1219-0011 Supporting Statement Final

1219-0011 Supporting Statement Final.doc

Respirable Coal Mine Dust Sampling

OMB: 1219-0011

Supporting Statement for Paperwork Reduction Act Submissions

Respirable Coal Mine Dust Sampling

OMB 30 CFR

Control Citations Title

1219-0011 70.201(c); 90.201(c); 71.201(c), (e) Sampling; general requirements;

70.205(c); 71.205(c); 90.205(c) Approved sampling devices; operation; air flowrate

70.209(a), (c), (d); 71.209(a), (c), (d); Respirable dust samples

90.209(a), (c), (d) transmission by operator Mine

Operator Dust Data Card;

70.210(b), 71.210(b) Respirable dust samples; report to operator; posting;

90.210(b) Respirable dust samples; report to operator.

70.220(a); 71.220(a); 90.220 Status change reports;

71.300(a); 90.300(a) Respirable dust control plan; filing requirements

71.301(d), (e) Respirable dust control plan; approval by District Manager and posting

90.301(d), (e) Respirable dust control plan; approval by District Manager; copy to part 90 Miner

Form Number(s): None

General Instructions

A Supporting Statement, including the text of the notice to the public required by 5 CFR 1320.5(a)(i)(iv) and its actual or estimated date of publication in the Federal Register, must accompany each request for approval of a collection of information. The Supporting Statement must be prepared in the format described below, and must contain the information specified in Section A below. If an item is not applicable, provide a brief explanation. When Item 17 or the OMB Form 83-I is checked “Yes”, Section B of the Supporting Statement must be completed. OMB reserves the right to require the submission of additional information with respect to any request for approval.

Specific Instructions

A. Justification

1. Explain the circumstances that make the collection of information necessary. Identify any legal or administrative requirements that necessitate the collection. Attach a copy of the appropriate section of each statute and regulation mandating or authorizing the collection of information.

Note: With this submittal, the title of the information collection is being changed from “Mine Operator Dust Data Card” to “Respirable Coal Mine Dust Sampling” to more accurately reflect the type of information that is collected.

Chronic exposure to respirable coal mine dust causes lung diseases including coal workers’ pneumoconiosis (CWP), emphysema, silicosis, and chronic bronchitis, known collectively as “black lung.” These diseases are debilitating and can result in disability and premature death. While considerable progress has been made in lowering dust levels since 1970 and, consequently, lowering the prevalence rate of black lung among coal miners, severe forms of black lung continues to be identified. Newly released information from the federally funded Coal Workers’ Health Surveillance Programs administered by the National Institute for Occupational Safety and Health (NIOSH) clearly indicates that black lung remains a key occupational health risk among our nation’s coal miners. According to NIOSH, 933 or 3.7 percent of the 25,558 underground coal miners x-rayed between January 2003 and September 2011 were found to have CWP. Also, in FY 2011, over 28,600 former coal miners and the dependents of miners received $417 million in "black lung" benefits. Since inception of the federal Black Lung Benefits Program in 1970, over $44 billion in total benefits have been paid out to former miners and their dependents.

Section 103(h) of the Federal Mine Safety and Health Act of 1977 (Mine Act), 30 U.S.C. 813(h), authorizes MSHA to collect information necessary to carry out its duty to protect the safety and health of miners. Further, Section 101(a) of the Mine Act, 30 U.S.C. 811(a), authorizes the Secretary to develop, promulgate, and revise as may be appropriate, improved mandatory health or safety standards for the protection of life and prevention of injuries in coal or other mines. MSHA’s standards in 30 CFR parts 70, 71, and 90 require each mine operator of an underground coal mine, surface coal mine and, surface areas of an underground coal mine, and each coal mine operator who employs a Part 90 miner, to protect miners from exposure to excessive respirable coal mine dust levels. Parts 70 and 71 require each coal mine operator to continuously maintain the average concentration of respirable coal mine dust in the mine atmosphere where miners normally work or travel at or below 2.0 milligrams per cubic meter (mg/m3). This standard is reduced using the formula 10 ÷ % quartz when the respirable dust contains more than 5 percent quartz. Overexposure to respirable coal mine dust containing quartz has been associated with silicosis (black lung). These lung diseases are irreversible and may be fatal, but they are preventable. Parts 70 and 71 also require each coal mine operator to continuously maintain the average concentration of respirable dust in intake airways at underground mines at or below 1.0 mg/m3.

If a Part 90 miner is employed at the mine, the coal mine operator is required to continuously maintain the average concentration of respirable dust in the mine atmosphere during each shift to which the Part 90 miner in the active workings of the mine is exposed at or below 1.0 mg/m3. This standard is also reduced if more than 5 percent quartz is found in the mine atmosphere during each shift to which the Part 90 miner is exposed.

The existing standards provide that each coal mine operator sample bimonthly the designated occupations or work locations of the mine and submit these samples to MSHA for analysis to determine if the mine is complying with the applicable dust standards. Specifically, under 30 CFR 70.207, each underground coal mine operator must sample the designated occupation (DO) in each mechanized mining unit (MMU) for five consecutive shifts or days and, under § 70.208, each designated area (DA) for one shift at locations specified in the operator’s approved mine ventilation plan. In addition, under § 71.208, each coal mine operator must sample designated work positions (DWPs) bimonthly at surface coal mines and surface areas of underground mines. Finally, under § 90.207, each coal mine operator must take five samples after employing a Part 90 miner and, under § 90.208, must sample bimonthly each Part 90 miner for a minimum of one shift.

If MSHA wishes to monitor operator sampling, §§ 70.201(c), 71.201(c), and 90.201(c) require the mine operator to submit the date on which sampling will begin. This information has been used by MSHA in scheduling MSHA sampling at the mine so as not to interfere with operator sampling.

