Form NHTSA Form 1080 NHTSA Form 1080 Request for Product Plan Information

49 CFR Parts 531 and 533 Passenger Car Average Fuel Economy Standards -- Model Years 2008-2020; Light Truck Average Fuel Economy Standards Model Years 2008-2020; Production Plan Data.

2127_0655_Product Plan Info Request -- NHTSA Form 1080

49 CFR Parts 531 and 533 Passenger Car Average Fuel Economy Standards -- Model Years 2008-2020; Light Truck Average Fuel Economy Standards Model Years 2008-2020; Production Plan Data

OMB: 2127-0655

OMB Control 2127-0655

Expiration Date XXX

Request for Product Plan Information

APPENDIX A

I. Definitions

As used in these appendices--

1. “Automobile,” “fuel economy,” “manufacturer,” and “model year (MY),” have the meaning given them in Section 32901 of Chapter 329 of Title 49 of the United States Code, 49 U.S.C. 32901.

2. “Basic engine” has the meaning given in 40 CFR 600.002‑93(a)(21).

3. “Cargo-carrying volume,” “gross vehicle weight rating” (GVWR), and “passenger-carrying volume” are used as defined in 49 CFR 523.2.

4. “CARB” means California Air Resource Board

5. “Domestically manufactured” is used as defined in Section 32904(b)(2)

of Chapter 329, 49 U.S.C. 32904(b)(2).

6. “Footprint” means the product of average track width (measured in inches and rounded to the nearest tenth of an inch) times wheelbase (measured in inches and rounded to the nearest tenth of an inch) divided by 144 and then rounded to the nearest tenth of a

square foot as described in 49 CFR Part 523.2.

7. “Light truck” means an automobile of the type described in 49 CFR Part 523.3 and 523.5.

8. A “model” of passenger car is a line, such as the Chevrolet Impala, Ford Fusion, Honda Accord, etc., which exists within a manufacturer's fleet.

9. “Model Type” is used as defined in 40 CFR 600.002‑93(a)(19).

10. “MY” means model year

11. “Passenger car” means an automobile of the type described in 49 CFR Part 523.3 and 523.4.

12. “Percent fuel economy improvements” means that percentage which corresponds to the amount by which respondent could improve the fuel economy of vehicles in a given model or class through the application of a specified technology, averaged over all vehicles of that model or in that class which feasibly could use the technology. Projections of percent fuel economy improvement should be based on the assumption of maximum efforts by respondent to achieve the highest possible fuel economy increase through the application of the technology (i.e., holding other performance characteristics constant such as 0-60 miles-per-hour (mph) time, towing capacity, etc.). The baseline for determination of percent fuel economy improvement is the level of technology and vehicle performance with respect to acceleration and gradeability for respondent's 2008 model year passenger cars or light trucks in the equivalent class.

13. “Percent production implementation rate” means that percentage which corresponds to the maximum number of passenger cars or light trucks of a specified class, which could feasibly employ a given type of technology if respondent made maximum efforts to apply the technology by a specified model year.

14. “Production percentage” means the percent of respondent's passenger cars or light trucks of a specified model projected to be manufactured in a specified model year.

15. “Project” or “projection” refers to the best estimates made by respondent, whether or not based on less than certain information.

16. “Redesign” means any change, or combination of changes, to a vehicle that would change its weight by 50 pounds or more or change its frontal area or aerodynamic drag coefficient by 2 percent or the implementation of new engine or transmission.

17. “Refresh” means any change, or combination of changes, to a vehicle that would change its weight by less than 50 pounds and would not change its frontal area or aerodynamic drag coefficient.

18. “Relating to” means constituting, defining, containing, explaining, embodying, reflecting, identifying, stating, referring to, dealing with, or in any way pertaining to.

19. “Respondent” means each manufacturer (including all its divisions) providing answers to the questions set forth in this appendix, and its officers, employees, agents or servants.

20. “RPE” means retail price equivalent

21. “Test Weight” is used as defined in 40 CFR 86.082‑2.

22. “Track Width” means the lateral distance between the centerlines of the base tires at ground, including the camber angle.

23. “Truckline” means the name assigned by the Environmental Protection Agency to a different group of vehicles within a make or car division in accordance with that agency's 2001 model year pickup, van (cargo vans and passenger vans are considered separate truck lines), and special purpose vehicle criteria.

24. “Variants of existing engines” means versions of an existing basic engine that differ from that engine in terms of displacement, method of aspiration, induction system or that weigh at least 25 pounds more or less than that engine.

25. “Wheelbase” means the longitudinal distance between front and rear wheel centerlines.

II. Assumptions

All assumptions concerning emission standards, damageability regulations, safety standards, etc., should be listed and described in detail by the respondent.

III. Specifications – Passenger Car and Light Truck Data

Go to ftp://ftpserver.volpe.dot.gov/pub/CAFE/templates/ for spreadsheet templates.

1. Identify all passenger car and light truck models offered for sale in MY 2008 whose production each respondent projects discontinuing before MY 2012 and identify the last model year in which each will be offered.

2. Identify all basic engines offered by respondent in MY 2008 passenger cars and light trucks which respondent projects it will cease to offer for sale in passenger cars and light trucks before MY 2012, and identify the last model year in which each will be offered.

