Regulatory Text

1156.16 Supplemental Regulatory Text.docx

NSPS for Synthetic Fiber Production Facilities (40 CFR Part 60, Subpart HHH) (Renewal)

Regulatory Text

OMB: 2060-0059

§ 60.7 Notification and record keeping.

(a) Any owner or operator subject to the provisions of this part shall furnish the Administrator written notification or, if acceptable to both the Administrator and the owner or operator of a source, electronic notification, as follows:

(1) A notification of the date construction (or reconstruction as defined under § 60.15) of an affected facility is commenced postmarked no later than 30 days after such date. This requirement shall not apply in the case of mass-produced facilities which are purchased in completed form.

(2) [Reserved]

(3) A notification of the actual date of initial startup of an affected facility postmarked within 15 days after such date.

(4) A notification of any physical or operational change to an existing facility which may increase the emission rate of any air pollutant to which a standard applies, unless that change is specifically exempted under an applicable subpart or in § 60.14(e). This notice shall be postmarked 60 days or as soon as practicable before the change is commenced and shall include information describing the precise nature of the change, present and proposed emission control systems, productive capacity of the facility before and after the change, and the expected completion date of the change. The Administrator may request additional relevant information subsequent to this notice.

(5) A notification of the date upon which demonstration of the continuous monitoring system performance commences in accordance with § 60.13(c). Notification shall be postmarked not less than 30 days prior to such date.

(b) Any owner or operator subject to the provisions of this part shall maintain records of the occurrence and duration of any startup, shutdown, or malfunction in the operation of an affected facility; any malfunction of the air pollution control equipment; or any periods during which a continuous monitoring system or monitoring device is inoperative.

(f) Any owner or operator subject to the provisions of this part shall maintain a file of all measurements, including continuous monitoring system, monitoring device, and performance testing measurements; all continuous monitoring system performance evaluations; all continuous monitoring system or monitoring device calibration checks; adjustments and maintenance performed on these systems or devices; and all other information required by this part recorded in a permanent form suitable for inspection. The file shall be retained for at least two years following the date of such measurements, maintenance, reports, and records, except as follows:

(1) This paragraph applies to owners or operators required to install a continuous emissions monitoring system (CEMS) where the CEMS installed is automated, and where the calculated data averages do not exclude periods of CEMS breakdown or malfunction. An automated CEMS records and reduces the measured data to the form of the pollutant emission standard through the use of a computerized data acquisition system. In lieu of maintaining a file of all CEMS subhourly measurements as required under paragraph (f) of this section, the owner or operator shall retain the most recent consecutive three averaging periods of subhourly measurements and a file that contains a hard copy of the data acquisition system algorithm used to reduce the measured data into the reportable form of the standard.

(2) This paragraph applies to owners or operators required to install a CEMS where the measured data is manually reduced to obtain the reportable form of the standard, and where the calculated data averages do not exclude periods of CEMS breakdown or malfunction. In lieu of maintaining a file of all CEMS subhourly measurements as required under paragraph (f) of this section, the owner or operator shall retain all subhourly measurements for the most recent reporting period. The subhourly measurements shall be retained for 120 days from the date of the most recent summary or excess emission report submitted to the Administrator.

(3) The Administrator or delegated authority, upon notification to the source, may require the owner or operator to maintain all measurements as required by paragraph (f) of this section, if the Administrator or the delegated authority determines these records are required to more accurately assess the compliance status of the affected source.

§ 60.8 Performance tests.

(a) Except as specified in paragraphs (a)(1),(a)(2), (a)(3), and (a)(4) of this section, within 60 days after achieving the maximum production rate at which the affected facility will be operated, but not later than 180 days after initial startup of such facility, or at such other times specified by this part, and at such other times as may be required by the Administrator under section 114 of the Act, the owner or operator of such facility shall conduct performance test(s) and furnish the Administrator a written report of the results of such performance test(s).

(1) If a force majeure is about to occur, occurs, or has occurred for which the affected owner or operator intends to assert a claim of force majeure, the owner or operator shall notify the Administrator, in writing as soon as practicable following the date the owner or operator first knew, or through due diligence should have known that the event may cause or caused a delay in testing beyond the regulatory deadline, but the notification must occur before the performance test deadline unless the initial force majeure or a subsequent force majeure event delays the notice, and in such cases, the notification shall occur as soon as practicable.

(2) The owner or operator shall provide to the Administrator a written description of the force majeure event and a rationale for attributing the delay in testing beyond the regulatory deadline to the force majeure; describe the measures taken or to be taken to minimize the delay; and identify a date by which the owner or operator proposes to conduct the performance test. The performance test shall be conducted as soon as practicable after the force majeure occurs.

(3) The decision as to whether or not to grant an extension to the performance test deadline is solely within the discretion of the Administrator. The Administrator will notify the owner or operator in writing of approval or disapproval of the request for an extension as soon as practicable.

(4) Until an extension of the performance test deadline has been approved by the Administrator under paragraphs (a)(1), (2), and (3) of this section, the owner or operator of the affected facility remains strictly subject to the requirements of this part.

