids separation | $ | $ | $ | |||||||

| Solids dewatering | $ | $ | $ | |||||||

| Hauling FGD solids | $ | $ | $ | |||||||

| Cost of on site disposal | $ | $ | $ | |||||||

| Cost of off site disposal | $ | $ | $ | |||||||

| Other: | $ | $ | $ | |||||||

| Other: | $ | $ | $ | |||||||

| Other: | $ | $ | $ | |||||||

| Total | $ | $ | $ | |||||||

Sheet 8: Part B Section 5

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | ||||||||||||||

| Plant ID: | Insert Plant ID | ||||||||||||||

| Plant Name: | Insert Plant Name | ||||||||||||||

| Part: | B | ||||||||||||||

| Section Title: | 5. FGD Wastewater Generation | ||||||||||||||

| Instructions: | Throughout this section, you will be required to provide information for all wet FGD systems that the plant operates, reported in Table B-1. This section does not need to be completed for planned systems. Please provide all free response answers in the highlighted yellow areas. | ||||||||||||||

| In Table B-7, provide information for each wet FGD system that the plant operates reported in Table B-1. This table does not need to be completed for planned systems. For the source of FGD reagent preparation water, absorber make-up water, and mist eliminator wash water, you may enter more than one source. Select a source from the dropdown menu. For the percent contribution of the flow rates, provide the percentage based on the total flow rate for all these sources entering the FGD system. | |||||||||||||||

| Table B-7. FGD System Water Sources and Flow Rates | |||||||||||||||

| FGD System ID | FGD Reagent Preparation Water, Absorber Make-Up Water, and Mist Eliminator Wash Water (Sources, Percent Contribution, and Flow Rate) |

||||||||||||||

| Source(s) | Percent | Flow Rate (gpd) |

|||||||||||||

| Example: | FGDB | 80% | 48,000 | ||||||||||||

| CTB | 20% | 12,000 | |||||||||||||

| Other | |||||||||||||||

| CBI? | B5-2. | In Table B-8, provide information for each wet FGD system that the plant operates reported in Table B-1. This table does not need to be completed for planned systems. | |||||||||||||

| Table B-8. Water Generated from Wet FGD Systems | |||||||||||||||

| FGD System ID | Absorber Type | Typical FGD Slurry Blowdown (or Slurry Discharge) Flow Rate Exiting the Absorber (gpd) |

Typical Range of Percent Solids of FGD Slurry Blowdown (or Slurry Discharge) Exiting the Absorber (%) |

Typical Amount of Solids Separation Recycle Returned to Absorber (gpd) |

Typical Amount of FGD Scrubber Purge (or Slurry Discharge) Sent to Wastewater Treatment or Discharge (gpm AND gpd) |

Typical Duration AND Frequency of FGD Scrubber Purge (or Slurry Discharge) Generation (hpd AND dpy) |

|||||||||

| Example: | |||||||||||||||

| 200 | gpm | 10 | hpd | ||||||||||||

| 240,000 | 12 | to | 16 | 180,000 | 120,000 | gpd | 365 | dpy | |||||||

| gpm | hpd | ||||||||||||||

| to | gpd | dpy | |||||||||||||

| gpm | hpd | ||||||||||||||

| to | gpd | dpy | |||||||||||||

| gpm | hpd | ||||||||||||||

| to | gpd | dpy | |||||||||||||

| gpm | hpd | ||||||||||||||

| to | gpd | dpy | |||||||||||||

| gpm | hpd | ||||||||||||||

| to | gpd | dpy | |||||||||||||

| gpm | hpd | ||||||||||||||

| to | gpd | dpy | |||||||||||||

| CBI? |

Provide the typical chlorides and solids concentrations of the untreated FGD scrubber purge (or slurry discharge) transferred to the wastewater treatment system (after the FGD solids separation process, but prior to commingling with other process wastewater). | ||||||||||||||

