Form 6100-079 Chromium Finishing Questionnaire

Chromium Finishing Industry Data Collection (New)

Form 6100-079, Chromium Finishing Questionnaire

Chrome Finishing Industry Data Collection

OMB: 2040-0308

O MB

Control No. 2040-NEW

MB

Control No. 2040-NEW

Approval Expires [Date]

UNITED STATES ENVIRONMENTAL PROTECTION AGENCY

Chromium Finishing Questionnaire

Form 6100-079

DRAFT

Form Approved OMB Control No. 2040-NEW Approval Expires [Date]

This collection of information is approved by OMB under the Paperwork Reduction Act, 44 U.S.C. 3501 et seq. (OMB Control No. 2040-NEW). Responses to this collection of information are mandatory (Section 308 of the Clean Water Act (Federal Water Pollution Control Act, 33 U.S.C. Section 1318)). An agency may not conduct or sponsor, and a person is not required to respond to, a collection of information unless it displays a currently valid OMB control number.

To comment on EPA’s need for this collection, the accuracy of the provided burden estimate, and any suggested methods for minimizing respondent burden EPA has established a public docket for this ICR under Docket ID No. EPA-HQ-OW-2022-0869, which is available for public viewing at the Water Docket in the EPA Docket Center (EPA/DC), EPA West, Room 3334, 1301 Constitution Ave., NW, Washington, DC 20004. The EPA Docket Center Public Reading Room is open from 8:30 a.m. to 4:30 p.m., Monday through Friday, excluding legal holidays. The telephone number for the Reading Room is (202) 566-1744, and the telephone number for the Water Docket is (202) 566-2426. An electronic version of the public docket is available through the Federal Docket Management System (FDMS) at http://www.regulations.gov. Use FDMS to submit or view public comments, access the index listing of the contents of the public docket, and access those documents in the public docket that are available electronically. Once in the system, select “search”, then key in the docket ID number identified above. Please include the EPA Docket ID No. (EPA-HQ-OW-2022-0869) and OMB control number (2040-NEW) in any correspondence.

|

NOTE 1: This questionnaire will be primarily administered as an online questionnaire using Qualtrics Survey Software (Qualtrics). However, EPA will offer a hardcopy version to respondents that do not have internet connection or cannot otherwise complete the Qualtrics version. The hardcopy version may also be used by respondents as a working file to help them compile all information needed to response prior to completing the Qualtrics version. The content of the hardcopy and Qualtrics versions will match, but the exact order of question and/or the presentation, format, and spacing of the questions may differ.

NOTE 2: For the purposes of this draft, all tables include minimal rows for data entry; these tables are intended simply to show the types of data EPA is requesting. In the final versions (hardcopy and Qualtrics format), all tables will include enough additional empty rows appropriate for most respondents.

NOTE 3: The final questionnaire will include confidential business information (CBI) designation checkboxes or dropdowns for each question, allowing the respondent to indicate if a response contains CBI. This draft questionnaire does not include these CBI checkboxes.

NOTE 4: Skipped questions and sections will be programmed in Qualtrics and written instructions omitted. As such, respondents will not see the questions or sections that are skipped based on their responses. Instructions on identifying applicable questions are included in this draft to show what will be included in the hardcopy version and demonstrate the intended questionnaire flow.

NOTE 5: As currently designed, the questionnaire will be administered as a census to all facilities in the chromium finishing industry profile (approx. 2,000 facilities). EPA prepared the questionnaire to be applicable to a variety of facilities; therefore, not all questions will apply to every company or facility. The questionnaire includes instruction to note when respondents do not need to complete a part or question. For example, facilities which have not conducted specific chromium finishing operations since 1995 or have permanently discontinued all metal finishing and electroplating operations as of 2023 are instructed to skip all remaining questions in the questionnaire. Additionally, facilities that did not generate, discharge, treat, or transfer off site certain wastewaters will be instructed to skip entire sections or sets of questions in the questionnaire.

INTRODUCTION AND PURPOSE

The United States Environmental Protection Agency (EPA) is conducting a survey of the metal finishing and electroplating industry as part of its effort to review and revise, as appropriate, effluent limitations guidelines and standards (ELGs) for these point source categories. The existing ELGs are codified in 40 Code of Federal Regulations (CFR) Part 433 and 40 CFR Part 413, respectively. This questionnaire is being conducted under the authority of Section 308 of the Clean Water Act (Federal Water Pollution Control Act, 33 U.S.C. Section 1318). Failure to respond, late filing, or failure to comply with the instructions may result in fines, civil penalties, and other sanctions, as provided by law.

This questionnaire requests data from sites engaged in specific chromium operations within the metal finishing and electroplating industry. For detailed information on how EPA plans to use data obtained from each question, see the document titled “Information Collection Request Supporting Statement –United States Environmental Protection Agency Metal Finishing and Electroplating Industry Data Collection” at EPA Docket ID No. (EPA-HQ-OW-2022-0869).

EPA’s Office of Water administered the questionnaire as a census to the subset of metal finishing and electroplating facilities engaged in specific chromium operations. All metal finishing and electroplating facilities which receive the data request are required to complete the questionnaire regardless of size, geography, classification as a captive facility or job shop, and other characteristics. The questionnaire consists of multiple sections, and they all must be completed as directed before submittal. The questionnaire is divided into the following sections:

Section 1: General Facility Information

Section 2: Facility Operations and Per- and Polyfluoroalkyl Substances (PFAS) Use

Section 3: Wastewater Generation

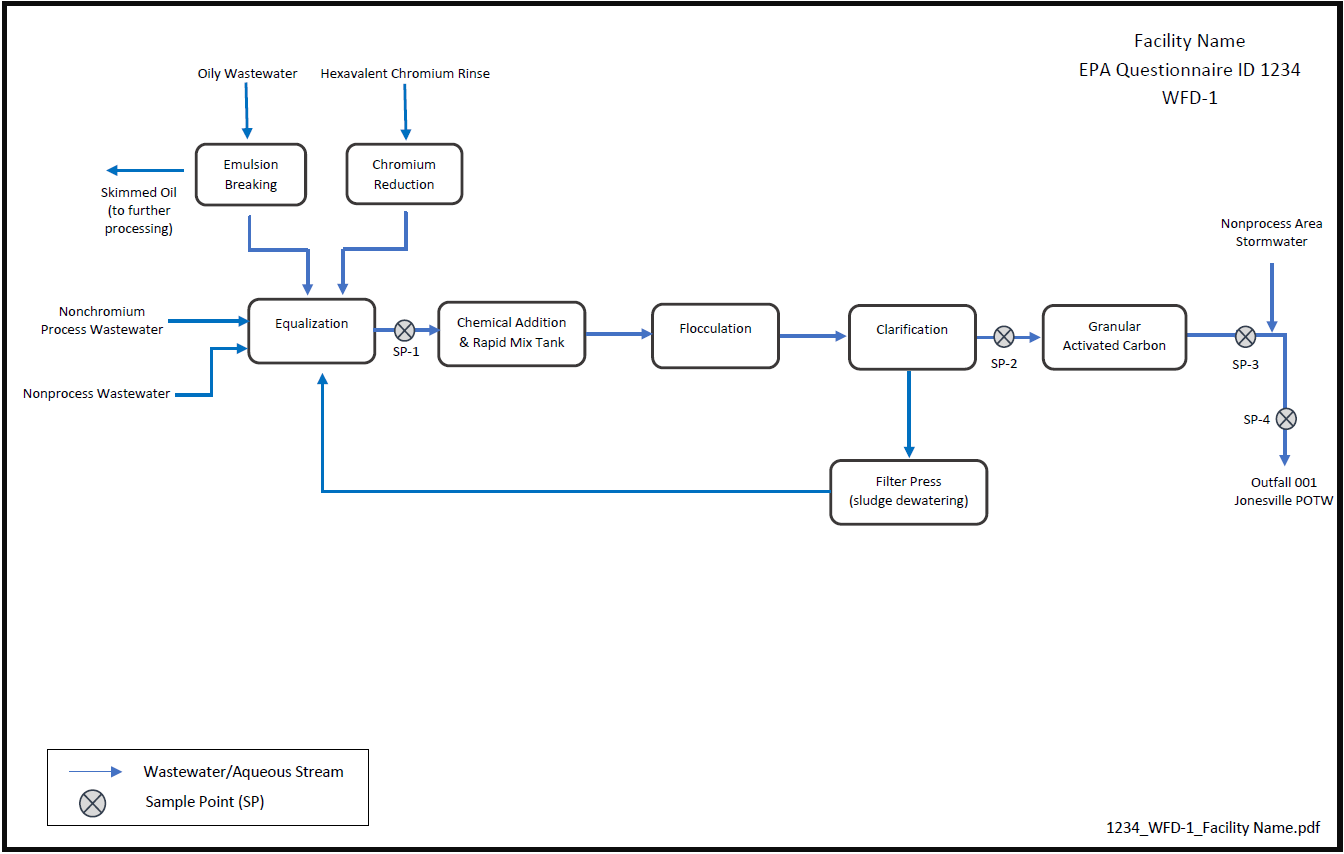

Section 4: Wastewater Flow Diagram

Section 5: Wastewater Management and Treatment

Section 6: Permit Requirements and Monitoring Data

Section 7: Environmental and Other Information

Section 8: Financial Information

Section 9: Comments

EPA prepared the questionnaire to be applicable to a variety of facilities; therefore, not all questions will apply to every company or facility. Complete all questions for all parts of the questionnaire unless otherwise specified. The questionnaire includes instruction to note when you do not need to complete a part or question. For example, facilities which have not conducted specific chromium finishing operations since 1995 or have permanently discontinued all metal finishing and electroplating operations as of 2023 are instructed to skip all remaining questions in the questionnaire. Additionally, facilities that did not generate, discharge, treat, or transfer off site certain wastewaters will be instructed to skip entire sections or sets of questions in the questionnaire.

