Task and Cognitive Task Analysis: Continuous Miner

Assessing and Evaluating Human Systems Integration Needs in Mining

Appendix D_Task and Cognitive Task Analysis_CM Operator

Task and Cognitive Task Analysis: Continuous Miner

OMB: 0920-0981

APPENDIX D:

Form Approved

OMB No. 0920-xxxx

Expires xx/xx/20xx

Subject ID: ______________ Continuous Miner Operator CTA Interviewer: ___________

Date: _______________________________

Demographics

Number of years mining experience__________

Number of years of continuous miner operating experience ____________

Task Analysis

I am going to ask you a few questions about your job. These questions are about your day to day work routine, what you typically have to do, who you typically work with. I’m interested in knowing about your normal routine.

What do you usually carry into the mine with you? How do you carry these items?

When you first get to your job site in the section– on a shift where you are cutting coal – what tasks or information do you need before you start your job?

What are you primarily responsible for doing during a shift?

Public reporting burden of this collection of information is estimated to average 2 hours per response, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information. An agency may not conduct or sponsor, and a person is not required to respond to a collection of information unless it displays a currently valid OMB control number. Send comments regarding this burden estimate or any other aspect of this collection of information, including suggestions for reducing this burden to CDC/ATSDR Reports Clearance Officer, 1600 Clifton Road NE, MS D-74, Atlanta, Georgia 30333; ATTN: PRA (0920-XXXX).

Who do you typically work with during a shift?

What continuous miner(s) have you operated?

What type of remote control unit or pendant do you use to run the continuous miner? Describe the pendant – how do you wear it, what issues do you have with how it operates?

Describe how you were trained to become a Continuous Miner Operator.

Probe: What was the most taxing thing for you to learn to do?

Probe: How did you learn the approved roof control and ventilation plans?

Probe: What did you have to practice – what did you know would only come to you through experience?

Now I am going to ask you to think about a few specific tasks you perform during your day – we will go through these tasks one at a time. I’d like you to think about what specifically you have to do in order to accomplish that task. What I’d like you to do is break that task into its parts and give me a bit of detail about each step. I may ask you to tell me what tools you might use, who may be working with you, and when you might do this – these are just a few examples of questions I might ask you while we go through each of the steps.

Task 1 - Insert the specific task prior to beginning CTA

Think about what you do when you _________________________________________. Can you break this task into less than six, but more than three steps?

1.

2.

3.

4.

5.

6.

Of the steps you have identified, which are the most cognitively challenging (which require you to think a lot?)?

[Prompts: which require you to make judgments? Which require you to make decisions? Which require you to problem solve or think on your feet? Which require you to concentrate a great deal? ]

Task 2

Think about what you do when you _________________________________________. Can you break this task into less than six, but more than three steps?

1.

2.

3.

4.

5.

6.

Of the steps you have identified, which are the most cognitively challenging (which require you to think a lot?)?

[Prompts: which require you to make judgments? Which require you to make decisions? Which require you to problem solve or think on your feet? Which require you to concentrate a great deal? ]

Task 3

Think about what you do when you _________________________________________. Can you break this task into less than six, but more than three steps?

1.

2.

3.

4.

5.

6.

Of the steps you have identified, which are the most cognitively challenging (which require you to think a lot?)?

[Prompts: which require you to make judgments? Which require you to make decisions? Which require you to problem solve or think on your feet? Which require you to concentrate a great deal? ]

Knowledge Elicitation

During the knowledge elicitation, I am going to ask you to think about the tasks we talked about just a few minutes ago – I’ll remind you what the tasks are when we get started. I am going to ask you some more specific questions about those tasks. There are no right or wrong answers to these questions. I am looking for information about how you see your work environment, what information is important for you to successfully (safely and productively) get the job done and your thoughts on how you use your skills while you do your job.

***I may also ask you to think about how a new continuous miner operator (a guy who hasn’t been doing the job for very long) may do the job differently. I am doing this because your experience gives you a different perspective than a newer guy and you may do the job in a different.

Task 1

____________________________________________________________________________________

Can you come up with an example of a time when you walked into the middle of a situation while you were ______________ and knew exactly how things got there and where they were headed?

Can you give me an example of what is important about the Big Picture for this task? What are the major elements you have to know and keep track of?

Have you had experiences where part of a situation related to [Task 1] just “popped” out at you; where you noticed things going on that others didn’t catch? What is an example?

When you do this task, are there ways of working smart or accomplishing more with less – that you have found especially useful?

Can you think of an example when you have improvised in this task or noticed an opportunity to do something better?

Can you think of a time when you realized that you would need to change the way you were performing in order to get the job done?