| ppm | |||||||||||||||

| ppm | |||||||||||||||

Sheet 9: Part B Section 6

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | |||||

| Plant ID: | Insert Plant ID | |||||

| Plant Name: | Insert Plant Name | |||||

| Part: | B | |||||

| Section Title: | 6. FGD Monitoring Data Instructions | |||||

| Instructions: | Throughout this section, you will be required to provide monitoring data for all wet FGD systems that the plant operates, reported in Table B-1. This section does not need to be completed for planned systems. Please provide all free response answers in the highlighted yellow areas. | |||||

| CBI? |

B6-1. | Has your plant collected monitoring data (for any reason) for untreated FGD scrubber purge (or slurry discharge) in the 12 months prior to recieving the ICR for any of the following analytes: | ||||

| · Metals (including monitoring data for total recoverable or dissolved metals analyses, or trace metals analyses); | ||||||

| · Ammonia; | ||||||

| · Nitrate/nitrite; and | ||||||

| · Total Kjeldahl nitrogen (TKN). | ||||||

| Note: The untreated FGD scrubber purge (or slurry discharge) stream is the FGD wastewater stream leaving the solids separation process prior to commingling with other water streams (see Figures B-1 and B-2). | ||||||

| (Provide the monitoring data as instructed below) | ||||||

| (Skip to Section 7) | ||||||

| Note: You are not required to perform non-routine tests or measurements solely for the purpose of responding to this question. | ||||||

| Provide the monitoring data in Table B-9 in the tab labeled "Part B Section 6 Table" for each different FGD scrubber purge stream for which the plant collected monitoring data. Report all results. Identify results that are less than the method detection limit (MDL), and results that are between the detection and reporting limits. Copy Table B-9 as many times as needed using the "Copy Table B-9" button below. |

||||||

| Note: If you operate mulitiple FGD solids separation processes (e.g., two sets of hydroclones), only provide monitoring data collected after the last solid separation process. If necessary, you may provide additional information regarding the sample collection techniques or analytical methods in the Comments section (e.g., sample collection followed EPA Method 1669 protocols, dynamic reaction cell was used in conjunction with analytical method). | ||||||

| The following information should be provided for each data point: | ||||||

| · Name of analyte and CAS Number; | ||||||

| · Measured value including units (if not detected, list the detection limit value preceded by a less than (<) symbol); | ||||||

| · Analytical method used; | ||||||

| · Sample-specific detection limit for the method used; | ||||||

| · Sample-specific nominal quantitation limit stipulated for the method used; | ||||||

| · Date the sample was collected; | ||||||

| · Location where the sample was collected (e.g., purge tank which collects secondary hydroclone overflow); | ||||||

| · Whether the sample was collected as a grab or as a composite (and note the compositing period used); | ||||||

| · Description of any qualifiers for the measurement; | ||||||

| · For metals, whether the sample was analyzed as total recoverable or dissolved; | ||||||

| · Identification of FGD system(s) and steam electric generating unit(s) that the sample represents (report FGD System IDs and associated steam electric generating units from Table B-1); and |

||||||

| · Flow rate (only if flow rate data were recorded at the sampling point during the sampling period). | ||||||

Sheet 10: Part B Section 6 Table

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | |||||||||||||||

| Plant ID: | Insert Plant ID | |||||||||||||||

| Plant Name: | Insert Plant Name | |||||||||||||||

| Part: | B | |||||||||||||||

| Section Title: | 6. FGD Monitoring Data | |||||||||||||||

| Instructions: | Throughout this section, you will be required to provide information on monitoring data for untreated FGD scrubber purge (or slurry discharge) for all wet FGD systems that the plant operates, reported in Table B-1. This section does not need to be completed for planned systems. Please provide all free response answers in the highlighted yellow areas. | |||||||||||||||