WHEN TO SUBMIT THE QUESTIONNAIRE

The response to this questionnaire is due [INSERT DUE DATE THAT ENSURES FACILITIES WILL HAVE AT LEAST 60 DAYS TO RESPOND AFTER NOTIFICATION]. If you wish to request an extension, you must do so in writing before [INSERT DATE 15 DAYS PRIOR TO THE DUE DATE]. Written requests may be emailed (preferred) or mailed to the EPA Metal Finishing and Electroplating Questionnaire Helpline at:

Mailing Address United States Environmental Protection Agency

c/o Eastern Research Group, Inc.

Metal Finishing and Electroplating Questionnaire

14555 Avion Pkwy, Suite 200

Chantilly, VA 20151-1102

Extension requests will be evaluated on a case-by-case basis. Submittal of an extension request to EPA does not alter the due date of your questionnaire unless and until EPA agrees to the extension and establishes a new date.

QUESTIONNAIRE INSTRUCTIONS

Complete and submit the questionnaire in Qualtrics Survey Software (Qualtrics). EPA created the questionnaire in Qualtrics to minimize burden, and it has been developed to meet the 1998 Government Paperwork Elimination Act (GPEA). If your facility lacks internet access or cannot complete the Qualtrics questionnaire, contact the Helpline; refer to QUESTIONNAIRE ASSISTANCE for contact information for the Helpline. EPA will allow facilities that cannot complete the Qualtrics questionnaire to complete a hardcopy version of the questionnaire.

Review the General Instructions before beginning your questionnaire response. The General Instructions are available for download on the EPA Metal Finishing and Electroplating Industry Data Collection webpage (https://www.epa.gov/eg/metal-finishing-effluent-guidelines#rulemaking-chromium) and pertain to all questionnaire responses, regardless of the format (Qualtrics or hardcopy). The instructions provided herein are specific to completing and submitting a hardcopy questionnaire.

Facilities are encouraged to use this hardcopy questionnaire to prepare for completing the questionnaire in Qualtrics. Facilities are also encouraged to save a hardcopy of their completed questionnaire for their records and future reference. Respondents will not be able to access the electronic questionnaire after it has been certified and submitted to EPA.

FILES SUBMITTED WITH THE QUESTIONNAIRE

For certain questions, you will be asked to provide copies of documents, figures, and diagrams. Additional questions provide template Excel workbooks and ask you to download, complete, and then submit the workbooks as responses. These template files are available for download in Qualtrics from the corresponding questions or can be downloaded from the EPA Metal Finishing and Electroplating Industry Data Collection webpage. When questionnaire respondents request a hardcopy questionnaire, these files are included in the materials mailed by the Helpline.

Respondents submitting hardcopy questionnaires should make copies of all attachments (submitting one copy to EPA and keeping one copy for their records) and mail all materials to the Helpline along with their questionnaire submission. Hardcopy questionnaire respondents should indicate within these files which files are claimed as CBI and include the EPA Questionnaire ID, which is the unique identification number assigned to your facility in the notification letter mailed by EPA, on any hardcopy materials.

DATA CONFIDENTIALITY

If no business confidentiality claim accompanies the information when it is received by EPA, EPA may make the information available to the public without further notice.

You may assert claims of business confidentiality for any information you submit to EPA. Information claimed as confidential will be treated in accordance with the procedures for handling information claimed as confidential under 40 CFR Part 2, Subpart B, and will be disclosed to the extent, and by means of procedures, set forth in Subpart B. If no claim of confidentiality is asserted when the information is received by EPA, it may be made available to the public without further notice to you. See 40 CFR 2.203(a), 41 Fed. Reg. 36,907. Furthermore, generally, effluent data and information already available to the public is not entitled to confidential treatment and will be made available to the public without further notice to you. See 40 CFR §§ 2.201(g), 2.302(e) & (f); 40 CFR § 403.14. Any knowing and willful misrepresentation is subject to criminal penalty pursuant to 18 U.S.C. § 1001.

In this questionnaire, designate responses as confidential business information (CBI) using the CBI checkboxes next to each question.

QUESTIONNAIRE ASSISTANCE

If you have any questions about your facility’s questionnaire, consult the List of Frequently Asked Questions (FAQs) on the EPA Metal Finishing and Electroplating Questionnaire webpage (https://www.epa.gov/eg/metal-finishing-effluent-guidelines#rulemaking-chromium). You may also request assistance from the Helpline using the email and telephone lines provided below. The Helpline is operated by Eastern Research Group, Inc. from 9:00 AM to 4:00 PM during Monday to Friday. When contacting the Helpline, please include your name, phone number, and the EPA Questionnaire ID (i.e., the unique identification number assigned to your facility in the notification letter mailed by EPA), assigned to your facility in the notification letter from EPA, in any voicemail or email messages.

EPA Metal Finishing and Electroplating Questionnaire Helpline

Phone Numbers L####or Toll-free: 877-353-####

Mailing Address United States Environmental Protection Agency

c/o Eastern Research Group, Inc.

Metal Finishing and Electroplating Questionnaire

14555 Avion Pkwy, Suite 200

Chantilly, VA 20151-1102

If your facility lacks internet access or you are unable to submit the questionnaire in Qualtrics, contact the Helpline to request a hardcopy questionnaire be mailed to you.

If your company operates one or more facilities in the United States that currently or previously conducted chromium finishing operations and these facilities did not receive a questionnaire, contact the Helpline to request a copy of the questionnaire for these facilities.

Questions regarding EPA’s associated rulemaking for the Metal Finishing and Electroplating Questionnaire should be directed to EPA at ####@epa.gov or via https://www.epa.gov/eg/metal-finishing-effluent-guidelines#rulemaking-chromium.

WHERE TO SUBMIT THE QUESTIONNAIRE

Complete and submit the questionnaire in the Qualtrics Survey Software. If your facility lacks internet access or cannot complete the Qualtrics questionnaire and requested a paper questionnaire, complete the entire questionnaire, enter your EPA Questionnaire ID (i.e., the unique identification number assigned to your facility in the notification letter mailed by EPA) in the header of each page, and certify your responses by completing the Certification Statement at the end of this document (see page 55). Mail the completed questionnaire, including requested attachments, template files on removable media (preferably USB drive), and the signed Certification Statement, to:

United States Environmental Protection Agency

c/o Eastern Research Group, Inc.

Metal Finishing and Electroplating Industry Questionnaire

14555 Avion Parkway, Suite 200

Chantilly, VA 20151-1102

ABBREVIATIONS

Ah ampere-hour or amp-hour

CAS Chemical Abstracts Service

CBI Confidential Business Information

CFR Code of Federal Regulations

Cr III trivalent chromium

Cr VI hexavalent chromium

ELGs effluent limitations guidelines and standards

EPA United States Environmental Protection Agency

FRS Facility Registry Service

FTE full-time equivalent

gal gallons

GPEA 1998 Government Paperwork Elimination Act

mg/l milligram per liter

mm/dd/yyyy month/day/year

N/A not applicable

NAICS North American Industry Classification System

ng/l nanogram per liter (equivalent to part-per-trillion)

NPDES National Pollutant Discharge Elimination System

PFAS per- and polyfluoroalkyl substances

RCRA Resource Conservation and Recovery Act

RL reporting limit

SBA Small Business Administration

GLOSSARY

Adsorption/Adsorptive Media: Removal of a pollutant from air or water by collecting the pollutant on the surface of a solid material (e.g., method of treating waste in which activated carbon removes pollutants from vented gases or wastewater).