3. For each model year 2009-2020, list all known or projected car and truck lines and provide the information specified below for each model type. Model types that are essentially identical except for their nameplates (e.g., Ford Fusion/Mercury Milan) may be combined into one item. Engines having the same displacement but belonging to different engine families are to be grouped separately. Within the fleet, the vehicles are to be sorted first by car or truck line, second by basic engine, and third by transmission type. For each model type, a specific indexed engine and transmission are to be identified. As applicable, an indexed predecessor model type is also to be identified. Spreadsheet templates can be found at tp://ftpserver.volpe.dot.gov/pub/CAFE/templates/. These templates include codes and definitions for the data that the Agency is seeking, including, but not limited to the following:

A. General Information

1. Vehicle Number – a unique number assigned to each model

2. Manufacturer – manufacturer’s name (e.g., Toyota)

3. Model – name of model (e.g., Corolla)

4. Nameplate – vehicle nameplate (e.g., Corolla Matrix)

5. Primary Fuel – classified as CNG = compressed natural gas; D = diesel; E = electricity; E-85 = ethanol; E100 = neat ethanol; G = gasoline; H = hydrogen; LNG = liquefied natural gas; LPG = propane; M85 = methanol; M100 = neat methanol

6. Fuel Economy on Primary Fuel – measured in miles per gallon; laboratory fuel economy (weighted FTP+highway gasoline-equivalent gallon (GEG), exclusive of any calculation under 49 U.S.C. 32905)

7. Secondary Fuel – classified as CNG = compressed natural gas; D = diesel; E = electricity; E-85 = ethanol; E100 = neat ethanol; G = gasoline; H = hydrogen; LNG = liquefied natural gas; LPG = propane; M85 = methanol; M100 = neat methanol

8. Fuel Economy on Secondary Fuel – measured in miles per gallon; laboratory fuel economy (weighted FTP+highway GEG, exclusive of any calculation under 49 U.S.C. 32905)

9. Tertiary Fuel – classified as CNG = compressed natural gas; D = diesel; E = electricity; E-85 = ethanol; E100 = neat ethanol; G = gasoline; H = hydrogen; LNG = liquefied natural gas; LPG = propane; M85 = methanol; M100 = neat methanol

10. Fuel Economy on Tertiary Fuel – measured in miles per gallon; laboratory fuel economy (weighted FTP+highway GEG, exclusive of any calculation under 49 U.S.C. 32905)

11. CAFE Fuel Economy – measured in miles per gallon; laboratory fuel economy (weighted FTP+highway GEG, inclusive of any calculation under 49 U.S.C. 32905)

12. Engine Code – unique number assigned to each engine

A. Manufacturer – manufacturer’s name (e.g., General Motors, Ford, Toyota, Honda)

B. Name – name of engine

C. Configuration – classified as V = V-shaped; I = inline; R = rotary, H = horizontally opposed (boxer)

D. Primary Fuel – classified as CNG = compressed natural gas, D = diesel, E85 = ethanol, E100 = neat ethanol, G = gasoline, H = hydrogen, LNG = liquefied natural gas, LPG = propane, M85 = methanol, M100 = neat methanol

E. Secondary Fuel – classified as CNG = compressed natural gas, D = diesel, E85 = ethanol, E100 = neat ethanol, G = gasoline, H = hydrogen, LNG = liquefied natural gas, LPG = propane, M85 = methanol, M100 = neat methanol

F. Country of Origin – name of country where engine is manufactured

G. Engine Oil Viscosity – ratio between the applied shear stress and the rate of shear, which measures the resistance of flow of the engine oil (as per SAE Glossary of Automotive Terms); typical values as text include 0W20, 5W20, etc.

H. Cycle – combustion cycle of engine; classified as A = Atkinson, AM = Atkinson/Miller, D = Diesel, M = Miller, O = Otto, OA = Otto/Atkinson

I. Air/Fuel Ratio – the weighted (FTP + highway) air/fuel ratio (mass); a number generally around 14.7 for gasoline engines

J. Fuel Delivery System – mechanism that delivers fuel to engine; classified as SGDI = stoichiometric gasoline direct injection; LBGDI = lean-burn gasoline direct injection; SFI = sequential fuel injection; MPFI = multipoint fuel injection; TBI = throttle body fuel injection; CRDI = common rail direct injection (diesel); UDI = unit injector direct injection (diesel)

K. Aspiration – breathing or induction process of engine (as per SAE Automotive Dictionary); classified as NA = naturally aspirated, S = supercharged, T = turbocharged, T2 = twin turbocharged, T4 = quad-turbocharged, ST = supercharged and turbocharged

L. Valvetrain Design – design of the total mechanism from camshaft to valve of an engine that actuates the lifting and closing of a valve (as per SAE Glossary of Automotive Terms); classified as CVA = camless valve actuation, DOHC = dual overhead cam, OHV = overhead valve, SOHC = single overhead cam

M. Valve Actuation/Timing – valve opening and closing points in the operating cycle (as per SAE J604); classified as F = fixed, ICP = intake cam phasing, CCP = coupled cam phasing, DCP = dual cam phasing

N. Valve Lift – describes the manner in which the valve is raised during combustion (as per SAE Automotive Dictionary); classified as F = fixed, DVVL = discrete variable valve lift, CVVL = continuously variable valve lift

