Instructions

EO12866_PCWP ICR_2060-AO66 Pre-Proposal Insturctions_20171002.docx

Plywood and Composite Wood Products National Emission Standards for Hazardous Air Pollutants (NESHAP) Residual Risk and Technology Review (RTR) (New Collection)

Instructions

OMB: 2060-0718

***E.O. 12866 Review-Draft-Do Not Cite, Quote, or Release During Review***

OMB Control No. ____-____

Approval Expires __/__/__

EO12866_PCWP ICR_2060-AO66 Pre-Proposal Instructions_20171002

Plywood and Composite Wood Products National Emission Standards for Hazardous Air Pollutants (NESHAP)

Residual Risk and Technology Review (RTR) Survey

Instructions

This survey instruction document provides instructions for completing the PCWP Information Collection Request (ICR). This instruction document is organized as follows:

Table of Contents

A2. Survey Spreadsheets and Scope 3

B. Confidential Business Information (CBI) 6

C. How to Submit Your Survey Response 6

C1. Submitting Your Non-CBI Response 7

D. How to Complete the Survey 9

D2. Facility Emission Point Map 10

D3. Process Data Tabs (PCWP_survey.xlsx) 11

c. Equipment Detail (EquipDetail) tab 20

d. Release Point Detail (ReleasePt) tab 29

e. Permit Limits (Permit) tab 36

f. Resin and Tank (Resin and Tank) tabs 36

g. Dryer (VeneerDry, RotaryDry, TubeDry, ConvDry, LKiln, and DFDryFuel) tabs 37

h. Fiberboard and Hardboard Equipment (FB_HB) tab 39

i. Press and Board Cooler (Press, BC, and EWPPress) tabs 39

j. Other Equipment (OtherEquip) tab 40

k. Control Devices (APCD) tab 41

l. Startup, Shutdown, Malfunction (SSM) tab 44

m. Miscellaneous Coatings (MiscCoat) tab 44

D4. Emissions Data (PCWP_survey.xlsx and PCWP_CEMS.xlsx) 46

a. Emissions Tests (EmTest) tab 46

b. Emissions Estimates (HAP Emissions) tab 49

c. CEMS data (PCWP_CEMS.xlsx) 59

Appendix 1A. Documentation of True Area Source, Non-Operational, or Non-Applicable Status 61