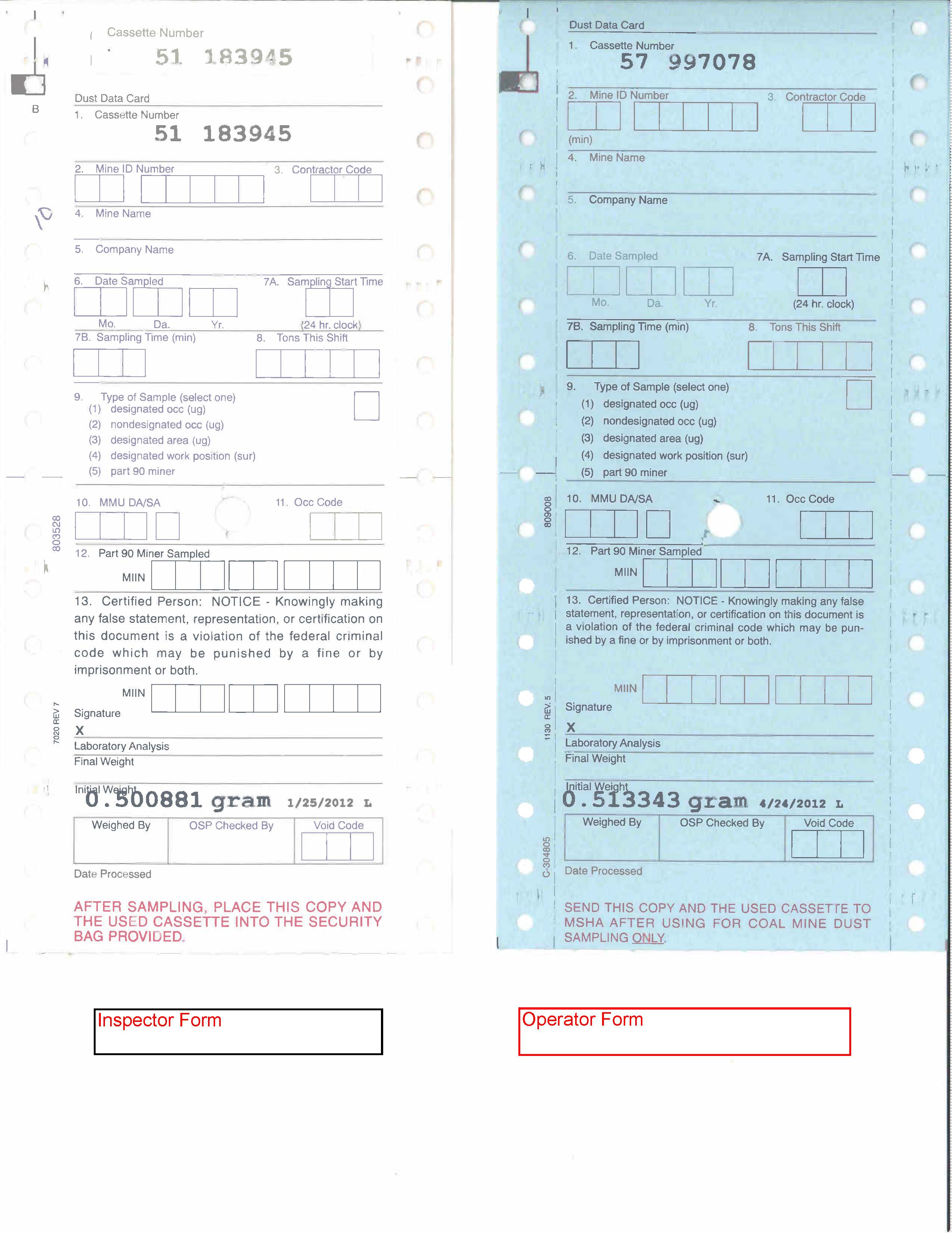

Sections 70.209(a) and (c); 71.209(a) and (c); and 90.209(a) and (c) require that a certified person complete all fields on the dust data card and submit the card along with the operator samples to MSHA for processing. The information on the dust data card includes the Mine ID Number, Contractor Code, Mine Name, Company Name, Date and Time Sampled, Tons this Shift, Type of Sample, MMU, Occupational Code, and MSHA Individual Identification Number (MIIN), for each dust sample submitted to MSHA for processing. According to §§ 70.209(d), 71.209(d), and 90.209(d), an operator sample submitted to MSHA is considered taken to fulfill the sampling requirements of parts 70, 71, and 90 unless the sample has been identified in writing by the operator to the District Manager that it is to be used for another purpose. In addition, the certified person must also note on the dust data card those occurrences when the sampling device was not operating properly and the proper flowrate was not maintained during a shift according to §§ 70.205(c), 71.205(c), and 90.205(c).

After MSHA processes the submitted samples, it sends a report of the results to the mine operator according to §§ 70.210(a), 71.210(a), and 90.210 (a). The report contains the following information: the mine identification number; the specific entity from which the samples were taken; the concentration of respirable dust for each valid sample; the average concentration for all valid samples; the occupation code, where applicable; and the reason for voiding any sample. When received by a mine operator, the report must be immediately posted on the mine bulletin board for at least 31 days so all coal miners will know the dust levels to which they were exposed, in accordance with §§ 70.210(b) and 71.210(b). For Part 90 sampling results, the mine operator must provide the report to the affected miner in accordance with § 90.210(b).

When a change occurs in the operational status of a mine, MMU, or designated area that affects the sampling requirements of 30 CFR parts 70, 71, and 90, the changes must be reported in writing to the MSHA District Office within 3 working days after the status change has occurred in accordance with §§ 70.220(a), 71.220(a), and 90.220.

Sections 70.201(c), 71.201(c), and 90.201(c), require that upon request of the District Manager, a mine operator must submit the date on which any respirable dust samples required by 30 CFR Part 70, 71, or 90 are collected. In addition, under § 71.201(e), a miner operator may request, in writing, that the rain restriction for a normal work shift as defined in § 71.2 be waived by the District Manager.

Sections 71.300(a) and 90.300(a) (affecting surface operations and Part 90 miners) require the submission of a written respirable dust control plan to MSHA for approval within 15 calendar days after the termination date of a citation for violation of the dust standard. The plan describes the specific dust control measures used by an operator to abate the dust violation and how each control measure will be used to ensure continued compliance.

Section 71.301(d) requires the approved dust control plan to be posted on the mine bulletin board to inform interested persons at the mine of the types and location of dust control measures that are required to be employed and maintained. However, for privacy reasons, § 90.301(d) prohibits posting of the dust control plan for Part 90 miners and, instead, requires that a copy be provided to the affected miner. In addition, §§ 71.301(e) and 90.301(e) allow the mine operator to review respirable dust control plans and submit proposed revisions to the District Manager for approval.

2. Indicate how, by whom, and for what purpose the information is to be used. Except for a new collection, indicate the actual use the agency has made of the information received from the current collection.

The information provided by the mine operator on the dust data card that accompanies each dust sample submitted to MSHA for processing, the reporting of when such samples will be taken when District Manager requests, and the reporting of any changes in operation status affecting sampling is vital to effectively administer and assess the effectiveness of the operator sampling program. MSHA has used the information received from the current collection to determine which mine operators have fully complied with MSHA’s sampling requirements, and which failed to adequately protect miners from excessive dust concentrations and needed to take appropriate measures to improve the quality of the mine air that miners breathe.

Once the dust samples submitted by a coal mine operator are processed by MSHA, the Agency transmits the results to the mine operator. The results enable the Agency to more effectively evaluate the adequacy of the operator’s dust control systems, to identify mine operators for targeted enforcement activities, and to plan and undertake special health emphasis initiatives.

In addition, according to §§ 70.210(b) and 71.210(b), the mine operator must post the results on the mine bulletin board. Moreover, according to § 90.210(b), the results must be given to the Part 90 miner.

