ASME 09-13 Final Regulatory Analysis

ASME 09-13 Final Rule - Regulatory Analysis.docx

10 CFR Part 50, Domestic Licensing of Production and Utilization Facilities

ASME 09-13 Final Regulatory Analysis

OMB: 3150-0011

Final Regulatory Analysis for Final Rule: Incorporation by Reference of American Society of Mechanical Engineers Codes and Code Cases

NRC-2011-0088; RIN 3150-AI97

U.S. Nuclear Regulatory Commission

Office of Nuclear Reactor Regulation

Contents

Section Page

Abbreviations and Acronyms xvii

2. Statement of the Problem and Objective 2

2.2 Statement of the Problem 4

3. Identification and Preliminary Analysis of Alternative Approaches 5

3.1.1 Take No Action on ASME BPV Code Case N‑729-4 6

3.1.2 Take No Action on ASME BPV Code Case N-770-2 6

3.1.3 Take No Action on ASME BPV Code Case N-824 7

4. Estimation and Evaluation of Benefits and Costs 8

4.1 Identification of Affected Attributes 8

4.2.5 Cost/Benefit Inflators 13

4.2.10 NRC Conditioned Codes 17

4.2.11 Dollar per Person-Rem Conversion Factor 17

5.1 Public Health (Accident) 19

5.2 Occupational Health (Accident and Routine) 20

5.3 Industry Implementation 20

5.3.2 Procedure Revision to Incorporate Concrete Containment Examinations 21

5.3.3 Procedure Revision to Underwater Welding Requirements 22

5.3.4 Procedure Revision to Incorporate Nondestructive Examination Personnel Certification 22

5.3.5 Procedure Revision to Prohibit the Use of Mechanical Clamping Devices 22

5.3.6 Procedure

Revision to Incorporate Summary Report Submittal

Requirements 22

5.3.7 Procedure

Revision to Prohibit the Use of Risk-Informed Allowable

Pressure

Methodology 23

5.3.9 Procedure

Revision to Specify the Use of Reference Temperature in the

Kla

and Klc Equations 23

5.3.10 Procedure

Revision to Incorporate Fracture Toughness of Irradiated

Material

Requirements 23

5.3.12 Procedure

Revision to Incorporate Motor-Operated Valve

Testing

Requirements 25

5.3.15 Procedure

Revision to Prohibit the Use of Subsection ISTB

(2011 Edition) 29

5.3.19 ASME OM Code Case OMN-20 Time Period Extension 31

5.3.20 Procedure

to Incorporate Cast Austenitic Stainless Steel Material

Examination

Requirements 32

5.3.22 Procedure

to Incorporate the Encoding of Ultrasonic

Volumetric

Examinations 33

5.3.23 Clarification of Valve Position Verification Requirements 34

5.4.1 Maintenance of Quality Assurance Program Description 36

5.4.2 Concrete Containment Examinations 36

5.4.3 Underwater Welding Requirements 39

5.4.4 Nondestructive Examination Personnel Certification 40

5.4.5 Control the Use of Mechanical Clamping Devices 40

5.4.6 Summary Report Preparation and Submittal 40

5.4.7 Prohibit the Use of Risk-Informed Allowable Pressure Methodology 40

5.4.8 Disposition of Flaws in Class 3 Components 41

5.4.9 Procedure

Revision to Specify the Use of Reference Temperature in the

Kla

and Klc Equations 41

5.4.10 Fracture Toughness of Irradiated Material Requirements 41

5.4.11 Ultrasonic Examination Using ASME BPV Code Case N-824 Techniques 41

5.4.12 ASME

OM Code Mandatory Appendix III Inservice Testing of

Motor-

Operated Valves 43

5.4.13 ASME OM Code Supplemental Requirements Testing for New Reactors 46

5.4.14 ASME

OM Code Requirements for Squib Valve Surveillance for

New

Reactors 46

5.4.15 Subsection ISTB (2011 Edition of the ASME OM Code) Testing 47

5.4.16 ASME

OM Code Mandatory Appendix V on Pump Periodic

Verification

Tests 47

5.4.18 ASME OM Code Subsection ISTF Pump Testing for New Reactors 50

5.4.19 ASME OM Code Case OMN-20 Time Period Extension 50

5.4.20 Program Revision to Inservice Testing Requirements 51

5.4.21 Cast Austenitic Stainless Steel Material Examination Requirements 51

5.4.22 Examination

Coverage Requirements for Butt Welds Joining Cast

Stainless

Steel Material 52

5.4.23 Encoding of Ultrasonic Volumetric Examinations 52

5.4.24 Clarification of Valve Position Verification Requirements 53

5.6.1 Quality Assurance Program Description Review 54

5.6.2 Procedure Revision to Incorporate Concrete Containment Examinations 54

5.6.3 Procedure Revision to Underwater Weld Requirements 54

5.6.4 Procedure Revision to Incorporate Nondestructive Examination Personnel Certification 54

5.6.5 Procedure Revision to Prohibit the Use of Mechanical Clamping Devices 54

5.6.6 Procedure

Revision to Incorporate Summary Report Submittal

Requirements 55

5.6.7 Procedure

Revision to Prohibit the Use of Risk-Informed Allowable

Pressure

Methodology 55

5.6.9 Procedure

Revision to Specify the Use of Reference Temperature in the

Kla

and Klc Equations 55

5.6.10 Procedure

Revision to Incorporate Fracture Toughness of Irradiated

Material

Requirements 55

5.6.12 Procedure

Revision to Incorporate Motor-Operated Valve

Testing

Requirements 56

5.6.14 Procedure

Revision to Incorporate Squib Valve Surveillance

Requirements

for New Reactors 56

5.6.19 ASME OM Code Case OMN-20 Time Period Extension 57

5.6.20 Program Revision to Inservice Testing Requirements 57

5.6.21 Procedure

to Incorporate Cast Austenitic Stainless Steel Material

Examination

Requirements 57

5.6.23 Procedure

to Incorporate Encoding of Ultrasonic Volumetric

Examinations 57

5.6.24 Clarification of Valve Position Verification Requirements 57

5.7.1 Quality Assurance Program Description Review 58

5.7.2 Concrete Containment Examinations 59

5.7.3 Underwater Welding Requirements 59

5.7.4 Nondestructive Examination Personnel Certification 59

5.7.5 Control the Use of Mechanical Clamping Devices 59

5.7.6 Summary Report Review 59

5.7.7 Control the Use of Risk-Informed Allowable Pressure Methodology 59

5.7.8 Review Disposition of Flaws in Class 3 Components 59

5.7.9 Review the Use of Reference Temperature in the Kla and Klc Equations 60

5.7.10 Review Fracture Toughness of Irradiated Material Requirements 60

5.7.11 Review Ultrasonic Examinations Using ASME BPV Code Case N-824 60

5.7.12 Review

ASME OM Code Mandatory Appendix III Motor-Operated

Valve

Inservice Testing Results 60

5.7.13 Review

ASME OM Code Supplemental Requirements Test Results for

New

Reactors 60

5.7.14 Procedure

Revision to Incorporate Squib Valve Surveillance

Requirements

for New Reactors 60

5.7.15 Review

Subsection ISTB (2011 Edition of the ASME OM Code)

Test

Results 60

5.7.16 Review

ASME OM Code Mandatory Appendix V Pump Periodic

Verification

Program 61

5.7.17 Review

ASME OM Code Subsection ISTE Risk-Informed Inservice

Testing

of Pumps and Valves 61

5.7.18 Review ASME OM Code Subsection ISTF Pump Testing Results for New Reactors 61

5.7.19 Review ASME OM Code Case OMN-20 Time Period Extension 61

5.7.20 Program Revision to Inservice Testing Requirements 62

5.7.21 Procedure

to Incorporate Cast Austenitic Stainless Steel Material

Examination

Requirements 62

5.7.23 Procedure

to Incorporate Encoding of Ultrasonic Volumetric

Examinations 62

5.7.24 Clarification of Valve Position Verification Requirements 63

5.9 Improvements in Knowledge 63

5.11.1 National Technology Transfer and Advancement Act of 1995 64

5.11.3 Risk-Informed Inservice Testing 65

5.11.4 Increased Public Confidence 65

5.11.5 Reliable Assessment of Cast Austenitic Stainless Steel Materials 66

5.12.1 Uncertainty Analysis Assumptions 66

5.12.2 Uncertainty Analysis Results 73

5.12.3 Summary of Uncertainty Analysis 77

5.14 Hypothetical Future Operating Reactors 82

5.15.1 Quantified Net Benefit 85

5.15.2 Nonquantified Benefits 87

5.16 Safety Goal Evaluation 90

5.16.4 Safety Goal Evaluation Result 92

5.17 Results for the Committee to Review Generic Requirements 92

List of Tables

Table Page

Table 1 Total Costs and Benefits for Alternative 2 xxi

Table 3 Position Titles and Occupations 15

Table 4 Dollar per Person-Rem Conversion Factor Sensitivity Values 18

Table 6 Industry Implementation—Fracture Toughness Provision (Operating Plants) 24

