DOE F 540.20 Better Buildings Better Plants Waste Data Collection

Better Buildings, Better Plants Voluntary Pledge Report

(11) BBBP Waste Data Collection (DOE F 540.20).xlsb

Better Buildings Challenge, Better Buildings, Alliance and the Better Buildings, Better Plants Voluntary Pledge Program

OMB: 1910-5141

Document [xlsx]

Download: xlsx | pdf

Reporting Form

Energy Recovery

Waste Types

Reporting Form Example

Overview

InstructionsReporting Form

Energy Recovery

Waste Types

Reporting Form Example

Sheet 1: Instructions

| Instructions for Completing the Better Buildings, Better Plants Waste Reduction Network Reporting Form | |||||||||||||

| Reporting Form Field | Instructions | ||||||||||||

| Company Name: | Provide the name of the organization that has committed to the Waste Reduction Network. | ||||||||||||

| Company Contact Name: | Provide the name of the person at the organization who is responsible and knowledgeable for the information reported on this form. | ||||||||||||

| Company Contact Title: | Provide the title of the person named as the Company Contact. | ||||||||||||

| Address: | Provide the address for the organizational contact. | ||||||||||||

| Phone: | Provide the phone number for the organizational contact. | ||||||||||||

| E-mail Address: | Provide the email address for the organizational contact. | ||||||||||||

| NAICS of Participating Facilities: | Provide the 6-digit North American Industry Classification System codes (NAICS) for the facilities that are under the scope of the pledge effort. If more than 1 NAICS code describes the facilities, please provide up to 3. To find your NAICs code, please visit: http://www.naics.com/search.htm | ||||||||||||

| Year of Reported Data: | Identify the current reporting year, in YYYY format. | ||||||||||||

| Baseline Year: | Identify the twelve-month period that you consider your baseline year for this Initiative and for your pledge agreement. If this is your first year tracking waste data, the reporting year will be the same as your baseline year. If you have tracked waste data prior to this Initiative, you may use any previous twelve-month period to be your baseline year. Provide the end month/year for the period in MM/YYYY format. | ||||||||||||

| Number of Participating Facilities: | Identify the number of facilities that are represented in the organization's baseline year and reporting year. | ||||||||||||

| Number of Participating Facilities that are manufacturing plants: |

Of the Number of Participating Facilities, indicate the number that are manufacturing plants. | ||||||||||||

| Waste Tracking Units | Use the drop down menu to indicate the unit(s) you will use to track waste for the Waste Initiative. The dropdown menu contains commonly used units for weight and volume. If you do not see your metric, you can add it to the drop down list by replacing "Other" with your unit of measure in the list of Units in the Waste Types tab. | ||||||||||||