| CBI? |

B6-2. | Complete Table B-9 for all monitoring data for untreated FGD scrubber purge (or slurry discharge) collected by the plant (for any reason) in the 12 months prior to receiving the ICR for any of the following analytes: metals (including monitoring data for total recoverable or dissolved metals analyses), ammonia, nitrate/nitrite, and total Kjeldahl nitrogen (TKN). Complete a separate table for each different FGD scrubber purge (or slurry discharge) stream for which the plant is providing monitoring data. Report all results. Identify results that are less than the method detection limit (MDL), and results that are between the detection and reporting limits. For Question B6-2, identify the FGD systems and steam electric generating units associated with the FGD scrubber purge data provided in the table. Refer to the instructions in Part B Section 6 if you need assistance completing Table B-9. | ||||||||||||||

| Identify the FGD systems and steam electric generating units associated with the FGD scrubber purge (or slurry discharge) monitoring data provided in the table below. Use the FGD system IDs identified in Table B-1 and the SE unit IDs identified in Table A-8. [Check all that apply.] | ||||||||||||||||

| Table B-9. Monitoring Data for Untreated FGD Scrubber Purge (or Slurry Discharge) | ||||||||||||||||

| Analyte | CAS Number | Measured Value Including Units* | Analytical method | Method Detection Limit | Reporting Limit | Date Sample Collected | Location Collected | Collected as a Grab or Composite | Description of Qualifiers | Analyzed as Total Recoverable or Dissolved** | Flow Rate of FGD Scrubber Purge (or Slurry Discharge) at Time of Sampling (gpm) | |||||

| Value | Units | Value | Units | Value | Units | |||||||||||

| *If not detected, list the detection limit value preceded by a less than (<) symbol | ||||||||||||||||

| **Only answer for metals | ||||||||||||||||

Sheet 11: Part B Section 7

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | |||||||||||

| Plant ID: | Insert Plant ID | |||||||||||

| Plant Name: | Insert Plant Name | |||||||||||

| Part: | B | |||||||||||

| Section Title: | 7. FGD Wastewater Treatment | |||||||||||

| Instructions: | Throughout this section, you will be required to provide information for all wet FGD systems that the plant operates, reported in Table B-1. This section does not need to be completed for planned systems. Please provide all free response answers in the highlighted yellow areas. | |||||||||||

| CBI? | B7-1. | Does the plant transfer the FGD scrubber purge (or slurry discharge) to a settling pond? | ||||||||||

| (Continue) | ||||||||||||

| (Skip to Question B7-4) | ||||||||||||

| CBI? | B7-2. | Indicate which process wastewaters are commingled with the FGD scrubber purge (or slurry discharge) in the settling pond. [Check all boxes that apply.] | ||||||||||

| CBI? |

B7-3. | If the FGD scrubber purge (or slurry discharge) is commingled with bottom ash or fly ash sluice water in the pond(s), select the option below that best describes the configuration of the pond(s). If neither option applies, provide an explanation in the space provided: | ||||||||||

| CBI? | B7-4. | Indicate wastewater treatment technologies used to treat the FGD scrubber purge (or slurry discharge). [Check all boxes that apply.] | ||||||||||

| CBI? | B7-5. | What is the destination(s) of the treated FGD scrubber purge (or slurry discharge)? If the plant recycles the FGD scrubber purge (or slurry discharge), indicate the plant process to which this water is recycled. [Check all that apply.] | ||||||||||

| CBI? |

B7-6. | Plants that produce gypsum from wet FGD systems may generate water from the storage and handling of gypsum. Examples of gypsum-related waters are gypsum wash water and gypsum pile runoff. Are gypsum-related waters generated at the plant? Note: gypsum-related water does not include FGD slurry blowdown or FGD scrubber purge (or slurry discharge). | ||||||||||

| (Continue) | ||||||||||||

| (Skip to Section 8) | ||||||||||||

| If yes, provide the typical volume of gypsum-related waters generated per day (gpd) and the frequency of water generation (dpy) for calendar year 2009. | ||||||||||||

| gpd | dpy | |||||||||||

| CBI? | B7-7. | Indicate how the gypsum-related waters are handled. [Check all boxes that apply.] | ||||||||||