Table 7 Industry Implementation—ASME BPV Code Case N-824 Optional Provision (Operating Plants) 25

Table 8 Industry Implementation—Mandatory MOV Diagnostic Test Provision (Operating Plants) 26

Table 9 Industry Implementation—Supplemental Requirements Provision (Future Units) 28

Table 10 Squib Valve Surveillance Provision (Future Units) 29

Table 13 Industry Operation—Averted Code Case Relief Request Costs 36

Table 14 Industry Operation—Concrete Containment Examinations Provision (Operating Reactors) 38

Table 15 Industry Operation—Concrete Containment Examinations Provision (Future Reactors) 39

Table 17 ASME BPV Code Case N-824 Dose—Proposed Conversion Factor 43

Table 18 Industry Operation—MOV IST Provision (Operating Reactors) 44

Table 19 Industry Operation—MOV IST Provision (Operating Reactors)—Dose 44

Table 20 Industry Operation—MOV IST Provision (Future Reactors) 45

Table 21 Industry Operation—MOV IST Provision (New Reactors)—Dose 45

Table 22 MOV IST Provision—Dose (Proposed Conversion Factor) 46

Table 28 Total Industry Costs 53

Table 29 NRC Implementation Costs 55

Table 30 NRC Operation Costs—Averted Code Alternative Request Review (Operating and New Reactors) 58

Table 31 Averted ASME BPV Code Case N-824 Weld Relief Requests 60

Table 32 NRC Operation—Review OMN-20 Code Case Alternative Request and Issue Safety Evaluation 62

Table 34 Uncertainty Analysis Variables 67

Table 35 Uncertainty Results Descriptive Statistics (7-Percent NPV) 75

Table 37 Program Revision to QAPD to Incorporate the ASME NQA-1 Program 82

Table 38 Squib Valve Surveillance Provision 83

Table 39 ASME OM Code Mandatory Appendix V Provision 83

Table 40 ASME OM Code Subsection ISTE Optional Provision 83

Table 41 ASME OM Code Mandatory Appendix V Pump Verification Test Provision 83

Table 42 ASME OM Code Case OMN-20 Time Period Extension Optional Provision 84

Table 43 Program Revision to QAPD to Incorporate the ASME NQA-1 Program 84

Table 44 ASME OM Code Case OMN-20 Time Period Extension Optional Provision 85

Table 45 Averted Code Alternative and Relief Request Review 85

Table 46 Total Costs for Alternative 2, Including All Provisions 86

Table 47 Total Costs for Alternative 2, Excluding Optional Provisions 86

Table 48 Total Net Benefit by ASME Code Section 87

Table 49 Specific CRGR Regulatory Analysis Information Requirements 92

Table 51 Motor-Operated Valve (MOV) Testing Program (Operating Reactors) 100

Table 52 MOV Testing Program (Operating Reactors)—Dose 103

Table 53 MOV Testing Program (New Reactors) 106

List of Figures

Figure Page

Figure 1 Total industry costs (7-percent NPV)—Alternative 2 73

Figure 2 Total NRC costs (7-percent NPV)—Alternative 2 74

Abbreviations and Acronyms

ADAMS Agencywide Documents Access and Management System

appm atomic parts per million

ASME American Society of Mechanical Engineers

ASME Codes ASME BPV and OM Codes

ASME OM Committee ASME Committee on Operation and Maintenance of Nuclear Power Plants

BLS Bureau of Labor Statistics

BPV boiler and pressure vessel

BPV Code ASME Boiler and Pressure Vessel Code

CASS cast austenitic stainless steel

CC concrete containment

CFR Code of Federal Regulations

CPI Consumer Price Index

CPI-U Consumer Price Index for all urban consumers

CRGR Committee to Review Generic Requirements

FR Federal Register

GALL generic aging lessons learned

GDC general design criterion/criteria

ISI inservice inspection

IST inservice testing

LOE level of effort

LWR light-water reactor

MC metal containment

MOV motor-operated valve

NDE nondestructive examination

NPV net present value

NRC U.S. Nuclear Regulatory Commission

NTTAA National Technology Transfer and Advancement Act of 1995

OM operation and maintenance

OM Code (ASME) Code for Operation and Maintenance of Nuclear Power Plants

OMB U.S. Office of Management and Budget

PERT program evaluation and review technique

POV power-operated valve

Pub. L. public law

PWR pressurized-water reactor

PWSCC primary water stress-corrosion cracking

QAPD quality assurance program description

RCPB reactor coolant pressure boundary

Ref. reference

RPV reactor pressure vessel

RT reference temperature

SOC standard occupational classification

tn nominal pipe wall thickness

TS technical specification(s)

VSL value of statistical life

Abstract

This draft final rule would incorporate by reference, all with conditions on their use, the 2009 Addenda, 2010 Edition, 2011 Addenda, and 2013 Edition of the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel (BPV) Code, Section III, Division 1, and Section XI, Division 1; the 2009 Edition, 2011 Addenda, and 2012 Edition of the ASME Code for Operation and Maintenance of Nuclear Power Plants; and ASME BPV Code Case N-729-4, “Alternative Examination Requirements for PWR Reactor Vessel Upper Heads With Nozzles Having Pressure-Retaining Partial-Penetration Welds Section XI, Division 1”; Code Case N‑770‑2, “Alternative Examination Requirements and Acceptance Standards for Class 1 PWR Piping and Vessel Nozzle Butt Welds Fabricated with UNS N06082 or UNS W86182 Weld Filler Material With or Without Application of Listed Mitigation Activities Section XI, Division 1”; and Code Case N‑824, “Ultrasonic Examination of Cast Austenitic Piping Welds From the Outside Surface Section XI, Division 1.” Additionally, the draft final rule would incorporate by reference ASME NQA-1, “Quality Assurance Requirements for Nuclear Facility Applications.”

Executive Summary

The U.S. Nuclear Regulatory Commission (NRC) is proposing to amend its regulations to incorporate by reference the 2009 Addenda, 2010 Edition, 2011 Addenda, and 2013 Edition of the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel (BPV) Code, Section III, Division 1, and Section XI, Division 1, with conditions on their use. The NRC also proposes to amend its regulations to incorporate by reference the 2009 Edition, 2011 Addenda, and 2012 Edition of the ASME Code for Operation and Maintenance of Nuclear Power Plants (OM Code), with conditions on their use. The NRC also proposes to incorporate by reference, with conditions on their use, ASME BPV Code Case N-729-4, “Alternative Examination Requirements for PWR Reactor Vessel Upper Heads With Nozzles Having Pressure-Retaining Partial‑Penetration Welds Section XI, Division 1”; Code Case N‑770‑2, “Alternative Examination Requirements and Acceptance Standards for Class 1 PWR Piping and Vessel Nozzle Butt Welds Fabricated with UNS N06082 or UNS W86182 Weld Filler Material With or Without Application of Listed Mitigation Activities Section XI, Division 1”; and Code Case N-824, “Ultrasonic Examination of Cast Austenitic Piping Welds from the Outside Surface Section XI, Division 1.” Additionally, the NRC proposes to incorporate by reference, for the first time, ASME NQA-1, “Quality Assurance Requirements for Nuclear Facility Applications,” including several editions and addenda to ASME NQA-1 from previous years with slightly varying titles. A significant portion of the averted costs from this final rule results from the reduction in burden of plant-specific requests for alternatives because these provisions are now incorporated by reference.

The analysis presented in this document examines the benefits and costs of the final rulemaking relative to the baseline case (i.e., the no-action alternative). The NRC staff makes the following key findings based on this analysis:

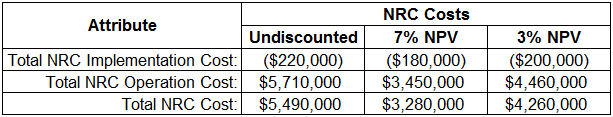

Final Rule Analysis. The final rule recommended by the NRC staff would result in a cost‑justified change based on a net (i.e., taking into account both costs and benefits) averted cost to the industry that ranges from $11.5 million using a 7-percent discount rate to $22.8 million using a 3-percent discount rate. Relative to the regulatory baseline, the NRC would realize a net averted cost that ranges from $3.3 million using a 7‑percent discount rate to $4.3 million using a 3-percent discount rate. Table 1 shows the separate total costs and benefits to the industry and the NRC. The alternative to the final rule would result in net averted costs to the industry and the NRC ranging from $14.7 million using a 7‑percent discount rate to $27.1 million using a 3‑percent discount rate.

