Regulatory Text

0186.17 Supplemental Document.docx

NESHAP for Vinyl Chloride (40 CFR part 61, subpart F) (Renewal)

Regulatory Text

OMB: 2060-0071

§ 61.07 Application for approval of construction or modification.

(a) The owner or operator shall submit to the Administrator an application for approval of the construction of any new source or modification of any existing source. The application shall be submitted before the construction or modification is planned to commence, or within 30 days after the effective date if the construction or modification had commenced before the effective date and initial startup has not occurred. A separate application shall be submitted for each stationary source.

(b) Each application for approval of construction shall include—

(1) The name and address of the applicant;

(2) The location or proposed location of the source; and

(3) Technical information describing the proposed nature, size, design, operating design capacity, and method of operation of the source, including a description of any equipment to be used for control of emissions. Such technical information shall include calculations of emission estimates in sufficient detail to permit assessment of the validity of the calculations.

(c) Each application for approval of modification shall include, in addition to the information required in paragraph (b) of this section—

(1) The precise nature of the proposed changes;

(2) The productive capacity of the source before and after the changes are completed; and

(3) Calculations of estimates of emissions before and after the changes are completed, in sufficient detail to permit assessment of the validity of the calculations.

§ 61.09 Notification of startup.

(a) The owner or operator of each stationary source which has an initial startup after the effective date of a standard shall furnish the Administrator with written notification as follows:

(1) A notification of the anticipated date of initial startup of the source not more than 60 days nor less than 30 days before that date.

(2) A notification of the actual date of initial startup of the source within 15 days after that date.

§ 61.13 Emission tests and waiver of emission tests.

(c) The owner or operator shall notify the Administrator of the emission test at least 30 days before the emission test to allow the Administrator the opportunity to have an observer present during the test.

(f) Unless otherwise specified in an applicable subpart, samples shall be analyzed and emissions determined within 30 days after each emission test has been completed. The owner or operator shall report the determinations of the emission test to the Administrator by a registered letter sent before the close of business on the 31st day following the completion of the emission test.

(g) The owner or operator shall retain at the source and make available, upon request, for inspection by the Administrator, for a minimum of 2 years, records of emission test results and other data needed to determine emissions.

(i)

(1) Emission tests may be waived upon written application to the Administrator if, in the Administrator's judgment, the source is meeting the standard, or the source is being operated under a waiver or compliance, or the owner or operator has requested a waiver of compliance and the Administrator is still considering that request.

(2) If application for waiver of the emission test is made, the application shall accompany the information required by § 61.10 or the notification of startup required by § 61.09, whichever is applicable. A possible format is contained in appendix A to this part.

(3) Approval of any waiver granted under this section shall not abrogate the Administrator's authority under the Act or in any way prohibit the Administrator from later cancelling the waiver. The cancellation will be made only after notice is given to the owner or operator of the source.

§ 61.14 Monitoring requirements.

(f) The owner or operator shall maintain records of monitoring data, monitoring system calibration checks, and the occurrence and duration of any period during which the monitoring system is malfunctioning or inoperative. These records shall be maintained at the source for a minimum of 2 years and made available, upon request, for inspection by the Administrator.

§ 61.15 Modification.

(a) Except as provided under paragraph (d) of this section, any physical or operational change to a stationary source which results in an increase in the rate of emission to the atmosphere of a hazardous pollutant to which a standard applies shall be considered a modification.

(b) Upon modification, an existing source shall become a new source for each hazardous pollutant for which the rate of emission to the atmosphere increases and to which a standard applies.

(c) Emission rate shall be expressed as kg/hr of any hazardous pollutant discharged into the atmosphere for which a standard is applicable. The Administrator shall use the following to determine the emission rate:

(1) Emission factors as specified in the background information document (BID) for the applicable standard, or in the latest issue of “Compilation of Air Pollutant Emission Factors,” EPA Publication No. AP–42, or other emission factors determined by the Administrator to be superior to AP–42 emission factors, in cases where use of emission factors demonstrates that the emission rate will clearly increase or clearly not increase as a result of the physical or operational change.