Appendix 1B. Documentation of Synthetic Area Source Status 62

Appendix 2. Process Units to Include in the PCWP Survey Response 63

Appendix 3. Previous Emissions Test Reports Requested 64

Appendix 4. Acronyms and Abbreviations 66

Appendix 5. Checklist of Materials to Submit with Your Survey Response 68

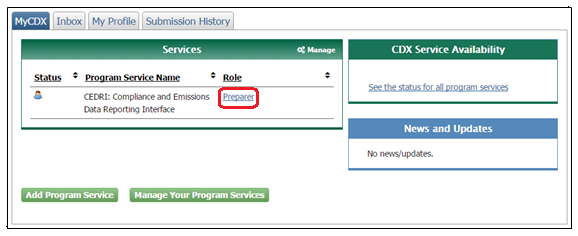

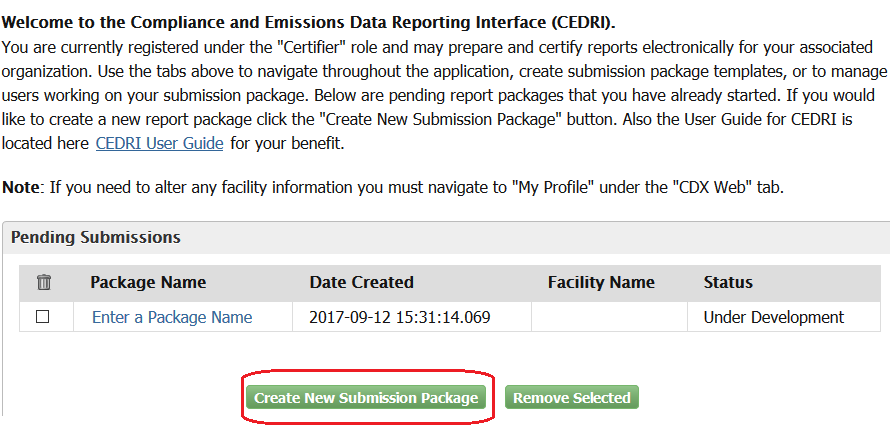

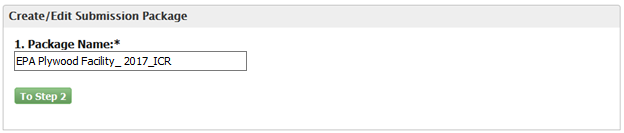

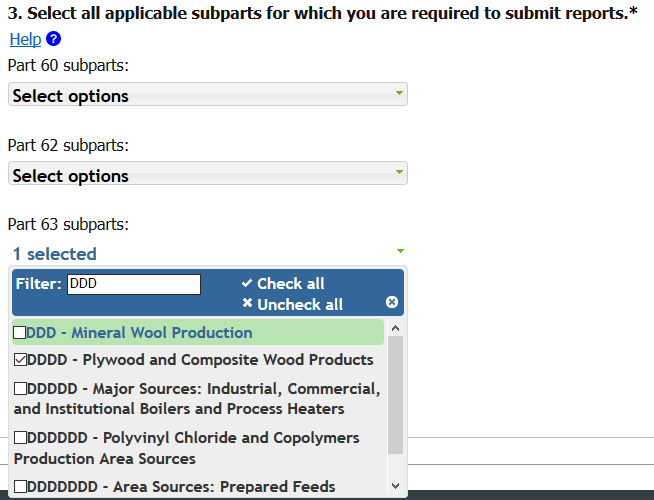

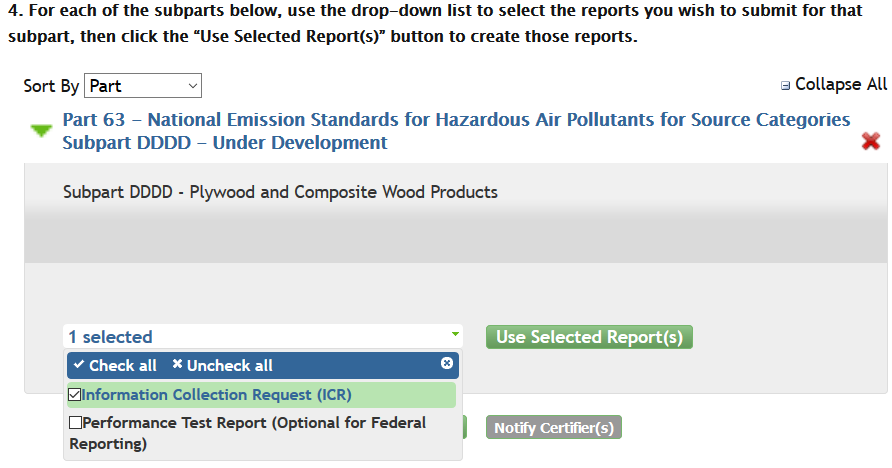

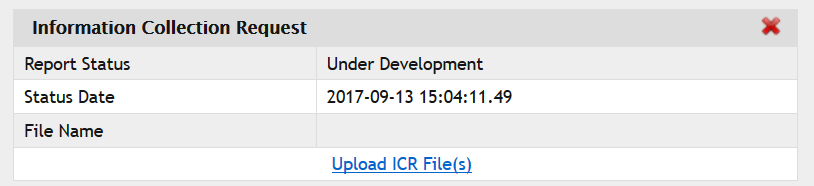

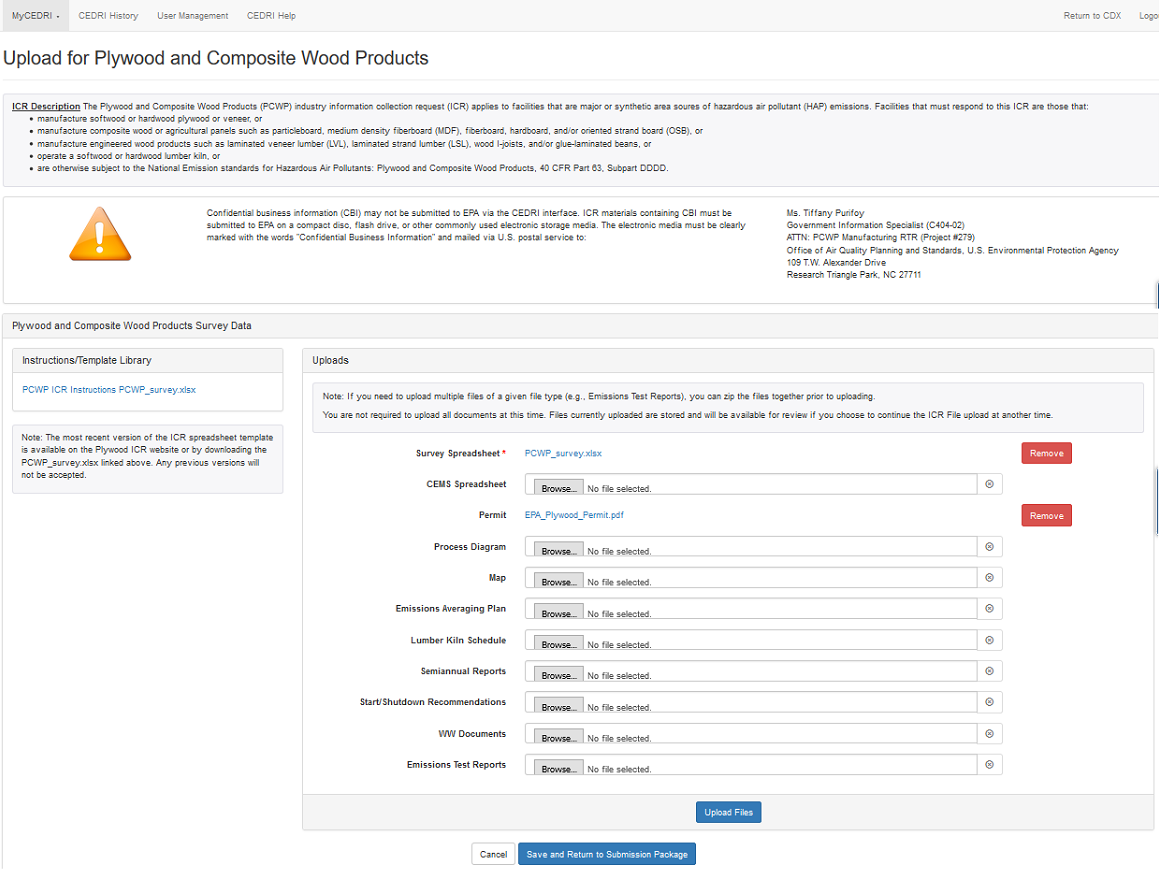

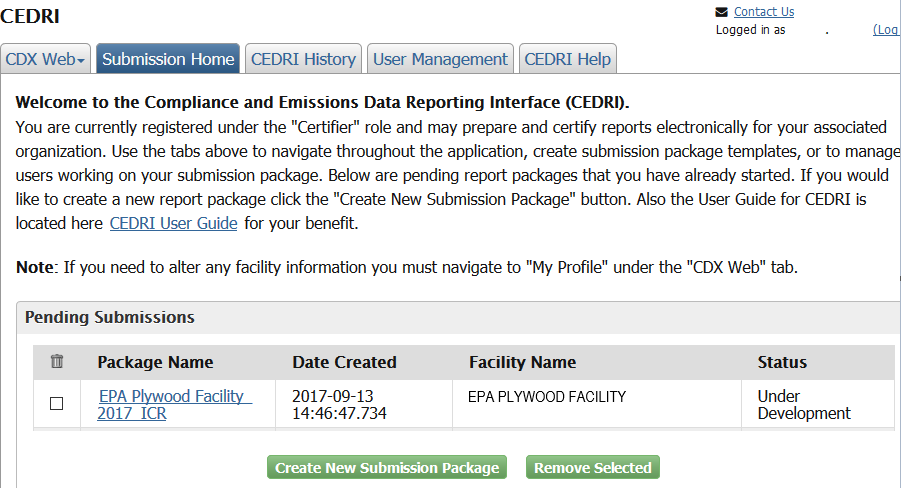

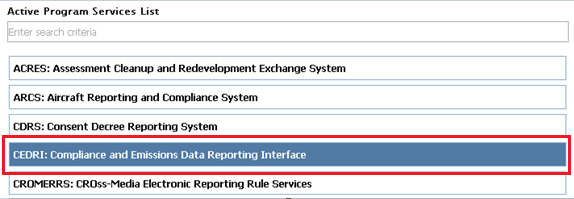

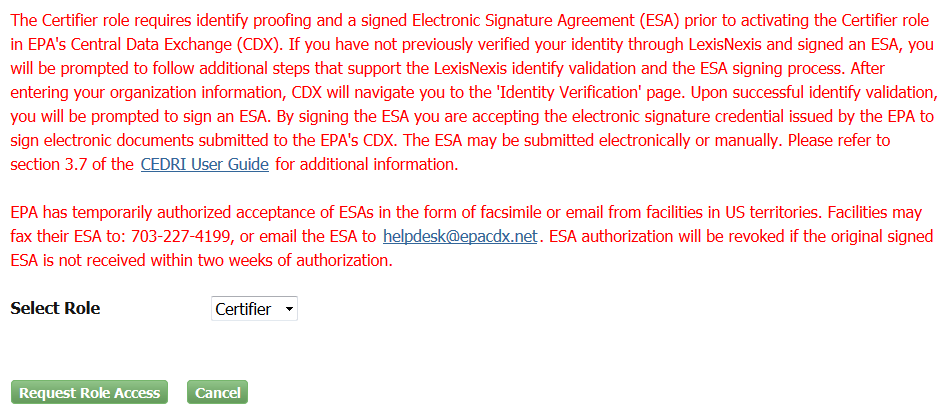

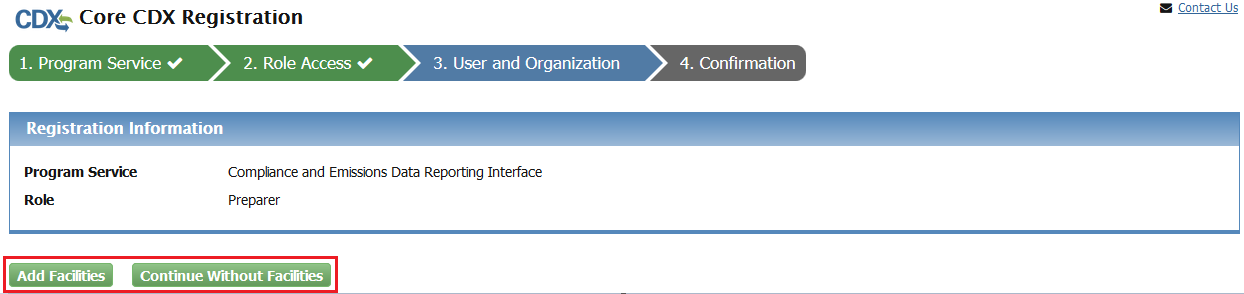

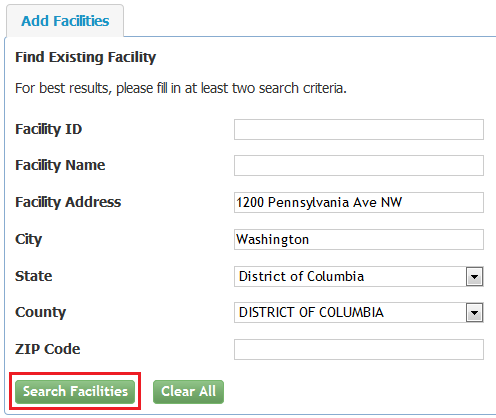

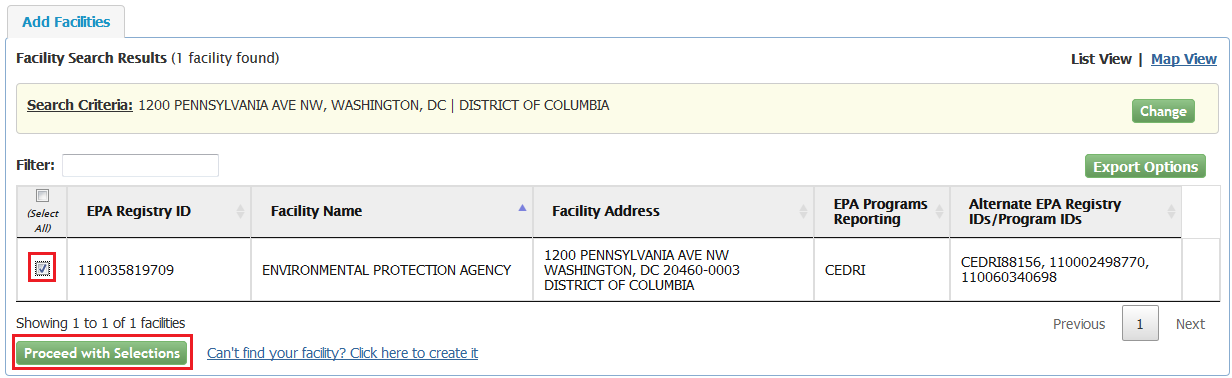

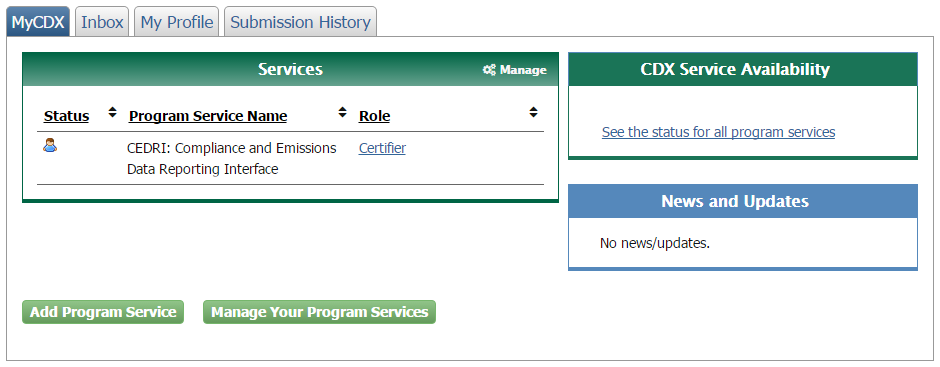

Appendix 6A. CEDRI Upload Instructions 69

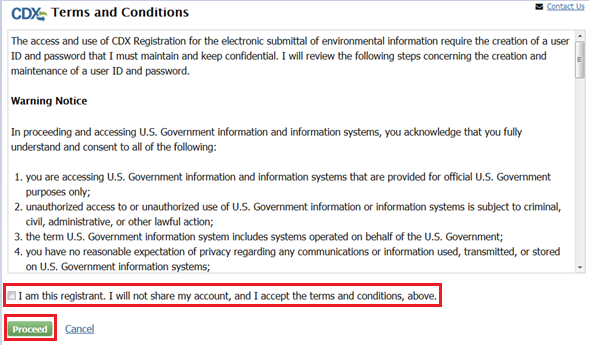

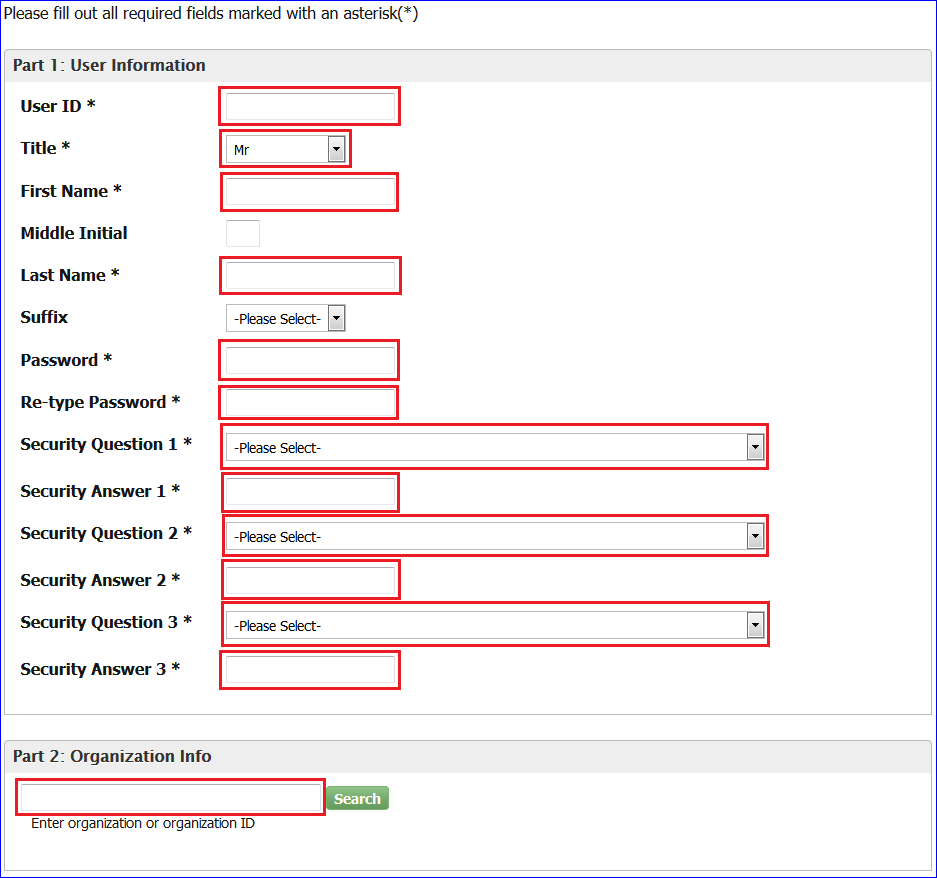

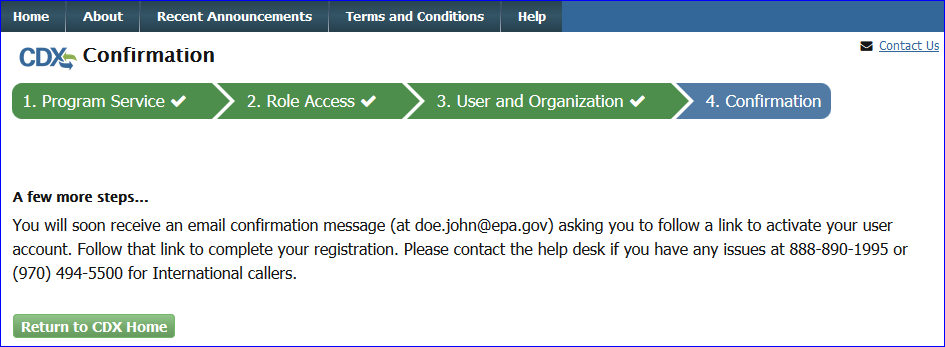

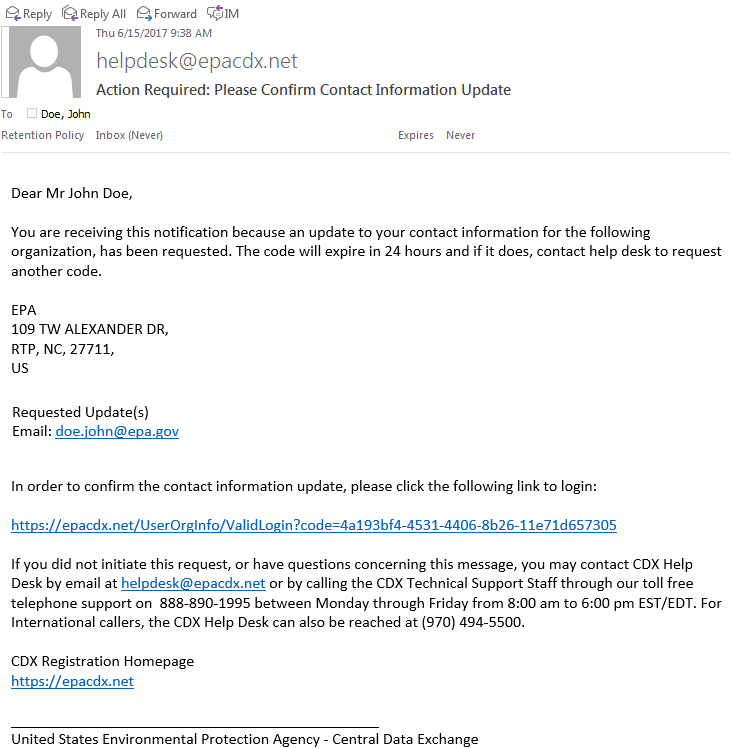

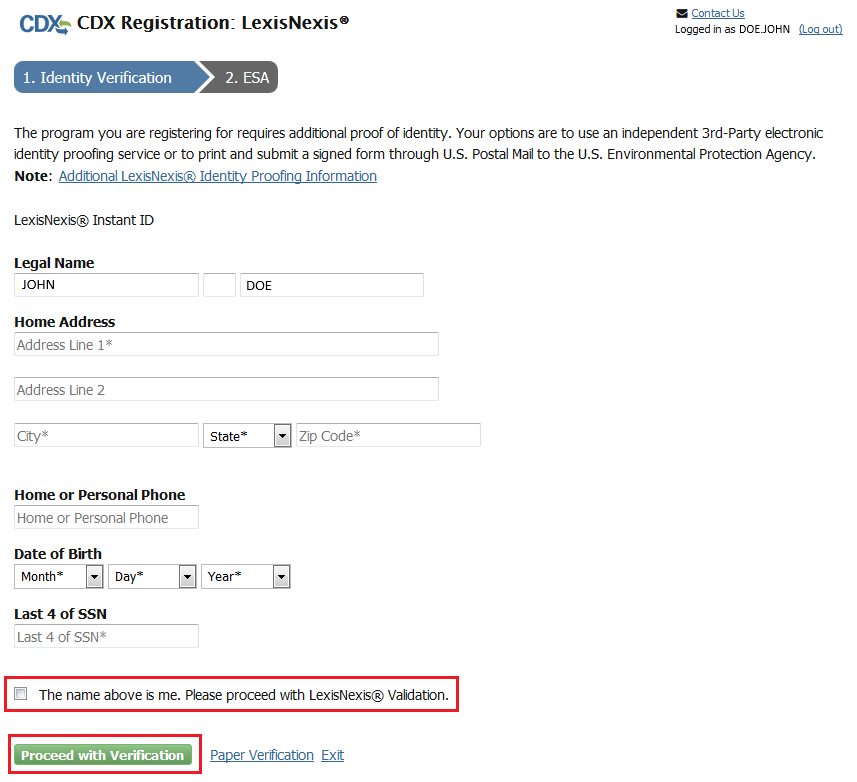

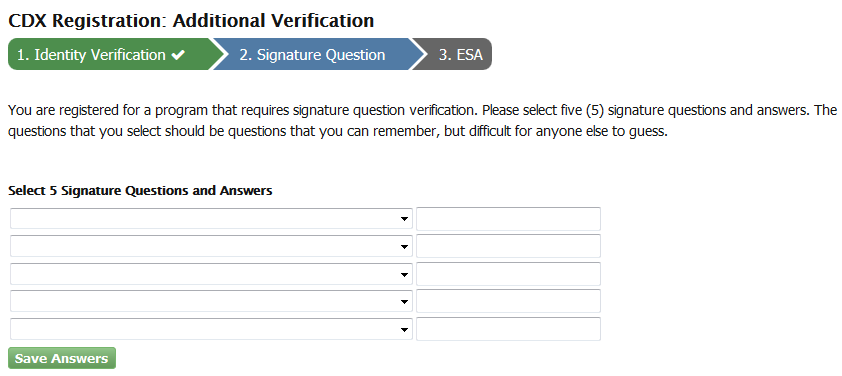

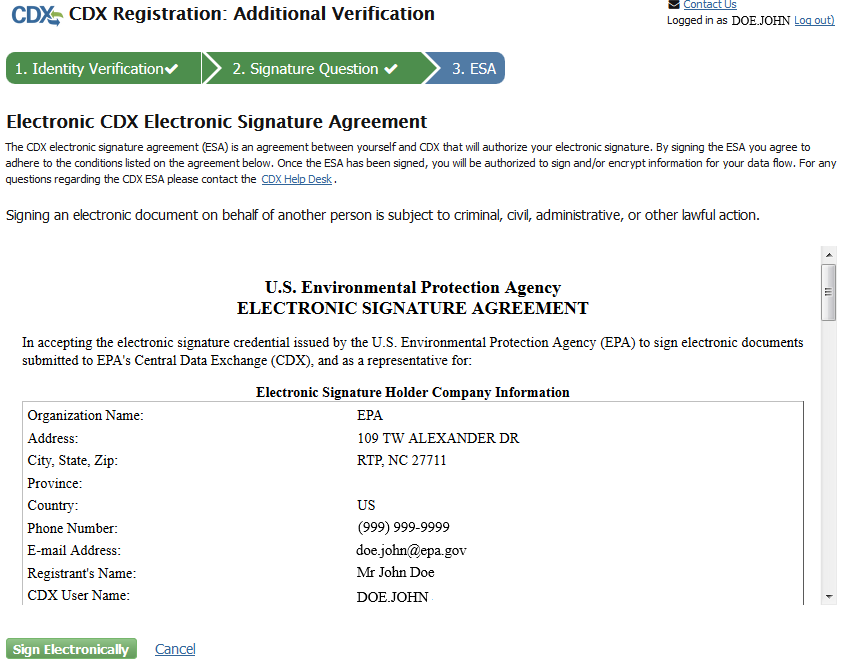

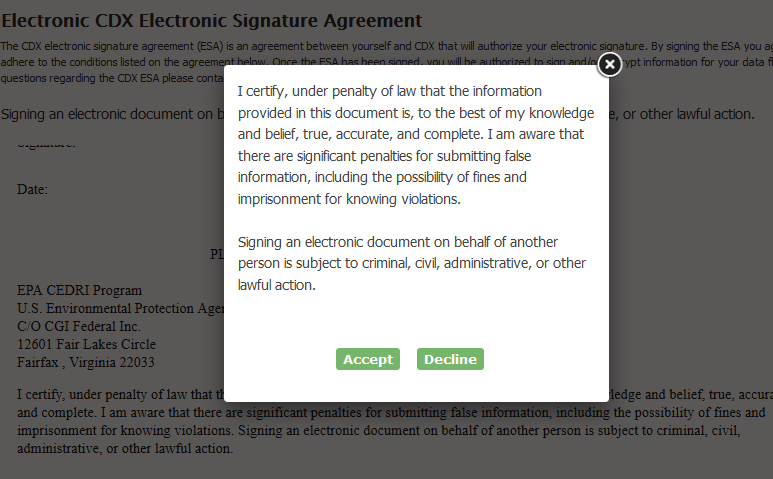

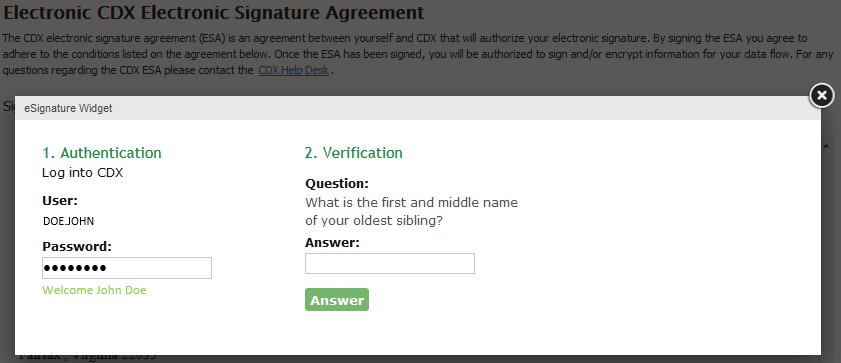

Appendix 6B. Instructions for CEDRI Registration Through CDX 75

Appendix 7. Plywood and Composite Wood Products NESHAP Definitions 91

Appendix 8. Industry Source Classification Code Crosswalk 101

Appendix 9. List of Hazardous Air Pollutants 143

Appendix 10. Resources for Estimating Emissions 147

A. Introduction

A1. Survey Applicability

The Plywood and Composite Wood Products (PCWP) industry information collection request (ICR) is a survey that applies to facilities that are major sources or synthetic area sources of hazardous air pollutant (HAP) emissions that produce PCWP or kiln-dried lumber or are otherwise subject to the National Emission standards for Hazardous Air Pollutants: Plywood and Composite Wood Products, 40 CFR part 63, subpart DDDD (hereafter referred to as the “PCWP NESHAP”).

The following types of facilities must respond to this ICR:

PCWP manufacturing facilities that produce:

Softwood plywood and/or veneer,

Hardwood plywood and/or veneer,

Oriented strandboard (OSB),

Particleboard,

Hardboard,

Fiberboard,

Medium density fiberboard (MDF) or related products such as high density fiberboard (HDF) or thin high density fiberboard (THDF),

Engineered wood products such as laminated veneer lumber (LVL), laminated strand lumber (LSL), parallel strand lumber (PSL), wood I-joists, or glue-laminated beams, or

Kiln-dried lumber

Lumber manufacturing facilities that produce:

Kiln-dried lumber

This survey is limited to sources that are major or synthetic area sources which are described as follows:

“Major source” means any stationary source or group of stationary sources located within a contiguous area and under common control that emits or has the potential to emit considering controls, in the aggregate, 10 tons per year or more of any hazardous air pollutant or 25 tons per year or more of any combination of hazardous air pollutants, unless the Administrator establishes a lesser quantity, or in the case of radionuclides, different criteria from those specified in this sentence.

A “synthetic area source” is a stationary source which is subject to federally-enforceable conditions that limit its potential to emit to below major source thresholds.

Certain facilities are not required to complete the PCWP survey. You received this survey because EPA records indicate the PCWP NESHAP is applicable to your facility or your facility is a synthetic area source. If your mill meets one of the following conditions, then you should complete the exemption form titled “Documentation of True Area Source, Non-Operational, or Non-Applicable Status” in Appendix 1A of this instruction document and email it to the EPA at [email protected]. You are required to complete this survey unless you meet one of the three exemption criteria listed below. Conditions for exemption from the PCWP survey are as follows:

Your facility is not a major source or synthetic area source of HAP emissions, or

Your facility was not operational in 2016, remains closed, and does not have an active operating permit, or

Your facility is not a PCWP manufacturing facility as defined in the PCWP NESHAP at 40 CFR 63.2292. The definition is as follows:

Plywood and composite wood products (PCWP) manufacturing facility means a facility that manufactures plywood and/or composite wood products by bonding wood material (fibers, particles, strands, veneers, etc.) or agricultural fiber, generally with resin under heat and pressure, to form a panel, engineered wood product, or other product defined in §63.2292. Plywood and composite wood products manufacturing facilities also include facilities that manufacture dry veneer and lumber kilns located at any facility. Plywood and composite wood products include, but are not limited to, plywood, veneer, particleboard, molded particleboard, oriented strandboard, hardboard, fiberboard, medium density fiberboard, laminated strand lumber, laminated veneer lumber, wood I-joists, kiln-dried lumber, and glue-laminated beams.

Completion of the survey is not required if your facility was not operational in 2016 and remains closed but still has an active operating permit. Closed facilities that maintain an active operating permit will be included in the EPA’s residual risk modeling based on the emissions allowed under their operating permit. Such facilities are asked in Appendix 1A to provide a copy of their active operating permit for the EPA to use in developing emission estimates for input into the risk model.

If your facility is a synthetic area source that is not subject to the PCWP NESHAP,1 then you should complete the form titled “Documentation of Synthetic Area Source Status” in Appendix 1B of this instruction document and email it to EPA at [email protected]. As noted in Appendix 1B, you are also asked to submit a valid operating permit and, if applicable, any stack test report(s) for air emissions testing used to verify HAP emissions qualify for synthetic area source status. Facilities eligible for completion of the form in Appendix 1B are not required to complete the full survey.

Who do I contact with questions about the ICR? If you have

questions, contact the EPA’s PCWP ICR Helpdesk at

[email protected] or by calling

866-522-7297 (toll free) from 8:00 to 5:00 Monday through Friday

eastern standard time. In order for us to better assist you, we ask

that you provide your ICR ID in any communications.

A2. Survey Spreadsheets and Scope

This survey is to be completed in Microsoft Excel© spreadsheet format that is divided into worksheets or “tabs” within the spreadsheet. Facilities submitting the forms in Appendix 1A or Appendix 1B are not required to complete the survey spreadsheet. There are two spreadsheets to be completed: (1) PCWP_survey.xlsx (hereafter also referred to as the “ICR survey spreadsheet”) for all major source facilities, and (2) PCWP_CEMS.xlsx for all major source facilities operating continuous emissions monitors. Blank copies of the survey spreadsheets can be downloaded from:

You must complete the worksheets that are relevant to the type facility you operate. Table 1 below denotes which worksheets to complete depending on the products you manufacture. A separate column denotes which worksheets are required for facilities that manufacture PCWP versus lumber facilities that do not otherwise produce PCWP. Lumber facilities that do not produce other PCWP only need to provide information for lumber kilns.