Air Emission Control: Any technology or practice intended to capture, reduce, or eliminate one or more contaminants in a gaseous stream. Includes chemical fume suppressants and air pollution control equipment that is used to reduce chromium emissions from chromium electroplating and chromium anodizing tanks.

Air Emission Control Wastewater: Any wastewater generated from an air emission control system (i.e., wasters generated from technologies or practices intended to capture, reduce, or eliminate one or more contaminants in a gaseous stream).

Analytical Method: Laboratory analytical methods (test procedures) that are used by industries and municipalities to analyze the chemical, physical, and biological components of wastewater and other environmental samples.

Anodizing: A process which produces a protective oxide film on aluminum, magnesium, or other light metal, usually by passing an electric current through an electrolyte bath in which the metal is suspended. Phosphoric acid, sulfuric acid, and boric acid may be used in anodizing. Anodizing may be followed by a sealant operation. These oxide coatings provide corrosion protection, decorative surfaces, a base for painting and other coating processes, and special electrical and mechanical properties. Wastewaters generated during anodizing include spent anodizing solutions, sealants, and rinse waters.

Basis Metal or Material: That substance of which the workpieces are made and that receives the electroplate and the treatments in preparation for plating.

Biological Treatment: Wastewater treatment intended to degrade and reduce organic matter in wastewater, primarily in the form of soluble organic compounds.

Capital Improvements: Any addition or alteration to a facility that substantially adds to its value or appreciably prolongs its use.

Captive Facility: A facility which owns more than 50 percent (annual area basis) of the materials undergoing metal finishing and electroplating.

Centralized Waste Treatment Agreement: Contract or other agreement associated with wastewater discharge from facility to centralized waste treatment facility.

Centralized Waste Treatment Facility: Any commercial facility that treats (for disposal, recycling or recovery of material) any hazardous or nonhazardous industrial wastes, hazardous or nonhazardous industrial wastewater, and/or used material received from off site.

Chemical Abstracts Service (CAS) Registry Number: A unique numeric identifier that provides an unambiguous means to distinguish chemical substances. Each CAS registry number designates only one substance, has no chemical significance, and can be used to search for information about a specific chemical substance.

Chemical Etching and Milling: These processes are used to produce specific design configurations and tolerances or surface appearances on parts (or metal-clad plastic in the case of printed circuit boards) by controlled dissolution with chemical reagents or etchants. Included in this classification are the processes of chemical milling, chemical etching and bright dipping. Chemical etching is the same process as chemical milling except the rates and depths of metal removal are usually much greater in chemical milling. Bright dipping is a specialized form of etching and is used to remove oxide and tarnish from ferrous and nonferrous materials and is frequently performed just prior to anodizing. Bright dipping can produce a range of surface appearances from bright clean to brilliant depending on the surface smoothness desired for the finished part. Bright dipping solutions usually involve mixtures of two or more of sulfuric, chromic, phosphoric, nitric and hydrochloric acids. Also included in this unit operation is the stripping of metallic coatings.

Chemical Fume Suppressant: Any chemical that reduces surface tension or suppresses fumes or mists at the surface of an electroplating, anodizing, or other process bath. Another term for chemical fume suppressant is chemical mist suppressant.

Chemical Precipitation/Flocculation: Wastewater treatment unit that uses the addition of chemicals to alter the physical state of dissolved and suspended solids (typically forming a substance which is partially or mainly insoluble and, therefore, appears as a solid) and facilitate their removal by sedimentation or filtration.

Chromic Acid: The common name for chromium anhydride (CrO3).

Chromium Finishing Operations: Any metal finishing or electroplating process that deposits a layer of chromium on any basis metal or material, or uses chromium materials in the fabrication of a metal product. Applicable processes include, but are not limited to, the activities listed and defined below. Another term for chromium finishing operations is chrome finishing operations.

Decorative Chromium Plating: Process by which a thin layer of chromium (typically 0.003 to 2.5 microns) is electrodeposited on a basis metal or material to provide a bright surface with wear and tarnish resistance. In this process, the part(s) serves as the cathode in the electrolytic cell and the solution serves as the electrolyte. Typical current density applied during this process ranges from 540 to 2,400 Amperes per square meter (A/m2) for total plating times ranging between 0.5 to 5 minutes. Decorative chromium plating is used for items such as automotive trim, metal furniture, bicycles, hand tools, and plumbing fixtures.

Functional/Hard Chromium Plating: Process by which a thick layer of chromium (typically 1.3 to 760 microns) is electrodeposited on a basis metal or material to provide a surface with functional properties such as wear resistance, a low coefficient of friction, hardness, and corrosion resistance. In this process, the part serves as the cathode in the electrolytic cell and the solution serves as the electrolyte. Hard chromium electroplating process is performed at current densities typically ranging from 1,600 to 6,500 A/m2 for total plating times ranging from 20 minutes to 36 hours depending upon the desired plate thickness. Hard chromium plating is used for items such as hydraulic cylinders and rods, industrial rolls, zinc die castings, plastic molds, engine components, and marine hardware.

Chromium Anodizing: Electrolytic process by which an oxide layer is produced on the surface of a basis metal or material for functional purposes (e.g., corrosion resistance or electrical insulation) using a chromic acid solution. In chromium anodizing, the part to be anodized acts as the anode in the electrical circuit, and the chromic acid solution, with a concentration typically ranging from 50 to 100 grams per liter (g/L), serves as the electrolyte.

Chromic Acid Etching: Process using a chromic acid solution in the removal of specific unwanted areas of silicon substrate, deposited film, or other material so that an underlying material may be exposed, or another material may be deposited, in the etched materials place.

Chromate Conversion Coating: Process involving formation of a conversion coating (protective coating) on a surface by immersing or spraying the basis metal or material with a hexavalent chromium compound solution (consisting substantially of chromic acid or water soluble salts of chromic acid) to produce a hexavalent or trivalent chromium compound coating. This also is known as chromate treatment, and is often applied to aluminum, zinc, cadmium or magnesium surfaces. Sealant operations using chromium also are included in this unit operation.

Clean Water Act: Federal legislation enacted by Congress to “restore and maintain the chemical, physical, and biological integrity of the Nation’s waters” (Federal Water Pollution Control Act of 1972, as amended, 33 USC 1251 et seq.).

Clarification: A sedimentation process to remove solid particles from a liquid stream by gravitational force.

Coating: Metal finishing operations which include chromating, phosphating, and metal coloring. These coatings are applied to previously deposited metal or basis material for increased corrosion protection, lubricity, preparation of the surface for additional coatings or formulation of a special surface appearance. In chromating, a portion of the basis metal or material is converted to one of the components of the protective film formed by the coating solution. This occurs by reaction with aqueous solutions containing hexavalent chromium and active organic or inorganic compounds. Chromate coatings are most frequently applied to zinc, cadmium, aluminum, magnesium, copper, brass, bronze and silver. In phosphating, phosphate coatings are used to provide a good base for paints and other organic coatings, to condition the surfaces for cold forming operations by providing a base for drawing compounds and lubricants, and to impart corrosion resistance to the metal surface by the coating itself or by providing a suitable base for rust-preventative oils or waxes. Phosphate conversion coatings are formed by the immersion of iron, steel, or zinc plated steel in a dilute solution of phosphoric acid plus other reagents. Metal coloring covers only chemical methods of coloring in which the metal surface is converted into an oxide or similar metallic compound. The most common colored finishes are used on copper, steel, zinc, and cadmium.

Code of Federal Regulations (CFR): A codification of the final rules published daily in the Federal Register. Title 40 of the CFR contains the environmental regulations.

Confidential business information (CBI): In accordance with 40 CFR §2, any information submitted to EPA pursuant to these regulations may be claimed as confidential by the submitter. Any such claim must be asserted at the time of submission in the manner prescribed on the application form or instructions or, in the case of other submissions, by stamping the words “confidential business information” on each page containing such information. If no claim is made at the time of submission, EPA may make the information available to the public without further notice. If a claim is asserted, the information will be treated in accordance with the procedures in 40 CFR §2 (Public Information). See 40 CFR §122.7.

Destination: The place to which a wastewater is sent. Immediate destinations refer to the first place a wastewater is sent to while final destinations refer to the ultimate place a wastewater is sent.

Discharge: The conveyance of wastewater or any pollutant via an outfall to: (1) surface waters; or (2) a publicly owned, privately owned, federally owned, combined, or other treatment works.

Effluent Limitation: Any restriction imposed on quantities, discharge rates, and concentrations of pollutants which are discharged from point sources into waters of the United States, the waters of the contiguous zone, or the ocean.