Once a respirable dust control plan submitted in accordance with either § 71.300 or § 90.300 is approved by MSHA, MSHA inspectors use the information provided in the plan to determine whether the operator is complying with all plan provisions. The inspectors also assess the plan’s continued effectiveness in maintaining compliance with the applicable standards. In addition, posting the plan in accordance with § 71.301(d) allows the affected miners to acquaint themselves with the types and locations of dust control measures that are required to be employed and maintained. If the plan involves a Part 90 miner, § 90.301(d) requires the mine operator to provide a copy of the dust control plan directly to the affected Part 90 miner.

3. Describe whether, and to what extent, the collection of information involves the use of automated, electronic, mechanical, or other technological collection techniques or other forms of information technology, e.g., permitting electronic submission of responses, and the basis for the decision for adopting this means of collection. Also describe any consideration of using information technology to reduce burden.

No improved information technology has been identified by MSHA that would reduce the burden associated with the completion of dust data cards. This is because each operator-collected sample when transmitted to MSHA for processing must be physically attached to its properly completed accompanying dust data card. The information recorded on the dust data card provides important details about the sample, when and where it was collected, the production conditions in effect during sampling, and who was responsible for certifying that it was properly collected. Consequently, this particular information collection technique does not lend itself to electronic submission. However, mine operators submit up to 90 percent of sampling dates (§§ 70.201(c), 71.201(c), and 90.201(c)), status change reports (§§ 70.220(a), 71.220(a), and 90.220), and respirable dust control plans (§§ 71.300 and 90.300) electronically. These electronic submissions account for about 16 percent of the total responses received.

4. Describe efforts to identify duplication. Show specifically why any similar information already available cannot be used or modified for use for the purposes described in Item 2 above.

A mine operator completes a dust data card for each individual dust sample collected and submitted to MSHA to demonstrate that the mine is free of excessive dust concentrations and, therefore, is complying with mandatory exposure limits. Without these samples and the accompanying specified information about each sample and the production conditions in effect during sampling, MSHA could not ascertain whether a mine operator is in compliance with the mandatory dust exposure limits. While MSHA also conducts dust sampling periodically, its purpose is not only to supplement the operator’s sampling program, but also to: (1) monitor the effectiveness of the operator's respirable dust control programs; (2) determine whether the occupation being sampled by the operator has been properly designated for sampling as the occupation at risk of being exposed to the highest dust concentrations; (3) determine if excessive levels of quartz are present, which would require the dust standard to be reduced further to be more protective; and (4) identify work positions at surface mines or surface areas of underground mines that should be designated for routine bimonthly monitoring by coal mine operators. Since the purpose of MSHA and operator sampling have somewhat different objectives, there is no duplication of effort. MSHA knows of no other federal, state, or local agency that collects similar information on dust samples required for compliance purposes or that collects similar information on respirable dust control plans.

5. If the collection of information impacts small businesses or other small entities (Item 5 of OMB Form 83-I), describe any methods used to minimize burden.

These information collection requirements are imposed on all coal mining operations and do not have a greater impact on small businesses or other small entities. However, MSHA believes that the burden on small mines could not be reduced without adversely affecting MSHA’s dust control enforcement efforts.

6. Describe the consequence to Federal program or policy activities if the collection is not conducted or is conducted less frequently, as well as any technical or legal obstacles to reducing burden.

Because mining conditions are constantly changing, the quality of the air that miners breathe must be monitored on a routine basis to ensure that it is free of excessive dust levels to prevent development of “black lung” disease. Therefore, the Mine Act and MSHA’s standards require specific occupations, miners, and work locations to be sampled by mine operators every 2 months (bimonthly). Since the frequency at which mine operators currently sample represents a very small percentage of the available shifts worked during a two-month period, monitoring the quality of the mine air that miners breathe less frequently, would provide an inadequate indication of the dust conditions to which miners are normally exposed. This would increase the likelihood that excessive dust conditions would go undetected. Consequently, the health of miners would be adversely impacted if excessive dust concentrations could not be detected and reduced.

7. Explain any special circumstances that would cause an information collection to be conducted in a manner:

* requiring respondents to report information to the agency more often than quarterly;

* requiring respondents to prepare a written response to a collection of information in fewer than 30 days after receipt of it;

* requiring respondents to submit more than an original and two copies of any document;

* requiring respondents to retain records, other than health, medical, government contract, grant-in-aid, or tax records, for more than three years;

* in connection with a statistical survey, that is not designed to produce valid and reliable results that can be generalized to the universe of study;

* requiring the use of a statistical data classification that has not been reviewed and approved by OMB;

* that includes a pledge of confidentiality that is not supported by authority established in statute or regulation, that is not supported by disclosure and data security policies that are consistent with the pledge, or which unnecessarily impedes sharing of data with other agencies for compatible confidential use; or

* requiring respondents to submit proprietary trade secrets, or other confidential information unless the agency can demonstrate that it has instituted procedures to protect the information's confidentiality to the extent permitted by law.

For the reasons stated earlier, under §§ 70.207, 70.208, 71.208, and 90.208, MSHA requires each mine operator to submit compliance samples bimonthly. In addition, under §§ 70.201, 71.201, and 90.201, each mine operator must submit abatement samples following issuance of a citation for the main purpose of demonstrating that the mine is free of excessive dust concentrations and in compliance with mandatory dust exposure limits. Also, when a change occurs in the operational status of a mine, MMU, or designated area that affects the sampling requirements of 30 CFR parts 70, 71, and 90, any change must be reported in writing to the MSHA District Office within 3 working days after the status change has occurred in accordance with §§ 70.220(a), 71.220(a), and 90.220. Proper notification prevents MSHA from taking unnecessary enforcement actions against mine operators for failing to submit the required number of dust samples during a bimonthly period.

Once adopted by the mine operator, a respirable dust control plan must remain in effect for the life of the surface mine, surface facility, or surface area of an underground mine, or until the MSHA district manager determines that the plan is no longer necessary. MSHA-approved respirable dust control plans provide the basis for MSHA to determine whether or not miners will be adequately protected from excessive dust concentrations during each shift. The collection of information is consistent with the guidelines in 5 CFR 1320.5.

8. If applicable, provide a copy and identify the date and page number of publication in the Federal Register of the agency's notice, required by 5 CFR 1320.8(d), soliciting comments on the information collection prior to submission to OMB. Summarize public comments received in response to that notice and describe actions taken by the agency in response to these comments. Specifically address comments received on cost and hour burden.

Describe efforts to consult with persons outside the agency to obtain their views on the availability of data, frequency of collection, the clarity of instructions and recordkeeping, disclosure, or reporting format (if any), and on the data elements to be recorded, disclosed, or reported.