O. Cylinders – the number of engine cylinders; an integer equaling 3, 4, 5, 6, 8, 10 or 12

P. Valves/Cylinder – the number of valves per cylinder, an integer from 2 through 5

Q. Deactivation – presence of cylinder deactivation mechanism; classified as Y = cylinder deactivation applied; N = cylinder deactivation not applied

R. Displacement – total volume displaced by a piston in a single stroke multiplied by the number of cylinders; measured in liters

S. Compression Ratio (min) – typically a number between 8 and 11; (for fixed CR engines, should be identical to maximum CR)

T. Compression Ratio (max) – typically a number between 8 and 20; (for fixed CR engines, should be identical to minimum CR)

U. Max. Horsepower – the maximum power of the engine, measured as horsepower

V. Max. Horsepower RPM – rpm at which maximum horsepower is achieved

W. Max. Torque – the maximum torque of the engine, measured as lb-ft.

X. Max Torque RPM – rpm at which maximum torque is achieved

13. Transmission Code – unique number assigned to each transmission

A. Manufacturer – manufacturer’s name (e.g., General Motors, Ford, Toyota, Honda)

B. Name – name of transmission

C. Country of origin - where the transmission is manufactured

D. Type – type of transmission; classified as M = manual, A = automatic (torque converter), AMT = automated manual transmission (single clutch w/ torque interrupt), DCT = dual clutch transmission, CVT1 = belt or chain CVT, CVT2 = other CVT (e.g., toroidal), HEVT = hybrid/electric vehicle transmission (for a BISG or CISG type hybrid, please define the actual transmission used, not HEVT)

E. Clutch Type – type of clutch used in AMT or DCT type transmission; D = dry, W = wet

F. Number of Forward Gears – classified as an integer indicating the number of forward gears; “CVT” for a CVT type transmission; or “n/a”

G. Logic – indicates aggressivity of automatic shifting; classified as A = aggressive bias toward improving fuel economy, C = conventional shifting. Provide rationale for selection in the transmission notes column.

14. Origin – classification (under CAFE program) as domestic or import, D = domestic, I = import

B. Production

1. Production – actual and projected US production for MY 2008 to MY 2020 inclusive, measured in number of vehicles

2. Percent of Production Regulated by CARB Standards – percent of production volume that will be regulated under CARB’s AB 1493 for MY 2008 to MY 2020 inclusive

C. MSRP – measured in dollars (2009); actual and projected average MSRP (sales-weighted, including options) for MY 2008 to MY 2020 inclusive

D. Vehicle Information

1. Subclass – for technology application purposes only and should not be confused with vehicle classification for regulatory purposes; classified as Subcompact, Subcompact Performance, Compact, Compact Performance, Midsize, Midsize Performance, Large, Large Performance, Minivan, Small LT, Midsize LT, Large LT; where LT = SUV/Pickup/Van; use tables below, with example vehicles, to place vehicles into most appropriate subclass

Subclass |

Example (MY 2008) vehicles |

Subcompact |

Chevy Aveo, Honda Civic, Volkswagen New Beetle |

Subcompact Performance |

Audi TT, Mazda Miata, Subaru Impreza |

Compact |

Chevy Cobalt, Ford Focus, Nissan Sentra |

Compact Performance |

Audi S4 Quattro, Mazda RX8, Mitsubishi Lancer Evolution |

Midsize |

Honda Accord, Hyundai Azera, Toyota Camry |

Midsize Performance |

Chevy Corvette, Ford Mustang GT, Nissan G37 Coupe |

Large |

Audi A8, Cadillac CTS, Ford Taurus |

Large Performance |

Bentley Arnage, BMW M5, Daimler CL600 |

Subclass |

Example (MY 2008) vehicles |

Minivans |

Dodge Caravan, Toyota Sienna |

Small SUV/Pickup/Van |

Ford Ranger, Nissan Rogue, Toyota RAV4 |

Midsize SUV/Pickup/Van |

Jeep Wrangler 4-door, Mazda CX-9, Toyota Tacoma |

Large SUV/Pickup/Van |

Chevy Silverado, Ford Econoline, Toyota Sequoia |

2. Style – classified as Convertible, Coupe, Hatchback, Sedan, Minivan, Pickup, Sport Utility, Van, Wagon

3. Light Truck Indicator – an integer(s); a unique number(s) assigned to each vehicle which represents the design feature(s) that classify it as a light truck. classified as:

(0) The vehicle neither has off-road design features (defined under 49 CFR 523.5(b) and described by numbers 1 and 2 below) nor has functional characteristics (defined under 49 CFR 523.5(a) and described by numbers 3 through 7 below) that would allow it to be properly classified as a light truck, thus the vehicle is properly classified as a passenger car.

> An automobile capable of off-highway operation, as indicated by

the fact that it:

(1) (i) Has 4-wheel drive; or

(ii) Is

rated at more than 6,000 pounds gross vehicle weight; and

(2)

Has at least four of the following characteristics calculated when

the automobile is at curb weight, on a level surface, with the front

wheels parallel to the automobile's longitudinal centerline, and the

tires inflated to the manufacturer's recommended pressure—

(i) Approach angle of not less than 28 degrees.

(ii)

Breakover angle of not less than 14 degrees.

(iii) Departure

angle of not less than 20 degrees.

(iv) Running clearance of

not less than 20 centimeters.

(v) Front and rear axle

clearances of not less than 18 centimeters each.