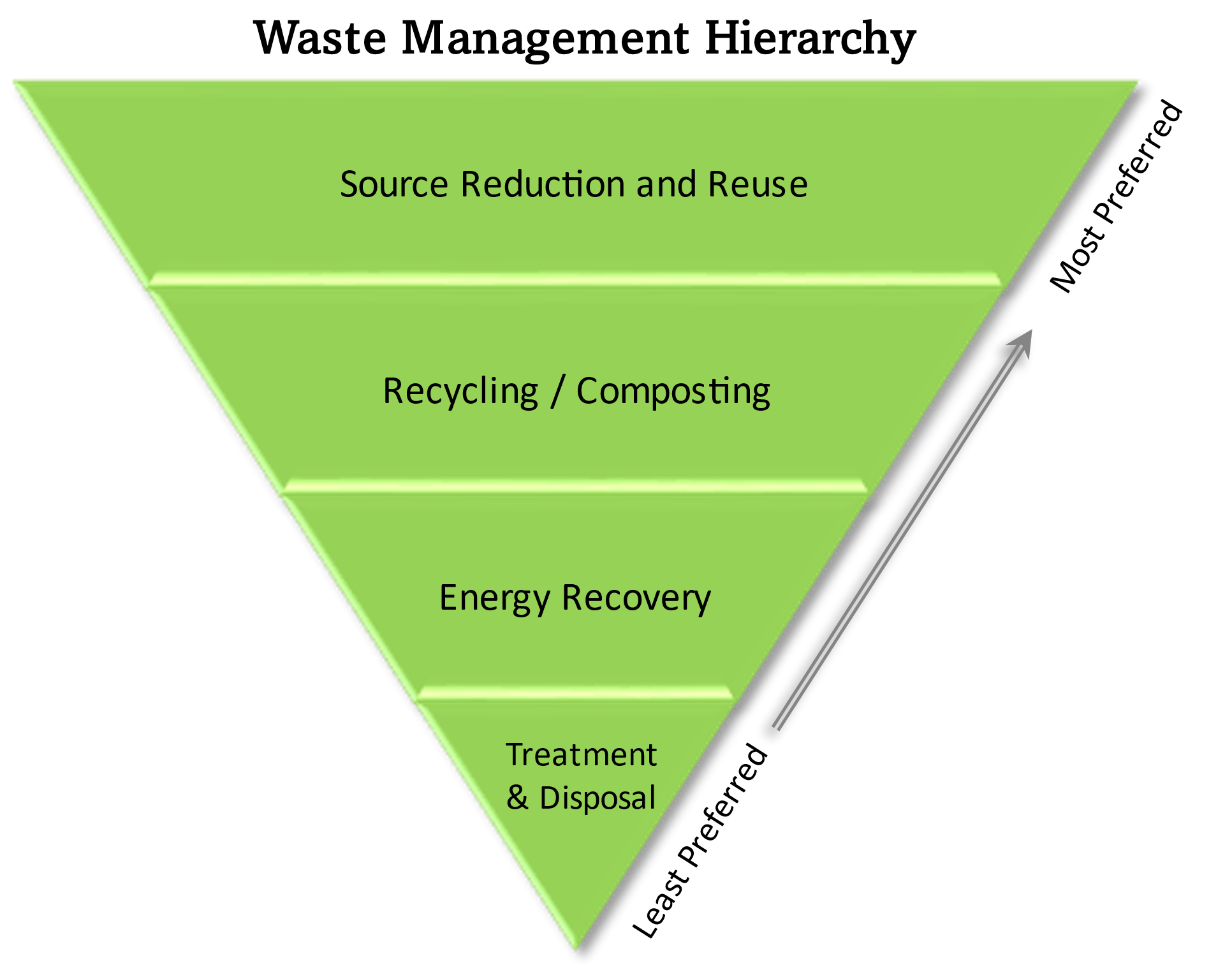

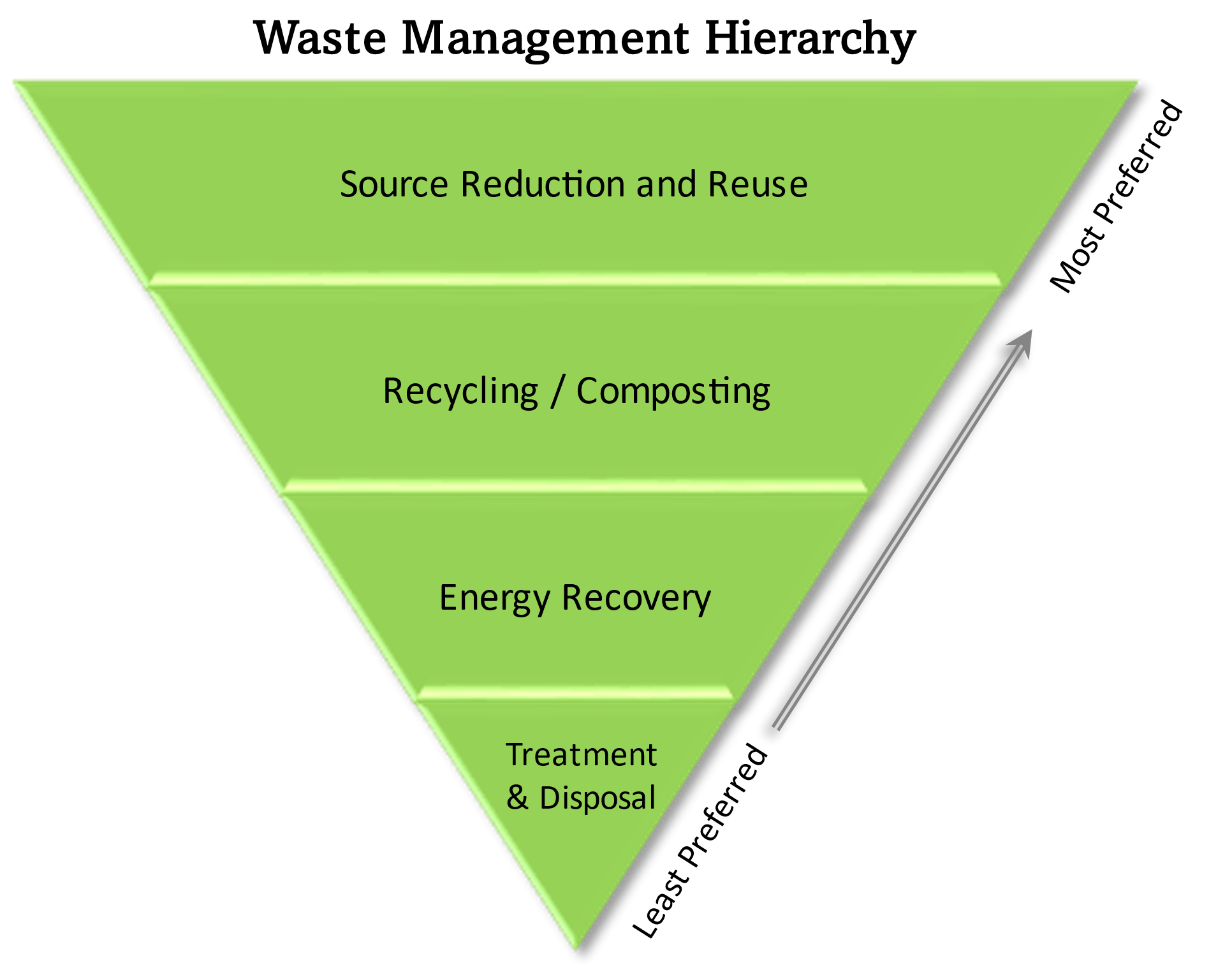

| Waste Data: | Use the Waste Hierarchy graphic to guide your recording of your treatment of wastes. For each row, select from the drop down menu one of the waste types you use to group your wastes. Enter weights or volumes in each relevant treatment type column. Be sure to use a common unit of measure for all entries. Select the same waste types for both the baseline year and the reporting year and in the same order. This will simplify analysis. If you do not see one or more of the waste types you use, you can enter them into the dropdown menu by replacing one or more of the "Other" lines with your waste type(s) in the Waste Types list in the Waste Types tab. | ||||||||||||

| Source Reduction and Reuse: Waste reduction that results from reusing materials previously disposed of, or materials sold or donated for use by others. Note: This includes remanufacturing and closed loop recycling. | |||||||||||||

| Recycling: Waste reduction resulting from recycling into a raw material that can be converted into something new. Also includes open loop recycling. | |||||||||||||

| Composting: Waste reduction resulting from composting food waste and other compostable materials. | |||||||||||||

| Energy Recovery: The conversion of waste materials into usable heat, electricity, or fuel through a variety of processes, including combustion, gasification, pyrolisis, anaerobic digestion, and landfill gas (LFG) recovery. This process is often called waste-to-energy (WTE). If you convert any of your wastes to energy, either on-site or off-site, please fill out the worksheet in the Energy Recovery tab to track the amont of energy recovered. | |||||||||||||

| Treatment and Disposal: All waste that is thrown away and goes to a landfill or an incinerator (combustion without energy recovery). | |||||||||||||

| Total Waste: These fields will total automatically by waste type (rows) and by treatment (columns). Be sure all the values entered into the spreadsheet for both Baseline Year and Reporting Year are of the same unit of measure. | |||||||||||||

| Waste Diversion Rate (%): | The fraction of the total waste diverted from landfills, calculated by dividing the waste diverted (through Reuse and Recycling/Composting) by the Total Waste. These three fields will total automatically. | ||||||||||||

| Waste Intensity Metric (unit/activity): | The waste intensity measurement is a way of normalizing total waste with respect to amount of manufacturing activity taking place at different facilities. It can have specific units and intensity reduction is tracked as percentage. Enter used unit which measures manufacturing activity level in the facilities and actual manufacturing output in the units. | ||||||||||||

| Unit(s) for waste intensity metric: | Indicate the unit(s) for the waste intensity metric(s) used for tracking waste reduction for the Waste Initiative. See below for the definition of waste intensity. Examples include pounds/square foot, pounds/ton of product, etc. If using an absolute metric, please indicate the unit for the total waste (e.g., pounds). | ||||||||||||