(2) Material balances, monitoring data, or manual emission tests in cases where use of emission factors, as referenced in paragraph (c)(1) of this section, does not demonstrate to the Administrator's satisfaction that the emission rate will clearly increase or clearly not increase as a result of the physical or operational change, or where an interested person demonstrates to the Administrator's satisfaction that there are reasonable grounds to dispute the result obtained by the Administrator using emission factors. When the emission rate is based on results from manual emission tests or monitoring data, the procedures specified in appendix C of 40 CFR part 60 shall be used to determine whether an increase in emission rate has occurred. Tests shall be conducted under such conditions as the Administrator shall specify to the owner or operator. At least three test runs must be conducted before and at least three after the physical or operational change. If the Administrator approves, the results of the emission tests required in § 61.13(a) may be used for the test runs to be conducted before the physical or operational change. All operating parameters which may affect emissions must be held constant to the maximum degree feasible for all test runs.

(d) The following shall not, by themselves, be considered modifications under this part:

(1) Maintenance, repair, and replacement which the Administrator determines to be routine for a source category.

(2) An increase in production rate of a stationary source, if that increase can be accomplished without a capital expenditure on the stationary source.

(3) An increase in the hours of operation.

(4) Any conversion to coal that meets the requirements specified in section 111(a)(8) of the Act.

(5) The relocation or change in ownership of a stationary source. However, such activities must be reported in accordance with § 61.10(c).

§ 61.64 Emission standard for polyvinyl chloride plants.

(a) Reactor. The following requirements apply to reactors:

(3) Manual vent valve discharge. Except for an emergency manual vent valve discharge, there is to be no discharge to the atmosphere from any manual vent valve on a polyvinyl chloride reactor in vinyl chloride service. An emergency manual vent valve discharge means a discharge to the atmosphere which could not have been avoided by taking measures to prevent the discharge. Within 10 days of any discharge to the atmosphere from any manual vent valve, the owner or operator of the source from which the discharge occurs shall submit to the Administrator a report in writing containing information on the source, nature and cause of the discharge, the date and time of the discharge, the approximate total vinyl chloride loss during the discharge, the method used for determining the vinyl chloride loss (the calculation of the vinyl chloride loss), the action that was taken to prevent the discharge, and measures adopted to prevent future discharges.

§ 61.65 Emission standard for ethylene dichloride, vinyl chloride and polyvinyl chloride plants.

Relief valve discharge (RVD). Except for an emergency relief discharge, and except as provided in § 61.65(d), there is to be no discharge to the atmosphere from any relief valve on any equipment in vinyl chloride service. An emergency relief discharge means a discharge which could not have been avoided by taking measures to prevent the discharge. Within 10 days of any relief valve discharge, except for those subject to § 61.65(d), the owner or operator of the source from which the relief valve discharge occurs shall submit to the Administrator a report in writing containing information on the source, nature and cause of the discharge, the date and time of the discharge, the approximate total vinyl chloride loss during the discharge, the method used for determining the vinyl chloride loss (the calculation of the vinyl chloride loss), the action that was taken to prevent the discharge, and measures adopted to prevent future discharges.

§ 61.66 Equivalent equipment and procedures.

Upon written application from an owner or operator, the Administrator may approve use of equipment or procedures which have been demonstrated to his satisfaction to be equivalent in terms of reducing vinyl chloride emissions to the atmosphere to those prescribed for compliance with a specific paragraph of this subpart.

§ 61.67 Emission tests.

(f) The owner or operator shall retain at the plant and make available, upon request, for inspection by the Administrator, for a minimum of 3 years, records of emission test results and other data needed to determine emissions.

§ 61.69 Initial report.

(a) An owner or operator of any source to which this subpart applies shall submit a statement in writing notifying the Administrator that the equipment and procedural specifications in § 61.65 (b)(1), (b)(2), (b)(3), (b)(4), (b)(5), (b)(6), (b)(7), and (b)(8) are being implemented.

(b)

(1) In the case of an existing source or a new source which has an initial startup date preceding the effective date, the statement is to be submitted within 90 days of the effective date, unless a waiver of compliance is granted under § 61.11, along with the information required under § 61.10. If a waiver of compliance is granted, the statement is to be submitted on a date scheduled by the Administrator.

(2) In the case of a new source which did not have an initial startup date preceding the effective date, the statement is to be submitted within 90 days of the initial startup date.

(c) The statement is to contain the following information:

(1) A list of the equipment installed for compliance,

(2) A description of the physical and functional characteristics of each piece of equipment,

(3) A description of the methods which have been incorporated into the standard operating procedures for measuring or calculating the emissions for which emission limits are prescribed in § 61.65 (b)(1)(i) and (b)(6)(i),

(4) A statement that each piece of equipment is installed and that each piece of equipment and each procedure is being used.

§ 61.70 Reporting.