Consultation with representatives of those from whom information is to be obtained or those who must compile records should occur at least once every 3 years - even if the collection of information activity is the same as in prior periods. There may be circumstances that may preclude consultation in a specific situation. These circumstances should be explained.

MSHA published a 60-day Federal Register notice on June 27, 2012 (77 FR 38323). One comment was received. The commenter strongly supported the continued collection of all the information contained in this information collection. The commenter voiced the position that protections afforded to miners by the existing standards must not be modified. The three-year information collection renewal process followed for this information collection focuses on whether there are more efficient means available to collect the required information mandated by existing standards and does not in any way modify these existing standards.

9. Explain any decision to provide any payment or gift to respondents, other than remuneration of contractors or grantees.

MSHA does not provide payments or gifts to respondents identified by this collection.

10. Describe any assurance of confidentiality provided to respondents and the basis for the assurance in statute, regulation, or agency policy.

While MSHA provides no confidentiality assurances in connection with this collection, as a practical matter, all records pertaining to Part 90 miners are kept confidential and stored in locked cabinets at applicable District Offices, and accessed only by authorized individuals. For the information collected under part 70, 71, and 90 that is entered into the MSHA Standard Information System (MSIS), only authorized persons have access to the information in this system.

In the event a mine operator should include proprietary information in the respirable dust control plan, such data will be kept confidential by MSHA consistent with the guidelines outlined in 5 U.S.C. 552(b)(4).

11. Provide additional justification for any questions of a sensitive nature, such as sexual behavior and attitudes, religious beliefs, and other matters that are commonly considered private. This justification should include the reasons why the agency considers the questions necessary, the specific uses to be made of the information, the explanation to be given to persons from whom the information is requested, and any steps to be taken to obtain their consent.

There are no questions of a sensitive nature.

12. Provide estimates of the hour burden of the collection of information. The statement should:

* Indicate the number of respondents, frequency of response, annual hour burden, and an explanation of how the burden was estimated. Unless directed to do so, agencies should not conduct special surveys to obtain information on which to base hour burden estimates. Consultation with a sample (fewer than 10) of potential respondents is desirable. If the hour burden on respondents is expected to vary widely because of differences in activity, size, or complexity, show the range of estimated hour burden, and explain the reasons for the variance. Generally, estimates should not include burden hours for customary and usual business practices.

* If this request for approval covers more than one form, provide separate hour burden estimates for each form and aggregate the hour burdens in Item 13 of OMB Form 83-I.

* Provide estimates of annualized cost to respondents for the hour burdens for collections of information, identifying and using appropriate wage rate categories. The cost of contracting out or paying outside parties for information collection activities should not be included here. Instead, this cost should be included in Item 13.

The number of responses for this submission is 43,820 from 800 unique respondents (mining operations). All wages in this supporting statement are fully loaded.

30 CFR 70.209(a) and (c); 71.209(a) and (c); and 90.209(a) and (c): A certified person must complete and sign the dust data card. The completed dust data card must be submitted to MSHA with the dust sample. In addition, under §§ 70.205(c), 71.205(c), and 90.205(c), if the proper flowrate was not maintained during sampling, the certified person will note this on the sample’s dust data card prior to submission of the sample to MSHA. Based on the Agency’s recent experience, the number of dust data cards it expects to receive and process annually will be approximately 43,820. MSHA estimates that it will take a certified dust technician, earning $30.83 per hour, approximately 6 minutes (0.1 hours) to complete and sign the dust card, and send it along with the sample to MSHA.

Hour Burden

43,820 samples x 0.1 hrs. = 4,382 hrs.

Hour Burden Cost

4,382 hrs. x $30.83 = $135,097

Sections 70.209(d), 71.209(d), and 90.209(d) require that an operator sample submitted to MSHA is considered to be taken to fulfill the sampling requirements of parts 70, 71, and 90 unless the sample has been identified in writing by the operator to the District Manager that it is to be used for another purpose. Although it is very rare that an operator submits a sample for reasons other than compliance with parts 70, 71, and 90, for purposes of this collection MSHA estimates that there will be one occurrence annually and that it will take a mine supervisor, earning a fully loaded wage rate of $78.35 an hour, 5 minutes (0.0833 hrs.) to notify the district manager in writing of the intent to submit samples for reasons other than compliance

Hour Burden

1 notification x 0.08 hrs. = 0 hours

30 CFR 70.201(c); 71.201(c) and (e); and 90.201(c): If MSHA chooses to observe operator sampling, these requirements give the District Manager the authority to require a mine operator to submit in advance the dates when sampling will be conducted. Operators can also make a written request under § 71.201(e) asking the District Manager to waive the rain restriction for a normal work shift as defined § 71.2. The Agency anticipates requesting and receiving 386 sampling schedules on average per year. MSHA estimates that it will take a mine supervisor, earning $78.35 per hour, an average of 20 minutes (0.33 hour) to prepare a bimonthly sampling schedule, and a clerical person, earning $26.44 per hour, another 10 minutes (0.17 hour) to type and either mail, fax, or transmit electronically the schedule to the MSHA District Office.

Hour Burden

386 schedules x 0.33 hr. = 127 hrs.

386 schedules x 0.17 hr. = 66 hrs.

total = 193 hrs.

Hour Burden Cost

127 hrs. x $78.35 = $ 9,950

66 hrs. x $26.44 = $ 1,745

total = $11,695

30 CFR 70.210(b) and 71.210(b): Upon receipt of the results of dust sampling from MSHA, the operator must post the report for at least 31 days on the mine bulletin board so that it can be viewed by all affected coal miners.

30 CFR 90.210(b): Upon receipt of the dust samling results from MSHA, the operator must provide a copy of the report to the Part 90 miner.

Based on the types of entities required to be sampled bimonthly (during the 2nd quarter of FY 2012: Mechanized Mining Units – 962; Designated Areas – 936; Part 90 miners – 67; and Designated Work Positions – 253), and historical experience, each will require a report of sampling results to be generated by MSHA every two months. MSHA projects that it will generate approximately 14,000 sampling reports annually. It will take a clerical person, earning $26.44 per hour, an average of 5 minutes (0.083 hour) to post it on the mine bulletin board.

Hour Burden

14,000 reports x 0.083 hr. = 1,162 hrs.

Hour Burden Cost

1,162 hrs. x $26.44 = $30,723

30 CFR 70.220(a); 71.220(a) and 90.220: When a change occurs in the operational status of a mine, MMU, or designated area that affects the sampling requirements of 30 CFR parts 70, 71, and 90, any change must be reported in writing to the MSHA District Office within 3 working days after the status change has occurred in accordance with §§ 70.220(a), 71.220(a), and 90.220. According to MSHA records, some 2,220 entities were in sampling status during the 2nd quarter of FY 2012. Based on FY 2009 – FY 2011 records, MSHA anticipates receiving on average approximately 4,970 status changes annually. It will take a mine supervisor, earning $78.35 per hour, an average of 5 minutes (0.083 hour) to prepare a status change report and a clerical person, earning $26.44 per hour, an average of 10 minutes (0.17 hour) to type and transmit by mail or electronically the report to MSHA.