Table 1 Total Costs and Benefits for Alternative 2

Nonquantified Benefits. Other benefits of the recommended final rule include its furtherance of the NRC’s ability to meet its goal of ensuring the protection of public health and safety and the environment through the NRC’s approval of new editions of the ASME BPV and OM Codes, which allow the use of the most current methods and technology. The recommended final rule is consistent with the provisions of the National Technology Transfer and Advancement Act of 1995 and implementing guidance in U.S. Office of Management and Budget Circular A-119, “Federal Participation in the Development and Use of Voluntary Consensus Standards and in Conformity Assessment Activities,” dated February 10, 1998, which encourage Federal regulatory agencies to consider adopting voluntary consensus standards as an alternative to de novo agency development of standards affecting an industry. Finally, the ASME Code consensus process is an important part of the regulatory framework.

Uncertainty Analysis. The simulation analysis shows that the estimated mean averted cost for this draft final rule is $14.7 million with a 90-percent confidence interval and that the total averted cost is between $8.19 million and $21.6 million, assuming a 7-percent discount rate. The number of motor-operated valves requiring quarterly testing and the hourly rate for plant technical staff performing that testing are the factors that are responsible for the largest variation in costs.

Decision Rationale. Relative to the no‑action baseline, the NRC staff concludes that the draft final rule is justified from a quantitative standpoint because its provisions would result in net averted costs (i.e., net benefits) to the NRC and the industry. In addition, the NRC staff concludes that the draft final rule is also justified when considering non-quantified costs and benefits, because the number and significance of the non-quantified benefits outweigh the non-quantified costs.

This document presents the regulatory analysis for the draft final rule to incorporate by reference specific American Society of Mechanical Engineers (ASME) Codes and Code Cases (Agencywide Documents Access and Management System (ADAMS) Accession No. ML16130A538). The recommended draft final rule incorporates by reference the following nine items:

the 2009 Addenda, 2010 Edition, 2011 Addenda, and 2013 Edition of the ASME Boiler and Pressure Vessel (BPV) Code, Section III, Division 1, and ASME BPV Code, Section XI, Division 1

the 2009 Edition, 2011 Addenda, and 2012 Edition of the ASME Code for Operation and Maintenance of Nuclear Power Plants (OM Code), specifically—

the 2009 Edition and 2011 Addenda to the ASME OM Code, Division 1, “Section IST Rules for Inservice Testing of Light‑Water Reactor Power Plants”

the 2012 Edition to the ASME OM Code, Division 1, “OM Code: Section IST”

ASME BPV Code Case N-729-4, “Alternative Examination Requirements for PWR Reactor Vessel Upper Heads with Nozzles Having Pressure-Retaining Partial‑Penetration Welds Section XI, Division 1,” ASME approval date: June 22, 2012 (with conditions on its use)

ASME BPV Code Case N-770-2, “Alternative Examination Requirements and Acceptance Standards for Class 1 PWR Piping and Vessel Nozzle Butt Welds Fabricated with UNS N06082 or UNS W86182 Weld Filler Material With or Without Application of Listed Mitigation Activities Section XI, Division 1,” ASME approval date: June 9, 2011 (with conditions on its use)

ASME BPV Code Case N-824, “Ultrasonic Examination of Cast Austenitic Piping Welds From the Outside Surface Section XI, Division 1,” ASME approval date: October 16, 2012 (with conditions on its use)

ASME BPV Code Case N-513-3, “Evaluation Criteria for Temporary Acceptance of Flaws in Moderate Energy Class 2 or 3 Piping Section XI, Division 1,” ASME approval date: January 26, 2009 (with conditions on its use)

ASME BPV Code Case N-852, “Application of the ASME NPT Stamp, Section III, Division 1; Section III, Division 2; Section III, Division 3; Section III, Division 5,” ASME approval date: February 9, 2015 (with conditions on its use)

ASME OM Code Case OMN-20, “Inservice Test Frequency”

ASME NQA-1, “Quality Assurance Requirements for Nuclear Facility Applications,” including the 1983 Edition through the 1992 Addenda to the 1989 Edition, 1994 Edition, 2008 Edition, and 2009-1a Addenda to the 2008 Edition (with conditions on their use)

ASME develops and publishes the ASME BPV Code that contains requirements for design, construction, and inservice inspection (ISI) of nuclear power plant components, and the ASME OM Code that contains requirements for operation and inservice testing (IST) of nuclear power plant components. Until 2012, ASME issued new editions of the ASME BPV Code every 3 years and addenda to the editions annually, except in years when it issued a new edition. Similarly, ASME periodically published new editions and addenda of the ASME OM Code. Starting in 2012, ASME decided to issue editions of its BPV and OM Codes (no addenda) every 2 years. The new editions and addenda typically revise provisions of the Codes to broaden their applicability, add specific elements to current provisions, delete specific provisions, or clarify them to narrow the applicability of the provision (or a combination of these). The revisions to the editions and addenda of the Codes do not significantly change Code philosophy or approach.

It has been the U.S. Nuclear Regulatory Commission’s (NRC’s) practice to establish requirements for the design, construction, operation, ISI, and IST of nuclear power plants by approving the use of editions and addenda of the ASME BPV and OM Codes (ASME Codes) in Title 10 of the Code of Federal Regulations (10 CFR) 50.55a, “Codes and Standards.” The NRC approves or mandates the use of certain parts of ASME Code editions and addenda in 10 CFR 50.55a through the rulemaking process of “incorporation by reference.” Upon incorporation by reference of the ASME Codes into 10 CFR 50.55a, the provisions of the ASME Codes are legally binding NRC requirements as delineated in 10 CFR 50.55a, subject to the conditions on certain specific ASME Code provisions that are set forth in 10 CFR 50.55a. The NRC last incorporated by reference the ASME Code editions and addenda into the regulations in a final rule dated June 21, 2011 (76 FR 36232) (Ref. 8.8), subject to NRC conditions.

2.1 Background

The general design criteria (GDC) for nuclear power plants contained in Appendix A, “General Design Criteria for Nuclear Power Plants,” to 10 CFR Part 50, “Domestic Licensing of Production and Utilization Facilities,” or, as appropriate, similar requirements in the licensing basis for a reactor facility, provide bases and requirements for the NRC’s assessment of the use of generally recognized codes and standards and the potential for, and consequences of, degradation of the reactor coolant pressure boundary (RCPB). The applicable GDC include GDC 1, “Quality Standards and Records,” GDC 14, “Reactor Coolant Pressure Boundary,” and GDC 32, “Inspection of Reactor Coolant Pressure Boundary.”

GDC 1 requires, in part, the following:

Structures, systems, and components important to safety shall be designed, fabricated, erected, and tested to quality standards commensurate with the importance of the safety function to be performed. Where generally recognized codes and standards are used, they shall be identified and evaluated to determine their applicability, adequacy, and sufficiency and shall be supplemented or modified as necessary to ensure a quality product in keeping with the required safety function.

GDC 14 establishes the following:

The reactor coolant pressure boundary shall be designed, fabricated, erected, and tested so as to have an extremely low probability of abnormal leakage, of rapidly propagating failure, and of gross rupture.

Additionally, GDC 32 establishes the following:

Components which are part of the reactor coolant pressure boundary shall be designed to permit (1) periodic inspection and testing of important areas and features to assess their structural and leak tight integrity, and (2) an appropriate material surveillance program for the reactor pressure vessel.

The National Technology Transfer and Advancement Act of 1995 (Pub. L. 104-113) (NTTAA) (Ref. 8.5) mandates the following:

All Federal agencies and departments shall use technical standards that are developed or adopted by voluntary consensus standards bodies, using such technical standards as a means to carry out policy objectives or activities determined by the agencies and departments.

In carrying out this legislation, Federal agencies are to consult with voluntary consensus standards bodies and participate with such bodies in the development of technical standards when such participation is in the public interest and compatible with the agency mission, priorities, and budget resources. If the technical standards are inconsistent with applicable law or otherwise impractical, a Federal agency may elect to use technical standards that are not developed or adopted by voluntary consensus bodies.