> An

automobile designed to perform at least one of the following

functions:

(3) Transport more than 10 persons;

(4) Provide

temporary living quarters;

(5) Transport property on an open

bed;

(6) Provide, as sold to the first retail purchaser, greater

cargo-carrying than passenger-carrying volume, such as in a cargo

van; if a vehicle is sold with a second-row seat, its cargo-carrying

volume is determined with that seat installed, regardless of whether

the manufacturer has described that seat as optional; or

(7)

Permit expanded use of the automobile for cargo-carrying purposes or

other nonpassenger-carrying purposes through:

(i) For

non-passenger automobiles manufactured prior to model year 2012, the

removal of seats by means installed for that purpose by the

automobile's manufacturer or with simple tools, such as screwdrivers

and wrenches, so as to create a flat, floor level, surface extending

from the forwardmost point of installation of those seats to the rear

of the automobile’s interior; or

(ii) For

non-passenger automobiles manufactured in model year 2008 and beyond,

for vehicles equipped with at least 3 rows of designated seating

positions as standard equipment, permit expanded use of the

automobile for cargo-carrying purposes or other nonpassenger-carrying

purposes through the removal or stowing of foldable or pivoting seats

so as to create a flat, leveled cargo surface extending from the

forwardmost point of installation of those seats to the rear of the

automobile's interior.

4. Structure – classified as either L = Ladder or U =Unibody

5. Drive – classified as A = all-wheel drive; F = front-wheel drive; R = rear-wheel-drive; 4 = 4-wheel drive1

6. Axle Ratio – ratio of the speed of the drive shaft to the speed of the driven wheels

7. Length – measured in inches; defined per SAE J1100, L103 (Sept. 2005)

8. Width – measured in inches; defined per SAE J1100, W116 (Sept. 2005)

9. Wheelbase – measured to the nearest tenth of an inch; defined per SAE J1100, L101 (Sept. 2005), and clarified above

10. Track Width (front) – measured to the nearest tenth of an inch; defined per SAE J1100, W101-1 (Sept. 2005), and clarified above

11. Track Width (rear) – measured to the nearest tenth of an inch; defined per SAE J1100, W101-2 (Sept. 2005), and clarified above

12. Footprint – the product of average track width (measured in inches and rounded to the nearest tenth of an inch) times wheelbase (measured in inches and rounded to the nearest tenth of an inch) divided by 144 and then rounded to the nearest tenth of a square foot: defined per 49 CFR 523.2.

13. Base Tire - the tire specified as standard equipment by a manufacturer on each vehicle configuration of a model type; (e.g. 275/40R17)

14. Running Clearance – measured in centimeters; defined per 49 CFR 523.2

15. Front Axle Clearance - measured in centimeters; defined per 49 CFR 523.2

16. Rear Axle Clearance - measured in centimeters; defined per 49 CFR 523.2

17. Approach Angle – measured in degrees; defined per 49 CFR 523.2

18. Breakover Angle - measured in degrees; defined per 49 CFR 523.2

19. Departure Angle - measured in degrees; defined per 49 CFR 523.2

20. Curb Weight – total weight of vehicle including batteries, lubricants, and other expendable supplies but excluding the driver, passengers, and other payloads, measured in pounds; per SAE J1100 (Sept. 2005)

21. Test Weight – weight of vehicle as tested, including the driver, operator (if necessary), and all instrumentation (as per SAE J1263); measured in pounds

22. GVWR – Gross Vehicle Weight Rating; as defined per 49 CFR 523.2 measured in pounds

23. Towing Capacity (Maximum) – measured in pounds

24. Payload – measured in pounds

25. Cargo volume behind the front row – measured in cubic feet, defined per Table 28 of SAE J1100 (Sept. 2005)

26. Cargo volume behind the second row – measured in cubic feet, defined per Table 28 of SAE J1100 (Sept. 2005)

27. Cargo volume behind the third row – measured in cubic feet, defined per Table 28 of SAE J1100 (Sept. 2005)

28. Enclosed Volume – measured in cubic feet

29. Passenger Volume – measured in cubic feet; the volume measured using SAE J1100 as per EPA Fuel Economy regulations (40 CFR 600.315-82, “Classes of Comparable Automobiles”). This is the number that manufacturers calculate and submit to EPA.

30. Cargo Volume Index – defined per Table 28 of SAE J1100 (Sept. 2005)

31. Luggage Capacity – measured in cubic feet; defined per SAE J1100, V1 (Sept. 2005)

32. Seating (max) – number of usable seat belts before folding and removal of seats (where accomplished without special tools); provided in integer form

33. Number of Standard Rows of Seating – number of rows of seats that each vehicle comes with as standard equipment; provided in integer form (e.g., 1,2,3,4, or 5).

34. Frontal Area – a measure of the wind profile of the vehicle, typically calculated as the height times width of a vehicle body, e.g., 25 square feet.

35. Aerodynamic Drag Coefficient, Cd – a dimensionless coefficient that relates the motion resistance force created by the air drag over the entire surface of a moving vehicle to the force of dynamic air pressure acting only over the vehicle's frontal area, e.g., 0.25.

36. Tire Rolling Resistance, Crr – a dimensionless coefficient that relates the motion resistance force due to tire energy losses (e.g., deflection, scrubbing, slip, and air drag) to a vehicle's weight, e.g., 0.0012. Normalized on (pound force/1000 pound) basis.