Effluent Limitations Guidelines and Standards: Regulations promulgated by EPA under authority of Sections 301, 304, 306, and 307 of the Clean Water Act that set out minimum, national technology-based standards of performance for point source wastewater discharges from specific industrial categories (e.g., iron and steel manufacturing plants). Effluent limitations guidelines and standards regulations are implemented through the NPDES permit and national pretreatment programs and include the following:

Best Practicable Control Technology Currently Available (BPT)

Best Available Technology Economically Achievable (BAT)

Best Conventional Pollutant Control Technology (BCT)

New Source Performance Standards (NSPS)

Pretreatment Standards for Existing Sources (PSES)

Pretreatment Standards for New Sources (PSNS)

The pretreatment standards (PSES, PSNS) are applicable to industrial facilities with process wastewater discharges to publicly owned treatment works. The effluent limitations guidelines and new source performance standards (BPT, BAT, BCT, and NSPS) are applicable to industrial facilities with direct discharges of process wastewaters to waters of the United States.

Effluent: Wastewater flowing out of a process, unit, or system.

Electroplating: The production of a thin surface coating of one metal upon another by electrodeposition. This surface coating is applied to provide corrosion protection, wear or erosion resistance, anti-frictional characteristics, enhanced aesthetics, or to obtain a surface with properties or dimensions different from those of the basis metal or material.

Electroless Plating: A process which involves applying a metallic coating to a part using a chemical reduction process in the presence of a catalysis. An electric current is not used in these operations.

End-of-Pipe Wastewater Treatment: The reduction and/or removal of pollutants by wastewater treatment processes just prior to actual discharge.

Equalization: Wastewater treatment unit used to dampen variations in flow rate and composition through the treatment system.

Equity Investment: Money that is invested in a company by purchasing shares of that company in the stock market.

Facility: A facility is generally one contiguous physical location at which manufacturing operations, such as to metal finishing or electroplating, are conducted. In some instances, a facility may include properties located within separate fence lines but located close to each other.

Facility Registry Services (FRS): A centrally managed database that identifies facilities, sites, or places subject to environmental regulations or of environmental interest using a unique identifier.

Factoring: A financial arrangement under which accounts receivable, such as invoices, are exchanged with another company for advanced cash that collects payment directly from customers.

Full-Time Equivalent (FTE) Employees: An employee who works 40 hours per week is a full-time equivalent of 1.0. An employee who works less than 40 hours is converted into a full-time equivalent by dividing part-time working hours by 40. Since a company usually has full-time and part-time employees, their working hours can be converted into full-time equivalent to determine the level of employment.

General Partnership: A business partnership structure made up of two or more owners, each sharing the business's debts, liabilities, and assets.

Granular Activated Carbon: Wastewater treatment unit that uses highly porous carbon material made from organic materials with high carbon contents (such as wood, lignite, and coal) to remove pollutants from water by adsorption.

Groundwater: Underground water that resides within the cracks, crevices, and spaces in soil, sand, and rock. Groundwater is generated at a facility when it is resurfaced or withdrawn from the ground by way of a well.

Hexavalent Chromium (Cr VI): The form of chromium in a valence state of +6. Substances that consist of or contain 0.1 percent or greater by weight of chromium trioxide, hexavalent VI oxide, chromic acid, or chromic anhydride are considered to contain hexavalent chromium.

Home Equity Line of Credit: A flexible financial arrangement under which access to a fixed amount of loan is granted against home equity for short-term needs. The money is used as the need arises. It is like a perpetual credit and interest is paid only on the amount used, not the entire loan amount.

Influent: Wastewater flowing into a process, unit, or system.

Ion Exchange: Wastewater treatment unit based on the reversible exchange of ions adsorbed on a mineral or synthetic polymer surface with ions in solution in contact with the surface.

Job Shop: A facility which owns not more than 50 percent (annual area basis) of the materials undergoing metal finishing and electroplating.

Leasing: Acquiring equipment, capital goods, or buildings with periodic payments, instead of paying cash up-front.

Limited Partnership: A business partnership structure where at least one owner bears full responsibility for the debts, liabilities, and assets as a general partner while another one or more owners only participate as a limited partner.

Local Ordinance: A law or requirement established by a municipality, city, or other local government.

Media Filtration: Wastewater treatment unit that uses that uses sand, coal, garnet, and/or other media to remove suspended or dissolved pollutants by straining.

Merchant Cash Advance: A sales agreement where the merchant (the “seller”) is selling their future revenue at a discount to the merchant cash advance company (the “buyer”).

Metal Finishing: The process of changing the surface of an object, for the purpose of improving its appearance and/or durability.

Microfiltration: A membrane filtration treatment process designed to separate particulate matter and bacteria from a liquid using a semi-permeable membrane, where transmembrane pressure is applied to the concentrated side of the membrane.

Monitoring: The measurement, sometimes continuous, of water quality.

Monitoring Requirement: Any requirement to collect wastewater monitoring/sampling data.

Nanofiltration: A membrane filtration treatment process designed to separate particulate, colloidal, and dissolved matter from a liquid using a semi-permeable membrane, where transmembrane pressure is applied to the concentrated side of the membrane.

National Pollutant Discharge Elimination System (NPDES): The national program authorized by Sections 307, 318, 402, and 405 of the Clean Water Act for issuing, modifying, revoking and reissuing, terminating, monitoring and enforcing permits, and imposing and enforcing pretreatment requirements under the Clean Water Act. The NPDES permit number is assigned by the respective state or EPA Region and generally includes the state abbreviation in the number.

National Pollutant Discharge Elimination System (NPDES) Permit: NPDES permits regulate discharges of pollutants from point sources to waters of the United States. Such discharges are illegal unless authorized by a NPDES permit.

General NPDES or Stormwater Permit: A general permit covers a group of dischargers with similar qualities within a given geographical location.

Individual NPDES Permit: A permit specifically tailored to an individual facility.

Neutralization/pH Adjustment: Changing the acidity or alkalinity of a substance by adding alkaline or acidic materials, respectively.

Nonprocess Area Stormwater: Water flow as a result of precipitation (rain, snow melt, etc.) over land or impervious surfaces in areas that do not process raw materials, intermediate products, finished products, byproducts, or waste products (i.e., precipitation not associated with industrial activity).

Nonprocess Wastewater: Any wastewater that does not come into direct contact with or result from storage, production, or use of any raw material, intermediate product, finished product, byproduct, or waste product (e.g., cooling water).

North American Industry Classification System (NAICS): The standard used by Federal statistical agencies in classifying business establishments for the purpose of collecting, analyzing, and publishing statistical data related to the United States business economy. Each facility is categorized within a NAICS code based on the type of operations conducted at the facility (e.g., NAICS code 332813 is for (Electroplating, Plating, Polishing, Anodizing, and Coloring).

Off Site/Offsite: Locations not on contiguous facility property.

Oil/Water Separation: Treatment unit that uses differences in specific gravity to separate water, oil, and sludge. In an oil/water separation unit, free oil rises to the surface and floats on water, the denser of the two liquids. The free oil that floats on the surface is skimmed off, while the sludge that settles to the bottom of the separation unit is removed periodically.

On Site/Onsite: Property and equipment under the operational control of the plant, including landfills, ponds/impoundments, and outfall structures located on noncontiguous property.

Outfall: A discharge point of a wastewater into a surface water, publicly owned treatment works, or municipal sewer system.

Parameter: A characteristic element of constant factor.

Per- and Polyfluoroalkyl Substances (PFAS): Per- and polyfluorinated substances that structurally contain the unit R-(CF2)-C(F)(R’)R’’ where both the CF2 and CF moieties are saturated carbons and none of the R groups (R, R’, or R’’) can be hydrogen.

Permit Monitoring Location: A location in the facility from which wastewater samples are taken for the purpose of monitoring for permit compliance.

Permit: An authorization, license, or equivalent control document issued by EPA or delegated authority to implement the requirements of 40 CFR §122, §123, and §124. See 40 CFR §122.2.

Point Source: Any discernible, confined and discrete conveyance, including but not limited to any pipe, ditch, channel, tunnel, conduit, well, discrete fissure, container, rolling stock, concentrated animal feeding operation, or vessel or other floating craft, from which pollutants are or may be discharged.

Pollutant: Dredged spoil, solid waste, incinerator residue, filter backwash, sewage, garbage, sewage sludge, munitions, chemical wastes, biological materials, radioactive materials (except those regulated under the Atomic Energy Act of 1954, as amended (42 USC 2011 et seq.)), heat, wrecked or discarded equipment, rock, sand, cellar dirt and industrial, municipal, and agricultural waste discharged into water. See 40 CFR §122.2. For the purposes of this data request, temperature and heat are not considered pollutants.