(a)

(1) The owner or operator of any source to which this subpart applies shall submit to the Administrator on March 15, June 15, September 15, and December 15 of each year a report in writing containing the information required by this section. The first report is to be submitted following the first full 3-month reporting period after the initial report is submitted.

(2) In the case of an existing source, the approved reporting schedule shall be used. In addition, quarterly reports shall be submitted exactly 3 months following the current reporting dates.

(b)

(1) In the case of an existing source or a new source which has an initial startup date preceding the effective date, the first report is to be submitted within 180 days of the effective date, unless a waiver of compliance is granted under § 61.11. If a waiver of compliance is granted, the first report is to be submitted on a date scheduled by the Administrator.

(2) In the case of a new source which did not have an initial startup date preceding the effective date, the first report is to be submitted within 180 days of the initial startup date.

(c) Unless otherwise specified, the owner or operator shall use the test methods in appendix B to this part to conduct emission tests as required by paragraphs (c)(2) and (c)(3) of this section, unless an alternative method has been approved by the Administrator. If the Administrator finds reasonable grounds to dispute the results obtained by an alternative method, he may require the use of a reference method. If the results of the reference and alternative methods do not agree, the results obtained by the reference method prevail, and the Administrator may notify the owner or operator that approval of the method previously considered to be alternative is withdrawn.

(1) The owner or operator shall include in the report a record of the vinyl chloride content of emissions for each 3-hour period during which average emissions are in excess of the emission limits in § 61.62(a) or (b), § 61.63(a), or § 61.64(a)(1), (b), (c), or (d), or during which average emissions are in excess of the emission limits specified for any control system to which reactor emissions are required to be ducted in § 61.64(a)(2) or to which fugitive emissions are required to be ducted in § 61.65(b)(I)(ii), (b)(2), (b)(5), (b)(6)(ii), or (b)(9)(ii). The number of 3-hour periods for which average emissions were determined during the reporting period shall be reported. If emissions in excess of the emission limits are not detected, the report shall contain a statement that no excess emissions have been detected. The emissions are to be determined in accordance with § 61.68(e).

(2) In polyvinyl chloride plants for which a stripping operation is used to attain the emission level prescribed in § 61.64(e), the owner or operator shall include in the report a record of the vinyl chloride content in the polyvinyl chloride resin.

(i) If batch stripping is used, one representative sample of polyvinyl chloride resin is to be taken from each batch of each grade of resin immediately following the completion of the stripping operation, and identified by resin type and grade and the date and time the batch is completed. The corresponding quantity of material processed in each stripper batch is to be recorded and identified by resin type and grade and the date and time the batch is completed.

(ii) If continuous stripping is used, one representative sample of polyvinyl chloride resin is to be taken for each grade of resin processed or at intervals of 8 hours for each grade of resin which is being processed, whichever is more frequent. The sample is to be taken as the resin flows out of the stripper and identified by resin type and grade and the date and time the sample was taken. The corresponding quantity of material processed by each stripper over the time period represented by the sample during the 8-hour period, is to be recorded and identified by resin type and grade and the date and time it represents.

(iii) The vinyl chloride content in each sample is to be determined by Method 107 as prescribed in § 61.67(g)(3).

(iv) [Reserved]

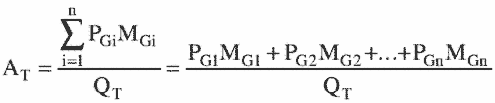

(v) The report to the Administrator by the owner or operator is to include a record of any 24-hour average resin vinyl chloride concentration, as determined in this paragraph, in excess of the limits prescribed in § 61.64(e). The vinyl chloride content found in each sample required by paragraphs (c)(2)(i) and (c)(2)(ii) of this section shall be averaged separately for each type of resin, over each calendar day and weighted according to the quantity of each grade of resin processed by the stripper(s) that calendar day, according to the following equation:

Where:

AT = 24-hour average concentration of type T resin in ppm (dry weight basis).

QT = Total production of type T resin over the 24-hour period, in kg (ton).

T = Type of resin.

MGi = Concentration of vinyl chloride in one sample of grade Gi resin in ppm.

PGi = Production of grade Gi resin represented by the sample, in kg (ton).

Gi = Grade of resin: e.g., G1, G2, G3.

n = Total number of grades of resin produced during the 24-hour period.

The number of 24-hour average concentrations for each resin type determined during the reporting period shall be reported. If no 24-hour average resin vinyl chloride concentrations in excess of the limits prescribed in § 61.64(e) are measured, the report shall state that no excess resin vinyl chloride concentrations were measured.