| Waste intensity metric (numeric value): | Waste intensity is the Total Waste normalized for a measure of activity/volume for an organization, like square feet of space or volume of product produced. For example, if an organization has 10,000 pounds of waste for 10,000 square feet, the waste intensity is 1 pound per square foot. Indicate the waste intensity at the organization level (if one exists) for the baseline and reporting year. If waste intensity improvements are calculated at the facility level and rolled up to the organization level, leave this field blank. | ||||||||||||

| Annual improvement in waste intensity for current year (%): | Provide the change in waste intensity experienced in current year. A simple way of calculating this value is to subtract last year's Total Improvement in Waste Intensity from the current year's Total Improvement in Waste Intensity. Another way is to subtract the Baseline Years' Total Improvement in Waste Intensity from the Reporting Year's Total Improvement Waste Intensity and divide by the number of years between the Reporting Year and the Baseline Year. | ||||||||||||

| Total improvement In waste intensity (%): | Provide the total change in waste intensity since the baseline year. This value can be calculated with the following equation: Total Improvement in Waste Intensity (%) = (Waste IntensityBaseline Year - Waste IntensityCurrent Year) / Waste IntensityBaseline Year |

||||||||||||

| Absolute Waste Reduction: | Absolute waste reduction is measured in terms of reduction in tracked units, e.g. mass or volume units. The baseline total waste and reporting year total waste are automatically populated. The improvement is automatically calculated as percentage improvement over baseline. The annual and total improvements are automatically calculated. | ||||||||||||

| Zero Waste: | Zero Waste tracks progress in terms of waste reduction through the waste management hierarchy. It also aims to divert waste from landfills and incineration. Zero Waste Diversion Rate is calculated slightly differently as the incineration form of energy recovery is excluded from this diversion rate. Enter waste sent to incineration plant to calculate zero waste diversion rate. A rate of 90% or higher is accepted as zero waste. The diversion rate and progress toward zero waste is automatically calculated. | ||||||||||||

| Waste-to-energy: | Waste-to-energy goal is tracks progress toward utilizing waste streams to extract useful energy and become more resource efficient. Enter the extra waste resulting from waste-to-energy activity. Waste used to recover energy fields are automatically populated. Waste-to-energy recovery ratio is automatically calculated and improvement is automatically calculated as percentage. The annual and total improvement is calculated as mentioned above. | ||||||||||||

| Circularity: | Circularity measurement is very complex and involves a much more detailed evaluation of raw materials, waste, and product use. At this point the form only tracks improvement in circularity index score obtained from participating company's internal sources. Enter tracked circularity index score as tracked and the total improvement and annual improvement are automatically calculated. | ||||||||||||

| Please describe the methodology used for calculating waste intensity improvements: |

Briefly describe the data and calculations to determine the reported waste intensity improvement, especially the process through which facility-level metrics are rolled up to the corporate level. | ||||||||||||

| Please briefly describe the technologies, strategies, and practices employed during the previous year to decrease waste intensity. Please identify: systems/processes impacted, approximate waste savings from projects, and implementation cost | Briefly describe, in general, the range of technologies, strategies and practices employed since the baseline year that resulted in a reduction in waste intensity. If possible, identify systems and/or facilities that were impacted, approximate waste reduction, and implementation cost . Optional details: geographic location, industry, and additional descriptive details about the projects. |

||||||||||||

| Waste Diversion Performance Improvement (Applies to Companies with Multiple Plants) | If you have more than one facility participating in this Initiative and collect waste reduction data at the facility level, we'd appreciate knowing how performance varies across your facilities. Please mark down the number of facilities that have achieved the level of "Waste Diversion Improvement Performance" indicated in the left hand column of the table. Facility-level waste performance should be measured on a cumulative basis against the organization's baseline year. | ||||||||||||

Sheet 2: Reporting Form

Sheet 3: Energy Recovery

| Energy Recovery | |||||

| Do you convert any of your waste to energy or a fuel or some other resource? If the answer is yes, please answer the following questions. If not, you do not need to fill out this tab. | |||||

| Energy Recovery | Baseline Year | Reporting Year | Units | ||

| How much waste was converted to energy (from Annual Form) | Err:520 | Err:520 | 0 | ||

| What units do you use to measure the energy recovered? (Examples: kWh, MWh, Btus, MMBtus, Ccf, Mcf) | |||||

| Was any energy recovery done off-site? If so, where? | |||||

| Was any waste converted to energy on-site. If so, how was it converted to energy | |||||

| Examples: Incinerator, biodigester, cogeneration, boiler, or cement kiln | |||||