Sheet 12: Part B Section 8

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | |||||||||||

| Plant ID: | Insert Plant ID | |||||||||||

| Plant Name: | Insert Plant Name | |||||||||||

| FGD System ID: | Insert System ID | |||||||||||

| Part: | B | |||||||||||

| Section Title: | 8. Dry FGD System Information | |||||||||||

| Instructions: | Throughout this section, you will be required to provide information for each dry FGD system that the plant operates, reported in Table B-1. This section does not need to be completed for planned systems. Please provide all free response answers in the highlighted yellow areas. | |||||||||||

| Make copies of Section 8 and Section 8 tables for each dry FGD system previously defined in Table B-1 using the Copy Section 8 and Section 8 Tables button below. Please note that you will create two new tabs for these sections. You may delete unneeded tabs, if accidently created. Enter the FGD system ID in the space provided above (use FGD system IDs assigned in Table B-1). | ||||||||||||

| CBI? | B8-1. | Did you report use of a dry FGD system in Table B-1? | ||||||||||

| (Continue) | ||||||||||||

| (Skip to next Questionnaire Part) | ||||||||||||

| CBI? | B8-2. | Indicate how the FGD solid is removed from the flue gas. | ||||||||||

| CBI? |

B8-3. | Is the FGD system located upstream or downstream of the fly ash collection system? | ||||||||||

| CBI? |

B8-4. | For water sources that may be used as a source of FGD reagent preparation water (e.g., fresh intake, recycled process water), indicate the maximum chlorides concentration and maximum solids percentage that is acceptable for the water to be used for those purposes. Identify any other criteria that the source water must meet. | ||||||||||

| ppm | ||||||||||||

| % | ||||||||||||

| CBI? |

B8-5. | Provide the flow rate, duration, and frequency of the FGD reagent preparation water for the FGD system for calendar year 2009. | ||||||||||

| gpm | ||||||||||||

| hpd | ||||||||||||

| dpy | ||||||||||||

| CBI? | B8-6. | Provide the source of the FGD reagent preparation water used. [Check all boxes that apply.] | ||||||||||

| CBI? | B8-7. | Is any FGD wastewater generated from the operation of the dry FGD scrubber? | ||||||||||

| (Continue) | ||||||||||||

| (Skip to Question B8-9) | ||||||||||||

| CBI? |

B8-8. | Indicate the destination(s) of the FGD wastewater. If the plant recycles the FGD wastewater, indicate the plant process to which this water is recycled. [Check all that apply.] | ||||||||||

| CBI? | B8-9. | Is any FGD wastewater generated from cleaning the dry FGD scrubber (e.g., power washing during scheduled generating unit outages)? | ||||||||||

| (Continue) | ||||||||||||

| (Skip to Question B8-11) | ||||||||||||

| CBI? | B8-10. | Indicate the destination(s) of the FGD wastewater from cleaning. If the plant recycles the FGD wastewater, indicate the plant process to which this water is recycled. [Check all that apply.] | ||||||||||

| CBI? |

B8-11. | What parameters affect the ability of the FGD solids to be marketed, sold and/or given away? [Check all boxes that apply.] | ||||||||||

| ppm | ||||||||||||

| ppm | ||||||||||||

| ppm | ||||||||||||

Sheet 13: Part B Section 8 Tables

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | |||||||||||||

| Plant ID: | Insert Plant ID | |||||||||||||

| Plant Name: | Insert Plant Name | |||||||||||||

| FGD System ID: | Insert System ID | |||||||||||||

| Part: | B | |||||||||||||

| Section Title: | 8. FGD Solids Disposition and Marketing for Dry FGD Systems | |||||||||||||

| Instructions: | Throughout this section, you will be required to provide information on FGD solids disposition for all dry FGD systems that the plant operates reported in Table B-1. This section does not need to be completed for planned systems. Please provide all free response answers in the highlighted yellow areas. | |||||||||||||