Optional Questions

Can you describe an instance when you spotted a deviation from the norm, or knew something was amiss?

Have there been times when the equipment pointed in one direction, but your own judgment told you to do something else? Or when you had to rely on experience to avoid being led astray by the equipment?

Probe: Have you ever had a near miss accident related to anything that we talked about for these last 2 questions?

Task 2

____________________________________________________________________________________

Can you come up with an example of a time when you walked into the middle of a situation while you were ______________ and knew exactly how things got there and where they were headed?

Can you give me an example of what is important about the Big Picture for this task? What are the major elements you have to know and keep track of?

Have you had experiences where part of a situation just “popped” out at you; where you noticed things going on that others didn’t catch? What is an example?

When you do this task, are there ways of working smart or accomplishing more with less – that you have found especially useful?

Can you think of an example when you have improvised in this task or noticed an opportunity to do something better?

Can you think of a time when you realized that you would need to change the way you were performing in order to get the job done?

Optional Questions

Can you describe an instance when you spotted a deviation from the norm, or knew something was amiss?

Have there been times when the equipment pointed in one direction, but your own judgment told you to do something else? Or when you had to rely on experience to avoid being led astray by the equipment?

Probe: Have you ever had a near miss accident related to anything that we talked about for these last 2 questions?

Task 3

____________________________________________________________________________________

Can you come up with an example of a time when you walked into the middle of a situation while you were ______________ and knew exactly how things got there and where they were headed?

Can you give me an example of what is important about the Big Picture for this task? What are the major elements you have to know and keep track of?

Have you had experiences where part of a situation just “popped” out at you; where you noticed things going on that others didn’t catch? What is an example?

When you do this task, are there ways of working smart or accomplishing more with less – that you have found especially useful?

Can you think of an example when you have improvised in this task or noticed an opportunity to do something better?

Can you think of a time when you realized that you would need to change the way you were performing in order to get the job done?

Optional Questions

Can you describe an instance when you spotted a deviation from the norm, or knew something was amiss?

Have there been times when the equipment pointed in one direction, but your own judgment told you to do something else? Or when you had to rely on experience to avoid being led astray by the equipment?

Probe: Have you ever had a near miss accident related to anything that we talked about for these last 2 questions?

Scenario Based Questions

Next, I am going to read you a few examples where a continuous mining operator is in danger. Both of the examples we will go through resulted in a fatality. As I explain the situation, imagine you are the continuous miner operator in the story. Afterwards, I am going to ask you a series of questions about how you would think and act in this situation.

Scenario 1

Mine Y currently operates two nine-hour production shifts on one section developed with a minimum of 60’ entry centers and 75’ crosscut centers. The maximum allowable extended cut depth was 40’. The section is mined with two continuous mining machines that alternate operation during the shift, where one takes a cut on the left side of the section and when completed, the other continuous mining machine takes a cut on the right side and so forth.

On Wednesday, the second shift mining began on the left side of the section in the No. 3 entry. The first cut on the right side was the No. 6 right crosscut, where one cut had previously been mined. The right side continuous miner cut through into the No. 7 entry. After cutting through he moved the continuous miner to the last open cross cut to be serviced.

After being serviced, the right side continuous miner operator asked the section foreman if he could cut the headings, but he was informed that the mine foreman instructed them to cut crosscuts only, except for the No. 2 and No. 3 entries where they could take one cut. Therefore, the continuous miner operator trammed the right side mining machine to continue the No. 5 right crosscut. The No. 5 crosscut had been turned-in and bolted with 5-foot, 5/8-inch diameter resin bolts during the first shift. Metal roof straps had been installed perpendicular to the entry on four rows of roof bolts in the turn in and on three rows of roof bolts in the intersection before the crosscut was started. The metal straps were installed to provide supplemental roof support due to the presence of a sandy slicken-side that created a weak plane in the roof. The continuous miner operator began the cut as normal.

During the mid-shift report, the right side continuous miner operator informed the section foreman that he had mined approximately 30 feet on the right side and 25 feet on the left side of the No. 5 crosscut. The continuous miner operator also reported that he had been having trouble mining this cut because it was rolling and dipping toward the right side of the crosscut. After the foreman left, the continuous miner continued mining the cut.

Please identify the major events that occur during this scenario.

For each event, what judgments or decisions do you have to make?

For each major event, elicit the following information:

As the continuous miner operator in this scenario, what action, if any, would you take at this point in time?

What do you think is going on here? What is your assessment of the situation at this point in time?

What pieces of information led you to this situation assessment and these actions?

What errors would an inexperienced person be likely to make in this situation?