Hour Burden

4,970 reports x 0.083 hr. = 413 hrs.

4,970 reports x 0.17 hr. = 845 hrs.

total = 1,258 hrs.

Hour Burden Cost

413 hrs. x $78.35 = $32,359

845 hrs. x $26.44 = $22,342

total = $54,701

30 CFR 71.300(a): In FY 2011, MSHA issued 6 excessive dust citations under §§ 71.100 or 71.101, which required the operator to either submit a new or revised dust control plan following termination of each citation. Since the Agency anticipates issuing annually approximately the same number of citations as issued in FY 2011, 4 new and 2 revised dust control plans are expected to be submitted under § 71.300. It will take a mine supervisor, earning $78.35 per hour, an average of 3 hours to prepare a new dust control plan and 1.5 hours to revise an existing plan, and a clerical person, earning $26.44 per hour, an average of 10 minutes (0.17 hour) to copy and transmit by mail or electronically to MSHA for review and approval.

Hour Burden

4 plans (new) x 3 hrs. = 12 hrs.

2 plans (revised) x 1.5 hrs. = 3 hrs.

6 plans x 0.17 hr. = 1 hr.

total = 16 hrs.

Hour Burden Cost

12 hrs. x $78.35 = $940

3 hrs. x $78.35 = $235

1 hrs. x $26.44 = $26

total = $1,201

30 CFR 71.301(d): This standard requires the mine operator to post a copy of the approved plan on the mine bulletin board. Copying and posting are estimated to take a clerical person, earning $26.44 per hour, an average of 15 minutes (0.25 hour).

Hour Burden

6 plans x 0.25 hr. = 2 hrs.

Hour Burden Cost

2 hrs. x $26.44 = $53

30 CFR 90.300(a): Based on the number of citations issued for violation of the applicable dust standard under §§ 90.100 or 90.101 in FY 2011, MSHA anticipates that in FY 2012 and beyond, operators will submit approximately 1 new and 1 revised dust control plan under § 90.300. The Agency estimates that it will take a mine supervisor, earning $78.35 per hour, an average of 3 hours to prepare a new dust control plan and 1.25 hours to revise an existing plan; and a clerical person, earning $26.44 per hour, an average of 10 minutes (0.17 hour) to copy and transmit electronically or mail the plans to MSHA for review and approval.

Hour Burden

1 plan (new) x 3 hrs. = 3 hrs.

1 plan (revised) x 1.25 hrs. = 2 hrs.

2 plans x 0.17 hr. = 0 hr.

total = 5 hrs.

Hour Burden Cost

5 hrs. x $78.35 = $392

total = $392

30 CFR 90.301(d): This standard requires the mine operator to provide a copy of the approved plan to the affected Part 90 miner. MSHA estimates that it will take a clerical person, earning $26.44 per hour, an average of 10 minutes (0.17 hour) to copy the plan and a mine supervisor, earning $78.35 per hour, an average of 15 minutes (0.25 hour) to provide a copy of the approved plan to the affected Part 90 miner.

Hour Burden

2 plans x 0.17 hr. = 0 hr.

2 plans x 0.25 hr. = 1 hr.

total = 1 hrs.

Hour Burden Cost

1 hr. x $78.35 = $79

total = $79

Total Responses = 63,193

Total Hour Burden = 7,019

Total Hour Burden Cost = $233,939

Total Responses = 63,193

13. Provide an estimate for the total annual cost burden to respondents or recordkeepers resulting from the collection of information. (Do not include the cost of any hour burden shown in Items 12 and 14).

* The cost estimate should be split into two components: (a) a total capital and start-up cost component (annualized over its expected useful life) and (b) a total operation and maintenance and purchase of services component. The estimates should take into account costs associated with generating, maintaining, and disclosing or providing the information. Include descriptions of methods used to estimate major cost factors including system and technology acquisition, expected useful life of capital equipment, the discount rate(s), and the time period over which costs will be incurred. Capital and start-up costs include, among other items, preparations for collecting information such as purchasing computers and software; monitoring, sampling, drilling and testing equipment; and record storage facilities.

* If cost estimates are expected to vary widely, agencies should present ranges of cost burdens and explain the reasons for the variance. The cost of purchasing or contracting out information collections services should be a part of this cost burden estimate. In developing cost burden estimates, agencies may consult with a sample of respondents (fewer than 10), utilize the 60-day pre-OMB submission public comment process and use existing economic or regulatory impact analysis associated with the rulemaking containing the information collection, as appropriate.

* Generally, estimates should not include purchases of equipment or services, or portions thereof, made: (1) prior to October 1, 1995, (2) to achieve regulatory compliance with requirements not associated with the information collection, (3) for reasons other than to provide information or keep records for the government, or (4) as part of customary and usual business or private practices.

Mailing Costs: 30 CFR 70.201(c); 71.201(c); and 90.201(c):

The average postage cost for the operator to send a sampling schedule is $0.45. Approximately 90% of the 386 schedules are submitted electronically; the remaining 39 are mailed.

39 schedules x $0.45 = $18

Mailing Costs: 30 CFR 70.209(a); 71.209(a); and 90.209(a):

The average postage cost for mailing a dust data card along with the dust sample in the pre-addressed mailer is approximately $1.00 per sample.

43,820 samples x $1.00 = $43,820

Mailing Costs: 30 CFR 70.220(a); 71.220(a) and 90.220:

The average postage cost for the operator to report changes in the operations status is $0.45. Approximately 90% of the 4,970 reports are submitted electronically; the remaining 497 are mailed.

497 reports x $0.45 = $224

Mailing Costs: 30 CFR 71.300(a) and 90.300(a):

The average postage cost for an operator to mail a new or revised plan is $1.00. Approximately 90% of the 8 plans are submitted electronically; the remaining 1 will be mailed.

1 plan x $1.00 = $1

Mailing Costs: 30 CFR 90.301(d)

The average postage cost for the operator to provide a copy of the plan to an affected Part 90 miner is $1.00.

2 plans x $1.00 = $2

Total annual cost = $44,065

14. Provide estimates of annualized costs to the Federal government. Also, provide a description of the method used to estimate cost, which should include quantification of hours, operational expenses (such as equipment, overhead, printing, and support staff), and any other expense that would not have been incurred without this collection of information. Agencies may also aggregate cost estimates from Items 12, 13, and 14 in a single table.

Under §§ 70.209(a), 71.209(a) and 90.209(a), MSHA incurs costs in processing operator samples submitted in response to the operator sampling requirements in §§ 70.207, 70.208, 71.207, 90.207, and 90.208. These costs are associated with processing of incoming samples involving sample preparation, weighing, recording the weights on the dust data cards, and making data entry into electronic data processing systems to record and utilize the dust sample data.