Provisions of the ASME BPV Code have been used since 1971 as one part of the framework to establish the necessary design, fabrication, construction, testing, and performance requirements for structures, systems, and components important to safety. Various technical interests (e.g., utility, manufacturing, insurance, regulatory) are represented on the ASME standards committees that develop, among other things, improved methods for the construction and ISI of ASME Class 1, 2, and 3; metal containment (MC); and concrete containment (CC) nuclear power plant components. This broad spectrum of stakeholders helps to ensure that the various interests are considered.

The ASME Board on Nuclear Codes and Standards directive transferred responsibility for the development and maintenance of rules for the IST of pumps and valves from the ASME Section XI Subcommittee on Nuclear Inservice Inspection to the ASME Committee on Operation and Maintenance of Nuclear Power Plants (ASME OM Committee); this led to the development of the OM Code. In 1990, ASME published the initial edition of the OM Code that provides rules for IST of pumps and valves. The ASME OM Committee continues to maintain the OM Code. ASME intended that the OM Code replace the ASME BPV Section XI rules for IST of pumps and valves. The ASME Section XI Committee no longer updates the Section XI rules for IST of pumps and valves that were previously incorporated by reference into NRC regulations.

In 10 CFR 50.55a, the NRC requires that nuclear power plant owners construct Class 1, 2, and 3 components in accordance with Section III, Division 1, of the ASME BPV Code. Regulations in 10 CFR 50.55a also require that owners perform ISI of Class 1, Class 2, Class 3, Class MC, and Class CC components in accordance with Section XI, Division 1, of the BPV Code, and that they perform IST of Class 1, 2, and 3 safety‑related pumps and valves in accordance with the OM Code. Code Cases are developed by ASME to gain experience with new technology before incorporating it into the ASME Code; permit licensees to use advancements in ISI and IST; provide alternative examinations for older plants; provide an expeditious response to user needs; and provide a limited, clearly focused alternative to specific ASME Code provisions.

2.2 Statement of the Problem

In this regulatory action, the NRC is conditioning the use of certain provisions of the 2009 Addenda, 2010 Edition, 2011 Addenda, and 2013 Edition of the ASME BPV Code, Section III, Division 1, and the ASME BPV Code, Section XI, Division 1, including ASME NQA-1, as well as the 2009 Edition, 2011 Addenda, and 2012 Edition of the ASME OM Code and ASME BPV Code Cases N-729-4, N-770-2, and N-824. In addition, the draft final rule regulatory action does not adopt (“excludes”) certain provisions of the ASME Codes.

If the NRC did not conditionally accept ASME Code editions, addenda, and Code Cases, the NRC would disapprove these provisions entirely. The effect would be that licensees and applicants could submit a petition for rulemaking requesting the incorporation by reference of the full scope of the ASME Code editions and addenda that would otherwise be approved as proposed in this final rulemaking (i.e., the request would not be simply for approval of a specific ASME Code provision with conditions). Alternatively, licensees and applicants could submit a larger number of requests for the use of alternatives under 10 CFR 50.55a(z) or requests for exemptions under 10 CFR 50.12 or 10 CFR 52.7, both entitled “Specific exemptions.” These alternative requests could also include similar broad-scope requests for approval to issue the full scope of the ASME Code editions and addenda. These requests would pose an unnecessary additional burden for both the licensee and the NRC, inasmuch as the NRC has already determined that the ASME Codes and Code Cases that are the subject of this regulatory action are acceptable for use (in some cases with conditions).

2.3 Objective

The objective of this regulatory action is to incorporate by reference the 2009 Addenda, 2010 Edition, 2011 Addenda, and 2013 Edition of the ASME BPV Code, Section III, Division 1, and Section XI, Division 1, with conditions on their use. The NRC also proposes to amend its regulations to incorporate by reference the 2009 Edition, 2011 Addenda, and 2012 Edition of the ASME OM Code, with conditions on their use. The NRC also proposes to incorporate by reference ASME BPV Code Cases N-729-4, N‑770‑2, and N-824, with conditions on their use. The NRC proposes to incorporate by reference, for the first time, ASME NQA-1, including the 1983 Edition through the 1992 Addenda to the 1989 Edition; the 1994 Edition; the 2008 Edition; and the 2009‑1a Addenda to the 2008 Edition, with conditions on their use.

This section analyzes the alternatives that the NRC considered with regard to conditioning the use of certain provisions of the ASME BPV and OM Codes and the regulatory alternatives associated with ASME BPV Code Cases N-729-4, N-770-2, and N-824 and ASME OM Code Case OMN-20. The NRC staff identified two alternatives for the conditioning of the use of certain provisions of the ASME Codes: (1) the no-action alternative (i.e., regulatory baseline) and (2) incorporate by reference the NRC‑approved ASME BPV Code and ASME OM Code with conditions.

3.1 Alternative 1—No Action

The no-action alternative is a non-rulemaking alternative. This alternative would not revise the NRC’s regulations to incorporate the following nine items by reference:

the 2009 Addenda, 2010 Edition, 2011 Addenda, and 2013 Edition of the ASME BPV Code, Section III, Division 1, and ASME BPV Code, Section XI, Division 1

the 2009 Edition and 2011 Addenda to the ASME OM Code, Division 1, “Section IST Rules for Inservice Testing of Light‑Water Reactor Power Plants,” and the 2012 Edition of the ASME OM Code, Division 1, “OM Code: Section IST”

ASME BPV Code Case N-729-4, “Alternative Examination Requirements for PWR Reactor Vessel Upper Heads with Nozzles Having Pressure‑Retaining Partial‑Penetration Welds Section XI, Division 1,” ASME approval date: June 22, 2012 (with conditions on its use)

ASME BPV Code Case N-770-2, “Alternative Examination Requirements and Acceptance Standards for Class 1 PWR Piping and Vessel Nozzle Butt Welds Fabricated with UNS N06082 or UNS W86182 Weld Filler Material With or Without Application of Listed Mitigation Activities Section XI, Division 1,” ASME approval date: June 9, 2011 (with conditions on its use)

ASME BPV Code Case N-824, “Ultrasonic Examination of Cast Austenitic Piping Welds From the Outside Surface Section XI, Division 1,” ASME approval date: October 16, 2012 (with conditions on its use)

ASME BPV Code Case N-513-3, “Evaluation Criteria for Temporary Acceptance of Flaws in Moderate Energy Class 2 or 3 Piping Section XI, Division 1,” ASME approval date: January 26, 2009 (with conditions on its use)

ASME BPV Code Case N-852, “Application of the ASME NPT Stamp, Section III, Division 1; Section III, Division 2; Section III, Division 3; Section III, Division 5,” ASME approval date: February 9, 2015 (with conditions on its use)

ASME OM Code Case OMN-20, “Inservice Test Frequency”

ASME NQA-1, “Quality Assurance Requirements for Nuclear Facility Applications,” including the 1983 Edition through the 1992 Addenda to the 1989 Edition; 1994 Edition; 2008 Edition; and 2009-1a Addenda to the 2008 Edition (with conditions on their use)

The no-action alternative would cause licensees and applicants that desire to use these ASME Code addenda, editions, or Code Cases to request and receive approval from the NRC for the use of alternatives under 10 CFR 50.55a(z).

3.1.1 Take No Action on ASME BPV Code Case N‑729-4

Under the regulatory baseline, the NRC would not amend the current regulations to require the use of ASME BPV Code Case N-729-4.

Not requiring the use of ASME BPV Code Case N-729-4 would leave in place the current ASME examination frequencies and methods for reactor pressure vessel (RPV) upper head penetration nozzles and welds. In the June 21, 2011, update to 10 CFR 50.55a, the NRC added the required use of ASME BPV Code Case N-729-1, “Alternative Examination Requirements for PWR Reactor Vessel Upper Heads With Nozzles Having Pressure-Retaining Partial‑Penetration Welds, Section XI, Division 1,” with certain conditions. The required implementation of this Code Case, with certain conditions, enhanced the examination requirements in ASME BPV Code, Section XI, for RPV upper head penetration nozzles and welds. This assures that ASME BPV Code allowable limits will not be exceeded and that primary water stress-corrosion cracking (PWSCC) will not lead to failure of the RPV upper head penetration nozzles or welds. However, ASME found that additional program changes were necessary to establish an effective long-term inspection program for RPV upper heads for pressurized-water reactors (PWRs).

3.1.2 Take No Action on ASME BPV Code Case N-770-2

Under the regulatory baseline, the NRC would not amend the current regulations to require the use of ASME BPV Code Case N-770-2.