37. Fuel Capacity – measured in gallons of diesel fuel or gasoline; MJ (LHV) of other fuels (or chemical battery energy)

38. Electrical System Voltage – measured in volts, e.g., 12 volt, 42 volts

2005)

39. Power Steering – H = hydraulic; E = electric; EH = electro-hydraulic

40. Percent of Production Volume Equipped with air conditioning (A/C)

41. A/C Refrigerant Type – e.g. HFC-134a; HFC-152a; CO2

42. A/C Compressor Displacement – measured in cubic centimeters

43. A/C CARB credit – measured in grams per mile; g/mile CO2 equivalent as reportable under California ARB’s AB 1493 Regulation

44. N2O Emission Rate – measured in grams per mile; as reportable under California ARB’s AB 1493 Regulation

45. CH4 Emission Rate – measured in grams per mile; as reportable under California ARB’s AB 1493 Regulation

46. Estimated Total CARB Credits - measured in grams per mile; g/mile CO2 equivalent as reportable under California ARB’s AB 1493 Regulation

E. Hybridization/Electrification

1. Type of Hybrid/Electric vehicle - classified as MHEV = 12V micro hybrid, BISG = belt mounted integrated starter generator, CISG = crank mounted integrated starter generator, PSHEV = power-split hybrid, 2MHEV = 2-mode hybrid, PHEV = plug-in hybrid, EV = electric vehicle, H = hydraulic hybrid, P = pneumatic hybrid

2. Voltage (volts) or, for hydraulic hybrids, pressure (psi)

3. Energy storage capacity – measured in MJ

4. Electric Motor Power Rating – measured in hp or kW

5. Battery type – classified as NiMH = Nickel Metal Hydride; Li-ion = Lithium Ion

6. Battery Only Range (charge depleting PHEV) – measured in miles

7. Maximum Battery Only Vehicle Speed – measured in miles per hour; maximum speed at which a HEV can still operate solely on battery power measured on a flat road using the vehicle’s FTP weight

8. Percentage of braking energy recovered and stored over weighted FTP + highway drive cycle

9. Percentage of maximum motive power provided by stored energy system

10. Electrified Accessories – list of electrified accessories; classified as WP = water (coolant) pump; OP = oil pump; AC = air conditioner compressor

F. Energy Consumption2 – of total fuel energy (higher heating value) consumed over FTP city and highway tests (each weighted as for items 5 and 6 above), shares attributable to the following loss mechanisms, such that the sum of the shares equals one

1. System irreversibility governed by the Second Law of Thermodynamics

2. Heat lost to the exhaust and coolant streams

3. Engine friction (i.e., the part of mechanical efficiency lost to friction in such engine components as bearings and rods, as could be estimated from engine dynamometer test results)

4. Pumping losses (i.e., the part of mechanical efficiency lost to work done on gases inside the cylinder, as could be estimated from engine dynamometer test results)

5. Accessory losses (i.e., the part of fuel efficiency lost to work done by engine-driven accessories, as could be estimated from bench test results for the individual components)

6. Transmission losses (i.e., the part of driveline efficiency lost to friction in such transmission components as gears, bearings, and hydraulics, as could be estimated from chassis dynamometer test results)

7. Aerodynamic drag of the body, as could be estimated from coast-down test results

8. Rolling resistance in the tires, as could be estimated from coast-down test results

9. Work done on the vehicle itself, as could be estimated from the vehicle’s inertia mass and the fuel economy driving cycles

G. Planning and Assembly

1. U.S. Content – overall percentage, by value, that originated in the U.S.

2. Canadian Content – overall percentage, by value, that originated in Canada

3. Mexican Content – overall percentage, by value, that originated in Mexico

4. Domestic Content - overall percentage, by value, that originated in the U.S, Canada and Mexico

5. Final Assembly City

6. Final Assembly State/Province (if applicable)

7. Final Assembly Country

8. Predecessor – number (or name) of model upon which current model is based, if any

9. Refresh Years – model years of most recent and future refreshes through the 2020 time period; e.g., 2010, 2015, 2020

10. Redesign Years – model years of most recent and future redesigns through the 2020 time period; e.g., 2007, 2012, 2017; where redesign means any change or combination of changes to a vehicle that would change its weight by 50 pounds or more or change its frontal area or aerodynamic drag coefficient by 2 percent or more.

11. Employment Hours Per Vehicle – number of hours of U.S. labor applied per vehicle produced

H. The agency also requests that each manufacturer provide an estimate of its overall passenger car CAFE and light truck CAFE for each model year. This estimate should be included as an entry in the spreadsheets that are submitted to the agency.

4. As applicable, please explain the differences between the product plans submitted in response to the March 2009 product plan request and the product plans being submitted in response to this request.