| What type of energy resources was your waste converted into? | |||||

| Examples: Electricity, steam, hot water, biogas, fuel, other. List all that apply | |||||

| Cogeneration/Combined Heat & Power (CHP) | |||||

| If consumed in a cogeneration/CHP system, was the waste consumed directly? (Y/N) | |||||

| If not consumed directly, was the waste first converted to biogas or other fuel before combustion? If so, please identify the fuel. | |||||

| How was the energy recovered? List all that apply. | |||||

| Examples: Electricity, steam, hot water, fuel, other | |||||

| Energy use on-site (if applicable) | |||||

| How much electricity from waste-to-energy conversion was used onsite? (e.g.: kWh, MWh) | |||||

| How much thermal energy from waste-to-energy conversion was used onsite? (e.g.:Btu, MMBtu, therms) | |||||

| Other Benefits of Energy Recovery | |||||

| For off-site conversion, did you receive credit on your electric, natural gas, or thermal utility bills? If so, how much? | |||||

| For on-site conversion, was any energy exported off-site? If so, how much? | |||||

| For off-site conversion, did you pay or sell the waste? (did you pay to have it disposed, or did you receive payment for the energy content?) | |||||

| Please list any other energy benefits realized from waste-to-energy conversion: | |||||

Sheet 4: Waste Types

| Waste Types | Units | Goals | |||||

| Depending on the facility type, waste categories may be more broad, such as "Trash" or "Mixed Recyclables", or may be specific to materials that are relevant to the organization, such as "Food and compostables" or "Chemicals". Pilot participants are not required to provide detailed categories for all waste, but are encouraged to do so if it is helpful for their waste tracking needs. Pilot participants may select from the list of categories below, or choose others as needed. We have consolidated that list into a more manageable number of categories and subcategories for pilot participants’ consideration. |

Pilot participants should identify one unit of measure to track the volume of waste(s) they are generating so that they can guage progress towards their goal. Common units of measure are by weight (lbs, tons, kilograms) or by volume (cubic yards, square feet, gallons). Measurements by container (such as dumpster, carboy, bales) should be converted into either a weight or volumetric unit. Ideally, all waste streams are tracked by the same unit of measure so that overall progress is easily determined. | Waste Reduction Network participants should identify one of six goals defined in the Waste Reduction Network factsheet. | |||||

| Appliances, metal cabinets and shelving | Units of Weight | Pounds | Goals | Diversion | |||

| Batteries | Tons | Intensity | |||||

| Ceramics | Kilograms | Absolute Reduction | |||||

| Construction and demolition debris | Metric tonnes | Zero Waste | |||||

| Chemicals | Units of Volume | Cubic feet | Waste-to-Energy | ||||

| Electronics, computers, printers | Cubic yards | Circularity | |||||

| Fabrics and clothing | Cubic meters | ||||||

| Food and compostables | Gallons | ||||||

| Furniture | Liters | ||||||

| Glass | Other | Other | |||||

| Hazardous wastes | |||||||

| Light bulbs and fluorescent lights | |||||||

| Medical wastes | |||||||

| Metals (mixed) | |||||||

| Metal-Aluminum | |||||||

| Metal-Copper | |||||||

| Metal-Ferrous | |||||||

| Mixed Recyclables | |||||||

| Paper (mixed) | |||||||

| Paper-office | |||||||

| Paperboard and cardboard | |||||||

| Paper-Glossy and other | |||||||

| Plastics (mixed) | |||||||

| Plastic code #1, PET | |||||||

| Plastic code #2, HDPE | |||||||

| Plastic code #3, PVC/Vinyl | |||||||

| Plastic code #4, LDPE | |||||||

| Plastic code #5, Poly propylene | |||||||

| Plastic code #6, Polystyrene | |||||||

| Other plastic | |||||||

| Rubber and tires | |||||||

| Sand, soil, dirt, rocks | |||||||

| Trash | |||||||

| Textiles | |||||||

| Wood (mixed) | |||||||

| Wood-lumber | |||||||

| Wood-yard trimmings | |||||||

| Other: A | |||||||

| Other: B | |||||||

| Other: C | |||||||

Sheet 5: Reporting Form Example

| File Type | application/vnd.openxmlformats-officedocument.spreadsheetml.sheet |

| File Modified | 0000-00-00 |

| File Created | 0000-00-00 |

© 2025 OMB.report | Privacy Policy