Table 1. Survey Worksheets (“tabs”) to Complete

Tab full name |

Tab abbreviation |

What types of PCWP facilities complete this tab? |

Do lumber facilities with kilns complete this tab? |

PCWP_survey.xlsx |

|||

Mill |

Mill |

All PCWP facilities |

Yes |

Products |

Prod |

All PCWP facilities |

Yes |

Equipment Detail |

EquipDetail |

All PCWP facilities |

Yes, for lumber kilns only |

Release Point Detail |

ReleasePt |

All PCWP facilities |

Yes, for lumber kilns only |

Permit |

Permit |

All PCWP facilities |

Yes, for lumber kilns only |

Resins |

Resin |

All PCWP facilities applying adhesive. Veneer-only facilities do not need to complete this tab. |

|

Tanks |

Tank |

All PCWP facilities applying resin. Veneer-only facilities do not need to complete this tab. |

|

Veneer Dryer |

VeneerDry |

Plywood, veneer and LVL mills that operate veneer dryers |

|

Rotary Dryer |

RotaryDry |

Particleboard, OSB and any other PCWP facility using a rotary dryer |

|

Tube Dryer |

TubeDry |

MDF, hardboard and any other PCWP facility using a tube dryer |

|

Conveyor Dryer |

ConDry |

OSB, LSL, and any other PCWP facility using a conveyor dryer |

|

Fiberboard-Hardboard Units |

FB_HB |

Fiberboard and hardboard mills |

|

Lumber Kilns |

LKiln |

PCWP facilities with lumber kilns |

Yes, for lumber kilns only |

Direct Fired Dryer Fuel |

DFDryFuel |

Any PCWP facility with a direct-fired dryer or lumber kiln |

Yes, for direct-fired lumber kilns only |

Press |

Press |

Any PCWP facility that uses a hot press |

|

Board Coolers |

BC |

Particleboard, MDF and any other PCWP facility using a board cooler |

|

Engineered Wood Press |

EWPPress |

LVL, LSL, PSL, glulam, I-joist or any other PCWP facility using an engineered wood press |

|

Other Equipment |

OtherEquip |

PCWP facilities with digesters, refiners, blenders, formers, sanders, saws, panel trim chippers, or log vats. |

|

Control Devices |

APCD |

Any PCWP facility with pollution control equipment |

Yes, for lumber kiln control devices only (if applicable) |

Startup, Shutdown & Malfunction |

SSM |

Any PCWP facility for which an SSM plan was developed under the PCWP NESHAP |

|

Miscellaneous Coatings |

MiscCoat |

All PCWP facilities applying a coating, including miscellaneous coating as defined in the PCWP NESHAP |

|

Wastewater |

WW |

Any PCWP facility that treats wastewater generated at the plant |

|

Emission Tests |

EmTest |

All PCWP facilities |

Yes, for lumber kilns only |

HAP Emissions |

HAP Emissions |

All PCWP facilities |

Yes, for lumber kilns only |

Certification |

Certification |

All PCWP facilities |

Yes |

PCWP_CEMS.xlsx |

|||

CEMS data |

CEMS, CEMS3hr, or CEMS24hr |

Facilities operating CEMS measuring THC, PM, CO or HAP on process units listed in Appendix 2 to this document |

|

This survey asks questions about the process units listed in Appendix 2 of this document. Section D of this document, How to Complete the Survey, explains how to treat various configurations of process units (e.g., multiple process units venting to the same pollution control device stack). Appendix 3 of this survey contains a table of pollutants for which stack test reports from previously conducted emissions test measurements are requested. Appendix 4 provides a list of acronyms and abbreviations used throughout this instruction document and the survey spreadsheets.

Please complete the survey for the facility listed in the CAA section 114 letter you received in the mail. If you received more than one CAA section 114 letter for multiple facilities in your company, you must create a separate survey response for each facility. Your survey response for each facility will be comprised of the survey spreadsheet(s) and other documentation requested throughout these instructions. Appendix 5 contains a checklist of materials to be provided with your response.

Only one ICR survey spreadsheet may be used for each facility with a unique Federal Registry System (FRS) identification number (ID). If your manufacturing site has collocated facilities producing multiple PCWP (e.g., your site produces both particleboard and softwood plywood but has one FRS ID) you should submit one ICR survey spreadsheet containing both facilities. Alternatively, if each of the PCWP category facilities at the manufacturing site operates under its own title V permit or has its own FRS ID, you should submit one ICR survey spreadsheet per title V-permitted facility. Relevant IDs for your facility, including the 12-digit FRS ID used in EPA systems and the shorter ICR ID assigned specifically for this PCWP project, are included in the letter your facility received to request completion of this survey. If the EPA assigned only one ICR ID to a facility that instead should be entered as two separate facilities, contact the EPA’s PCWP ICR Helpdesk (see section A1) for assistance in assigning ICR IDs for your facilities. The EPA’s PCWP project team will rely most heavily on the ICR ID for linkages between tables in the PCWP data base developed from ICR responses.

Use the 2016 calendar year as the base year for all survey responses (e.g., 2016 capacity, 2016 equipment configurations, 2016 HAP emissions inventory, etc.), except where other years are specified in the instructions (e.g., for submittal of previously-conducted emissions test data).

Note: If 2016 is not a representative year because the facility recently submitted a permit application or received a permit for equipment modifications that impact emissions, then you may provide post-project projections of your operations instead of 2016 information. Please note in the “comments” columns in the appropriate tabs throughout the survey that you are providing projected information. Alternatively, if your project is not far enough along to be included in your ICR response, it is acceptable to provide 2016 information and use the “comments” columns to note planned configuration changes that impact emissions. Regardless of the base year you choose, the equipment information, emissions release parameters, and emission estimates provided throughout the ICR response must be consistent.

Note that the information submitted by a facility is not a compliance assessment. If actual data are not available, the facility should provide the best engineering estimates where appropriate. In addition, it is not the intent of the EPA to use this data to confirm data/information submitted in the facility’s Toxic Release Inventory (TRI) or other regulatory required reports. It is understood that data submitted in this survey could vary due to the nature of the questions.

B. Confidential Business Information (CBI)

The EPA’s procedures for handling confidential business information (CBI) are described in the letter (and attachments) accompanying the ICR. If you believe that providing any specific information to us would reveal a trade secret, please identify this information clearly in your spreadsheet response by shading the worksheet cell containing the CBI with red highlight and indicating in the red block at the top of each worksheet that the tab contains information you believe is CBI. (You will find the red highlighting and red CBI block at the top of the worksheet helpful when you separate your claimed CBI data from non-CBI data for submittal as indicated in Section C2 below). Also, please clearly label any flow diagrams or other attachments submitted with your survey that contain claimed CBI. However, please do not label your entire response as CBI. Only label as CBI the portions of your survey response that include information you believe contains trade secrets. The EPA is likely to follow up with a request for validation of CBI claims for facilities claiming large amounts of information as trade secrets, especially information that is reported by other facilities without such claims or that is otherwise publicly available. The following information is generally not regarded by the EPA as CBI:

General contact information. This information is requested in the Mill tab of the ICR survey spreadsheet.

Emission tests and emission data.

Continuous emissions monitoring data (although the accompanying production data may be claimed as CBI).

C. How to Submit Your Survey Response

If your response to this ICR includes data with a claim of CBI, you should follow the instructions in this section to ensure the protection of your data. Please note that if you submit claimed CBI, you will be separating your data into two portions and sending your data to the EPA using two different procedures.

When is my ICR Response Due? Your non-CBI and

CBI responses are due by the date specified in the letter you

received requesting completion of the ICR.

C1. Submitting Your Non-CBI Response

Follow these instructions for the non-CBI portions of your survey response (or for complete responses that are entirely non-CBI.)

After you have completed and reviewed your survey response, sign and date the certification tab in the ICR survey spreadsheet. Remove the claimed CBI components2 from your ICR survey spreadsheet and your CEMS spreadsheet (if applicable) as instructed in Section C2, leaving only the red shading and replacing the claimed CBI data with the letters “CBI.” Assemble the Excel® spreadsheet(s) containing the non-CBI portions of your completed response, non-CBI flow diagrams, emission test reports, and any other electronic non-CBI attachments. Assemble any non-CBI hard copy attachments to your survey (such as flow diagrams, test data, air emissions modeling reports, etc.). Electronic copies of attachments are preferred in lieu of hard copies. A checklist of materials to be provided with your response is included in Appendix 5.

CEDRI Upload (Preferred): Upload your non-CBI materials into the EPA’s Compliance and Emissions Data Reporting Interface (CEDRI) following the instructions in Appendix 6. Do not upload CBI into CEDRI. All CBI must be mailed separately to Ms. Purifoy as explained in Section C2.

Optional Disk Mail-in: If you would prefer to mail your ICR response to the EPA instead of using CEDRI, please save the non-CBI portions of your response on a disk (CD or DVD) or flash drive. Please clearly label and mail the non-CBI disk (or flash drive) and any non-CBI hard copy materials in one envelope postmarked to the EPA at the address specified below. (Note: If the spreadsheet, diagrams, or attachments contain claimed CBI, use the address for Ms. Purifoy provided in Section C2 of this document.)

U.S. Environmental Protection Agency

Office of Air Quality Planning and Standards

U.S. EPA Mailroom (E143-03)

Attn: John Bradfield

109 T.W. Alexander Drive

Research Triangle Park, NC 27711

The EPA recommends sending your non-CBI files via Registered U.S. Mail with a return receipt requested, Federal Express, or any other method for which a receipt signature is required.

C2. Submitting Claimed CBI

Follow these instructions for any portion of your survey response that contains claimed CBI. The deadline for submittal of the CBI portion of your response is the same as the deadline for the non-CBI submittal.

Please create two separate versions of your spreadsheet response. Retain the red highlighted CBI data in the ICR survey spreadsheet as shown in Example 1 below for the confidential copy of your spreadsheet. Create a separate non-CBI version of your response by redacting the confidential data in the red shaded cells and entering “CBI” instead. This non-CBI version should appear as Example 2 and be submitted to the address in Section C1 above. (Follow a similar procedure for your CEMS spreadsheet if you are claiming the production data as CBI.)

Example 1: Example showing CBI portion of ICR survey spreadsheet response:

Example 2: Example showing non-CBI ICR survey spreadsheet response after removal of CBI:

Please create and label a separate flash drive or disk containing the claimed CBI portion of your data. Include on the CBI disk the confidential version of your spreadsheet(s). You should also include any flow diagrams or pages of other attachments to your survey response containing claimed CBI, with the claimed CBI portions of the diagrams/pages clearly marked (e.g., highlighted or circled). Clearly mark the confidential disk with the words “Confidential Business Information” and send only these claimed CBI files, separately from the non-CBI data, to one of the two addresses below.

For the security of your data, the EPA recommends sending your confidential files to Ms. Purifoy via Registered U.S. Mail with a return receipt requested, Federal Express, or any other method for which a receipt signature is required.

Please use the address below for CBI sent via U.S. postal service:

Ms. Tiffany Purifoy

Government Information Specialist (C404-02)

ATTN: PCWP Manufacturing RTR (Project #279)

Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency

109 T.W. Alexander Drive

Research Triangle Park, NC 27711

Please use the address below for CBI sent via commercial package carriers, such as FedEx and UPS:

Ms. Tiffany Purifoy

Government Information Specialist (C404-02)

ATTN: PCWP Manufacturing RTR (Project #279)

Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency

4930 Old Page Rd.

Research Triangle Park, NC 27709

DO NOT ELECTRONICALLY TRANSMIT CLAIMED CONFIDENTIAL BUSINESS INFORMATION TO THE EPA. E-mail and facsimile are not secure forms of communication and should never be used to transmit claimed CBI. Similarly, do not upload CBI into CEDRI.

D. How to Complete the Survey

As noted previously, your survey response will consist of completed Microsoft© Excel® spreadsheets (PCWP_survey.xlsx and PCWP_CEMS.xlsx), flow diagrams, test reports, and other materials. A checklist of materials to be provided with your response is included in Appendix 5.

You must complete certain tabs of the ICR survey spreadsheet (PCWP_survey.xls) depending on the type of facility you operate as shown in Table 1 above. The instructions in Sections D3a through D4b below will guide you through completion of the ICR survey spreadsheet.

Complete the PCWP_CEMS.xlsx spreadsheet following the instructions in Section D4c if you have continuous emissions monitoring data to submit.

The spreadsheets will be used by the EPA to construct a nationwide data base of responses from all PCWP facilities. The spreadsheets have been designed and locked with features to reduce data entry time and ensure the data are provided in the most consistent and quality-assured manner possible. The beginning of Section D3 describes key features of the spreadsheets.

D1. Flow Diagrams

Please provide a process flow diagram (or diagrams) showing the equipment listed in Appendix 2.

Readily available block flow diagrams (e.g., such as those used for permit applications) will suffice. Electronic or hard copies are acceptable. You need not prepare any new flow diagrams unless you currently do not have diagrams that adequately represent your facility. It is acceptable to hand-mark changes on an older diagram that may no longer be completely reflective of current operations.

How detailed must my diagram(s) be? The EPA will use

the diagram(s) to aid in understanding the general facility flow and

any unique characteristics in the facility layout. It is not

necessary to show every single vent of every process unit on the

diagrams. However, the diagram should provide enough information so

it is clear how emissions are collected and controlled.

D2. Facility Emission Point Map

The EPA is requesting that each facility provide a facility emission point map. This map should be an aerial view of the facility and at a minimum, should clearly indicate the Emission Release Point ID and location of each emission point expected to emit HAP from process units listed in Appendix 2. The locations of the emission points provided in the map should correspond with the coordinates (longitude and latitude) for the Emission Release Point IDs required to be provided in the Release Point (ReleasePt) tab described in Section D3d. These coordinates are used for residual risk modeling; specifying coordinates for each Emission Release Point ID improves the accuracy of the risk modeling. Creating the emission point map assures that the coordinates provided are correctly positioned on the facility property.