| CBI? |

B8-12. | In Table B-10, indicate the ultimate destination of FGD solids from the FGD system and provide the tonnage for each type of storage/handling technique for calendar years 2005, 2007, and 2009. If the FGD solids are stored in a landfill or pond/impoundment, provide the amount of FGD solids stored permanently and/or temporarily. For example, a plant may operate a gypsum landfill, and some amount of FGD solids that are transferred to the landfill may later be removed from the landfill and sold for use in wallboard manufacturing. In this case, the amount of FGD solids sold for wallboard manufacturing should be identified in BOTH the "Landfills reported in Table A-6: Stored temporarily" category AND the "Marketed and Sold" category. In this same example, all the FGD solids that are transferred to the landfill and left in the landfill should be identified as "Landfills reported in Table A-6: Stored permanently." |

||||||||||||

| Table B-10. FGD Solids Disposition for 2005, 2007, and 2009 | ||||||||||||||

| Ultimate Destination of FGD Solids | Amount Disposed in 2005 (tons) | Amount Disposed in 2007 (tons) | Amount Disposed in 2009 (tons) | |||||||||||

| Sent to Landfills reported in Table A-6 | Stored permanently | |||||||||||||

| Stored temporarily (later hauled off-site/marketed) | ||||||||||||||

| Sent to Pond/Impoundment reported in Table A-4 | Stored permanently | |||||||||||||

| Stored temporarily (later hauled off-site/marketed) | ||||||||||||||

| Sent to Landfills not reported in Table A-6 | ||||||||||||||

| Sent to Pond/Impoundment not reported in Table A-4 | ||||||||||||||

| Marketed and sold | ||||||||||||||

| Given away | ||||||||||||||

| Other, explain: | ||||||||||||||

| Other, explain: | ||||||||||||||

| CBI? |

B8-13. | Complete Table B-11 if the plant markets, sells, and/or gives away the FGD solids from this FGD system. For each destination, provide the tons of FGD solids for which the FGD solids are marketed, sold, and/or given away. Also provide the gross revenue generated from marketing/selling the FGD solids for each destination. | ||||||||||||

| Table B-11. FGD Solids Marketed/Sold in 2005, 2007, and 2009 | ||||||||||||||

| Destination | 2005 | 2007 | 2009 | |||||||||||

| Tons | Gross Revenue Generated ($) | Tons | Gross Revenue Generated ($) | Tons | Gross Revenue Generated ($) | |||||||||

| CBI? |

B8-14. | In Table B-12, provide the total cost incurred to remove or dispose of FGD solids from 2005 to 2009 including the cost for labor, materials, transportation, and energy. Also provide the cost by component. Include other components not provided in the list of processes in the yellow box provided. | ||||||||||||

| Table B-12. Cost Incurred to Remove or Dispose of FGD Solids | ||||||||||||||

| Process | 2005 | 2007 | 2009 | |||||||||||

| Total Costs Incurred | Total Costs Incurred | Total Costs Incurred | ||||||||||||

| Solids separation | $ | $ | $ | |||||||||||

| Solids dewatering | $ | $ | $ | |||||||||||

| Hauling FGD solids | $ | $ | $ | |||||||||||

| Cost of on site disposal | $ | $ | $ | |||||||||||

| Cost of off site disposal | $ | $ | $ | |||||||||||

| Other: | $ | $ | $ | |||||||||||

| Other: | $ | $ | $ | |||||||||||

| Other: | $ | $ | $ | |||||||||||

| Total | $ | $ | $ | |||||||||||

Sheet 14: Part B Comments

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | ||||

| Plant Name: | Insert Plant ID | ||||

| Plant ID: | Insert Plant Name | ||||

| Part: | B | ||||

| Section Title: | Part B Comments | ||||

| Instructions: | Cross reference your comments by question number and indicate the confidential status of your comment by checking the box next to “Yes” under "CBI?" (Confidential Business Information). | ||||