Pretreatment: Treatment of wastewaters from sources before discharge or transfer to a publicly owned treatment works or municipal sewer system.

Pretreatment Agreement/Permit: Permit for discharge from facility to a publicly owned treatment works or municipal sewer system.

Pretreatment Standard: Any restriction imposed on quantities, discharge rates, and concentrations of pollutants which are discharged from point sources to a publicly owned treatment works or municipal sewer system.

Printed Circuit Board Manufacture: The formation of a circuit pattern of conductive metal (e.g., copper) on nonconductive board materials such as plastic or glass. There are five basic steps involved in the manufacture of printed circuit boards: cleaning and surface preparation, catalyst and electroless plating, pattern printing and masking, electroplating, and etching.

Process Area Stormwater: Water flow as a result of precipitation (rain, snow melt, etc.) over land or impervious surfaces in areas that process raw materials, intermediate products, finished products, byproducts, or waste products (i.e., precipitation associated with industrial activity).

Process Wastewater: Any water which, during manufacturing or processing, comes into direct contact with or results from the storage, production, or use of any raw material, intermediate product, finished product, byproduct, or waste product. Includes waters resulting from metal finishing and electroplating operations (e.g., chromium plating/anodizing bath water), equipment cleaning wastewater, rinse water, and leachate captured from surface impoundments and landfills. Process wastewater may also include wastewater that is contract hauled for offsite disposal. Sanitary wastewater, cooling water, stormwater, and groundwater that is not used in manufacturing or process operations is not considered process wastewater.

Product Recovery: Physical or chemical treatment to remove metal or other materials from wastewater for later reuse.

Publicly Owned Treatment Works (POTW): Any device or system owned and operated by a public entity and used in the storage, treatment, recycling, or reclamation of liquid municipal sewage and/or liquid industrial wastes. The sewerage system that conveys wastewaters to treatment works is considered part of the publicly owned treatment works.

Regulatory Authority: An entity, usually branches of state or federal government, that enforces environmental, health, or safety related requirements set by set by law or permits.

Reporting Limit: The laboratory reporting limit in the matrix analyzed. Usually this is a multiple of the method detection limit. Also known by terms such as minimum level of quantification or quantification limit.

Reverse Osmosis: A membrane filtration treatment process designed to separate particulate, colloidal, and dissolved matter from a liquid using a semi-permeable membrane, where pressure in excess of the osmotic pressure is applied to the concentrated side of the membrane.

Rinse Water: Water for removal of dragout by dipping, spraying, fogging, etc.

Sanitary Wastewater: Wastewater that is generated from restrooms, cafeterias, showers, and domestic (versus industrial) activities.

Sole Proprietor: Someone who owns an unincorporated business by himself or herself. The owner pays taxes on the income he or she generates. A self-employed individual is an example of a sole proprietor.

Solid Waste/Sludge/Concentrated Waste Stream: Any solid, semi-solid, or liquid waste generated from a municipal, commercial, or industrial wastewater treatment plant, unit operation or process, water supply plant, or air emission control exclusive of the treated water effluent from a wastewater treatment system. For the purpose of this data request, includes byproducts, off-spec materials, spent materials, and solid wastes generated by unit operations, product recovery units, or wastewater treatment units.

Stormwater: Water flow as a result of precipitation (rain, snowmelt, etc.) over land or impervious surfaces.

Subchapter C Corporation/Limited Liability Corporation: Limited liability corporation that is subject to Chapter C of the Internal Revenue Code. It is a legal business organization under which owner or shareholder lability is limited to the company itself.

Surface Water: Waters of the United States as is consistent with the pre-2015 regulatory regime. Refer to the Current Implementation of Waters of the United States for further detail and definition of terms (https://www.epa.gov/wotus/current-implementation-waters-united-states#Pre-2015).

Technology vendor: The company that manufactured or provided a wastewater treatment unit.

Third-Party Wastewater: Wastewater that is not generated at the given facility and is transferred to the facility from another source.

Trade Credit: A business arrangement under which a buyer can purchase goods without paying cash at the time of transaction, with a promise to pay on a certain later date. In essence, it is a short-term interest-free loan advanced by the seller.

Trivalent Chromium (Cr III): Form of chromium in a valence state of +3.

Ultrafiltration: A membrane filtration treatment process designed to separate particulate and colloidal matter from a liquid using a semi-permeable membrane, where low transmembrane pressure is applied to the concentrated side of the membrane.

Ultimate Parent Company: The business organization at the highest position in the facility's ownership structure that is organized domestically (e.g., the highest-level United States incorporated company). An ultimate parent company owns more than 50 percent of one or more other domestic businesses. A business organization that is owned by another United States business is not an ultimate parent company but a subsidiary or branch. Subsidiary business organizations to the ultimate parent can include “headquarters” business organizations. A “headquarters” is a business that has branches or divisions reporting to it. Branches or divisions can also report directly to the Ultimate Parent Company. In this case, the ultimate parent company is also a headquarters organization. The ultimate parent company typically resides in a different physical location than its subsidiary headquarters or division/branch locations.

Underground Injection: Long-term or permanent disposal of untreated, partially treated, or treated wastewaters by pumping the wastewater into underground formations of suitable character through a bored, drilled, or driven well. Sometimes referred to as “subsurface injection” or “deep-well injection.”

Underground Injection Control (UIC) Permit: Underground injection control permits regulate discharges of waste streams into underground formations of suitable character. Such discharges are illegal unless authorized by a permit.

Wastewater: Includes process wastewater, nonprocess wastewater, process area stormwater, nonprocess area stormwater, air emission control wastewater, third-party wastewater, sanitary wastewater, and groundwater.

Wastewater Discharge Permit: Documentation of authorization to discharge wastewater to a surface water or publicly owned treatment works. See definitions for NPDES permit and pretreatment agreement/permit.

Wastewater Flow Diagram: A simplified schematic outlining the flows and process units in a system.

Wastewater Treatment: The processing of wastewater by physical, chemical, biological, or other means to remove specific pollutants from the wastewater or to alter the physical or chemical state of specific pollutants in the wastewater. Treatment is performed for discharge of treated wastewater, recycle of treated wastewater to the same process which generated the wastewater, or for reuse of the treated wastewater in another process.

Wastewater Treatment System: A combination of one or more wastewater treatment units designed to achieve wastewater treatment.

Wastewater Treatment Unit: A unit operation used to remove pollutants from process wastewater. Wastewater treatment units include, but are not limited to: pond/impoundments, chemical precipitation, pH adjustment, clarification, biological reactor, thickeners, filters, constructed wetlands, activated carbon adsorption, ion exchange, and membrane filtration.

Facility Name

Facility Street Address Line 1

Facility Street Address Line 2 (Optional)

City State ZIP Code

Provide the name, title, telephone number, email, and mailing address for a primary and secondary contact for technical information reported in this questionnaire response.

Primary Technical Contact Name Primary Technical Contact Title

Telephone Number Email

Mailing Address Line 1

Mailing Address Line 2 (Optional)

City State ZIP Code

Secondary Technical Contact Name Secondary Technical Contact Title

Telephone Number Email

Mailing Address Line 1

Mailing Address Line 2 (Optional)

City State ZIP Code

Provide the name, title, telephone number, email, and mailing address for a primary and secondary contact for financial information reported in this questionnaire response.

Primary Financial Contact Name Primary Financial Contact Title

Telephone Number Email

Mailing Address Line 1

Mailing Address Line 2 (Optional)

City State ZIP Code

Secondary Financial Contact Name Secondary Financial Contact Title

Telephone Number Email

Mailing Address Line 1

Mailing Address Line 2 (Optional)

City State ZIP Code

Is the facility owned, controlled, or managed by an ultimate parent company, as defined in the GLOSSARY and below?

Ultimate Parent Company: The business organization at the highest position in the facility's ownership structure that is organized domestically (e.g., the highest-level United States incorporated company). An ultimate parent company owns more than 50 percent of one or more other domestic businesses. A business organization that is owned by another United States business is not an ultimate parent company but a subsidiary or branch. Subsidiary business organizations to the ultimate parent can include “headquarters” business organizations. A “headquarters” is a business that has branches or divisions reporting to it. Branches or divisions can also report directly to the ultimate parent company. In this case, the ultimate parent company is also a headquarters organization. The ultimate parent company typically resides in a different physical location than its subsidiary headquarters or division/branch locations.

If yes, identify the ultimate parent company and provide the name, title, telephone number, email, and mailing address for a primary point of contact for the ultimate parent company. If the facility does not have an ultimate parent company, select “No ultimate parent company.”