Although optional, it would also be helpful if the facility fence-line (property boundary) is indicated on the map. If you choose to do so, you may also indicate the length and width parameters for fugitive area and volume sources (i.e., draw a rectangle on the map that corresponds to the lengths and widths described in Section D3d of these instructions). The EPA will use the release point map to answer any questions that arise from the risk modeling. Having a map showing the emission points and property boundary will usually allow the EPA to resolve questions about the location of emission releases or nearby human receptors without having to contact your facility to ask questions.

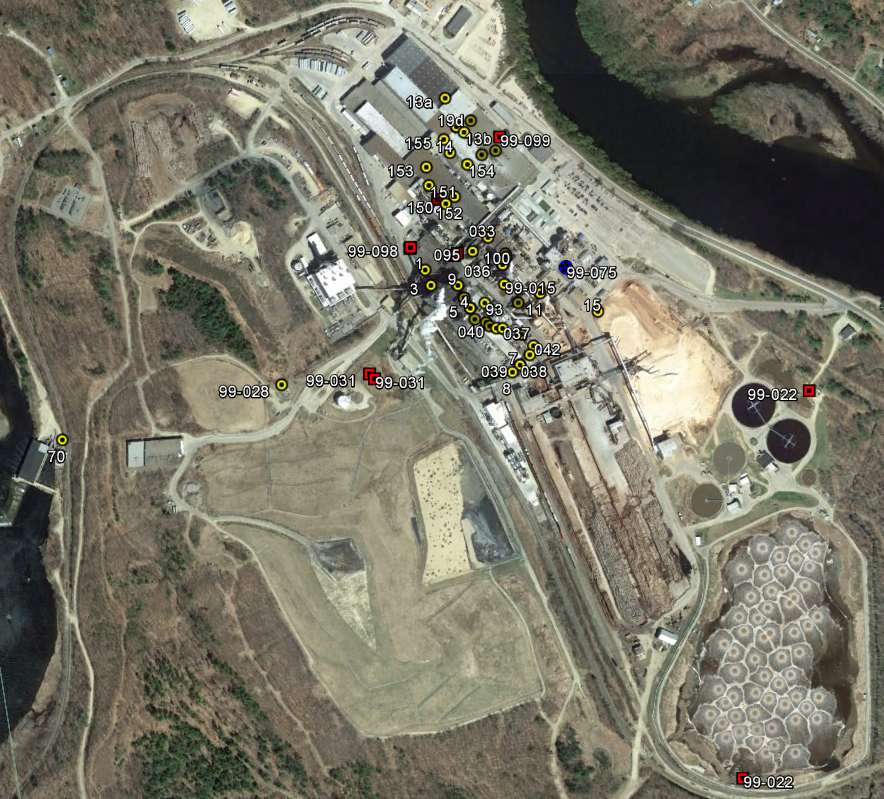

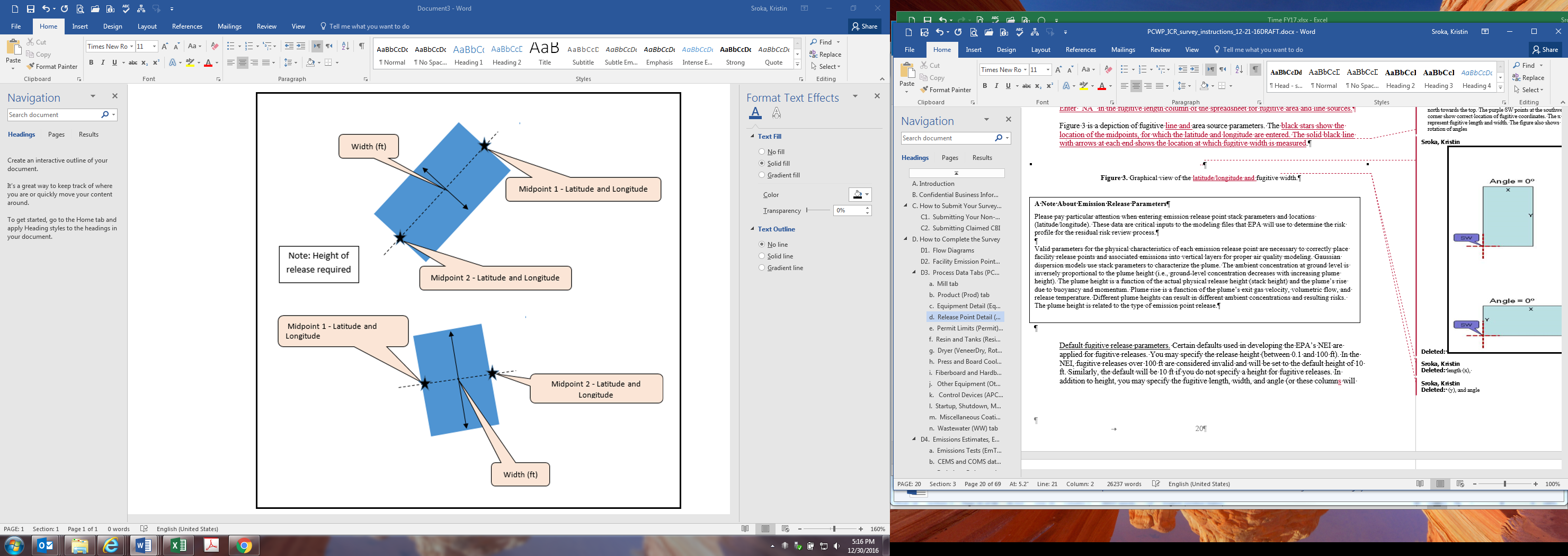

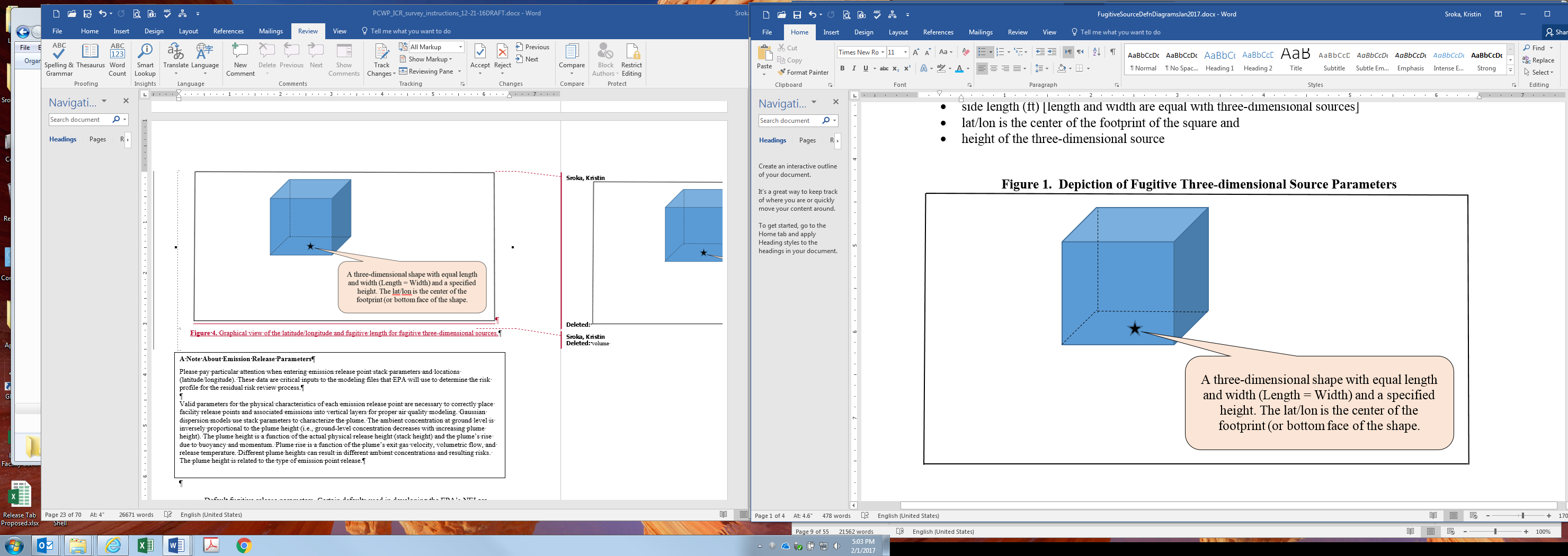

See Figure 1 for an example of a facility emission point map without the optional features of the facility fence-line and length and width parameters. The numbers shown in Figure 1 are the Emission Release Point IDs. The yellow circles denote point sources, the red squares denote the midpoint coordinates for fugitive two-dimensional sources, and the blue stars denote the center of a fugitive three-dimensional source.

Figure 1: Example facility emission point map

D3. Process Data Tabs (PCWP_survey.xlsx)

In this portion of the survey, you are asked to add data to the various tabs in the ICR survey spreadsheet (Mill, Prod, etc.). Many of the instructions you need for completing the tabs are included in the “Instruction” row of each tab in the ICR survey spreadsheet. Additional information is provided in this document to account for common situations and to provide information on how the data will be used by the EPA.

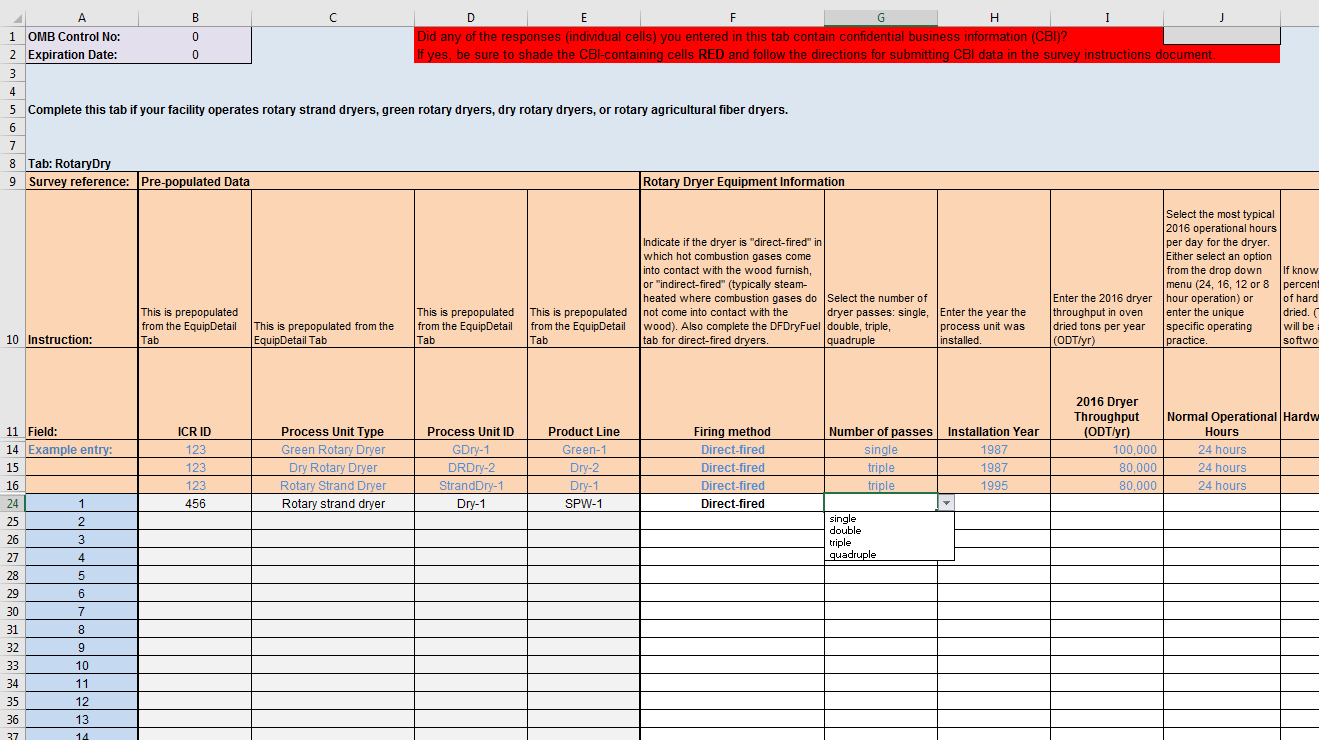

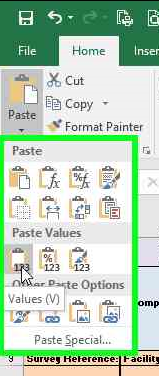

You will enter data into the white (unshaded) cells. Gray shaded columns are prepopulated based on inputs from previous tabs. Information in these gray columns will update automatically as you work. The spreadsheet contains drop-down menus for common entries. The drop-down menus are indicated by the triangle that appears next to the cell when clicked.3 Figure 2 provides a screen shot with annotations illustrating the spreadsheet format. Cells where data entry is not permitted are locked to prevent inclusion of data outside of the area that will be incorporated into the EPA’s data base of responses.

Figure 2: Screenshot of survey shading

Tab completion order. Refer to Table 1 in Section A2 to determine which of the PCWP Process tabs you will need to fill out for your facility. The tabs are organized by process unit type.4 If your facility does not operate a process covered by the tab, ignore that tab.