(vi) The owner or operator shall retain at the source and make available for inspection by the Administrator for a minimum of 3 years records of all data needed to furnish the information required by paragraph (c)(2)(v) of this section. The records are to contain the following information:

(A) The vinyl chloride content found in all the samples required in paragraphs (c)(2)(i) and (c)(2)(ii) of this section, identified by the resin type and grade and the time and date of the sample, and

(B) The corresponding quantity of polyvinyl chloride resin processed by the stripper(s), identified by the resin type and grade and the time and date it represents.

(3) The owner or operator shall include in the report a record of any emissions from each reactor opening in excess of the emission limits prescribed in § 61.64(a)(2). Emissions are to be determined in accordance with § 61.67(g)(5), except that emissions for each reactor are to be determined. The number of reactor openings during the reporting period shall be reported. If emissions in excess of the emission limits are not detected, the report shall include a statement that excess emissions have not been detected.

(4) In polyvinyl chloride plants for which stripping in the reactor is used to attain the emission level prescribed in § 61.64(f), the owner or operator shall include in the report a record of the vinyl chloride emissions from reactor opening loss and all sources following the reactor used as a stripper.

(i) One representative sample of polyvinyl chloride resin is to be taken from each batch of each grade of resin immediately following the completion of the stripping operation, and identified by resin type and grade and the date and time the batch is completed. The corresponding quantity of material processed in each stripper batch is to be recorded and identified by resin type and grade and the date and time the batch is completed.

(ii) The vinyl chloride content in each sample is to be determined by Method 107 as prescribed in § 61.67(g)(3).

(iii) The combined emissions from reactor opening loss and all sources following the reactor used as a stripper are to be determined for each batch stripped in a reactor according to the procedure prescribed in § 61.67(g)(6).

(iv) The report to the Administrator by the owner or operator is to include a record of any 24-hour average combined reactor opening loss and emissions from all sources following the reactor used as a stripper as determined in this paragraph, in excess of the limits prescribed in § 61.64(f). The combined reactor opening loss and emissions from all sources following the reactor used as a stripper associated with each batch are to be averaged separately for each type of resin, over each calendar day and weighted according to the quantity of each grade of resin stripped in reactors that calendar day as follows:

For each type of resin (suspension, dispersion, latex, bulk, other), the following calculation is to be performed:

Where:

AT = 24-hour average combined reactor opening loss and emissions from all sources following the reactor used as a stripper, in g vinyl chloride/kg (lb/ton) product (dry weight basis).

QT = Total production of resin in batches for which stripping is completed during the 24-hour period, in kg (ton).

T = Type of resin.

CGi = Average combined reactor opening loss and emissions from all sources following the reactor used as a stripper of all batches of grade Gi resin for which stripping is completed during the 24-hour period, in g vinyl chloride/kg (lb/ton) product (dry weight basis) (determined according to procedure prescribed in § 61.67(g)(6)).

PGi = Production of grade Gi resin in the batches for which C is determined, in kg (ton).

Gi = Grade of resin: e.g., G1, G2, G3.

n = Total number of grades of resin in batches for which stripping is completed during the 24-hour period.

The number of 24-hour average emissions determined during the reporting period shall be reported. If no 24-hour average combined reactor opening loss and emissions from all sources following the reactor used as a stripper in excess of the limits prescribed in § 61.64(f) are determined, the report shall state that no excess vinyl chloride emissions were determined.

§ 61.71 Recordkeeping.

(a) The owner or operator of any source to which this subpart applies shall retain the following information at the source and make it available for inspection to the Administrator for a minimum of 3 years:

(1) A record of the leaks detected by the vinyl chloride monitoring system, as required by § 61.65(b)(8), including the concentrations of vinyl chloride measured, analyzed, and recorded by the vinyl chloride detector, the location of each measurement and the date and approximate time of each measurement.

(2) A record of the leaks detected during routine monitoring with the portable hydrocarbon detector and the action taken to repair the leaks, as required by § 61.65(b)(8), including a brief statement explaining the location and cause of each leak detected with the portable hydrocarbon detector, the date and time of the leak, and any action taken to eliminate that leak.

(3) A record of emissions measured in accordance with § 61.68.

(4) A daily operating record for each polyvinyl chloride reactor, including pressures and temperatures.

| File Type | application/vnd.openxmlformats-officedocument.wordprocessingml.document |

| Author | Leslie Smith |

| File Modified | 0000-00-00 |

| File Created | 2025-03-01 |

© 2026 OMB.report | Privacy Policy