| Question Number |

Comment | ||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

| CBI? |

|||||

Sheet 15: Code Tables

| Steam Electric Questionnaire | Part B. Flue Gas Desulfurization (FGD) Systems | ||||

| Steam Electric Questionnaire Code Tables | |||||

| Process Wastewaters | Treated Wastewaters | ||||

| For Use in Tables and Questions throughout Parts A, B, C, D, and F. | For Use as Effluents from Pond/Impoundment Systems and/or Wastewater Treatment Systems in Part D, Table D-4. | ||||

| Air heater cleaning water | AHCW | ||||

| Ash pile runoff | APR | Effluent - 1 | EFF-1 | ||

| Boiler blowdown | BB | Effluent - 2 | EFF-2 | ||

| Boiler fireside cleaning water | BFCW | Effluent - 3 | EFF-3 | ||

| Boiler tube cleaning water | BTCW | Effluent - 4 | EFF-4 | ||

| Bottom ash sluice | BAS | Effluent - 5 | EFF-5 | ||

| Carbon capture wastewater | CCAPW | Effluent - 6 | EFF-6 | ||

| Coal pile runoff | CPR | Filter backwash | FltBW | ||

| Combined ash sluice | CAS | Sludge | SLDG | ||

| Combustion turbine cleaning (combustion gas portion of turbine) water | COMBCW | For Use as Influents to Pond/Impoundment Systems and/or Wastewater Treatment Systems in Part D, Table D-3, AND Recycled Waters Throughout Questionnaire. | |||

| Combustion turbine cleaning (compressor portion of the turbine) water | COMPRCW | POND-1 Effluent | POND-1-EFF | ||

| Combustion turbine evaporative coolers blowdown | TECB | POND-2 Effluent | POND-2-EFF | ||

| Cooling tower blowdown | CTB | POND-3 Effluent | POND-3-EFF | ||

| FGD scrubber purge | SCRBP | POND-4 Effluent | POND-4-EFF | ||

| FGD slurry blowdown | FGDB | POND-5 Effluent | POND-5-EFF | ||

| Filter Backwash | FLTBW | POND-6 Effluent | POND-6-EFF | ||

| Floor drain wastewater | FDW | POND-7 Effluent | POND-7-EFF | ||

| Flue gas mercury control system wastewater | FGMCW | POND-8 Effluent | POND-8-EFF | ||

| Fly ash sluice | FAS | POND-9 Effluent | POND-9-EFF | ||

| General runoff | GR | POND-10 Effluent | POND-10-EFF | ||

| Gypsum pile runoff | GPR | POND-A Effluent | POND-A-EFF | ||

| Gypsum wash water | GYPWW | POND-B Effluent | POND-B-EFF | ||

| Ion exchange wastewater | IXW | POND-C Effluent | POND-C-EFF | ||

| Landfill runoff - capped landfill | LRC | WWT-1 Effluent | WWT-1-EFF | ||

| Landfill runoff - uncapped landfill | LRUC | WWT-2 Effluent | WWT-2-EFF | ||

| Leachate | LEACH | WWT-3 Effluent | WWT-3-EFF | ||

| Limestone pile runoff | LPR | WWT-4 Effluent | WWT-4-EFF | ||

| Mill reject sluice | MRS | WWT-5 Effluent | WWT-5-EFF | ||

| Process Wastewaters | Treated Wastewaters | ||||

| For Use in Tables and Questions throughout Parts A, B, C, D, and F. | For Use as Influents to Pond/Impoundment Systems and/or Wastewater Treatment Systems in Part D, Table D-3, AND Recycled Waters Throughout Questionnaire. | ||||