☐ No ultimate parent company.

OR

Ultimate Parent Company Name

Primary Contact Name Primary Contact Title

Telephone Number Email

Mailing Address Line 1

Mailing Address Line 2 (Optional)

City State or Territory ZIP or Postal Code

Country

Provide all six-digit North American Industry Classification System (NAICS) code(s) applicable to the facility. If you do not know which NAICS code(s) the facility falls under, please visit the United States Census Bureau website (https://www.census.gov/naics/) and search for the operation(s) that most accurately describes the facility’s operation. NAICS codes starting with 31 through 33 are for manufacturing facilities. Facilities responding to this questionnaire are likely to fall under NAICS code 332813 (Electroplating, Plating, Polishing, Anodizing, and Coloring) or 332812 (Metal Coating, Engraving (except Jewelry and Silverware), and Allied Services to Manufacturers). If the facility is associated with more than three NAICS codes, list additional codes in Section 9 (Comments).

Facility NAICS Code(s)

☐ Primary NAICS code

Primary NAICS code:

☐ Secondary NAICS code

Secondary NAICS code:

☐ Tertiary NAICS code

Tertiary NAICS code:

Provide the applicable 12-digit Facility Registry Service (FRS) identification number associated with the facility (also known as EPA Registry ID). If you do not know the facility’s FRS identification number, please visit EPA’s FRS Search website (https://www.epa.gov/frs/frs-query#facility) and search for the facility using the facility’s address and/or name. If the facility does not have an associated FRS identification number, select “Facility does not have an FRS identification number.”

☐ Facility does not have an FRS identification number

OR

FRS Identification Number:

Did the facility engage in metal finishing or electroplating operations, as defined in the GLOSSARY and below, at any time since the facility began operation? Include operations that previously occurred even if they do not reflect current operations. Include operations that occurred under other ownership, if known. If unknown, use best professional judgement to provide an estimate.

Metal Finishing: The process of changing the surface of an object, for the purpose of improving its appearance and/or durability.

Electroplating: The production of a thin surface coating of one metal upon another by electrodeposition. This surface coating is applied to provide corrosion protection, wear or erosion resistance, anti-frictional characteristics, enhanced aesthetics, or to obtain a surface with properties or dimensions different from those of the basis metal or material.

☐ No

☐ Yes. Provide an overview of the types of metal finishing and/or electroplating services conducted by or products manufactured by the facility.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

If

you answered “No” to this question, proceed to Section 9

(Comments).

If

you answered “No” to this question, proceed to Section 9

(Comments).

DO NOT COMPLETE THE REMAINDER OF THIS QUESTIONNAIRE.

Did the facility engage in chromium finishing operations, as defined in the GLOSSARY and below, at any time since calendar year 1995?1 Include operations that previously occurred even if they do not reflect current operations. Include operations that occurred under other ownership, if known. If unknown, use best professional judgement to provide an estimate.

Chromium Finishing Operations: Any metal finishing or electroplating process that deposits a layer of chromium on any basis metal or material, or uses chromium materials in the fabrication of a metal product. Applicable processes include, but are not limited to, the activities listed below (a definition for each applicable process is provided in the GLOSSARY). Another term for chromium finishing operations is chrome finishing operations.

Decorative chromium plating.

Functional/hard chromium plating.

Chromium anodizing.

Chromic acid etching.

Chromate conversion coating.

☐ No

☐ Yes

If

you answered “No” to this question, proceed to Section 9

(Comments).

If

you answered “No” to this question, proceed to Section 9

(Comments).

DO NOT COMPLETE THE REMAINDER OF THIS QUESTIONNAIRE.

What year did chromium finishing operations begin at the facility? Chromium finishing operations at the facility may have begun under other ownership and may not reflect current operations. If unknown, use best professional judgement to provide an estimate.

Year Operations Began:

What industry (or industries) are the primary customers or ultimate users of chromium finishing services and related products produced by the facility? Select all that apply.

☐ Aerospace

☐ Aviation (e.g., aircraft, helicopters)

☐ Automotive (e.g., cars, buses, trucks, motor vehicles)

☐ Electronic equipment

☐ Hardware

☐ Household equipment

☐ Instruments

☐ Marine (e.g., ships, boats)

☐ Mobile industrial equipment

☐ Office machine

☐ Ordnance (e.g., weapons, ammunition)

☐ Precious metals and jewelry

☐ Railroad

☐ Stationary industrial equipment

☐ Miscellaneous metal products

☐ Other, specify: ______________________________

☐ Other, specify: ______________________________

☐ Other, specify: ______________________________

Did the facility permanently close or permanently discontinue all metal finishing and electroplating operations as of January 1, 2023?

☐ No. Facility will perform one or more metal finishing or electroplating operations after January 1, 2023.

☐ Yes. Facility has permanently closed as of January 1, 2023.

☐ Yes. Facility is not permanently closed but has permanently discontinued all metal finishing and electroplating operations as of January 1, 2023.

If

you answered “Yes” to this question, proceed to Section 9

(Comments).

If

you answered “Yes” to this question, proceed to Section 9

(Comments).

DO NOT COMPLETE THE REMAINDER OF THIS QUESTIONNAIRE.

Will the facility permanently close or permanently discontinue all metal finishing and electroplating operations by December 31, 2028? If unknown, use best professional judgement to provide an estimate.

☐ No. Facility will perform one or more metal finishing or electroplating operations after December 31, 2028.

☐ Yes. Provide the planned date of permanent closure or cessation of all metal finishing and electroplating operations: _____

If the facility is regulated by any water discharge requirement(s) (e.g., general National Pollutant Discharge Elimination System (NPDES) permit, individual NPDES permit, stormwater permit, pretreatment agreement/permit, centralized waste treatment agreement, underground injection control permit) or local ordinance, complete the table below and provide copies of relevant documents. Complete a row for each applicable water discharge permit and requirement. For each applicable water discharge permit or requirement, identify the type of requirement and provide the identification or permit number(s), the regulatory authority, the expiration date(s), and specify the types of wastewaters covered.

Do not include requirement(s) that only apply to solid waste or air emissions (only water discharge requirements should be reported).

Do not include the following types of permits: construction permits, erosion and sediment control permits associated with construction activities, temporary or general permits for hydrostatic testing water, water obstruction and encroachment permits, and/or water allocation permits.

Do not include any water discharge requirement(s) that no longer apply to the facility (e.g., permits that have expired or been superseded). Include administratively continued permits if they are the basis for the facility's current water discharge requirements.

Attach copies of all applicable discharge requirement documents to your questionnaire response. Examples of such documents include permits, factsheets, permit applications, Form 2C data, and statements of basis. See the FILES SUBMITTED WITH THE QUESTIONNAIRE section for guidance on submitting hardcopy or electronic copies of discharge requirement documents and other attachments with the completed questionnaire.

☐ Facility does not hold any water discharge permit(s), requirements, or local ordinance(s).

OR

Water Discharge Requirements and Permits |

||||

Identification or Permit Number (enter “N/A” if no number) |

Type of Requirement (select only one) |

Regulatory Authority |

Expiration Date (mm/dd/yyyy) |

Type of Wastewater Covered by Requirement (select all that apply) |

|

☐ General NPDES or stormwater permit ☐ Individual NPDES permit ☐ Pretreatment agreement/permit ☐ Centralized waste treatment agreement ☐ Underground injection control permit ☐ Local ordinance ☐ Other, specify: _____ |

|

__ / __ / ____ |

☐ Process wastewater ☐ Nonprocess wastewater ☐ Process area stormwater ☐ Nonprocess area stormwater ☐ Air emission control wastewater ☐ Third-party wastewater ☐ Sanitary wastewater ☐ Groundwater ☐ Other, specify: _____ |

|

☐ General NPDES or stormwater permit ☐ Individual NPDES permit ☐ Pretreatment agreement/permit ☐ Centralized waste treatment agreement ☐ Underground injection control permit ☐ Local ordinance ☐ Other, specify: _____ |

|

__ / __ / ____ |

☐ Process wastewater ☐ Nonprocess wastewater ☐ Process area stormwater ☐ Nonprocess area stormwater ☐ Air emission control wastewater ☐ Third-party wastewater ☐ Sanitary wastewater ☐ Groundwater ☐ Other, specify: _____ |

Facilities that engage in the manufacturing, forming, milling, processing, or finishing of metals and may be subject to one or more effluent limitations guidelines and standards (ELGs). Identify the ELGs that apply to the operations conducted at the facility in calendar year 2022. If you do not know which ELGs are applicable to the facility, please visit the EPA weblink provided and review the applicability information or visit www.epa.gov/eg/industrial-effluent-guidelines. Select all that apply.

