2349ss02-Annexes

GreenChill ICR_ANNEXES_2019.Feb14[1].docx

Green Chill Advanced Refrigeration Partnership (Renewal)

2349ss02-Annexes

OMB: 2060-0702

Annexes Accompanying

Supporting Statement for

EPA Information Collection Request Number 2349.02

EPA’s GreenChill Advance Refrigeration Partnership (Renewal)

Introduction to GreenChill Partnership - Corporate Emission Reduction Program [Informational/Instruction]

GreenChill Advanced Refrigeration Partnership Agreement [Form]

GreenChill Advanced Refrigeration Partnership Agreement for Supermarket Partners

This is a voluntary agreement between [ ] (herein referred to as the “Partner”) and the U.S. Environmental Protection Agency’s (EPA) GreenChill Advanced Refrigeration Partnership (herein referred to as the “Program,” “GreenChill Partnership,” or “GreenChill”). The goal of the Program is to reduce refrigerant emissions from food retailers and decrease their impact on the ozone layer and climate change. This agreement takes effect when signed by both Parties. GreenChill is a non-regulatory initiative. It does not provide relief for any violations of the Clean Air Act and/or its Amendments.

EPA’s Responsibilities

Track and report partners’ annual corporate-wide refrigerant inventory and emissions.

Identify, research, compile and communicate news, successful strategies, and cost-saving opportunities for reducing refrigerant emissions in commercial refrigeration systems.

Sponsor research relating to such strategies and new technologies.

Benchmark Partner progress in reducing refrigerant emissions in commercial refrigeration, allowing the Partner to compare progress to others within the industry.

Identify an EPA representative responsible for assisting the Partner in implementing the Program and notify the Partner of any change in the designated liaison.

Provide Partner recognition for achievements through press releases, brochures, articles, and awards.

Protect all information and data submitted to EPA or its partners to the fullest extent of the law in accordance with EPA regulations at 40 CFR Part 2, including the provisions on protecting confidential business information (CBI). For information to be treated as CBI, it must be designated by the Partner as CBI at the time of submittal.

Partner Responsibilities

Establish a base year for annual corporate-wide (aggregated) reporting of the inventory of refrigerant stock and refrigerant emissions. The base year may be the year in which this agreement is signed or up to two years prior.

Complete and submit annually to EPA a corporate-wide inventory of refrigerant stock and emissions (aggregate, not by facility).

Develop and submit annually to EPA a Corporate Refrigerant Management Plan that sets a refrigerant emissions reduction goal (goal to be approved by EPA) and describes technologies, strategies, and practices that will be used to achieve that goal.

Commit to using only non-ozone-depleting refrigerant substitutes found acceptable under EPA’s Significant New Alternatives Policy (SNAP) Program in all commercial refrigeration applications in new construction and store remodels involving rack additions or replacements.

Exchange information on Program development/implementation and best practices with other Program partners.

Designate a GreenChill Partnership Representative and notify EPA of any change in the designated liaison.

Communicate the Program to employees and cooperate with EPA efforts to publicize the Program.

EPA Form No.: 5900-214

General Terms

As a general principle of the Program, each party to this agreement agrees to assume the good faith of the other party and to notify the other if any issues arise. Either party can terminate this agreement at any time without prior notification or penalties, with no further obligation. EPA will not comment publicly regarding withdrawal of Partners.

Any violation of the Clean Air Act or its Amendments is grounds for EPA, at its discretion, to terminate this agreement with a partner and for removal from the GreenChill Partnership.

The Partner agrees to cease, upon termination of this agreement, any written, electronic, or oral representation that could be reasonably construed to indicate continued participation in the Program, including the use of the GreenChill Partnership name and mark.

The Partner agrees that it will adhere to the “Guidelines for Using the GreenChill Advanced Refrigeration Partnership Mark.”

The Partner agrees that the activities it undertakes connected with this agreement are not intended to provide services to the federal government and that the Partner will not submit a claim for compensation to any federal agency/department.

The Partner agrees that it will not claim or imply that its participation in the Program constitutes EPA approval or endorsement of anything other than the commitment to the GreenChill Advanced Refrigeration Partnership.

This agreement does not create any right or benefit, substantive or procedural, enforceable by law, and does not direct or apply to any person outside of the parties referenced in the agreement.