Not requiring the use of ASME BPV Code Case N-770-2 would leave in place the current ASME inspection requirements for butt welds. In the June 21, 2011, update to 10 CFR 50.55a, the NRC added the required use of ASME BPV Code Case N-770-1, “Alternative Examination Requirements and Acceptance Standards for Class 1 PWR Piping and Vessel Nozzle Butt Welds Fabricated with UNS N06082 or UNS N86182 Weld Filler Material With or Without Application of Listed Mitigation Activities,” with certain conditions. The required implementation of this Code Case with conditions provides inspection frequencies and methods for Alloy 82/182 butt welds that are unmitigated as well as butt welds that have been mitigated for PWSCC by any of several mitigation methods. However, this alternative does not establish an effective long‑term inspection program for ASME BPV Code Class 1 butt welds in the RCPB, does not establish a new ASME BPV Code Case Table 1 inspection item classification for optimized weld overlay, and does not allow alternatives when complete inspection coverage cannot be met.

3.1.3 Take No Action on ASME BPV Code Case N-824

Under the regulatory baseline, the NRC would not amend the current regulations to allow the use of ASME BPV Code Case N-824.

Not allowing the use of ASME BPV Code Case N-824 would leave in place the current ASME inspection requirements as regulatory requirements for the examination of cast austenitic stainless steel (CASS). These requirements, provided in 10 CFR 50.55a, do not give sufficient guidance to assure that the CASS components are being inspected adequately. To illustrate that the ASME BPV Code does not provide adequate guidance, ASME Code, Section XI, Appendix III, Supplement 1, states “Cast materials may preclude meaningful examinations because of geometry and attenuation variables.” For this reason, over the past several decades, licensees have been unable to perform effective inspections of welds joining CASS components. To allow for continued operation of their plants, licensees have submitted to the NRC hundreds of requests for relief from the ASME BPV Code requirements for ISI of CASS components, resulting in a significant regulatory burden.

3.2 Alternative 2—Incorporate by Reference ASME BPV and OM Codes and New and Revised Code Cases with Conditions

Alternative 2 consists of incorporating by reference into the Code of Federal Regulations certain provisions, with conditions on their use, of the 2009 Addenda, 2010 Edition, 2011 Addenda, and 2013 Edition of the ASME BPV Code, Section III, Division 1, and the ASME BPV Code, Section XI, Division 1, including ASME NQA-1, as well as the 2009 Edition, 2011 Addenda, and 2012 Edition of the ASME OM Code. Under this alternative, the NRC would also incorporate by reference, with conditions on their use, ASME BPV Code Cases N-729-4, N-770-2, and N‑824 into 10 CFR 50.55a. As a result, the provisions of the ASME Codes would be legally binding NRC requirements as delineated in 10 CFR 50.55a and subject to the conditions on certain specific ASME Code provisions that are set forth in 10 CFR 50.55a.

The NRC recommends this rulemaking alternative for the following reasons:

This alternative reduces the regulatory burden on applicants or holders of licenses for nuclear power plants by eliminating the need to submit plant-specific requests for alternatives in accordance with 10 CFR 50.55a(z), and it reduces the need for the NRC to review those submittals.

This alternative meets the NRC’s goal of ensuring the protection of public health and safety and the environment by continuing to provide NRC approval of new ASME Code editions and Code Cases that allow the use of the most current methods and technology.

This alternative supports the NRC’s goal of maintaining an open regulatory process by informing the public about the process and by giving the public the opportunity to participate in it.

This alternative supports the NRC’s commitment to participate in the national consensus standard process through the approval of these ASME Code editions, addenda, and Code Cases, and it conforms to NTTAA requirements.

The initial burden on the NRC to update the regulations by incorporating by reference the editions and addenda of the ASME BPV and OM Codes cited here is more than offset by the reduction in the number of plant-specific alternative requests that the NRC would otherwise evaluate. Section 5 of this analysis discusses the costs and benefits of this alternative relative to the regulatory baseline (Alternative 1).

This section presents the process for evaluating the benefits and costs expected to result from each proposed alternative relative to the regulatory baseline (Alternative 1). All costs and benefits are monetized, when possible. The total costs and benefits are then summed to determine whether the difference between the costs and benefits results in a positive benefit. In some cases, costs and benefits are not monetized because meaningful quantification is not possible.

4.1 Identification of Affected Attributes

This section identifies the components of the public and private sectors, commonly referred to as attributes, that are expected to be affected by the alternatives identified in Section 3. The alternatives would apply to licensees and applicants for nuclear power plants and nuclear power plant design certifications. The NRC believes that nuclear power plant licensees would be the primary beneficiaries. The staff developed an inventory of the impacted attributes using the list provided in Chapter 5 of NUREG/BR-0184, “Regulatory Analysis Technical Evaluation Handbook,” issued 1997 (NRC Regulatory Analysis Handbook) (Ref. 8.14).

The rule would affect the following attributes:

Public Health (Accident). This attribute accounts for expected changes in radiation exposure to the public caused by changes in accident frequencies or accident consequences associated with the alternative (i.e., delta risk). A decrease in public radiological exposure is a decrease in risk (i.e., benefit); an increase in public exposures is an increase in risk (i.e., cost).

Occupational Health (Accident). This attribute measures immediate and long-term health effects on site workers because of changes in accident frequency or accident consequences associated with the alternative (i.e., delta risk). A decrease in worker radiological exposure is a decrease in risk (i.e., benefit); an increase in worker exposures is an increase in risk (i.e., cost).

Occupational Health (Routine). This attribute accounts for radiological exposures to workers during normal facility operations (i.e., non-accident situations). A proposed action could result in an increase in worker exposures. Sometimes this will be a one‑time effect (e.g., installation or modification of equipment in a hot area), and sometimes it will be an ongoing effect (e.g., routine surveillance or maintenance of contaminated equipment or equipment in a radiation area).

Industry Implementation. This attribute accounts for the projected net economic effect on the affected licensees to implement the mandated changes. Costs include procedural and administrative activities related to maintenance, inspection, or testing. Additional costs above the regulatory baseline are considered negative, and cost savings and averted costs are considered positive.

Industry Operation. This attribute accounts for the projected net economic effect caused by routine and recurring activities required by the proposed alternative on all affected licensees. For example, an alternative that would allow a nuclear power plant licensee to use an ASME BPV Code Case without submitting an alternative request would provide a net benefit (i.e., averted cost) to the licensee.

The effect on industry operation would be the changes to the licensees’ design, fabrication, construction, testing, and inspection practices because of the new ASME Code and NRC requirements included in this rule. Some of the changes would result in an increase in burden, and some of the changes would result in a decrease in burden.

The ASME Code Case requests and subsequent costs are considered sunk (i.e., already incurred) for issued design certifications, submitted design certifications under review, and reactor applications already submitted to the NRC.

NRC Implementation. This attribute accounts for the projected net economic effect on the NRC to place the proposed alternative into operation. It includes NRC implementation costs and benefits incurred in addition to those expected under the regulatory baseline.

NRC Operation. This attribute accounts for the projected net economic effect on the NRC after the draft final rule is implemented. If the NRC does not approve changes to licensee design, fabrication, construction, testing, and inspection practices because the licensee or applicant wants to use an unapproved ASME Code, the licensee or applicant must request, under 10 CFR 50.55a(z), permission to use the updated ASME Code by submitting a request to apply the updated edition or addenda as an alternative to the ASME Code provisions. This submittal requires additional NRC staff time to evaluate the ASME Code to determine its acceptability and whether any limitations or modifications should apply. Under the draft final rule (Alternative 2), these alternative requests would not be necessary, which would result in a net benefit (i.e., averted cost) for the NRC.

The NRC review costs for any ASME Code alternative requests submitted to the NRC before the effective date of the final rule are considered sunk costs and are not analyzed further in this regulatory analysis.

Improvements in Knowledge. This attribute accounts for improvements in knowledge by enhancing the ability of the industry and the NRC staff to gain experience with new technology before its incorporation into the ASME Codes, and by permitting licensees to use advancements in ISI and IST. Improved ISI and IST may also result in the earlier identification of material degradation that, if undetected, could result in further degradation that eventually results in a plant transient.

Regulatory Efficiency. This attribute accounts for regulatory and compliance improvements resulting from the implementation of Alternative 2 relative to the regulatory baseline. Alternative 2 would continue the best practice of aligning NRC regulations with ASME Code standards, providing the industry with regulatory provisions for which it has sought permission via relief and alternative requests. This rulemaking would ameliorate the effort the industry expends generating these requests and considering alternative means to accomplish the goals of these provisions.