Most job shops (i.e., facilities which owns not more than 50 percent (annual area basis) of the materials undergoing metal finishing and electroplating) only conduct operations covered by the ELGs for the Metal Finishing Point Source Category (40 CFR Part 433) or Electroplating Point Source Category (40 CFR Part 413).

Metal Equipment Manufacturing, Assembly, Rebuilding, Maintenance, and Surface Finishing

☐ Metal Finishing (40 CFR Part 433)

☐ Electroplating (40 CFR Part 413)

☐ Metal Products and Machinery (40 CFR Part 438)

Metal Manufacturing

☐ Iron and Steel Manufacturing (40 CFR Part 420)

☐ Nonferrous Metals Manufacturing (40 CFR Part 421)

☐ Ferroalloy Manufacturing (40 CFR Part 424)

Metal Forming

☐ Metal Molding and Casting (Foundries) (40 CFR Part 464)

☐ Aluminum Forming (40 CFR Part 467)

☐ Copper Forming (40 CFR Part 468)

☐ Nonferrous Metals Forming and Metal Powders (40 CFR Part 471)

Metal Mill Products

☐ Battery Manufacturing (40 CFR Part 461)

☐ Coil Coating (40 CFR Part 465)

☐ Porcelain Enameling (40 CFR Part 466)

☐ Electrical and Electronic Components (40 CFR Part 469)

Other Metal Related Effluent Limitations Guidelines and Standards

☐ Plastics Molding and Forming (40 CFR Part 463)

☐ Other ELG not listed above, specify: _____________

☐ Other ELG not listed above, specify: _____________

☐ Other ELG not listed above, specify: _____________

Identify the chromium finishing operation(s) performed at the facility at any time since calendar year 1995 and the form of chromium used in such operation.2 Complete a row in the table below for each type of chromium finishing operation performed and report the form(s) of chromium used as well as the most recent year that hexavalent chromium (Cr VI) and trivalent chromium (Cr III) were used in the operation. If applicable, include operations that previously occurred even if they do not reflect current operations and include operations that occurred under other ownership, if known. If unknown, use best professional judgement to provide an estimate.

Chromium Finishing Operations Performed Since 1995

Chromium Finishing Operation

(select only one)

Form of Chromium Used in Operation

(select all that apply)

Year Operation Was Most Recently Performed

With Cr VI

With Cr III

☐ Decorative chromium plating

☐ Functional/hard chromium plating

☐ Chromium anodizing

☐ Chromic acid etching

☐ Chromate conversion coating

☐ Other, specify: _____

☐ Cr VI

☐ Cr III

☐ Decorative chromium plating

☐ Functional/hard chromium plating

☐ Chromium anodizing

☐ Chromic acid etching

☐ Chromate conversion coating

☐ Other, specify: _____

☐ Cr VI

☐ Cr III

Complete a row in the table for each tank at the facility where any chromium finishing operation was performed at any time during calendar year 2022. For each applicable tank, report the chromium finishing operation performed, report the form(s) of chromium used, the volume of the tank, the number of days the operation was performed during calendar year 2022, how much power was applied for the purpose of chromium finishing to the tank during calendar year 2022 in amp-hours (Ah) (if any), and whether any wastewater was generated from the operation.

☐ Facility did not perform any chromium finishing operations at any time during calendar year 2022.

OR

Tanks Performing Chromium Finishing Operations in 2022 |

|||||||

Tank Name, Number, or Description |

Chromium Finishing Operation (select only one) |

Form of Chromium Used in Operation (select all that apply) |

Tank Volume |

Tank Volume Units |

Number of Days Performed in 2022 |

Power Applied During Chromium Finishing in 2022 (Ah) |

Wastewater Generated From Operation |

|

☐ Decorative chromium plating ☐ Functional/hard chromium plating ☐ Chromium anodizing ☐ Chromic acid etching ☐ Chromate conversion coating ☐ Other, specify: _____ |

☐ Cr VI ☐ Cr III |

|

☐ Liters ☐ Gallons ☐ Other, specify: _____

|

|

☐ ___ ☐ N/A |

☐ Yes ☐ No |

|

☐ Decorative chromium plating ☐ Functional/hard chromium plating ☐ Chromium anodizing ☐ Chromic acid etching ☐ Chromate conversion coating ☐ Other, specify: _____ |

☐ Cr VI ☐ Cr III |

|

☐ Liters ☐ Gallons ☐ Other, specify: _____

|

|

☐ ___ ☐ N/A |

☐ Yes ☐ No |

Complete a row in the table for each chemical fume suppressant used at any time since calendar year 1995. Include chemical fume suppressants used as an air emission control for Cr VI emissions. If applicable, include operations that previously occurred even if they do not reflect current operations and include operations that occurred under other ownership, if known. If unknown, use best professional judgement to provide an estimate.

☐ Facility did not use one or more chemical fume suppressants at any time since calendar year 1995.

OR

Chemical Fume Suppressant Use Since 1995 |

||||||

Chemical Fume Suppressant Product Name |

Manufacturer Name |

Target Pollutant(s) and Control Level (select all that apply) |

Contains PFAS? |

Year(s) Product Was Used (select all that apply) |

Total Annual Volume Used in 2022 (gal) |

Number of Days Used in 2022

|

|

|

☐ Cr VI Target level: _____ ☐ Other, specify Pollutant: _____ Target level: _____ |

☐ Yes ☐ No ☐ Unknown

|

☐ 2022 ☐ 2021 ☐ 2020 ☐ 2019 ☐ 2018 ☐ 2017 ☐ 2016 ☐ 2010 – 2015 ☐ 2000 – 2009 ☐ Prior to 2000 |

|

|

|

|

☐ Cr VI Target level: _____ ☐ Other, specify Pollutant: _____ Target level: _____ |

☐ Yes ☐ No ☐ Unknown

|

☐ 2022 ☐ 2021 ☐ 2020 ☐ 2019 ☐ 2018 ☐ 2017 ☐ 2016 ☐ 2010 – 2015 ☐ 2000 – 2009 ☐ Prior to 2000 |

|

|

Complete a row in the table for each air emission control (excluding chemical fume suppressants reported in Question 17) operated at any time in calendar year 2022. If applicable, select the type of air emission control, describe the air emission control and target pollutant(s), designate whether the air pollution control receives emissions from chromium finishing operations, and designate whether wastewater was generated.

☐ Facility did not operate one or more air emission controls (excluding use of chemical fume suppressants reported in Question 17) at any time in calendar year 2022.

OR

Air Emission Controls Operated During 2022 (excluding chemical fume suppressants) |

|||

Air Emission Control Type (select only one) |

Description of Air Emission Control and Target Pollutant(s) |

Receives Emissions from Chromium Finishing Operations |

Wastewater Generated From Operation |

☐ Wet scrubber ☐ Dry scrubber ☐ Composite mesh pad scrubber ☐ Physical/mechanical fume suppression ☐ Enclosed lines ☐ Air jet systems ☐ Other, specify: _____ |

|

☐ Yes ☐ No |

☐ Yes ☐ No |

☐ Wet scrubber ☐ Dry scrubber ☐ Composite mesh pad scrubber ☐ Physical/mechanical fume suppression ☐ Enclosed lines ☐ Air jet systems ☐ Other, specify: _____ |

|

☐ Yes ☐ No |

☐ Yes ☐ No |

Complete a row in the table below for each metal finishing operation, electroplating operation, and air emission control controls (excluding chemical fume suppressants) that the facility intentionally used, blended, integrated, or applied one or more PFAS (including a mixture or product containing PFAS) for any other purpose at any time since calendar year 1995? Use of chemical fume suppressants containing PFAS should be reported in Question 17 and do not need to be reported in this question. If applicable, include operations that previously occurred even if they do not reflect current operations and include operations that occurred under other ownership, if known. If unknown, use best professional judgement to provide an estimate.

☐ Facility did not intentionally use, blend, integrate, or apply one or more PFAS (including a mixture or product containing PFAS) for any other purpose in metal finishing operations, electroplating operations, or air emission controls (excluding chemical fume suppressants reported in Question 17) at any time since calendar year 1995.