Upon receiving the operator’s dust sample and the accompanying data card, MSHA’s Respirable Dust Processing Laboratory in Pittsburgh, PA, prepares each sample received by weighing it using a robotic weighing system employing micro-balances, records the results on the data card, and enters the information recorded on the data card into a personal computer for electronic transmission to the main computer in Denver, CO for processing. There, the transmitted information is processed, which involves checking the information for accuracy and completeness, performing the required calculations of average concentration, and producing various computer-generated reports called data mailers. These data mailers, which contain specific information obtained from the dust sample and dust data card, are mailed in accordance with §§ 70.210(a), 71.210(a), and 90.210(a) to coal mine operators to communicate the disposition of each submitted dust sample and any required follow-up action.

Sample processing and data transmission to main frame:

MSHA personnel cost = $ 252,147

Equipment and annual maintenance cost

(vacuum pump, robotic weighing system,

analytical balances, and PCs) = $40,469

Misc. supplies (labels, paper, etc.) = $2,410

Subtotal = $295,026

Data processing and reporting of results to mine operators:

MSHA personnel cost = $163,033

Contractor Staff = $127,783

Maintenance (Software licensing, printer, and supplies) = $5,126

Data mailers (52,000 unlabeled mailers x $0.0954) = $4,960

and 5,200 labeled mailers x $1.246 = $6,480

Postage (57,200 x $0.88) = $50,336

Subtotal = $357,718

30 CFR 70.201(c); 71.201(c); and 90.201(c): MSHA anticipates requesting approximately 100 sampling schedules beginning in FY 2012, and expects to receive approximately 398 responses from mine operators, as some mine operators submit schedules automatically. It will take an Agency clerical employee, earning $42.18 per hour (GS-9), an average of 15 minutes (0.25 hour) to type and mail each request, and an average of 10 minutes (0.17 hour) to process each operator response; and an Agency health supervisor, earning $68.61 per hour (GS 13), an average of 15 minutes (0.25 hour) to review and distribute each response to respective field offices for follow-up action.

Hour Burden

100 requests x 0.25 hr. = 25 hrs.

398 responses x 0.17 hr. = 68 hrs.

398 responses x 0.25 hr. =100 hrs.

Subtotal = 193 hrs.

Hour Burden Cost

93 hrs. x $42.18 = $3,923

100 hrs. x $68.61 = $6,861

Subtotal = $10,784

30 CFR 70.220(a); 71.220(a); 90.220: These standards require the operator to report operational status changes of the mine, MMU, or designated area that affect the sampling requirements of 30 CFR parts 70, 71, and 90. Such changes must be reported in writing to the MSHA District Office within 3 working days after the status change has occurred. MSHA expects to process approximately 4,970 status change reports annually, beginning in FY 2012. These reports are subsequently reviewed again by Agency personnel to determine whether to cite a particular operator for failure to comply with the sampling requirements upon receiving an advisory from Denver notifying the responsible MSHA office of an operator’s failure to submit the required number of respirable dust samples. It will take an Agency clerical employee earning $42.18 per hour, and average of 5 minutes (0.083 hour) to process and file each report.

Hour Burden

4,970 status change reports x 0.083 hr. = 413 hrs.

Hour Burden Cost

413 hrs. x $42.18 = $17,420

30 CFR 71.300(a) and 71.301(e): Within 15 calendar days after the termination date of a citation for a violation of § 71.100 or § 71.101, the operator must submit to MSHA for approval a written respirable dust control plan. Based on MSHA’s experience in FY 2008, the Agency anticipates that mine operators will submit 4 new and 2 revised dust control plans under § 71.300 annually, beginning with FY 2009. It will take an Agency GS 13 health supervisor, earning $68.61 per hour, per OPM Data, All Fed/All Fulltime 2010,, 45 minutes (0.75 hour) to review the average plan (new) and 30 minutes (0.5 hour) per revision, and an Agency clerical employee, earning $42.18 per hour, another 45 minutes (0.75 hour) to process a plan (new or revised).

Hour Burden

4 plans (new) x 0.75 hr. = 3 hrs.

2 plans (revised) x 0.5 hr. = 1 hrs.

6 plans x 0.75 hr. = 5 hrs.

Subtotal = 9 hrs.

Hour Burden Cost

4 hrs. x $68.61 = $275

5 hrs. x $42.18 = $211

Subtotal = $486

30 CFR 90.300(a) and 90.301(e): If an operator abates a violation of § 90.100 or § 90.101 by reducing the respirable dust level in the position of the Part 90 miner, the operator must submit a written respirable dust control plan. MSHA anticipates the submission of 1 new and 1 revised respirable dust control plans annually under § 90.300, beginning in FY 2009. It will take an MSHA health supervisor, earning $68.61 per hour, 45 minutes (0.75 hour) to review the average new plan and 30 minutes (0.5) per revision, and an Agency clerical person, earning $42.18 per hour, another 45 minutes (0.75 hour) to process a Part 90 miner dust control plan (new or revised).

Hour Burden

1 plan (new) x 0.75 hr. = 1 hr.

1 plan (revised) x 0.5 hr. = 1 hr.

2 plans x 0.75 = 2 hrs.

Subtotal = 4 hrs.

Hour Burden Cost

2 hrs. x $68.61 = $137

2 hrs. x $42.18 = $84

Subtotal = $221

Total Annualized Cost to Federal Government = $681,655

15. Explain the reasons for any program changes or adjustments reported in Items 13 or 14 of the OMB Form 83-I.

Responses, Respondents: There was a decrease of 30 respondents (from 830 to 800) due to a decrease in the number mines. There was an increase of 22,193 (from 41,000 to 63,193) in responses due to a correction of the calculation used in the previous update.

Burden hours: The decrease in burden hours of 24,628 hours (from 33,199 hrs. to 8,571 hrs.) is due primarily to the removal of the provision for dust sampling as a paperwork burden as the completion time for 70.209, 71.209 and 90.209 was reduced to .1 hours from .58 hours in the previous submission. It was determined that the remainder of that completion time did not constitute necessary burden time resulting in a decrease of 24,469 burden hours for those provisions.

Costs: There is a decrease in costs of $3,795,649 (from $3,839,714 to $44,065). This is due to the removal of maintenance and calibration costs of the gravimetric sampler as a capital cost related to the collection burden as costs for 70.204(a), 71.204(a), and 90.204(a) were removed and should have not been included in the last approved information collection.

16. For collections of information whose results will be published, outline plans for tabulation and publication. Address any complex analytical techniques that will be used. Provide the time schedule for the entire project, including beginning and ending dates of the collection of information, completion of report, publication dates, and other actions.