It is very important that you work through the ICR survey spreadsheet tabs moving from left to right, beginning with the Mill tab because many tabs will contain prepopulated data from other tabs previously completed. A few columns of data that you supply include notations in bold in the spreadsheet “Instruction” row to indicate that these columns contain data that will be used to prepopulate other tabs of the ICR survey spreadsheet.

As you work through the ICR survey spreadsheet, you may realize that you do not have the information in front of you that you need to answer certain detailed questions. The general instruction to work through the spreadsheet from left to right does not necessarily mean that you must answer every question on a tab before you may move forward. However, there are certain fields that should be completed at a minimum to ensure that the data prepopulate correctly throughout the spreadsheet. The left side of Table 2 shows the fields carried forward from each tab that must be completed before moving on to the tabs listed on the right side of Table 2.

Table 2. Completion Order for ICR survey spreadsheet

Complete… |

|

Before you complete… |

Tab Name |

Field Carried Forward to Other Tabs |

Tab Name |

Mill |

|

All |

Prod |

|

EquipDetail, Resin, Tank, BC, EWPPress, APCD, MiscCoat, EmTest |

|

|

EquipDetail, Resin, Tank, VeneerDry, RotaryDry, TubeDry, ConvDry, Press, EmTest |

|

|

Resin |

EquipDetail |

|

ReleasePt, Permit, Tank, VeneerDry, RotaryDry, TubeDry, ConvDry, FB_HB, LKiln, DFDryFuel, Press, BC, EWPPress, OtherEquip, SSM, EmTest, HAP Emissions |

|

|

ReleasePt, Permit, VeneerDry, RotaryDry, TubeDry, ConvDry, FB_HB, DFDryFuel, Press, OtherEquip, APCD, SSM, EmTest, HAP Emissions |

|

|

OtherEquip |

|

|

APCD |

|

|

APCD, HAP Emissions |

|

|

ReleasePt, EmTest, HAP Emissions |

|

|

HAP Emissions* |

|

|

Permit |

Release Pt |

|

HAP Emissions* |

Resin |

|

Tank, OtherEquip |

VeneerDry |

|

DFDryFuel |

|

|

HAP Emissions* |

RotaryDry |

|

DFDryFuel |

|

|

HAP Emissions* |

TubeDry |

|

DFDryFuel |

|

|

HAP Emissions* |

ConvDry |

|

DFDryFuel |

|

|

HAP Emissions* |

FB_HB |

|

HAP Emissions* |

LKiln |

|

DFDryFuel |

|

|

HAP Emissions* |

DFDryFuel |

|

HAP Emissions* |

Press |

|

HAP Emissions* |

BC |

|

HAP Emissions* |

EWPPress |

|

HAP Emissions* |

OtherEquip |

|

HAP Emissions* |

*The field is used to prepopulate the optional provisional calculations included in the HAP Emissions tab.

Regardless of the presence or absence of prepopulated information in other tabs, you should carefully review the list of tabs in Table 1 of this instruction document to determine which tabs are relevant and required to be completed for your facility. In some tabs, prepopulation occurs as you begin entering data (e.g., the ICR ID populates once you enter a product in Prod).

Also, as you work through the ICR survey spreadsheet from left to right, if you determine that you need to return to a tab to make adjustments, it is suggested that you review the subsequent tabs that may be affected by the change (see Table 2 for guidance regarding which tabs may be affected based on the field you change). Please be aware that adding a process unit or changing its process unit type in the EquipDetail tab after completing subsequent tabs can cause information entered in the white cells of subsequent tabs to misalign with the prepopulated process units. Adding units at the end of the process unit list in the EquipDetail tab should prevent these issues. Reviewing subsequent tabs after making a change will allow you to catch and correct any errors in the information.

Drop-down menus. The ICR survey spreadsheet contains drop-down menus that function best in Excel® version 2010 or higher. See the box below if you have an older version of Excel. Use these drop-down menus whenever possible.

Note: A printout of the spreadsheet showing the survey questions and most drop-down menu choices is available on the ICR website for reference. Lengthy drop-down menus that do not fit on a single page are noted to indicate where to locate the menu choices appearing in the spreadsheet.

Some columns with drop-down menus allow you to write in information if your selection is not contained in the drop-down menu, while others require use of the drop-down menu choices. Selections appearing as “Other: {specify}” indicate that you may write in a site-specific response in place of the word {specify}. For example, your written-in response may be “Other: use a unique low-emitting material.”

Note: By default, only eight drop-down menu choices are visible on the screen at one time. Where more than eight menu choices exist, you may need to scroll up or down in the menu to find your choice. If you encounter a menu that appears blank, try scrolling up to see the choice.

What if I do not have Excel® 2010 or

higher? Users without a

recent version of Microsoft Excel (2010 or later), including those

on Mac or Linux computers may use LibreOffice

(http://www.libreoffice.org) to open the ICR survey spreadsheet.

LibreOffice is open source software available without cost. Detailed

installation instructions are available at

https://www.libreoffice.org/get-help/install-howto/. Once the

LibreOffice suite has been installed, you may use LibreOffice Calc

to open the ICR survey spreadsheet. If you choose to use LibreOffice

Calc, please keep the ICR survey spreadsheet in Excel format (xlsx)

when saving your changes (i.e., do not change to LibreOffice format

if prompted during the save).

Adding Comments. A “comments” column is included as the right-most column of each tab should you wish to supply any comments on the information provided. Please use the “comments” column for any notes. The in-cell pop-up comments feature has been disabled in the locked spreadsheets because notes made using pop-up comments will not transfer into the EPA’s PCWP data base.

In addition to the drop-down menus, other data validation criteria are included in many of the spreadsheet cells. For example, many cells require entry of 255 characters or less to ensure there are no truncation issues when the data are imported into the EPA’s data base. If you receive an error message for responses exceeding the allotted number of characters, use the comments column to continue your response. Cells with production rate units, such as (MSF/yr), will also provide a warning if values lower than expected are entered. These warnings are designed to help prevent common data entry errors, such as preventing facilities from entering million square feet data when the required data are in thousand square feet units.

Identification numbers. Several IDs are requested throughout the ICR survey spreadsheet, including:

ICR ID

FRS Site ID

Process Unit ID

Emission Release Point ID

APCD_ID

As noted in Section A2 above, the ICR ID and FRS Site IDs are used to identify your facility. The ICR and FRS IDs may be found in the letter that you received from the EPA instructing you to complete this survey. It is important you enter the correct ICR ID for your facility as this ID will be used to identity your facility’s data when we compile all of the ICR responses into the PCWP data base.

The Process Unit IDs, Emission Release Point IDs, and APCD_IDs are identifiers for each process unit (e.g., dryer), emission release point (e.g., dryer stack), and air pollution control device (APCD) (e.g., a wet scrubber). One option for creating these IDs is to use IDs from your permit. Regardless of the IDs you specify, it is imperative that you use this same ID to identify the facility, equipment/process unit, and emission release point consistently throughout all parts of this survey.

Although many PCWP facilities have emissions estimates in the most recent version of the EPA’s National Emission Inventory (NEI), the EPA is requesting you provide more recent emission estimates in this ICR, specifically for HAP. This ICR has been designed to facilitate compilation of a nationwide PCWP emissions inventory designed specifically for the residual risk modeling required by the Clean Air Act. However, NEI data for 2014 are available at https://www.epa.gov/air-emissions-inventories/2014-national-emissions-inventory-nei-data if you would like to see the information available for your facility. If HAP data are included in the NEI for your facility, the NEI data base may provide Process Unit IDs, Emission Release Point IDs, and other information that you may wish to use to complete your PCWP ICR response. You are not required to use the NEI data for your facility.

Supplying process data. In several parts of the survey, the EPA requests production, throughput, capacity, operating hours and related process information. Unless otherwise specified, the EPA is seeking nominal or typical operating rates that can be used by the agency to compare the relative size of facilities or process units. The EPA is interested in capacity values that can be used for estimating emissions (for example, values used in your permit application). We are not interested in maximum capacity values for each piece of equipment outside of the constraints of the production process within which it is located. You may use the press line nominal capacity (throughput) for all equipment in the press line.

Similarly, several questions in the spreadsheet ask for process parameters such as exhaust flow rate (ACFM), temperature, etc. Unless otherwise specified, typical values are requested, and are subject to the respondent’s discretion. For example, if you measure a parameter with an online meter and you have data available for most operating hours of the year, then you may choose to provide an annual average for the parameter. However, if the parameter is only measured periodically, then you may want to provide the most recent measurement.

What if I do not know or have the information to answer a survey

question? There may be

survey questions that you do not know the answer to, or for which

information is not readily available. The following codes may be

used: Unknown (UK): If

you do not have the requested information, cannot obtain the

information without extraordinary effort, and cannot provide a

reasonable estimate, then you may enter “UK” for

unknown. Not Applicable

(NA): If a question is not applicable to your operations, then you

may enter “NA” for not applicable. Blanks: You may

also leave obviously inapplicable questions blank. Survey

respondents are reminded that their certification of the accuracy of

their response includes a certification that any identification of

information as “unknown” or “not applicable”

is accurate. Further, surveys with an excessive number of responses

as “UK,” “NA” or blank will receive

additional scrutiny and survey respondents are more likely to

receive follow-up inquiries from the EPA related to their survey

responses.

You may also use the Excel ribbon

commands, choosing “paste values” as shown.

Can I paste data into the ICR survey spreadsheet? Yes, with Caution! If you

choose to copy information from another document or from another

location within the ICR survey spreadsheet, you MUST paste the

data using the “paste as values” function, following

the steps outlined below. Failure to do so may override programming

and formatting needed for the ICR survey spreadsheet to work

correctly. Steps to paste values: Copy the desired data. Select the first cell of the

ICR survey spreadsheet into which you plan to paste the data. Right click and select “Paste

Special.” Select “Values.” Note: It is highly recommended that

you copy and paste small amounts of data at one time until you are

sure that the data you are pasting are being inserted into the

correct cells and meet all the data validation criteria for those

cells. Do not paste formats. Also, please use caution if copying

data by dragging down columns. Watch for and correct any

unintended incrementing of numbers, and do not copy data into

the hidden area below the data entry table.

a. Mill tab

Complete the columns following the instructions provided in the “Instruction” row. Your response in the Mill tab will consist of one row of data. These data will be used by the EPA to characterize your facility and identify applicable regulations.

Facility identifiers. Enter your ICR ID and FRS ID in the appropriate column. These IDs may be found in the letter instructing you to complete this survey.5

Facility Location, Contact and Owner Information. Enter the location, a facility contact name for facility-specific follow up on the survey (if needed), and the facility owner. If the facility is located on tribal land, select from the tribal name drop-down menu to get the tribal code. If the physical and mailing address are identical, answering “Yes” in the first mailing address column will fill in the mailing address.

Operating status. Indicate the operating status for the facility by selecting one of the following: operating, seasonal/partial year, or temporarily closed. Facilities that operated more or less continuously throughput the year should choose “operating.” Facilities that were temporarily closed for all of 2016 should indicate “temporarily closed,” and facilities closed for a large portion of 2016 may choose “seasonal/partial year.” The next column asks for an explanation for facilities selecting “seasonal/partial year” or “temporarily closed.”

Company Revenue and Dun & Bradstreet. Provide the 2016 revenue for the parent company. This information will be used in economic analyses.

Size of entity. The EPA needs to identify small businesses for consideration in impact analyses. The U.S. Small Business Administration has set the threshold for the definition of a small businesses in the wood products industry based on the number of employees shown in Table 3 below. The threshold metric applies to all full or part time employees in a corporation, not just at a location. Please use the thresholds in Table 3 for small business questions in the PCWP survey. For reference, the Small Business Size Regulations codified at 12 CFR 121.06.

Table 3. Small Business Size Standards for NAICS Subsector 321

–

Wood Product Manufacturing

NAICS code |

NAICS U.S. industry title |

Size standards in number of employees |

321113 |

Sawmills |

500 |

321211 |

Hardwood Veneer and Plywood Manufacturing |

500 |

321212 |

Softwood Veneer and Plywood Manufacturing |

1,250 |

321213 |

Engineered Wood Member (except Truss) Manufacturing |

750 |

321219 |

Reconstituted Wood Product Manufacturing |

750 |

321999 |

All Other Miscellaneous Wood Product Manufacturing |

500 |

Source: U. S. Small Business Administration Table of Small Business Size Standards Matched to North American Industry Classification System Codes, 2016. Accessed June 6, 2017 at: https://www.sba.gov/sites/default/files/files/Size_Standards_Table.pdf.

Federal rule coverage. Use the drop-down menu to identify the Federal rules that are applicable to the facility. Choose “NA” if the rule is not applicable because the facility has a permit condition that makes the facility a synthetic area source. Indicate applicable subcategories if subject to the Wood Building Products surface coating NESHAP. The most-likely rules applicable to industry sources are listed. List other NESHAP or NSPS rules that are applicable.

b. Product (Prod) tab

Enter information about PCWP products or kiln-dried lumber produced, product lines, production, and capacity in this tab.