(d) The owner or operator of an affected facility shall provide the Administrator at least 30 days prior notice of any performance test, except as specified under other subparts, to afford the Administrator the opportunity to have an observer present. If after 30 days notice for an initially scheduled performance test, there is a delay (due to operational problems, etc.) in conducting the scheduled performance test, the owner or operator of an affected facility shall notify the Administrator (or delegated State or local agency) as soon as possible of any delay in the original test date, either by providing at least 7 days prior notice of the rescheduled date of the performance test, or by arranging a rescheduled date with the Administrator (or delegated State or local agency) by mutual agreement.

§ 60.603 Performance test and compliance provisions.

(a) Section 60.8(f) does not apply to the performance test procedures required by this subpart.

(b) Each owner or operator of an affected facility shall determine compliance with the applicable standard in § 60.602(a) by determining and recording monthly the VOC emissions per unit mass solvent feed from each affected facility for the current and preceding 5 consecutive calendar months and using these values to calculate the 6-month average emissions. Each calculation is considered a performance test. The owner or operator of an affected facility shall use the following procedure to determine VOC emissions for each calendar month;

(1) Install, calibrate, maintain, and operate monitoring devices that continuously measure and permanently record for each calendar month the amount of makeup solvent and solvent feed. These values shall be used in calculating VOC emissions according to paragraph (b)(2) of this section. All monitoring devices, meters, and peripheral equipment shall be calibrated and any error recorded. Total compounded error of the flow measuring and recording devices shall not exceed 1 percent accuracy over the operating range. As an alternative to measuring solvent feed, the owner or operator may:

(i) Measure the amount of recovered solvent returned to the solvent feed storage tanks, and use the following equation to determine the amount of solvent feed:

Solvent Feed = Makeup Solvent + Recovered

Solvent + Change in the Amount of Solvent

Contained in the Solvent Feed Holding Tank.

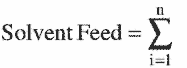

(ii) Measure and record the amount of polymer introduced into the affected facility and the solvent-to-polymer ratio of the spinning solutions, and use the following equation to determine the amount of solvent feed:

where subscript “i” denotes each particular spinning solution used during the test period; values of “i” vary from one to the total number of spinning solutions, “n,” used during the calendar month.

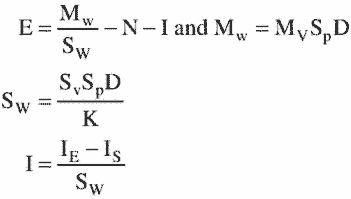

(2) VOC emissions shall be determined each calendar month by use of the following equations:

where all values are for the calendar month only and where

E = VOC Emissions, in kg/Mg (lb/ton) solvent;

SV = Measured or calculated volume of solvent feed, in liters (gallons);

SW = Weight of solvent feed, in Mg (ton);

MV = Measured volume of makeup solvent, in liters (gallons);

MW = Weight of makeup, in kg (lb);

N = Allowance for nongaseous losses, 13 kg/Mg (26 lb/ton) solvent feed;

SP = Fraction of measured volume that is actual solvent (excludes water);

D = Density of the solvent, in kg/liter (lb/gallon);

K = Conversion factor, 1,000 kg/Mg (2,000 lb/ton);

I = Allowance for solvent inventory variation or changes in the amount of solvent contained in the affected facility, in kg/Mg (lb/ton) solvent feed (may be positive or negative);

IS = Amount of solvent contained in the affected facility at the beginning of the test period, as determined by the owner or operator, in kg (lb);

IE = Amount of solvent contained in the affected facility at the close of the test period, as determined by the owner or operator, in kg (lb).

(3) N, as used in the equation in paragraph (b)(2) of this section, equals 13 kg/Mg (26 lb/ton) solvent feed to the spinning solution preparation system and precipitation bath. This value shall be used in all cases unless an owner or operator demonstrates to the satisfaction of the Administrator that greater nongaseous losses occur at the affected facility. In this case, the greater value may be substituted in the equation.

[49 FR 13651, Apr. 5, 1984; 49 FR 18096, Apr. 27, 1984, as amended at 65 FR 61769, Oct. 17, 2000]

§ 60.604 Reporting requirements.

(a) The owner or operator of an affected facility shall submit a written report to the Administrator of the following:

(1) The results of the initial performance test; and

(2) The results of subsequent performance tests that indicate that VOC emissions exceed the standards in § 60.602. These reports shall be submitted quarterly at 3-month intervals after the initial performance test. If no exceedances occur during a particular quarter, a report stating this shall be submitted to the Administrator semiannually.

(b) Solvent-spun synthetic fiber producing facilities exempted from these standards in § 60.600(a) (those producing less than 500 Mg (551 ton) annually) shall report to the Administrator within 30 days whenever extruded fiber for the preceding 12 calendar months exceeds 500 Mg (551 ton).

| File Type | application/vnd.openxmlformats-officedocument.wordprocessingml.document |

| Author | Kylie Arnold |

| File Modified | 0000-00-00 |

| File Created | 2025-07-01 |

© 2026 OMB.report | Privacy Policy