OR

Intentional PFAS Use in Metal Finishing and Electroplating Processes and Air Emission Controls Since 1995 (excluding chemical fume suppressants) |

|||||||

Process Name |

Process Category (select only one) |

Description of Process and Purpose for Intentional Use of PFAS or PFAS-Containing Product |

Manufacturer(s) and Name(s) of PFAS or PFAS-Containing Product |

Year(s) PFAS or PFAS-Containing Product Was Used (select all that apply) |

Wastewater Generated From Operation |

Total Annual Volume Used in 2022 (gal) |

Number of Days Used in 2022

|

|

☐ Chromium metal finishing or electroplating operation ☐ Nonchromium metal finishing or electroplating operation ☐ Air emission control |

|

|

☐ 2022 ☐ 2021 ☐ 2020 ☐ 2019 ☐ 2018 ☐ 2017 ☐ 2016 ☐ 2010 – 2015 ☐ 2000 – 2009 ☐ Prior to 2000 |

☐ Yes ☐ No

|

|

|

|

☐ Chromium metal finishing or electroplating operation ☐ Nonchromium metal finishing or electroplating operation ☐ Air emission control |

|

|

☐ 2022 ☐ 2021 ☐ 2020 ☐ 2019 ☐ 2018 ☐ 2017 ☐ 2016 ☐ 2010 – 2015 ☐ 2000 – 2009 ☐ Prior to 2000 |

☐ Yes ☐ No

|

|

|

Provide the facility's total annual production of metal finishing and electroplating services or products (i.e., all chromium and nonchromium metal finishing and electroplating services and saleable materials produced by result) during calendar year 2022. Also provide the facility's total annual production volume of metal finishing and electroplating services or products associated with intentional use, blending, integrating, or application of one or more PFAS (including a mixture or product containing PFAS) during calendar year 2022. Total annual production may be estimated in terms of number of units finished, surface area finished, mass of materials finished, sales volume associated with finishing, or a user-defined metric. If unknown, use best professional judgement to provide an estimate.

Total Annual Production of Metal Finishing and Electroplating Services or Products in 2022 |

||||

Basis of Estimate (select only one) |

Total Annual Metal Finishing and Electroplating Production in 2022 |

Total Annual Metal Finishing and Electroplating Production Using PFAS or PFAS-Based Chemical Fume Suppressants in 2022 |

||

Quantity |

Unit of Measure |

Quantity |

Unit of Measure |

|

☐ Number of units finished ☐ Surface area finished ☐ Power applied ☐ Mass of materials finished ☐ Sales volume ☐ Other, specify: _____ |

|

|

|

|

Provide the facility's total annual production of chromium finishing services or products (i.e., all chromium finishing services and saleable materials produced by result) during calendar year 2022. Also provide the facility's total annual production volume of chromium finishing services or products associated with intentional use, blending, integrating, or application of one or more PFAS (including a mixture or product containing PFAS) during calendar year 2022. Total annual production may be estimated in terms of number of units finished, surface area finished, mass of materials finished, sales volume associated with finishing, or a user-defined metric. If unknown, use best professional judgement to provide an estimate.

Total Annual Production of Chromium Finishing Services or Products in 2022 |

||||

Basis of Estimate (select only one) |

Total Annual Chromium Finishing Production in 2022 |

Total Annual Chromium Finishing Production Using PFAS or PFAS-Based Chemical Fume Suppressants in 2022 |

||

Quantity |

Unit of Measure |

Quantity |

Unit of Measure |

|

☐ Number of units finished ☐ Surface area finished ☐ Power applied ☐ Mass of materials finished ☐ Sales volume☐ Other, specify: _____ |

|

|

|

|

If the facility used Cr VI during calendar years 2018 to 2022, complete the table below with the total annual consumption of Cr VI (as chromic acid or other Cr VI source) by the facility’s chromium finishing operations in pounds on a dry-weight equivalent basis. Do not include any chromic acid or other Cr VI source used for new bath makeups. If unknown, use best professional judgement to provide an estimate. If the facility did not use Cr VI for one or more of the calendar years, enter “N/A” for those years.

☐ Facility did not use Cr VI during calendar years 2018 to 2022.

OR

Total Annual Consumption of Cr VI (as chromic acid or other Cr VI source) for 2018 – 2022 |

|||||

Calendar Year |

2018 |

2019 |

2020 |

2021 |

2022 |

Total Cr VI consumption (pounds dry-weight equivalent basis) |

|

|

|

|

|

Is the facility planning to modify operations in a manner which will substantively change or eliminate the use of Cr VI at the facility by December 31, 2028? If yes, complete a row in the table below for each applicable planned modification and report the estimated change in Cr VI use and planned completion date. Examples of what should be reported include, but are not limited to, are specific plans to reduce the annual consumption of Cr VI used, convert existing Cr VI processes to Cr III processes, or discontinue use of Cr VI before December 31, 2028.

☐ Facility does not plan to modify operations in a manner which will change or eliminate the use of hexavalent chromium at the facility by December 31, 2028.

OR

Planned Modifications Reducing or Eliminating Hexavalent Chromium |

|||

Description of Planned Modification |

Estimated Change in Cr VI Use (reported as percent reduction relative to 2022) |

Planned Completion Month |

Planned Completion Year |

|

|

|

|

|

|

|

|

Is the facility planning to add, remove, or modify operations in a manner which will substantively change the quantity or type of PFAS intentionally used, blended, integrated, or applied in metal finishing operations, electroplating operations, or air emission controls (including chemical fume suppressants) at the facility by December 31, 2028? If yes, complete a row in the table below for each applicable planned modification and report the estimated change in PFAS and planned completion date. Examples of what should be reported include, but are not limited to, are specific plans to reduce or eliminate use of all PFAS-containing chemical fume suppressants or other PFAS-containing products before December 31, 2028.

☐ Facility does not plan to modify operations in a manner which will change the quantity or type of PFAS intentionally used, blended, integrated, or applied in metal finishing operations, electroplating operations, or air emission controls (including chemical fume suppressants) at the facility by December 31, 2028.

OR

Planned Modifications Changing PFAS Intentionally Used, Blended, Integrated, or Applied |

|||

Description of Planned Modification |

Estimated Change in PFAS (reported as percent change relative to 2022) |

Planned Completion Month |

Planned Completion Year |

|

|

|

|

|

|

|

|

Did the facility generate on site or receive from off site any of the following types of wastewaters at any time during calendar year 2022?

Process Wastewater: Any water which, during manufacturing or processing, comes into direct contact with or results from the storage, production, or use of any raw material, intermediate product, finished product, byproduct, or waste product. Includes waters resulting from metal finishing and electroplating operations (e.g., chromium plating/anodizing bath water), equipment cleaning wastewater, rinse water, and leachate captured from surface impoundments and landfills. Process wastewater may also include wastewater that is contract hauled for offsite disposal. Sanitary wastewater, cooling water, stormwater, and groundwater that is not used in manufacturing or process operations is not considered process wastewater.

Nonprocess Wastewater: Any wastewater that does not come into direct contact with or result from storage, production, or use of any raw material, intermediate product, finished product, byproduct, or waste product (e.g., cooling water).

Process Area Stormwater: Water flow as a result of precipitation (rain, snow melt, etc.) over land or impervious surfaces in areas that process raw materials, intermediate products, finished products, byproducts, or waste products (i.e., precipitation associated with industrial activity).

Nonprocess Area Stormwater: Water flow as a result of precipitation (rain, snow melt, etc.) over land or impervious surfaces in areas that do not process raw materials, intermediate products, finished products, byproducts, or waste products (i.e., precipitation not associated with industrial activity).

Air Emission Control Wastewater: Any wastewater generated from an air emission control system (i.e., wasters generated from technologies or practices intended to capture, reduce, or eliminate one or more contaminants in a gaseous stream).

Third-Party Wastewater: Wastewater that is not generated at the given facility and is transferred to the facility from another source.

Sanitary Wastewater: Wastewater that is generated from restrooms, cafeterias, showers, and domestic (versus industrial) activities.

Groundwater: Underground water that resides within the cracks, crevices, and spaces in soil, sand, and rock. Groundwater is generated at a facility when it is resurfaced or withdrawn from the ground by way of a well.

☐ No

☐ Yes

If

you answered “No” to this question, proceed to Section 7

Question 44 (Environmental

and Other Information).

If

you answered “No” to this question, proceed to Section 7

Question 44 (Environmental

and Other Information).

DO NOT COMPLETE SECTIONS 3, 4, 5, OR 6.

Complete a row in the table below for each wastewater generated on site or transferred to the facility during calendar year 2022. Include rows for each process wastewater, nonprocess wastewater, process area stormwater, nonprocess area stormwater, air emission control wastewater, third-party wastewater, sanitary wastewater, and groundwater. See the GLOSSARY or previous question for a definition of each wastewater type. If the wastewater does not fit within any of these classifications, select "other" and specify the wastewater type in the space provided. Multiple rows per wastewater type may be reported (e.g., if the facility generates three types of process wastewater, each of the three process wastewaters should be entered in a separate row of the table).