| Once -through cooling water | CW | WWT-6 Effluent | WWT-6-EFF | ||

| Reverse osmosis reject water | RORW | WWT-A Effluent | WWT-A-EFF | ||

| SCR catalyst regeneration wastewater | SCRRW | WWT-B Effluent | WWT-B-EFF | ||

| SCR catalyst washing wastewater | SCRWW | WWT-C Effluent | WWT-C-EFF | ||

| Soot blowing wash water | SOOTW | ||||

| Steam turbine cleaning water | STCW | ||||

| Yard drain wastewater | YARDW | ||||

| Wastewater Treatment Units | Destinations | ||||

| For Use in Tables and Questions Throughout Parts D and F. | For Use in Tables and Questions Throughout Parts A, C, D, and F. | ||||

| Adsorptive media | ADSORB | Burned on site | BURN | ||

| Aerobic Biological Reactor | AERBIO | Deep-well injection | DWELL | ||

| Anaerobic Biological Reactor | ANBIO | Discharge to POTW | POTW | ||

| Aerobic/Anaerobic Biological Reactor | AER/ANBIO | Discharge to PrOTW | PrOTW | ||

| Chemical Precipitation Reaction Tank 1 - 1 | CP-1-1 | Discharge to surface water | SW | ||

| Chemical Precipitation Reaction Tank 1 - 2 | CP-1-2 | Evaporation | EVAP | ||

| Chemical Precipitation Reaction Tank 2 - 1 | CP-2-1 | Hauled off site for reuse (removal fee) | HAULR - RF | ||

| Chemical Precipitation Reaction Tank 2 - 2 | CP-2-2 | Hauled off site for reuse (given away) | HAULR - GA | ||

| Chemical Precipitation Reaction Tank 3 - 1 | CP-3-1 | Hauled off site for reuse (marketed and sold) | SOLD | ||

| Chemical Precipitation Reaction Tank 3 - 2 | CP-3-2 | Hauled off site for disposal | HAUL | ||

| Clarification, Primary - 1 | CL-P-1 | Mixed with fly ash for disposal | MFA | ||

| Clarification, Primary - 2 | CL-P-2 | On-site landfill (as reported in Table A-6) | LANDF | ||

| Clarification, Secondary - 1 | CL-S-1 | POND-1 | POND-1 | ||

| Clarification, Secondary - 2 | CL-S-2 | POND-2 | POND-2 | ||

| Clarification, Tertiary - 1 | CL-T-1 | POND-3 | POND-3 | ||

| Clarification, Tertiary - 2 | CL-T-2 | POND-4 | POND-4 | ||

| Constructed wetland - Cell 1 | CWL -1 | POND-5 | POND-5 | ||

| Constructed wetland - Cell 2 | CWL -2 | POND-6 | POND-6 | ||

| Constructed wetland - Cell 3 | CWL -3 | POND-7 | POND-7 | ||

| Constructed wetland - Cell 4 | CWL -4 | POND-8 | POND-8 | ||

| Constructed wetland - Cell 5 | CWL -5 | POND-9 | POND-9 | ||

| Constructed wetland - Cell 6 | CWL -6 | POND-10 | POND-10 | ||

| Constructed wetland system | CWTS | POND-A | POND-A | ||

| Equalization, Primary | EQ-P | POND-B | POND-B | ||

| Equalization, Secondary | EQ-S | POND-C | POND-C | ||

| Filter, Microfiltration - 1 | FLT-M-1 | WWT-1 | WWT-1 | ||

| Filter, Microfiltration - 2 | FLT-M-2 | WWT-2 | WWT-2 | ||

| Wastewater Treatment Units | Destinations | ||||

| For Use in Tables and Questions Throughout Parts D and F. | For Use in Tables and Questions Throughout Parts A, C, D, and F. | ||||

| Filter, Microfiltration - 3 | FLT-M-3 | WWT-3 | WWT-3 | ||

| Filter, Microfiltration - 4 | FLT-M-4 | WWT-4 | WWT-4 | ||

| Filter, Sand/Gravity - 1 | FLT-S-1 | WWT-5 | WWT-5 | ||

| Filter, Sand/Gravity - 2 | FLT-S-2 | WWT-6 | WWT-6 | ||

| Filter, Sand/Gravity - 3 | FLT-S-3 | WWT-A | WWT-A | ||

| Filter, Sand/Gravity - 4 | FLT-S-4 | WWT-B | WWT-B | ||

| Filter, Ultrafiltration - 1 | FLT-U-1 | WWT-C | WWT-C | ||

| Filter, Ultrafiltration - 2 | FLT-U-2 | Reuse as boiler water | RECYC - BW | ||