Conclusion:

The ram car operator backed up to let continuous miner operator reposition his continuous mining machine from the left side to the right side. While he was waiting for the operator to finish aligning the continuous miner he saw a metal strap pull down from the roof and a small piece of rock fall. He then heard the pump motor on the continuous mining machine shut off.

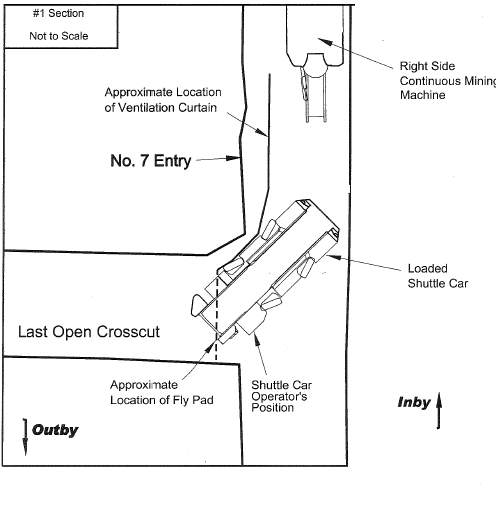

Looking at the picture ABOVE, what might you conclude? Final thoughts?

Scenario 2

Mine X operates two sections with two continuous mining machines on each section that alternate operation during a shift. On each section, three shuttles cars are used to transport coal from the continuous mining machines to the belt feeder, where the outside cars are alternated with their respective mining machines and the center car runs for both so that only two cars are operating at a time. At Mine X, they typically run two nine-hour production shifts, five days a week.

At 7:15 on Monday morning, the No. 1 section crew arrived on the section. They performed preventative maintenance, serviced the equipment, prepared for production, and then began mining. Normal mining progressed with three cuts of coal mined in the first four hours of the shift. The left side continuous mining machine was mining the No. 2 left Crosscut and the No. 4 entry. After the left side mining was completed, the right side continuous mining machine mined the No. 6 right crosscut.

At 11:00 a.m., the right side continuous mining machine started mining the No. 7 entry. The shuttle cars were changing out one crosscut inby the loading point in the No. 5 entry, which allowed them to travel to the continuous mining machine from No. 5 heading through the second line of crosscuts outby the face. Shortly after completing mining in the No. 7 entry, while starting to move the continuous mining machine to the next cut, the section experienced a power outage.

During the power outage, the section crew worked on the construction of a permanent stopping in the crosscut between the No. 5 and 6 entries, which had been the roadway just used by the shuttle cars during the cut in No. 7. The power was then restored to the section. While the power was off, draw rock fell in the unsupported portion of the No. 7 entry. The roof bolters could not install support in No.7 entry. So, instead of taking the next cut, the right side continuous mining machine was positioned in the No. 7 entry to clear the fallen rock.

With the stopping recently installed in the crosscut between the No. 5 and No. 6 entries, the haul road previously used at the second open crosscut was blocked. This required the shuttle cars to use the last open crosscut and travel through ventilation fly pads installed at the mouth of the No. 7 entry.

Please identify the major events that occur during this scenario.

For each event, what judgments or decisions do you have to make?

For each major event, elicit the following information:

As the continuous miner operator in this scenario, what action, if any, would you take at this point in time? Where would you stand and why while the shuttle car is loading? Where and why would you stand when the shuttle car is not in the area?

What do you think is going on here? What is your assessment of the situation at this point in time?

What pieces of information led you to this situation assessment and these actions?

What errors would an inexperienced person be likely to make in this situation?

Conclusion:

When the shuttle car went through the fly pads into the No. 7 entry, the continuous miner operator positioned himself in the intersection. Once the shuttle car was in the entry and under the continuous mining machine, the continuous miner operator went into the entry, stood along the right rib and loaded the car using his mining machine remote control unit. As the shuttle car left the entry, the continuous miner operator stayed in the entry near the continuous mining machine. A second shuttle carload was needed to clean the area. When the shuttle car returned, the continuous miner operator again positioned himself in the intersection as it traveled into the entry. When the shuttle car was under the conveyor boom of the continuous mining machine, the continuous miner operator went back into the entry to load the car. After the shuttle car was loaded, the continuous miner operator signaled “that was all,” and positioned himself along the right rib. The shuttle car started tramming out of the area. As the shuttle car was leaving the area, the continuous miner operator took a step and a half at a 45 degree angle, toward the continuous mining machine. The shuttle car either caught or pushed the continuous miner operator into the rib.

Final Thoughts?

| File Type | application/vnd.openxmlformats-officedocument.wordprocessingml.document |

| Author | CDC User:bme |

| File Modified | 0000-00-00 |

| File Created | 2021-01-24 |

© 2026 OMB.report | Privacy Policy