Other Considerations. This attribute accounts for considerations that are not captured in the preceding attributes. Specifically, this attribute accounts for how Alternative 2 meets specific requirements of the Commission, helps achieve NRC policy, and provides other advantages or detriments.

Attributes with No Effects. Attributes that are not expected to be affected under any of the alternatives include public health (routine); offsite property; onsite property; other government, general public, and antitrust considerations; safeguards and security considerations; and environmental considerations.

4.2 Analytical Methodology

This section describes the process used to evaluate benefits and costs associated with the proposed alternatives. The benefits include any desirable changes in affected attributes (e.g., monetary savings, improved safety, and improved security). The costs include any undesirable changes in affected attributes (e.g., monetary costs, increased exposures).

Of the 11 affected attributes, the analysis evaluates five attributes—industry implementation, industry operation, occupational health (routine), NRC implementation, and NRC operation—on a quantitative basis. Quantitative analysis requires a baseline characterization of the affected society, including factors such as the number of affected entities, the nature of the activities currently performed, and the types of systems and procedures that licensees or applicants would implement, or would no longer implement, because of the proposed alternatives. Where possible, the staff calculated costs for these five attributes using three-point estimates to quantify the uncertainty in these estimates. The majority of the tables used in this regulatory analysis are included in the individual sections for each of the provisions, but certain detailed cost tables are included in Appendix A. The staff evaluated the remaining six attributes on a qualitative basis because the benefits relating to consistent policy application and improvements in ISI and IST techniques are not quantifiable or because the data necessary to quantify and monetize the impacts on these attributes are not available.

The staff documents its assumptions throughout this regulatory analysis. For reader convenience, Appendix B summarizes the major assumptions and input data.

4.2.1 Regulatory Baseline

This regulatory analysis provides the incremental impacts of the draft final rule relative to a baseline that reflects anticipated behavior in the event the NRC does not undertake regulatory or non-regulatory action. The regulatory baseline assumes full compliance with existing NRC requirements, including current regulations and relevant orders. This is consistent with NUREG/BR-0058, “Regulatory Analysis Guidelines of the U.S. Nuclear Regulatory Commission,” Revision 4, issued September 2004 (Ref. 8.13), which states that “in evaluating a new requirement…, the staff should assume that all existing NRC and Agreement State requirements have been implemented.” Section 5 of this regulatory analysis presents the estimated incremental costs and benefits of the alternatives relative to this baseline.

4.2.2 Affected Entities

This draft final rule could affect all operating light-water nuclear power reactors and those operating in the future:

Nuclear facilities. The analysis models 59 plant sites containing one or more operating U.S. light-water nuclear power reactor units in 2017, which reduces to 55 plant sites in 2019.1

Operating reactor units. The analysis models 102 reactor units in 2017 and 97 reactor units in 2019. This list of operating reactor units includes Watts Bar Unit 2, Vogtle Units 3 and 4 (expected to begin operations in 2019 and 2020, respectively), and V.C. Summer Units 2 and 3 (expected to begin operations in 2019 and 2020, respectively) for the purposes of this analysis.

Future operating reactor units. The NRC staff assumes that the draft final rule would affect five future operating light‑water nuclear power reactors and considered them in this analysis. The future nuclear power reactors are South Texas Project Units 3 and 4, Enrico Fermi Unit 3, Levy County, and Lee Station. For the purposes of this analysis, these future operating reactor units are considered below with future nuclear power reactor applicants.2

To account for future nuclear power reactor applicants and license holders and current license holders that are anticipated to begin construction after the draft final rule’s effective date, the NRC modeled a hypothetical nuclear power reactor based on existing approved future light‑water reactor designs to analyze the specific costs and benefits. In such designs, the ASME OM Code would apply to pumps, valves, and snubbers in the same manner as for the known future operating reactor units. The NRC assumes that for safety system design features addressed by the ASME Codes, there would be minimal differences in implementing the draft final rule provisions between the future operating reactor units listed above and the modeled hypothetical nuclear power reactor. However, as the timing of a hypothetical reactor is speculative, the analysis is provided for information purposes only and is not included as part of the decision rationale.

4.2.3 Base Year

All monetized costs are expressed in 2017 dollars. Ongoing costs of operation related to the alternative being analyzed are assumed to begin no earlier than 30 days after publication of the final rule in the Code of Federal Regulations unless otherwise stated, and they are modeled on an annual cost basis.

Estimates are made for one-time implementation costs. The NRC assumes that these costs will be incurred in the first year of the analysis unless otherwise noted.

Estimates are made for recurring annual operating expenses. The values for annual operating expenses are modeled as a constant expense for each year of the analysis horizon. The staff performed a discounted cash flow calculation to discount these annual expenses to 2017 dollar values.

4.2.4 Discount Rates

In accordance with guidance from U.S. Office of Management and Budget (OMB) Circular No. A‑4, “Regulatory Analysis,” issued September 2003 (Ref. 8.21), and NUREG/BR‑0058, Revision 4 (Ref. 8.13), present-worth calculations are used to determine how much society would need to invest today to ensure that the designated dollar amount is available in a given year in the future. By using present-worth values, costs and benefits, regardless of when the cost or benefit is incurred in time, are valued to a reference year for comparison. The choice of a discount rate, and its associated conceptual basis, is a topic of ongoing discussion within the Federal Government. Based on OMB Circular No. A-4 and consistent with NRC past practice and guidance, present-worth calculations in this analysis use 3-percent and 7-percent real discount rates. A 3‑percent discount rate approximates the real rate of return on long-term government debt, which serves as a proxy for the real rate of return on savings to reflect reliance on a social rate of time preference discounting concept3. A 7-percent discount rate approximates the marginal pretax real rate of return on an average investment in the private sector, and it is the appropriate discount rate whenever the main effect of a regulation is to displace or alter the use of capital in the private sector. A 7-percent rate is consistent with an opportunity cost4 of capital concept to reflect the time value of resources directed to meet regulatory requirements.

4.2.5 Cost/Benefit Inflators

The staff estimated the analysis inputs for some attributes based on the values published in the NRC Regulatory Analysis Handbook (Ref. 8.14) or other sources as referenced, which are provided in prior‑year dollars. To evaluate the costs and benefits consistently, these inputs are put into base year dollars. The most common inflator is the Consumer Price Index for all urban consumers (CPI‑U), developed by the U.S. Department of Labor, Bureau of Labor Statistics (BLS). Using the CPI-U, the prior‑year dollars are converted to 2017 dollars. The formula to determine the amount in 2017 dollars is:

Table 2 summarizes the values of CPI-U used in this regulatory analysis.

Base Year |

CPI-U Annual Average |

Forecast Percent Change from Previous Year |

2014 |

236.736 |

|

2015 |

239.34 |

1.10% |

2016 |

242.212 |

2.20% |

2017 |

247.783 |

2.30% |

Source: BLS Statistics, “Databases, Tables & Calculators by Subject: CPI Inflation Calculator” (Ref. 8.6).

4.2.6 Labor Rates

For the purposes of this regulatory analysis, the staff applied strict incremental cost principles to develop labor rates that include only labor and material costs that are directly related to the implementation and operation and maintenance of the draft final rule requirements. This approach is consistent with the guidance in NUREG/CR-3568, “A Handbook for Value-Impact Assessment,” issued December 1983 (Ref. 8.7), and general cost-benefit methodology. The NRC incremental labor rate is $128 per hour.5

The NRC staff used the 2015 Occupational Employment and Wages data, which provided labor categories and the mean hourly wage rate by job type, and used the inflator discussed above to inflate these labor rate data to 2017 dollars. The labor rates used in the analysis reflect total hourly compensation, which includes wages and nonwage benefits (using a burden factor of 2.4, applicable for contract labor and conservative for regular utility employees). The NRC staff used the BLS data tables to select appropriate hourly labor rates for performing the estimated procedural, licensing, and utility-related work necessary during and following implementation of the proposed alternative. In establishing this labor rate, wages paid for the individuals performing the work plus the associated fringe benefit component of labor cost (i.e., the time for plant management over and above those directly expensed) are considered incremental expenses and are included. Table 3 summarizes the BLS labor categories that were used to estimate industry labor costs to implement this draft final rule, and Appendix B lists the industry labor rates used in the analysis. The NRC staff performed an uncertainty analysis, which is discussed in Section 5.12.