Products and Other Product Information. List all PCWP products produced at the plant site. Use one row per product. Mills with multiple products will have multiple rows.

Veneer and plywood mills should list veneer and plywood as two separate products entered on separate rows even if all the veneer is used onsite to manufacture plywood. A separate question in column K asks facilities to specify the proportion of the “product used or sold within company to manufacture other products” and provides the choices: NA, <50%, 50-100%, and 100%. Plywood producers using all the veneer produced to make plywood should select 100%. An answer of “NA” is appropriate for other products that are not used to make other PCWP products. Facilities transferring products within the company, either onsite or at a different site, to make additional PCWP products should enter the appropriate percentage of product used within the company. Information is also requested for major markets. This information will be informative for the EPA’s economic analysis.

The core material for hardwood plywood is requested with hardwood/softwood plywood and veneer, MDF, particleboard, and lumber provided as menu choices.

Facilities integrating agricultural fiber into products are asked to describe the “use of agricultural fiber.” The description provided should include the type of agricultural fiber (e.g., bagasse, wheat straw). The EPA is interested in understanding whether the product is primarily agricultural fiber or a blend of wood and agricultural fiber. For a product that is made from wood and wheat straw, for example, you should indicate the product is approximately 75% wood and 25% wheat straw.

Questions regarding whether a product uses a resin and the number of resins used seek to identify significantly different types of adhesives such as phenol-formaldehyde resin, MDI, or PVA. If you select “Yes” indicating that the product uses resin, you are asked to enter details about the resin in Resin tab. Select “No” for products such as fiberboard that do not require resin but rely on natural binders (e.g., lignin) to adhere fibers. Select “NA” for products such as softwood veneer or lumber that do not require resin. Do not consider waxes or other non-adhesive additives when making your selection.

Product lines. Product lines often correspond with press lines. For example, if there are two presses at a mill making two distinctly different products, then you should enter two different product lines on separate rows. However, if a mill with multiple presses makes the same product on all presses (i.e., with the same general resin formulation) then it is acceptable to enter only one product line that sums the capacity/production from all presses. If your facility uses multiple significantly different resin systems to make the same product on the same press (e.g., UF and UF/MDI at different times), a separate Product Line should be specified on two rows for the two significantly different resin systems. For this ICR, significantly different resin systems are defined as separate product lines.

When considering which product lines and resin systems to specify, resins applied more than 5% of the time on a product line are of interest. Do not provide information for temporary mill trials or minor variations of different resin formulations.

Production and capacity. Provide the nominal mill production rate and capacity for each product line identified for the survey base year (2016). Use the units of measure in Table 4 for reporting production and capacity.

Table 4. Production and Capacity Units of Measure

Product |

Units of measure for reporting production and capacity1 |

Veneer |

MSF/yr |

Lumber and glulam |

MBF/yr |

Fiberboard |

MSF/yr 1/2” |

Hardboard |

MSF/yr 1/8” |

Particleboard, MDF2 |

MSF/yr 3/4” |

Hardwood and softwood plywood, OSB, and any other plywood panel products |

MSF/yr 3/8” |

LVL, LSL, and PSL |

MCF/yr |

I-joists |

MLF/yr |

1 “M” refers to thousand (e.g., MSF = thousand square feet)

2 Includes molded particleboard and particleboard or MDF produced with agricultural fiber.

c. Equipment Detail (EquipDetail) tab

All facilities must complete the EquipDetail tab. This tab asks for information for each individual process unit, its air pollution control device(s) (APCD), and emission release points. The purpose of this tab is to provide the EPA with equipment-specific details needed for the Agency to review the technology-based emission standards. This tab will provide the EPA with nationwide numbers of equipment, configuration of controls, pertinent equipment details, and the regulatory compliance options used. The process units and IDs you list in the EquipDetail tab will prepopulate into subsequent spreadsheet tabs prompting you to enter additional equipment-specific details for each process unit.

The types of process units listed in Appendix 2 that you operate should be included in the EquipDetail tab. Appendix 7 provides definitions from the PCWP rule, including supplemental definitions. These definitions are helpful for understanding the types of process units and how they are delineated within the PCWP source category.

Important Notes: As indicated

in Table 1 of these instructions, sawmills that produce kiln-dried

lumber and no other PCWP products are only required to provide

information for their lumber kilns in the EquipDetail tab.

You are not

required to provide information for process units outside of the

PCWP NESHAP source category such as boilers or coating processes

subject to other NESHAP. You are not

required to provide information for process units that do not emit

HAP.

The Process Unit Types available in the drop-down menu for selection include:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For the process units listed in Appendix 2, specify the Process Unit ID, Process Unit Type, APCD Type and IDs, and Emission Release Point IDs by following the directions in the Instruction row of the tab. The APCD IDs you enter in the EquipDetail tab will be used to prepopulate the APCD tab. The Emissions Release Point IDs you enter in the EquipDetail tab will be used to prepopulate the ReleasePt and HAP Emissions tabs.

Choose the Process Unit Type from the menu consistent with how process units are defined in Appendix 7, whenever possible. An “other” process unit type option is provided for HAP-emitting process units that may fall within the PCWP NESHAP source category but do not fit within the menu of PCWP process unit types provided. For example, if you have a known HAP-emitting dryer within the PCWP process that does not fit within the dryer types listed above and defined in Appendix 7, you may enter the dryer as an “other” process unit. If you use the “other” process unit option, please provide a description of the other process unit in the optional process unit description column in the EquipDetail tab. The “other” process unit type option is intended to be used with process units known to emit HAP (e.g., process units with HAP limits in the facility’s operating permit and/or with quantified HAP emissions reported in an existing inventory). The “other” process unit option is not intended to suggest that facilities attempt to estimate traces of HAP emissions from process units that are not expected to be significant sources of HAP emissions.

Select the Product Line and Product associated with each process unit based on information supplied in the Prod tab. Individual process units should be listed once in the EquipDetail tab even if the same process unit is used to manufacture multiple products. Duplicate Process Unit IDs are not allowed because the EPA will use the information supplied in this tab to develop nationwide counts of the different types of PCWP process units. Data validation is included in the Process Unit ID column to prevent duplicate entries. Column G (Product Line) allows for write-in specification of multiple product lines, if needed. Enter each product line separated by a comma. For example, if “press 1” is used for two product lines each labeled “PrimoEcoPanel” and “StandardPanel” then “PrimoEcoPanel, StandardPanel” can be specified in column G.

Enter information in the EquipDetail tab representative of the primary operating scenario with respect to process unit, APCD, and emissions release point configuration. If the description of an alternate operating scenario is pertinent, please make a note of the alternate operating scenario in the Comments column at the far right of the EquipDetail tab.

Air Pollution Control Device Information. The EPA is interested in knowing what APCDs are in place for each process unit regardless of whether the APCD is used as a material handling dust collector (such as a cyclone or baghouse), as a particulate matter (PM) control, or as an organic HAP control device. Knowing what equipment is in place for each process unit is essential for the EPA to characterize equipment trends on nationwide basis and to perform regulatory baseline and regulatory impact analyses.

If a process unit is uncontrolled, select “None” for the APCD 1 type and leave the APCD 1 ID column blank. Otherwise select the APCD type and provide an APCD ID for each control device. Provide APCDs in the order they appear in the control sequence for your process unit. The following APCD Type codes are included in the selection menu:

None

RTO - Regenerative Thermal Oxidizer

RCO - Regenerative Catalytic Oxidizer

TCO - Thermal Catalytic Oxidizer

TO - Thermal Oxidizer

PINC - Process incineration (incineration of 100% of the exhaust in a combustion unit such as a boiler)

SINC - Partial process incineration (incineration of a portion of the exhaust in a combustion unit)

BIO – Biofilter or Bioscrubber

WESP - Wet Electrostatic Precipitator

ESP - Dry ESP

BH - Baghouse

MC - Multiclone

CYC - Cyclone

RBP - Rotary bed protector

SCBR - Wet scrubber

EFB - Electrified filter bed

SF - Sand filter

Other: {specify}1 1 Replace the word “{specify}” with a description.

Notes for the APCD columns:

You may omit product recovery cyclones that precede other air pollution controls from the APCD columns (e.g., where furnish exiting a dryer is collected in a cyclone that vents to another control device). Product recovery cyclones are understood to be in place, and the subsequent controls are of interest.

If you have APCDs in parallel, provide both of them and add a note in the Comments column to explain the configuration (for example, if WESP-a and WESP-b each control a portion of dryer-1 exhaust, label WESP-a as APCD 1 and WESP-b as APCD 2 in the APCD type and ID columns and note the WESPs are arranged in parallel in the comments column).

Consider the predominant venting mechanism for the process unit when identifying APCDs. For example, include dust control baghouses for former pick up points in the APCD columns for the formers. You may find it helpful to review the instructions for identifying emission release points below before completing the APCD columns.

Specify the overall type of Air Pollution Control System in column Q using combinations of the APCD type codes, as needed. For an uncontrolled process unit, select “None.” For a combination of controls, indicate the types of controls in the sequence, such as a “WESP/RTO” system. For systems with process units and/or controls in parallel, such as four dryers venting to four multiclones, two WESPs and two RTOs, you should enter the overall air pollution control system sequence (i.e., MC/WESP/RTO), regardless of the number of parallel units.

Emission Release Point Information. Enter the “Total Number of Emission Release Points” for each process unit. Emission release points are each stack, vent, or a fugitive emissions release from a process unit. The number of emission release points triggers conditional formatting in the Emission Release Point ID columns to indicate the number of IDs required. Some common process unit, control, and release point configurations are described below.

Note: You may find it helpful to review the ReleasePt tab instructions for selection of a release point type prior to assigning Emission Release Point IDs.

Multiple process units ducted to a single release point. You should list each process unit on a separate row in the EquipDetail tab even if the exhaust from the process unit is ducted to a common release point. For multiple process units ducted to the same release point, list each Process Unit ID (and corresponding APCD ID) separately but enter the same Emission Release Point ID.

For example, for dryers venting into a press enclosure, the APCD ID specified for the dryer should be the same as the press APCD ID. The same Emission Release Point ID should be provided for the press and the dryer exhaust stream vented through the press enclosure and out through the press control device.

Single process unit with multiple release points. If the process unit has multiple uncontrolled vents or stacks then you should list the process unit on one row, specify the APCD type (“None” for uncontrolled stacks), specify the number of release points, and provide the release point IDs in columns S through W.

If a single process unit has multiple release points with different controls (or some release points controlled and others uncontrolled), you should enter the process unit on one row in the EquipDetail tab using one Process Unit ID. Specify the applicable APCD ID(s) and APCD types for the process unit, using the Comments column to describe the configuration for the differently controlled and/or uncontrolled portions of the process unit. Add all the applicable emission release point IDs for the process unit. This will allow the Process Unit ID to prepopulate into the appropriate unit tab as one process unit, while each separate Emission Release Point ID will parse into the ReleasePt and HAP Emissions tabs for further point-by-point description. Each APCD ID will prepopulate into the APCD tab.

Process units with more than five emission release points. Space for five Emission Release Point IDs has been provided in the EquipDetail tab with the expectation the nearly all PCWP process units have or can be characterized with five or fewer emission release points. If there are more than five emission release points, particularly if the release points are uncontrolled vents located close to one-another, such as on a lumber kiln or veneer dryer cooling section, you may group these emission release points into one Emission Release Point ID. For example, if there are four roof fans near each other on a dryer cooling section you may label one release point “cooling” to represent the gas flow from all four fans). Another example would be specifying three emission release points for a 9-zone oven with uncontrolled zones a-b, followed by controlled zones c-e, followed by uncontrolled zones f-i.

The number of release points specified (and later detailed in the ReleasePt tab) will impact dispersion modeling, but grouping release points is acceptable if the HAP emissions from the release points are low and expected to be inconsequential in risk modeling. It is suggested that you review the ReleasePt tab instructions for selection of a release point type prior to grouping Emission Release Point IDs.

As a last resort, if there are more than five emission release points that are not reasonably grouped due to relatively high process unit HAP emissions and different controls or characteristics, then you should break the process unit into multiple rows in the EquipDetail tab to accommodate all the release points. For example, a large conveyor-type dryer with 10 release points could be broken into “dryer north end” and “dryer south end” to accommodate all the 10 emission release points. This approach will prepopulate both the “dryer north end” and “dryer south end” into the ConvDry tab where you should use the ConvDry comments column to explain.