5. Relative to MY 2008 levels, for MYs 2009-2020 please provide information, by carline and as an average effect on a manufacturer's entire passenger car fleet and by truckline and as an average effect on a manufacturer's entire light truck fleet, on the weight (increases or decreases) and/or fuel economy impacts of the following standards or equipment:

A. Federal Motor Vehicle Safety Standard (FMVSS No. 208) Automatic Restraints

B. FMVSS No. 201 Occupant Protection in Interior Impact

C. Voluntary installation of safety equipment (e.g., antilock brakes)

D. Environmental Protection Agency regulations

E. California Air Resources Board requirements

F. Other applicable motor vehicle regulations affecting fuel economy.

6. For each specific model year and model of respondent’s passenger car and light truck fleets projected to implement one or more of the following and/or any other weight reduction methods:

A. Substitution of materials

B. “Downsizing” of existing vehicle design, dimensions (interior and exterior), footprint, systems or components

C. Use of new vehicle, structural, system or component designs

Please provide the following information:

(i) description of the method, for example:

- For material substitution, substituting a composite body panel for a steel panel;

- For downsizing, reducing front, rear, or side overhang (the dimensions of the vehicle outside the “footprint” area), or reducing track width or wheelbase;

- For use of new vehicle, structural, system or component designs, replacing a body-on-frame structure with a unibody structure, or replacing an existing fuel tank with a smaller fuel tank (i.e., maintaining range).

(ii) the weight reduction, in pounds, averaged over the model;

(iii) the percent fuel economy improvement averaged over the model;

(iv) the basis for your answer to (iii), (e.g., data from dynamometer tests conducted by respondent, engineering analysis, computer simulation, reports of test by others);

(v) the incremental RPE cost (in 2007 dollars), averaged over the model, associated with the method;

(vi) the percent production implementation rate and the reasons limiting the implementation rate

7. For each specific model year and model of respondent’s passenger car and light truck fleets projected to implement one or more of the following and/or any other aerodynamic drag reduction methods:

A. Revised exterior components (e.g., front fascia or side view mirrors)

B. Addition of underbody panels

C. Vehicle design changes (e.g., change in ride height or optimized cooling flow path)

Please provide the following information:

(i) description of the method/aerodynamic change

(ii) the percent reduction of the aerodynamic drag coefficient (Cd) and the Cd prior to the reduction, averaged over the model;

(iii) the percent fuel economy improvement averaged over the model;

(iv) the basis for your answer to (iii), (e.g., data from dynamometer tests conducted by respondent, wind tunnel testing, engineering analysis, computer simulation, reports of test by others);

(v) the incremental RPE cost (in 2007 dollars), averaged over the model, associated with the method;

(vi) the percent production implementation rate and the reasons limiting the implementation rate

8. For each specific model year and model of respondent’s passenger car and light truck fleets projected to implement one or more of the following and/or any other A/C leakage reduction or A/C efficiency improvement methods:

A. Low permeation hoses

B. Improved system fittings, connections and seals (including compressor shaft seal)

C. Externally controlled fixed or variable displacement compressor

D. Automatic default to recirculated cabin air

E. Improved blower and fan motor controls

F. Electronic expansion valve

G. Improved-efficiency evaporators and condensers

H. Oil separator

Please provide the following information:

(i) description of the method, (e.g., implementation of electronic control valve)

(ii) the g/mile CO2 equivalent as reportable under California ARB’s AB 1493 Regulation, averaged over the model;

(iii) the basis for your answer to (ii), (e.g., data from dynamometer tests conducted by respondent, engineering analysis, computer simulation, reports of test by others);

(iv) the incremental RPE cost (in 2007 dollars), averaged over the model, associated with the method;

(v) the percent production implementation rate and the reasons limiting the implementation rate

9. Indicate any MY 2009-2020 passenger car and light truck model types that have higher average test weights than comparable MY 2008 model types. Describe the reasons for any weight increases (e.g., increased option content, less use of premium materials) and provide supporting justification.

10. Please provide your estimates of projected total industry U.S. passenger car sales and light truck sales, separately, for each model year from 2009 through 2020, inclusive.

11. Please provide your company's assumptions for U.S. gasoline and diesel fuel prices during 2009 through 2020.

12. Please provide projected production capacity available for the North American market (at standard production rates) for each of your company's passenger carline and light truckline designations during MYs 2009‑2020.

13. Please provide your estimate of production lead-time for new models, your expected model life in years, and the number of years over which tooling costs are amortized. Additionally, the agency is requesting that manufactures provide vehicle or design changes that characterize a freshening and those changes that characterize a redesign.

IV. Technologies, Cost and Potential Fuel Economy Improvements

Spreadsheet templates for the tables mentioned in the following section can be found at ftp://ftpserver.volpe.dot.gov/pub/cafe/templates/.

The agency requests that manufacturers, for each passenger car and light truck model projected to be manufactured by respondent between MY 2009-2020, provide the following information on new technology, including A/C technologies that will be eligible under EPA’s proposed GHG standards, applications:

(i) description of the nature of the technological improvement; including the vehicle’s baseline technology that the technology replaces (e.g., 6-speed automatic transmission replacing a 4-speed automatic transmission)

(ii) the percent fuel economy improvement or the g/mile CO2 equivalent reduction for A/C technologies, averaged over the model; please indicate if the weight saving (or increase), associated with the implementation of the technology, is accounted for in the fuel economy improvement estimate.

(iii) the basis for your answer to (ii), (e.g., data from dynamometer tests conducted by respondent, engineering analysis, computer simulation, reports of test by others);

(iv) the incremental RPE cost (in 2007 dollars), averaged over the model, associated with implementing the new technology;

(v) the percent production implementation rate and the reasons limiting the implementation rate

In regards to costs, the agency is requesting information on cost reductions available through learning effects that are anticipated, so information should be provided regarding what the learning effects are, when and at what production volumes they occur, and to what degrees such learning is expected to be available.3 The agency is also asking that the RPE markup factor (used to determine the RPE cost estimates) is stated in the response.