The transmittal and processing of dust data cards is not required for publication. Results are reported back to mine operators and the electronic data base is used by MSHA to plan enforcement activities and evaluate programs. The data base is also used by NIOSH to monitor effectiveness of dust controls, plan and undertake dust control research initiatives, and assess trends in disease prevention. The underlying purpose of the transmittal and processing of dust data cards is to monitor compliance with mandatory exposure limits for respirable coal dust to assure healthful work environments. Likewise, information provided by mine operators in respirable dust control plans is not collected for the purpose of publication.

17. If seeking approval to not display the expiration date for OMB approval of the information collection, explain the reasons that display would be inappropriate.

MSHA is seeking approval to not display the expiration date for OMB approval of this information collection on the dust data card. MSHA has no direct control over the production or distribution of the cassettes and data cards. Dust sampling cassettes and the accompanying dust data cards are manufactured by the Mine Safety Appliances Company for sale to coal mine operators.

18. Explain each exception to the certification statement identified in Item 19, "Certification for Paperwork Reduction Act Submissions," of OMB Form 83-I.

There are no certification exceptions identified with this information collection.

B. COLLECTIONS OF INFORMATION EMPLOYING STATISTICAL METHODS

This information collection does not employ any statistical methods.

FEDERAL MINE SAFETY & HEALTH ACT OF 1977 (MINE ACT)

MANDATORY SAFETY AND HEALTH STANDARDS

SEC. 101. (a) The Secretary shall by rule in accordance with procedures set forth in this section and in accordance with section 553 of title 5, United States Code (without regard to any reference in such section to sections 556 and 557 of such title), develop, promulgate, and revise as may be appropriate, improved mandatory health or safety standards for the protection of life and prevention of injuries in coal or other mines.

INSPECTIONS, INVESTIGATIONS, AND RECORDKEEPING

SEC. 103. (h) In addition to such records as are specifically required by this Act, every operator of a coal or other mine shall establish and maintain such records, make such reports, and provide such information, as the Secretary or the Secretary of Health, Education, and Welfare may reasonably require from time to time to enable him to perform his functions under this Act. The Secretary or the Secretary of Health, Education, and Welfare is authorized to compile, analyze, and publish, either in summary or detailed form, such reports or information so obtained. Except to the extent otherwise specifically provided by this Act, all records, information, reports, findings, citations, notices, orders, or decisions required or issued pursuant to or under this Act may be published from time to time, may be released to any interested person, and shall be made available for public inspection.

RELEVANT STANDARDS 30 CFR 70, 71, and 90

Part 70 – Mandatory Health Standards – Underground Coal Mines

Subpart C – Sampling Procedures

§ 70.201 Sampling; general requirements

* * * * *

(c) Upon request from the District Manager, the operator shall submit the date on which collecting any respirable dust samples required by this part will begin.

* * * * *

§ 70.205 Approved sampling devices; operation; air flowrate

* * * *

(c) Each sampling device shall be examined each shift by a person certified in accordance with §70.202 (Certified person; sampling) during the last hour of operation to assure that the sampling device is operating properly and at the proper flowrate. If the proper flowrate is not maintained, the respirable dust sample shall be transmitted to MSHA with a notation by the certified person on the dust data card stating that the proper flowrate was not maintained.

* * * * *

§ 70.209 Respirable dust samples; transmission by operator Mine Operator Dust Data Card

(a)

The operator shall transmit within 24 hours after the end of the

sampling shift all samples collected to fulfill the requirements of

this part in containers provided by the manufacturer of the filter

cassette to: Respirable Dust Processing Laboratory, Pittsburgh Safety

and Health Technology Center, Cochrans Mill Road, Building 38, P.O.

Box 18179, Pittsburgh, Pennsylvania 15236-0179, or to any other

address designated by the District Manager.

* * *

(c)

A person certified in accordance with §70.202

(Certified person; sampling) shall properly complete the dust data

card that is provided by the manufacturer for each filter cassette.

The card shall have an identification number identical to that on the

cassette used to take the sample and be submitted to MSHA with the

sample. Each card shall be signed by the certified person and shall

include that person's certification number. Respirable dust samples

with data cards not properly completed will be voided by MSHA.

(d)

All respirable dust samples collected by the operator shall be

considered taken to fulfill the sampling requirements of part 70,

71

or 90

of this title, unless the sample has been identified in writing by

the operator to the District Manager, prior to the intended sampling

shift, as a sample to be used for purposes other than required by

part 70,

71

or 90

of this title.

* * * * *

§ 70.210 Respirable dust samples; report to operator; posting

(a)

The Secretary shall provide the operator with a report of the

following data on respirable dust samples as soon as

practicable:

(1) The mine identification number;

(2)

The mechanized mining unit or designated area within the mine from

which the samples were taken;

(3) The concentration of

respirable dust, expressed in milligrams per cubic meter of air, for

each valid sample;

(4) The average concentration of

respirable dust, expressed in milligrams per cubic meter of air, for

all valid samples;

(5) The occupation code, where

applicable, and;

(6) The reason for voiding any

samples.

(b) Upon receipt, the operator shall post this

data for at least 31 days on the mine bulletin board.

§ 70.220 Status change reports

(a) If there is a change in operational status that affects the respirable dust sampling requirements of this part, the operator shall report the change in operational status of the mine, mechanized mining unit, or designated area to the MSHA District Office or to any other MSHA office designated by the District Manager. Status changes shall be reported in writing within 3 working days after the status change has occurred.

* * * * *

Part 71 – Mandatory Health Standards – Surface Coal Mines and

Surface Work Areas of Underground Coal Mines

Subpart C – Sampling Procedures

§ 71.201 Sampling; general requirements

* * * * *

(c)

Upon request from the District Manager, the operator shall submit the

date on which collecting any respirable dust samples required by this

part will begin.

* * *

§

71.205 Approved sampling devices; operation; air flowrate

* * * * *

(c) Each sampling device shall be examined each shift by a person certified in accordance with §71.202 (Certified person; sampling) during the last hour of operation to assure that the sampling device is operating properly and at the proper flowrate. If the proper flowrate is not maintained, the respirable dust sample shall be transmitted to MSHA with a notation by the certified person on the dust data card stating that the proper flowrate was not maintained.

§ 71.209 Respirable dust samples; transmission by operator

(a)

The operator shall transmit within 24 hours after the end of the

sampling shift all samples collected to fulfill the requirements of

this part in containers provided by the manufacturer of the filter

cassette to: Respirable Dust Processing Laboratory, Pittsburgh Safety

and Health Technology Center, Cochrans Mill Road, Building 38, P.O.

Box 18179, Pittsburgh, Pennsylvania 15236-0179, or to any other

address designated by the District Manager.

* * *

(c)

A person certified in accordance with §71.202

(Certified person; sampling) shall properly complete the dust data

card that is provided by the manufacturer for each filter cassette.