Tips of the Number of Emission Release Point IDs

For every Emission Release Point ID specified in the EquipDetail tab, you will be asked to provide release parameters and coordinates in the ReleasePt tab plus emissions estimates by process unit and pollutant in the HAP Emissions tab. For very-low-emitting process units with numerous release points or for fugitive emissions emanating from numerous building vents, you should balance the number of Emission Release Point IDs specified in EquipDetail with the level of detail you can feasibly provide in later tabs. Reviewing the emission release point types in the instructions for the ReleasePt tab may help you identify ways to group numerous related vents into fewer Emission Release Point IDs. You may want to pick the closest building vent for a low-emitting process unit emitting fugitives into the building instead of identifying all possible building vents. For higher-emitting sources, it is generally better not to group emission release points because providing details for all points will improve the dispersion modeling.

To improve spreadsheet calculation speed, the HAP Emissions tab was designed to hold 100 Emission Release Point IDs instead of the theoretical maximum of 500 Emission Release Point IDs that can potentially be entered into the EquipDetail tab. Facilities are not expected to have more than 100 Process Units or more than 100 Emission Release Point IDs. The number of Emission Release Point IDs entered are counted in EquipDetail Row 5, Column S. Although not expected, should a facility need space for more than 100 Process Units or more than 100 Emission Release Points, please contact the EPA at [email protected] to obtain an expanded version of the spreadsheet prior to proceeding beyond the EquipDetail tab.

Process units that are not vented. Include process units that are not vented in the EquipDetail tab by specifying a Process Unit ID as for any other process. Enter zero (0) for the total number of emission release points. Do not enter an Emission Release Point ID. Indicate in the “comments” column that the process unit is “not vented.”

Process units vented into the building. Include process units that vent into a building in the EquipDetail tab, and enter “BLDG” in the Emission Release Point ID column. Select “Vented into building (fugitive source)” from the menu in the “Uncontrolled Process Unit Emission Routing and Control Configuration” column.* If there are multiple building vents with emission releases to be characterized for the process unit, you may enter BLDG1, BLDG2, etc. The same building vents should be listed as Emission Release Point IDs for all process units that impact emissions from the building vent.

Process units with fugitive emissions. Include process units with fugitive emissions in the EquipDetail tab, and include an Emission Release Point ID to represent the fugitive emissions. If a process unit produces both fugitive emissions and emissions that are emitted though a conveyance, then you need to specify the fugitive emissions in a separate “Emission Release Point ID” column (e.g., as a “single process unit with multiple release points” as described above.*

*Note that the predominant venting mechanism is to be described. Incidental fugitives or small amounts of dust escaping from equipment in the building such as sanders, saws, or blender transfer points is not of interest when the process unit has a material/dust collection system that may be considered the primary and predominant means of collecting and ventilating emissions from the process unit. Units labeled “BLDG” or as fugitive sources are those with no primary means of collecting and ventilating the process unit. For example, if there are some incidental fugitive emissions within the building because of blended material being transferred, but the blender also has a dust collection system, you only need to list the dust collection system associated with the blender and you are not required to list the insignificant, incidental fugitive emissions associated with transferring blended material.

Bypass stacks. Do not include data for bypass stacks or control system bypasses in the EquipDetail tab, but do include them in the process flow diagram. In addition, you are asked to provide a maximum short-term emission rate (lb/hr) for each process unit in the HAP Emissions tab, which could reflect bypass emissions.

Process units routed to a boiler/combustion unit for emissions control. Choose PINC or SINC for the APCD type depending on the amount of PCWP process unit exhaust controlled (PINC for 100% control and SINC for partial control), and enter a combustion unit ID for the boiler (or other type of combustion unit) in the APCD ID column. Provide the Emission Release Point ID(s) for the boiler/combustion unit stack(s).

For example, when press exhaust is used as direct-fired dryer burner makeup air and subsequently combusted in the dryer burner, the dryer burner is a form of process incineration (PINC or SINC). The APCD ID for the press should be the dryer process unit ID or dryer burner combustion unit ID (if the combustion unit is separate from the dryer). The press Emission Release Point ID should be the same as the dryer Emission Release Point ID.

Alternate controls. Alternate (or backup) controls include alternative controls used when gas flow from a process unit is diverted from the primary control device to a less frequently used control device as part of a routine operating scenario. If the facility has such a system, please enter a separate APCD ID for the system in addition to the primary APCD ID(s) and describe the typical use circumstances in the “Comments” column of this tab. Similarly, you could enter a separate Emissions Release Point ID for the alternate control that will prepopulate into the ReleasePt and HAP Emissions tabs for further specification and inclusion in the risk modeling.

Wastewater/process water operations. Complete the questions in EquipDetail for any wastewater (or process water) operations that are closed and/or vent through a conveyance, or are potential sources of fugitive HAP emissions. Include wastewater/process water operations that are potential sources of HAP emissions and/or participate in biological degradation of HAP to prevent HAP emissions. Wastewater operations may include individual treatment units that reduce HAP within wastewater treatment plants (WWTP), or enhanced biological treatment units. You may aggregate multiple treatment units with similar venting characteristics within a single “wastewater operations” entry in the EquipDetail tab. For example, if the entire wastewater treatment system is a fugitive source, you may choose to include it on one row of the EquipDetail tab. Do not include sewage handling equipment.

What if I need to remove or add a process unit and/or emission

release points after working past the EquipDetail and

ReleasePt tabs? If

you have already completed the ReleasePt

tab or subsequent tabs and you later decide to remove a Process Unit

or Emission Release Point from the EquipDetail

tab, you have two choices:

(1)

Remove the process unit and/or emission release point and use paste

values to adjust the alignment of data in subsequent tabs impacted

by the change (including ReleasePt,

HAP Emissions,

and process-specific tabs); or

(2)

Label the Process Unit ID and/or Emission Release Point ID with

“[REMOVE]” to prevent any misalignment of rows in the

ReleasePt

and subsequent tabs. The EPA will remove Process Units and Emission

Release Point IDs labeled in this manner when the EPA compiles its

data base from the ICR responses.

Ex:

To remove Process Unit ID “Dryer1” and its Emission

Release Point ID “Dryer1Ep1” label these IDs

“Dryer1[REMOVE]” AND “Dryer1Ep1[REMOVE]” in

columns D and S-W (as applicable).

Additional

Process Units and associated Emission Release Points may be added to

the bottom of the EquipDetail

tab without risk of misalignment of data previously entered in

subsequent tabs. If

you already listed a Process Unit on row 5, but would like to add

more Emission Release Points to it after completing the ReleasePt

tab, then you could flag the Process Unit ID and Emission Release

Point IDs on row 5 for removal in the EquipDetail

tab (i.e., label

them “[REMOVE]” as described above) and then add the

Process Unit and corrected Emission Release Point ID to the bottom

of the EquipDetail

tab.

Operations and Emissions Testing. In the Operations section of the EquipDetail tab, you are asked to provide an estimate of the 2016 operating hours for the process unit. The EPA will use this value in regulatory impact calculations.

You are also asked for more details regarding how each process unit is vented. These questions will be particularly helpful for the EPA as we consider miscellaneous process units that do not already have emission limits under the PCWP NESHAP. The EPA is interested in whether these units are currently configured to capture HAP emissions, and whether process units are isolated from other process unit HAP emissions. Process units that are not isolated from other process units may have comingled HAP emissions. The questions in columns Y through AA are intended to help the EPA understand the types of process units where non-isolation of emissions is an issue.

In column Y, you are asked to indicate yes/no whether emissions from an uncontrolled process unit are captured through an enclosure or conveyance for discharge to the atmosphere. Uncontrolled process units are those you labeled with APCD = None.

In column Z, you are asked to indicate if uncontrolled process units are:

Vented to atmosphere (uncontrolled),

Vented into building (fugitive source), or

Fugitive source (outdoor)

If none of these configurations apply, please leave the column blank and add a note in the “comments” field to describe the configuration.

In column AA, you are asked to indicate by selecting “yes” or “no” whether emissions from the process unit are isolated from other process units that produce HAP emissions. If you answer “no,” indicating that the HAP emissions from process unit may be comingled with HAP emissions from another process unit, then you are asked to explain how other process unit emission points may be contributing to emissions in column AB. As a guideline, a process unit is considered to be isolated from other process unit emissions when: (1) there are no physical connections between ventilation systems and/or material collection systems; or (2) there is no mechanism for collection of significant amounts of point or fugitive emissions from other process units.

The Emissions Testing section of the EquipDetail tab asks if the process unit has a stack suitable for gas flow measurement in order to assess whether different types of process units are already configured to allow for emissions testing.

Resins. Indicate whether the process unit processes wood containing resin, also referred to as adhesive in this survey. This will allow the EPA to quickly identify post-resin application process units in the inventory.

COMS. The EPA is requesting that you indicate whether you installed a continuous opacity monitoring system (COMS) on APCD controlling process units regulated under the PCWP NESHAP. As an example, if you use a combustion device with COMS as an add-on control to demonstrate compliance with the PCWP NESHAP, answer “yes” to this question. If you answer “yes,” also provide the opacity limit from your operating permit on the Permit tab.

Rule Compliance. Use the drop-down menus to respond to the questions regarding the PCWP compliance options and work practices used to demonstrate compliance with the PCWP NESHAP. You only need to select one of the compliance options even if you can demonstrate compliance with more than one of the PCWP compliance options. Select the option associated with your most recent compliance demonstration. Choose “NA” if no compliance option applies under the PCWP NESHAP. The menu choices are as follows:

|

|

|

|

|

|

|

|

|

|

Similarly, you are asked to list any applicable work practices that you must demonstrate compliance with under the PCWP NESHAP. The menu choices are as follows:

|

|

|

|

|

|

If emissions averaging is used, provide a short description of the emissions averaging approach, indicate whether the process unit listed in the row is a debit or credit generating source in the emissions average, and submit a copy of the Emission Averaging Plan (EAP) required under §63.2280(f) with your survey responses if the EAP is not already included in the facility permit (also submitted with the survey response). In an emissions average:

“Debit” sources are process units that are required to meet the emission limits in Table 1B to Subpart DDDD of Part 63.

“Credit” sources are process units that are over-controlled in order to offset emissions from “debit” sources that are either not controlled or under-controlled.

If the facility uses the production based compliance option (PBCO), you are asked to describe any methods used to meet the PBCO such as pollution prevention measures (P2), use of low-HAP resins, or other measures. If your process unit meets the PBCO simply because it is inherently lower-emitting without the use of any deliberate P2 measures, select “no P2 measures required.”

d. Release Point Detail (ReleasePt) tab

The purpose of the ReleasePt tab is to gather details on the conditions and location of HAP emissions releases. These details will be used in the residual risk assessment. As noted in Section D2 above, you are asked to supply an emission release point map displaying the location of each Emission Release Point ID specified in the ReleasePt tab. Accurately accounting for emission release location and characteristics improves the accuracy of the risk modeling.

A Note About Emission Release Parameters Please pay

particular attention when entering emission release point parameters

and locations (latitude/longitude). These data are critical inputs

to the modeling files that EPA will use to determine the risk

profile for the residual risk review process. Valid parameters

for the physical characteristics of each emission release point are

necessary to correctly place facility release points and associated

emissions into vertical layers for proper air quality modeling.

Gaussian dispersion models use stack parameters to characterize the

plume. The ambient concentration at ground level is inversely

proportional to the plume height (i.e., ground-level concentration

decreases with increasing plume height). The plume height is a

function of the actual physical release height (stack height) and

the plume’s rise due to buoyancy and momentum. Plume rise is a

function of the plume’s exit gas velocity, volumetric flow,

and release temperature. Different plume heights can result in

different ambient concentrations and resulting risks. The plume

height is related to the type of emission point release.

As noted in the instructions for EquipDetail above, there may be one or more emission release points for a given Process Unit ID. There may also be multiple Process Unit IDs ducted to the same Emission Release Point ID. The ReleasePt tab is prepopulated with Process Unit IDs and Emission Release Point IDs (referred to as “Release Point IDs”) from the EquipDetail tab. For each combination of Process Unit ID and Release Point ID, you will specify emission release parameters (e.g., stack gas parameters or fugitive release parameters), and longitude/latitude coordinates in the ReleasePt tab. You must complete all appropriate fields for each Release Point ID.

Note: Later, in the HAP Emissions tab, you will specify emission rates using a separate row for each pollutant and each combination of Process Unit ID and Release Point ID. Information from the ReleasePt and HAP Emissions tabs will be used to construct the EPA’s residual risk modeling file.

Release Point ID. Review the prepopulated Release Point IDs and note if any of your IDs are duplicated because they are associated with multiple process units. Duplicate Release Point IDs appear in bold purple. With the exception of the source classification code (SCC), which can vary by process type, you should enter the exact same information for every instance of a duplicated Release Point ID in the ReleasePt tab. This includes the same emission release point type, release parameters, and coordinates.

Source Classification. Select the source classification code (SCC) that best represents the process and emission release point. Some process unit types have multiple SCCs for different release points. For example, veneer dryers have separate SCCs for heated and cooling zones. Appendix 8 provides a list of the SCCs for PCWP process units grouped by product type. Once you key in an SCC code, its description appears in the next column. Please use the description as a check that the proper SCC was entered.