Additionally, the agency requests that manufactures and other interested parties provide the same information, as requested above, for the technologies listed in the following tables and any other potential technologies that may be implemented to improve fuel economy. These potential technologies can be inserted into additional rows at the end of each table. Examples of other potential technologies could include but are not limited to: Homogenous Charge Compression Ignition (HCCI), Electric Vehicle (EV), Fuel Cell Vehicle and Belt Mounted Integrated Starter Generator (BISG) and Crank Mounted Integrated Starter Generator (CISG) specific technologies. In an effort to standardize the information received the agency requests that if possible respondents fill in the following tables:

Table IV-1 with estimates of the model year of availability for each technology listed and any other identified technology.

Table IV-2 with estimated phase-in rates4 by year for each technology listed and any other additional technologies. Engineering, planning and financial constraints can prohibit many technologies from being applied across an entire fleet of vehicles within a year, so the agency requests information on possible constraints on the rates at which each technology can penetrate a manufacturer’s fleet.

Tables IV-3a, b and IV-4a, b with estimates for incremental RPE costs (in 2007 dollars) and incremental fuel consumption reductions for each technology listed and any other additional technologies. These estimates, for the technologies already listed, should assume that the preceding technologies, as defined by the decision trees in Appendix B, have already been applied and/or will be superseded. The agency is requesting that respondents fill in incremental RPE costs and fuel consumption reductions estimates for all vehicle subclasses listed. If a respondent feels that the incremental RPE cost and fuel consumption reduction estimates are similar for different subclasses they may combine subclasses.

Table IV-5 with estimates for the percentage by which each technology reduces energy losses attributable to each of nine energy loss mechanisms.

Tables IV-6a, b with estimates for synergies5 that can occur when multiple technologies are applied.

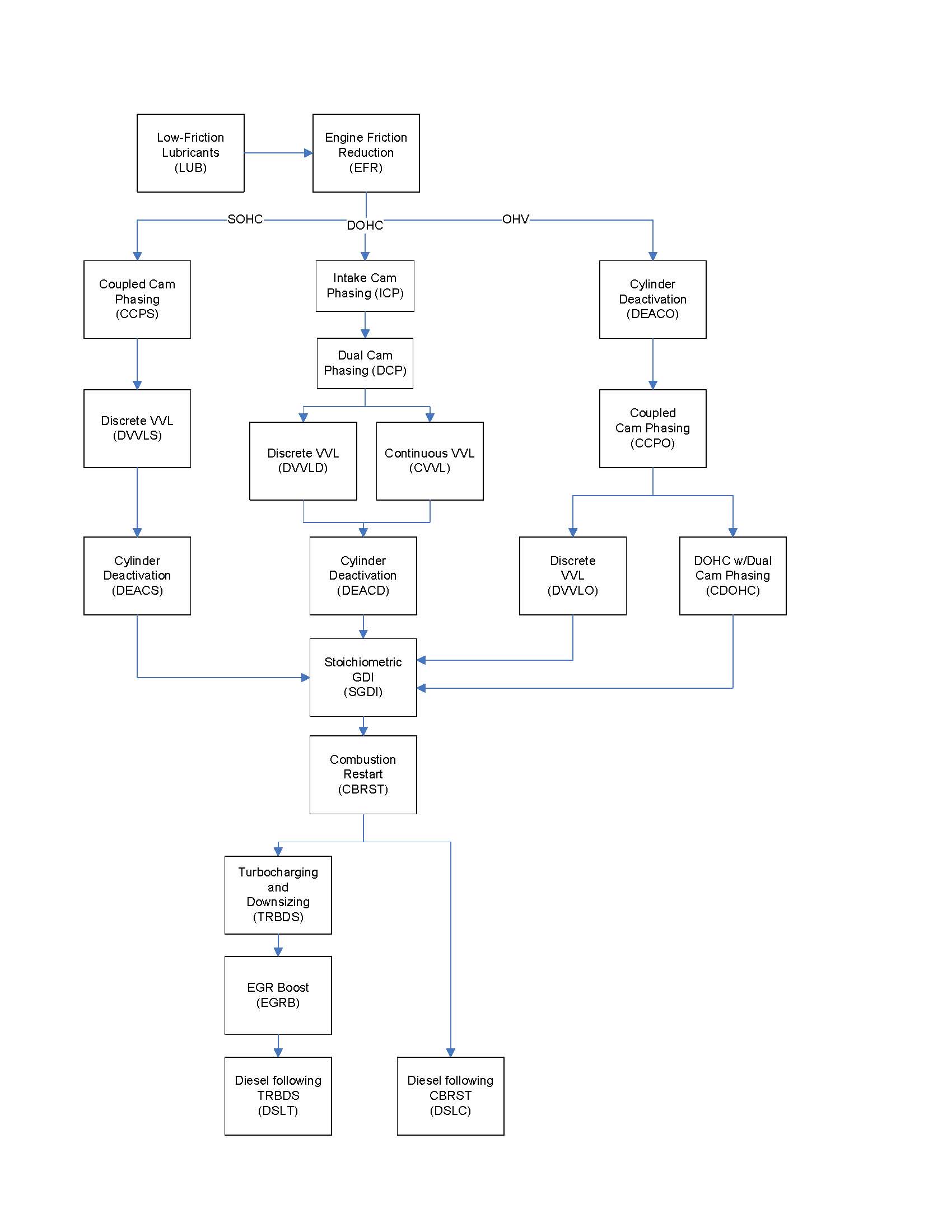

3. The agency also asks that manufacturers or other interested parties provide information on appropriate sequencing of technologies, so that accumulated cost and fuel consumption effects may be evaluated incrementally. As examples of possible technology sequences, “decision trees” are shown in Appendix B below.