The card shall have an identification number identical to that on the

cassette used to take the sample and be submitted to MSHA with the

sample. Each card shall be signed by the certified person and shall

include that person's certification number. Respirable dust samples

with data cards not properly completed will be voided by MSHA.

(d)

All respirable dust samples collected by the operator shall be

considered taken to fulfill the sampling requirements of part 70,

71

or 90

of this title, unless the sample has been identified in writing by

the operator to the District Manager, prior to the intended sampling

shift, as a sample to be used for purposes other than required by

part 70,

71

or 90

of this title.

* * * * *

§ 71.210 Respirable dust samples; report to operator; posting

(a) The Secretary shall provide the

operator with a report of the following data on respirable dust

samples as soon as practicable:

(1) The mine

identification number;

(2) The designated work position at

the mine from which the samples were taken;

(3) The

concentration of respirable dust, expressed in milligrams per cubic

meter of air, for each valid sample;

(4) The average

concentration of respirable dust, expressed in milligrams per cubic

meter of air, for all valid samples; and

(5) The reason

for voiding any samples.

(b) Upon receipt, the operator shall post this data for at least 31 days on the mine bulletin board.

§ 71.220 Status change reports

(a) If there is a change in operational status that affects the respirable dust sampling requirements of this part, the operator shall report the change in operational status of the mine or designated work position to the MSHA District Office or to any other MSHA office designated by the District Manager. Status changes shall be reported in writing within 3 working days after the status change has occurred.

* * * * *

Subpart D – Respirable Dust Control Plans

§ 71.300 Respirable dust control plan; filing requirements

(a) Within 15 calendar days after the termination date of a citation for violation of §71.100 (Respirable dust standard) or §71.101 (Respirable dust standard when quartz is present), the operator shall submit to the District Manager for approval a written respirable dust control plan applicable to the work position identified in the citation. The respirable dust control plan and revisions thereof shall be suitable to the conditions and the mining system of the coal mine and shall be adequate to continuously maintain respirable dust within the permissible concentration at the surface work position identified in the citation.

* * * * *

§ 71.301Respirable dust control plan; approval by District Manager and posting

* * * * *

(d) The operator shall post on the

mine bulletin board a copy of each current respirable dust control

plan approved by the District Manager.

(e) The operator

may review respirable dust control plans and submit proposed

revisions to such plans to the District Manager for approval.

Part 90 – Mandatory Health Standards – Coal Miners Who have

Evidence of the Development of Pneumoconiosis

Subpart C – Sampling Procedures

§ 90.201(c) Sampling; general requirements

* * * * *

(c) Upon request from the District Manager, the operator shall submit the date on which collecting any respirable dust samples required by this part will begin.

* * * * *

§ 90.205 Approved sampling devices; operation; air flowrate

* * * * *

(c) Each sampling device shall be examined each shift by a person certified in accordance with §90.202 (Certified person; sampling) during the last hour of operation to assure that the sampling device is operating properly and at the proper flowrate. If the proper flowrate is not maintained, the respirable dust sample shall be transmitted to MSHA with a notation by the certified person on the dust data card stating that the proper flowrate was not maintained.

* * * * *

§ 90.209 Respirable dust samples; transmission by operator Mine Operator Dust Data Card

(a)

The operator shall transmit within 24 hours after the end of the

sampling shift all samples collected to fulfill the requirements of

this part in containers provided by the manufacturer of the filter

cassette to: Respirable Dust Processing Laboratory, Pittsburgh Safety

and Health Technology Center, Cochrans Mill Road, Building 38, P.O.

Box 18179, Pittsburgh, Pennsylvania 15236-0179, or to any other

address designated by the District Manager.

* * *

(c)

A person certified in accordance with §90.202

(Certified person; sampling) shall properly complete the dust data

card that is provided by the manufacturer for each filter cassette.

The card shall have an identification number identical to that on the

cassette used to take the sample and be submitted to MSHA with the

sample. Each card shall be signed by the certified person and shall

include that person's certification number. Respirable dust samples

with data cards not properly completed will be voided by MSHA.

(d)

All respirable dust samples collected by the operator shall be

considered taken to fulfill the sampling requirements of part 70,

71

or 90

of this title, unless the sample has been identified in writing by

the operator to the District Manager, prior to the intended sampling

shift, as a sample to be used for purposes other than required by

part 70,

71

or 90

of this title.

§

90.210 Respirable dust samples; report to operator

(a)

The Secretary shall provide the operator with a report of the

following data on respirable dust samples as soon as

practicable:

(1) The mine identification number;

(2)

The mechanized mining unit, if any, within the mine from which the

samples were taken;

(3) The concentration of respirable

dust, expressed in milligrams per cubic meter of air, for each valid

sample;

(4) The average concentration of respirable dust,

expressed in milligrams per cubic meter of air, for all valid

samples;

(5) The occupation code;

(6) The

reason for voiding any samples; and,

(7) The Social

Security Number of the part 90

miner.

(b) Upon receipt, the operator shall provide a copy of this report to the part 90 miner. The operator shall not post the original or a copy of this report on the mine bulletin board.

§ 90.220 Status change reports

If there is a change in the status of a part 90 miner that affects the respirable dust sampling requirements of this part (such as entering a terminated, injured or ill status, or returning to work), the operator shall report the change in the status of the part 90 miner to the MSHA District Office or to any other MSHA office designated by the District Manager. Status changes shall be reported in writing within 3 working days after the status change has occurred.

Subpart

D--Respirable Dust Control Plans

§ 90.300 Respirable dust control plan; filing requirements

(a)

If an operator abates a violation of §90.100

(Respirable dust standard) or §90.101

(Respirable dust standard when quartz is present) by reducing the

respirable dust level in the position of the part 90

miner, the operator shall submit a written respirable dust control

plan for that part 90

miner in that position within 15 calendar days after the citation is

terminated to the District Manager for approval. The respirable dust

control plan and revisions thereof shall be suitable to the

conditions and the mining system of the coal mine and shall be

adequate to continuously maintain respirable dust within the

permissible concentration for the part 90

miner in the position identified in the citation.

* * * *

*

§ 90.301 Respirable dust control plan; approval by District Manager; copy to Part 90 Miner

* * * * *

(d)

The operator shall provide a copy of the current respirable dust

control plan required under this part to the part 90

miner. The operator shall not post the original or a copy of the plan

on the mine bulletin board.

(e) The operator may review

respirable dust control plans and submit proposed revisions to such

plans to the District Manager for approval.

Dust Data Card 1219-0011 Front and Back

September 2012

| File Type | application/msword |

| File Title | 1219-0011 |

| Author | janes.debra |

| Last Modified By | Bouchet, Nicole - MSHA |

| File Modified | 2012-09-20 |

| File Created | 2012-09-20 |

© 2026 OMB.report | Privacy Policy