| Filter, Ultrafiltration - 3 | FLT-U-3 | Reuse as bottom ash sluice | RECYC - BAS | ||

| Filter, Ultrafiltration - 4 | FLT-U-4 | Reuse as combined ash sluice | RECYC - CAS | ||

| Filter press - 1 | FP-1 | Reuse as FGD slurry preparation water | RECYC - FGDP | ||

| Filter press - 2 | FP-2 | Reuse as FGD absorber makeup | RECYC - FGDAB | ||

| Holding tank | HT | Reuse as fly ash sluice | RECYC - FAS | ||

| Ion exchange | IX | Reuse as mill reject sluice | RECYC - MRS | ||

| Natural wetlands | NW | Reuse in cooling towers | RECYC - CW | ||

| pH adjustment - 1 | PH-1 | ||||

| pH adjustment - 2 | PH-2 | ||||

| pH adjustment - 3 | PH-3 | ||||

| Reverse osmosis | ROS | ||||

| Pond Unit - 1 | SPD-1 | ||||

| Pond Unit - 2 | SPD-2 | ||||

| Pond Unit - 3 | SPD-3 | ||||

| Pond Unit - 4 | SPD-4 | ||||

| Pond Unit - 5 | SPD-5 | ||||

| Pond Unit - 6 | SPD-6 | ||||

| Pond Unit - 7 | SPD-7 | ||||

| Pond Unit - 8 | SPD-8 | ||||

| Pond Unit - 9 | SPD-9 | ||||

| Wastewater Treatment Units | Solids Handling | ||||

| For Use in Tables and Questions Throughout Parts D and F. | For Use as Planned Solids Handling for the FGD Slurry Blowdown in Part B Table B-2. | ||||

| Pond Unit - 10 | SPD-10 | Centrifuge - 1 | CENT-1 | ||

| Pond Unit - 11 | SPD-11 | Centrifuge - 2 | CENT-2 | ||

| Pond Unit - 12 | SPD-12 | Centrifuge - 3 | CENT-3 | ||

| Pond Unit - 13 | SPD-13 | Centrifuge - 4 | CENT-4 | ||

| Pond Unit - 14 | SPD-14 | Hydrocyclones - 1 | HYC-1 | ||

| Settling tank - 1 | ST-1 | Hydrocyclones - 2 | HYC-2 | ||

| Settling tank - 2 | ST-2 | Hydrocyclones - 3 | HYC-3 | ||

| Settling tank - 3 | ST-3 | Hydrocyclones - 4 | HYC-4 | ||

| Settling tank - 4 | ST-4 | Filter press - 1 | FP-1 | ||

| Settling tank - 5 | ST-5 | Filter press - 2 | FP-2 | ||

| Thickener - 1 | TH-1 | Thickener - 1 | TH-1 | ||

| Thickener - 2 | TH-2 | Thickener - 2 | TH-2 | ||

| Vacuum drum filter - 1 | VF-1 | Vacuum drum filter - 1 | VF-1 | ||

| Vacuum drum filter - 2 | VF-2 | Vacuum drum filter - 2 | VF-2 | ||

| Vacuum filter belt - 1 | VFB-1 | Vacuum filter belt - 1 | VFB-1 | ||

| Vacuum filter belt - 2 | VFB-2 | Vacuum filter belt - 2 | VFB-2 | ||

| File Type | application/vnd.ms-excel |

| Author | Jennifer O'Neil |

| Last Modified By | BSchwantes |

| File Modified | 2010-02-22 |

| File Created | 2008-05-21 |

© 2026 OMB.report | Privacy Policy