Table 3 Position Titles and Occupations

Position Title (in This Regulatory Analysis) |

Occupation (SOC Code) |

Managers |

Top Executives (111000) |

Chief Executives (111011) |

|

General and Operations Managers (111021) |

|

Industrial Production Managers (113051) |

|

First-Line Supervisors of Mechanics Installers and Repairers (491011) |

|

First-Line Supervisors of Production and Operating Workers (511011) |

|

Technical Staff |

Nuclear Engineers (172161) |

Physicists (192012) |

|

Nuclear Technicians (194051) |

|

Industrial Machinery Mechanics (499041) |

|

Nuclear Power Reactor Operators (518011) |

|

Administrative Staff |

Office and Administrative Support Occupations (430000) |

First-Line Supervisors of Office and Administrative Support Workers (431011) |

|

Office Clerks, General (439061) |

|

Licensing Staff |

Lawyers (231011) |

Paralegals and Legal Assistants (232011) |

4.2.7 Sign Conventions

The sign conventions used in this analysis are that all favorable consequences for the alternative are positive and all adverse consequences for the alternative are negative. Negative values are shown using parentheses (e.g., negative $500 is displayed as ($500)).

4.2.8 Analysis Horizon

The average expiration date of the operating licenses for the 102 operating reactor units is June 2041, which results in 24 remaining years of operation. Assuming the year 2020 as the commencement of commercial operations for Vogtle Unit 4 and V.C. Summer Unit 3 and assuming a 20-year license renewal, these units would end commercial operation in 2080.

The NRC staff assumes that incorporation of ASME Code Cases for operating plants would occur within three cycles of issuing a new edition of the ASME BPV or OM Code or within 6 years, whichever would occur first. The staff used a 6-year period for the effective use of the ASME Code Cases, a relatively short period, for two reasons. First, because ASME updates the edition of the BPV and OM Codes every 2 years, it is likely that those ASME Code Cases used by industry would be incorporated into the relevant Code. Secondly, as the alternatives within this regulatory analysis have up-front costs with benefits that accrue in later years through averted costs (e.g., licensees and applicants no longer need to submit an ASME Code alternative request), shorter time horizons place heavier emphasis on the implementation costs than on the alternative’s benefits.

4.2.9 Cost Estimation

To estimate the costs associated with the evaluated alternatives, the NRC staff used a work breakdown approach to deconstruct each requirement down to its mandated activities. For each required activity, the NRC further subdivided the work across labor categories (i.e., executives, managers, technical staff, administrative staff, and licensing staff). The NRC staff estimated the required level of effort (LOE) for each required activity and used a blended labor rate to develop bottom-up cost estimates.

The NRC staff gathered data from several sources and consulted ASME Code working group members to develop levels of effort and unit cost estimates. The NRC staff applied several cost estimation methods in this analysis. The staff used its collective professional knowledge and judgment to estimate many of the costs and benefits. Additionally, the staff used a build-up method, solicitation of licensee input, and extrapolation techniques to estimate costs and benefits.

The NRC staff began by estimating some activities using the engineering build-up method of cost estimation, which combines incremental costs of an activity from the bottom up to estimate a total cost. For this step, the NRC reviewed previous license submittals and determined the number of pages in each section, then used these data to develop preliminary levels of effort.

The NRC staff consulted subject matter experts within and outside the agency to develop most of the LOE estimates used in the analysis. For example, to estimate licensee costs and averted costs (benefits) related to the proposed NRC conditions on the ASME Codes in the draft final rule, the NRC staff consulted licensees for information on the associated LOE. The NRC staff contributed to the estimation of LOE for review-related activities.

The NRC staff extrapolated to estimate some cost activities, relying on actual past or current costs to estimate the future cost of similar activities. For example, to calculate the estimated averted costs of alternative requests and the costs for preparation of the draft final rule and accompanying regulatory guidance, the NRC staff used data on past projects to determine the labor categories of the staff who would perform the work and estimate the amount of time required under each category to complete the work. If data were not available, the NRC staff estimated the LOE based on similar steps in the process for which data were available.

To evaluate the effect of uncertainty in the model, the NRC staff employed Monte Carlo simulation, which is an approach to uncertainty analysis where input variables are expressed as distributions. The simulation was run 10,000 times and values were chosen at random from the distributions of the input variables provided in Table 34. The result was a distribution of values for the output variable of interest. Monte Carlo simulation also enables users to determine the input variables that have the greatest effect on the value of the output variable. Section 5.12 gives a detailed description of the Monte Carlo simulation methods and presents the results.

4.2.10 NRC Conditioned Codes

The NRC staff analyzed the ASME BPV and OM Codes and Code Cases to determine whether the ASME Codes are (1) acceptable without conditions, (2) generally acceptable with conditions, or (3) not approved. Generally, when the NRC approves codes with conditions, licensees may experience additional regulatory burden to meet the conditioned requirements. For each applicable case, the conditions would specify the additional activities that must be performed, the limits on the activities specified, or the supplemental information needed to provide clarity (or a combination of these). The draft final rule discusses the NRC’s evaluation of the ASME Codes and the reasons for the NRC’s proposed conditions. The NRC staff estimated the additional burden for each NRC-proposed condition for an ASME Code provision or Code Case under the affected attributes of industry implementation and industry operation and then its contribution to costs and benefits were integrated into the overall costs and benefits.

4.2.11 Dollar per Person-Rem Conversion Factor

The dose averted and the dose conversion factors are only provided in tables that relate to health benefits. The dose averted is the amount of probability-weighted dose (i.e., risk) that is prevented as a result of the alternative based on a linear no-threshold dose response model per year (i.e., the delta risk per year between the regulatory baseline and the alternative). The dose conversion factor (dollar per person-rem) is used to monetize the averted dose to allow comparison to other attributes. The product of the dose averted and the dose conversion factor provides the monetized benefit per year.

Using the dollar value of the health detriment and a risk factor that establishes the nominal probability for stochastic health effects attributable to radiological exposure (i.e., fatal and nonfatal cancers and hereditary effects) provides a dollar per person-rem of $2,000, rounded to the nearest thousand, according to NUREG-1530, “Reassessment of NRC’s Dollar per Person‑Rem Conversion Factor Policy,” issued December 1995 (Ref. 8.25).

The NRC currently uses a value of statistical life (VSL)6 of $3 million based on NUREG-1530 and a cancer risk factor of 7.0x10-4 per rem, which is a reduction to the closest significant digit of a recommendation by the International Commission on Radiation Protection in Publication No. 60. Therefore, the dollar per person-rem conversion factor is equal to $3 million multiplied by 7.0x10-4 per rem and rounded to the nearest thousand dollars (because of uncertainties) or $2,000 per person-rem. However, the staff is currently revising NUREG‑1530. To estimate the effect of a change in this conversion factor on the results of this regulatory analysis, Table 4 provides the parameter evaluated, the parameter value for the base case for the staff’s recommendation, and the values from the sensitivity analysis that the staff performed.

Table 4 Dollar per Person-Rem Conversion Factor Sensitivity Values

Parameter |

Base Case |

Sensitivity Analysis Values (2017 dollars) |

||

Low Estimate |

Proposed Value |

High Estimate |

||

Dollar per person-rem conversion factor |

$2,000 |

$3,100 |

$5,200 |

$7,700 |

4.3 Data

This analysis discusses the data and assumptions used in analyzing the quantifiable impacts associated with each proposed alternative. The NRC staff used data from subject matter experts, knowledge gained from past rulemakings, and information gained during public meetings and from correspondence to collect data for this analysis. Quantitative and qualitative (i.e., nonquantified) information on attributes affected by the proposed regulatory framework alternatives in the draft final rule were obtained from the NRC staff and comments on the regulatory analyses provided with the proposed rule. The NRC considered the potential differences between the new requirements and the current requirements and incorporated the proposed incremental changes into this regulatory analysis.

This section presents the quantitative and qualitative results by attribute for Alternative 2, relative to the regulatory baseline. As described in the previous sections, costs and benefits are quantified where possible and are shown to be either positive or a negative, depending on whether the proposed alternative has a favorable or adverse effect relative to the regulatory baseline (Alternative 1). Those attributes not easily represented in monetary values are discussed in qualitative terms. This ex ante cost-benefit analysis7 provides useful information that can be used when deciding whether to select an alternative, even if the analysis is based on estimates of the future costs and benefits.