4. For each new or redesigned vehicle identified in response to Question III-3 and each new engine or fuel economy improvement identified in your response to Questions IV-1 and IV-2 provide your best estimate of the following, in terms of constant 2007 dollars:

A. Total capital costs required to implement the new/redesigned model or improvement according to the implementation schedules specified in your response. Subdivide the capital costs into tooling, facilities, launch, and engineering costs.

B. The maximum production capacity, expressed in units of capacity per year, associated with the capital expenditure in (a) above. Specify the number of production shifts on which your response is based and define “maximum capacity” as used in your answer.

C. The actual capacity that is planned to be used each year for each new/redesigned model or fuel economy improvement.

D. The increase in variable costs per affected unit, based on the production volume specified in (b) above.

E. The equivalent retail price increase per affected vehicle for each new/redesigned model or improvement. Provide an example describing methodology used to determine the equivalent retail price increase.

Table IV-1: List of Technologies and Year of Availability

Table IV-2: Phase-In Caps

Table IV-3a: Technology Cost Estimates

Table IV-3b: Technology Cost Estimates

Table IV-4a: Technology Effectiveness Estimates

Table IV-4b: Technology Effectiveness Estimates

Table IV-5: Energy Loss Mechanism Estimates

Table IV-6a: Technology Synergy Estimates

Table IV-6b: Technology Synergy Estimates

Appendix B. Technology Decision Trees

Figure 1. Engine Technology Decision Tree

Figure 2. Electrification/Accessory, Transmission and Hybrid Technology

Decision Tree

Figure 3. Vehicle Technology Decision Tree

Paperwork Reduction Act Burden Statement

A federal agency may not conduct or sponsor, and a person is not required to respond to, nor shall a person be subject to a penalty for failure to comply with a collection of information subject to the requirements of the Paperwork Reduction Act unless that collection of information displays a current valid OMB Control Number. The OMB Control Number for this information collection is 2127-0655. Public reporting for this collection of information is estimated to be approximately XX minutes per response, including the time for reviewing instructions, completing and reviewing the collection of information. All responses to this collection of information are required to obtain or retain benefits. Send comments regarding this burden estimate or any other aspect of this collection of information, including suggestions for reducing this burden to: Information Collection Clearance Officer, National Highway Traffic Safety Administration, 1200 New Jersey Ave, S.E., Washington, DC, 20590.

1 NHTSA considers “4-wheel drive” to refer only to vehicles that have selectable 2- and 4-wheel drive options, as opposed to all-wheel drive, which is not driver-selectable.

2 This information is sought in order to account for a given vehicle model’s fuel economy as partitioned into nine energy loss mechanisms. The agency may use this information to estimate the extent to which a given technology reduces losses in each mechanism.

3 “Learning effects” describes the reduction in unit production costs as a function of accumulated production volume and small redesigns that reduce costs. Applying learning effects, or “curves,” requires estimates of three parameters: (1) the initial production volume that must be reached before cost reductions begin to be realized (referred to as “threshold volume”); (2) the percent reduction in average unit cost that results from each successive doubling of cumulative production volume (usually referred to as the “learning rate”); and (3) the initial cost of the technology. The method applies this effect for up to two doublings of production volume. For example, a 20 percent learning effect would be applied once at the 300,000 unit threshold volume and an additional 20 percent learning would be applied at a volume of 600,000, resulting in total reduction cost of 36 percent.

4 In NHTSA’s 2006 rulemaking establishing CAFE standards for MY 2008-2011 light trucks, the agency considered phase-in caps by ceasing to add a given technology to a manufacturer’s fleet in a specific model year once it has increased the corresponding penetration rate by at least the amount of the cap. Having done so, it applied other technologies in lieu of the “capped” technology.

5 When two or more technologies are added to a particular vehicle model to improve its fuel efficiency, the resultant fuel consumption reduction may sometimes be higher or lower than the product of the individual effectiveness values for those items. This may occur because one or more technologies applied to the same vehicle partially address the same source or sources of engine or vehicle losses. Alternately, this effect may be seen when one technology shifts the engine operating points, and therefore increases or reduces the fuel consumption reduction achieved by another technology or set of technologies. The difference between the observed fuel consumption reduction associated with a set of technologies and the product of the individual effectiveness values in that set is sometimes referred to as a “synergy.” Synergies may be positive (increased fuel consumption reduction compared to the product of the individual effects) or negative (decreased fuel consumption reduction).

| File Type | application/msword |

| File Title | DEPARTMENT OF TRANSPORTATION |

| Author | julie.abraham |

| Last Modified By | Walter.Culbreath |

| File Modified | 2009-11-12 |

| File Created | 2009-11-12 |

© 2026 OMB.report | Privacy Policy