The NRC Regulatory Analysis Guidelines (Ref. 8.13) state that the NRC’s periodic review and endorsement of consensus standards, such as new versions of the ASME BPV and OM Codes and associated Code Cases, is a special case. This is because consensus standards have already undergone extensive external review and have been endorsed by the industry. In addition, endorsement of the ASME Codes and Code Cases has been longstanding NRC policy. Licensees and applicants participate in the development of the ASME Codes and Code Cases and are aware that periodic updating of the ASME Codes is part of the regulatory process. Code Cases are ASME‑developed alternatives to the ASME BPV and OM Codes that licensees and applicants may voluntarily choose to adopt without submitting an alternative request, if the Code Cases are approved through incorporation by reference in the NRC’s regulations. Finally, endorsement of the ASME Codes and Code Cases is consistent with the NTTAA, inasmuch as the NRC has determined that there are sound regulatory reasons for establishing regulatory requirements for design, construction, operation, ISI, and IST by rulemaking.

In a typical incorporation of new versions of ASME Codes and associated Code Cases, the NRC endorsements can involve hundreds, if not thousands, of individual provisions. Evaluating the benefit vis-à-vis the cost of each individual provision in this regulatory analysis would be prohibitive, and the value gained by performing such an exercise would be limited. Thus, the scope of this regulatory analysis does not include an evaluation of individual requirements of the consensus standards that are proposed to be incorporated by reference without any conditions.

5.1 Public Health (Accident)

The industry’s practice of adopting the latest ASME BPV and OM Codes and associated Code Cases may incrementally reduce the likelihood of a radiological accident in a positive, but not easily quantifiable, manner. Pursuing Alternative 2 would continue to meet the NRC goal of maintaining safety by continuing to provide NRC approval of the latest ASME Code editions and addenda and to allow the use of Code Cases so that the industry can gain experience with new technology before it is incorporated into the ASME Codes. The allowed use of Code Cases permits licensees to use advancements in ISI and IST and provide alternative examinations for older plants, an expeditious response to user needs, and a limited, clearly focused alternative to specific ASME Code provisions. Improvements in ISI and IST may also result in the earlier identification of material degradation that, if undetected, could result in further degradation that eventually results in a plant transient. As such, Alternative 2 would maintain the same level of safety, or may provide an incremental improvement in safety, when compared to the regulatory baseline.

Relative to the regulatory baseline (Alternative 1), Alternative 2 meets the NRC’s goal of ensuring the protection of public health and safety and the environment by continuing to provide NRC approval of the latest ASME Codes and associated Code Cases. This allows the industry’s use of the most current methods and technology and may decrease the potential for an accident, thus decreasing the overall risk to public health.

Relative to the regulatory baseline, Alternative 2 may decrease the probability of an accident because it ensures that plant safety systems are designed with equipment relied upon to remain functional during and following design-basis accidents and are essential to maintain plant parameters within acceptable limits established for a design-basis event. Therefore, the draft final rule would prevent a potential introduction of a reduction in margin of safety or the introduction of a new failure mode or a common-cause failure mode not previously evaluated that would present an undue hazard, via an accident, to public health and safety and the environment.

Relative to the regulatory baseline, Alternative 2 may also decrease the probability of an accident because licensees would meet the criteria stated in the latest ASME Codes and associated Code Cases for modifications to major safety or protection systems. This includes replacements or installations that address safety issues associated with major changes to the underlying basis of safety systems and protection systems that could adversely affect dependability and reliability arising from potential new failure modes at the system level.

5.2 Occupational Health (Accident and Routine)

The NRC practice of reviewing the latest ASME BPV and OM Codes and associated Code Cases that are then incorporated by reference into the regulations ensures that the mandated ASME Code requirement and approved Code alternatives result in an acceptable level of quality and safety. Pursuing Alternative 2 would continue to meet the NRC goal of maintaining safety by continuing to provide NRC approval of the latest ASME Code editions and addenda and continuing to allow the use of ASME Code Cases to gain experience with new technology before it is incorporated into the ASME Codes. Alternative 2 would permit licensees to use advancements in ISI and IST and provide alternative examinations for older plants, an expeditious response to user needs, and a limited, clearly focused alternative to specific ASME Code provisions. The use of ASME Code Cases may affect occupational health in a positive, but not easily quantifiable, manner. For example, the advancements in ISI and IST may result in an incremental decrease in the likelihood of an accident resulting in worker exposure or in worker radiological exposures during routine inspections or testing when compared to the regulatory baseline. The IST testing of MOVs called for in Mandatory Appendix III, “Preservice and Inservice Testing of Active Electric Motor Operated Valve [MOV] Assemblies in Light-Water Reactor Power Plants,” of the ASME OM Code and the provisions in ASME BPV Code Case N-824 have quantifiable effects on the occupational health (routine) attribute. Section 5.4 on industry operation details these effects, including the sensitivity analysis using different dollar per person-rem conversion factors, as they correspond to operational activities resulting from those provisions.

5.3 Industry Implementation

This attribute accounts for the projected net economic effect on the affected licensees as a result of implementation of the proposed regulatory changes. Additional costs above the regulatory baseline are negative, and cost savings and averted costs are positive.

5.3.1 Program Revision to Quality Assurance Program Description to Incorporate the ASME NQA-1 Program

The draft final 10 CFR 50.55a rule that incorporates by reference the 2008 Edition and the 2009-1a Addenda of ASME NQA-1 is optional for licensees to implement. The existing 10 CFR 50.54(a)(3) regulations allow licensees to make changes to a previously accepted quality assurance program description (QAPD) included or referenced in their safety analysis reports without prior NRC approval, provided the changes do not reduce the commitments in the program description as accepted by the NRC. Regulations in 10 CFR 50.54(a)(4) state that licensees that make changes to the QAPD that reduce the commitments must submit these changes to the NRC for review and approval before implementation. Therefore, the implementation of this draft final rule would not impose additional cost on the industry because the rule’s provisions are already required under the existing 10 CFR 50.54(a)(4).

5.3.2 Procedure Revision to Incorporate Concrete Containment Examinations

5.3.2.1 Concrete Containment Examinations—ISI Summary Report

The NRC proposes to add 10 CFR 50.55a(b)(2)(viii)(H) to specify the information that must be provided in the ISI Summary Report required by IWA-6000 when inaccessible concrete surfaces are evaluated under the new code provision IWL-2512. This new condition would replace the existing condition 10 CFR 50.55a(b)(2)(viii)(E) when using the 2007 Edition with the 2009 Addenda through the 2013 Edition of Subsection IWL. Because licensees already perform equivalent actions under the existing condition in 10 CFR 50.55a(b)(2)(viii)(E) when using the 2007 Edition, this change would have negligible impact.

5.3.2.2 Concrete Containment Examinations—Aging Management

The proposed condition in 10 CFR 50.55a(b)(2)(viii)(I) would impose a condition on the technical evaluation requirements in the new article IWL-2512(b) for consistency with NUREG‑1801, Revision 2, “Generic Aging Lessons Learned (GALL) Report,” issued December 2010 (Ref. 8.10), with regard to aging management of below-grade concrete. This condition would apply only to holders of renewed licenses under 10 CFR Part 54, “Requirements for Renewal of Operating Licenses for Nuclear Power Plants,” during the period of extended operation (i.e., beyond the expiration date of the original 40-year license) of a renewed license when using IWL-2512(b) of the 2007 Edition with 2009 Addenda through the 2013 Edition of Subsection IWL. The impact would be that the licensees for the 46 sites with renewed licenses under 10 CFR Part 54 would have to perform more frequent inspections and technical evaluations during the period of extended operation. These costs are estimated under Section 5.4 (industry operation) of this regulatory analysis. The NRC estimates that updating inspection procedures to reflect this requirement would require a one-time cost of 23 hours of engineering work per site. Therefore, the estimated cost of updating the inspection procedures for all operating reactors would cost ($108,400) based on a 7‑percent net present value (NPV) and ($116,983) based on a 3‑percent NPV.

Table 5 Industry Implementation—Update Concrete Containment Examination Procedures for Operating Plant Sites

The future reactor applicants and license holders and the existing combined license holders without a construction schedule have not developed their examination procedures and therefore are not expected to be impacted by this provision.

5.3.3 Procedure Revision to Underwater Welding Requirements

The proposed conditions in 10 CFR 50.55a(b)(2)(xii) would allow underwater welding of some irradiated materials (ferritic and austenitic materials, subject to different conditions) based on certain criteria (fast/thermal neutron fluence and helium concentration in atomic parts per million (appm)). The existing regulation in 10 CFR 50.55a(b)(2)(xii) prohibits underwater welding of all irradiated materials without the submission of relief/alternative requests to the NRC and NRC approval of those requests. Therefore, implementing the proposed conditions would not result in additional work or cost to the industry.

5.3.4 Procedure Revision to Incorporate Nondestructive Examination Personnel Certification