The undersigned officials execute this partnership agreement on behalf of their Parties.

EPA: Cindy Newberg, Chief, Alternatives and Emissions Reduction Branch, Stratospheric Protection Division, U.S. EPA

Signature: Date:

Authorized Partner Company Representative:

Name: Title:

Signature: Date:

Partner’s Designated GreenChill Representative:

Name: Title:

Company:

Address:

City: State: Zip:

Telephone: Fax: Email:

Please sign the partnership agreement and send a scanned copy by email to: [email protected]

The public reporting and recordkeeping burden for this collection of information is estimated to average 5.5 hours per response. Send comments on the Agency's need for this information, the accuracy of the provided burden estimates, and any suggested methods for minimizing respondent burden, including through the use of automated collection techniques to the Director, Collection Strategies Division, U.S. Environmental Protection Agency (2822T), 1200 Pennsylvania Ave., NW, Washington, D.C. 20460. Include the OMB control number in any correspondence. Do not send the completed form to this address.

Guidelines for Partner Annual Reporting [Informational/Instruction]

Fictitious Model of a Refrigerant Management Plan [Informational/Instruction]

Suggested Template - Partners Are Not Required to Complete This Document

-- EXAMPLE --

Corporate Refrigerant Management Plan

GreenChill Partners

Supermarket |

Curly-Cue Supermarkets |

Year |

2015 |

Each GreenChill Partner is required to submit an annual corporate refrigerant management plan. GreenChill uses the information “qualitatively” to help determine GreenChill projects for the coming year. Partners are not evaluated based on information in their plans.

Although there is no standard form for the plan, this two-part template provides a suggested format Partners are welcome to use.

Part 1: a suggested format for identifying emissions rate goal(s) for the present year. Partners are not required to use this format. They must provide an emissions rate goal.

Part 2: a suggested format for the refrigerant management plan. Partners must describe their refrigerant management activities and how they plan to reach their emissions rate goal(s).

Part 1. Emissions Rate Goals

Partners are required to submit an emissions rate goal for the present year, for commercial systems with 50 or more pounds of refrigerant. Partners are encouraged (but not required) to also set a more aggressive “stretch” goal, for which they can receive a second award. Table 1 presents a suggested format for identifying emissions rate goal(s).

REMINDER: To be eligible for GreenChill goal achievement awards, Partners’ goal(s) for the present year must be lower than their emissions rate from the previous year.

Table 1. Past goals and emissions rates for commercial systems with more than 50 pounds of refrigerant. |

|||

Year |

Goal (Required) |

Stretch Goal (Optional) |

Emissions Rate |

2008 (Baseline Year) |

Not applicable |

Not applicable |

16% |

2009 |

10% |

None identified |

12% |

2010 |

10% |

None identified |

10% |

2011 |

9.1% |

None identified |

9% |

2012 |

8.5% |

None identified |

8.5% |

2013 |

8.25% |

8% |

8.2% |

2014 |

8% |

7.5% |

8% |

2015 |

7.5% |

7.25% |

7.25%* |

2016 |

7.0% |

6.9% |

** |

* The emissions rate for the most recent past year should be from the GreenChill data reporting form. ** The emissions rate for the present year will be calculated next year. |

|||

Part 2. Corporate Refrigerant Management Plan

Partners are welcome to use the following structure to organize their refrigerant management plan for the present year.

REMINDER: Partners do not need to address all the topics listed below; it is understood that not all topics will be relevant to each Partner.

A. Review of Previous Year’s Goal(s) and Achievements (suggested topics, complete relevant ones) |

What went well last year? |

In 2014, we achieved our goal, but missed our stretch goal by 0.5%. Our achievement was a result of the acceleration of our “leak tightness” strategy to make up for our losses due to catastrophic equipment failures in previous years. All potentially faulty components were replaced in all our stores (not just the ones that failed), and as a result, we got back on track in 2015 and achieved our goal. As we continue to reduce our refrigerant emissions, we feel it is necessary to become more conservative in our goals. We hope to achieve a reduction in our emissions rate to 7.0% in 2016. Our stretch goal for 2016 is 6.9%. |

What did not go well last year? How will these challenges be addressed in the present year? |

|

What were the key factors that helped you meet (or prevented you from meeting) your goal(s) for the year? |

|

Other notes |

|

B. Leak Prevention and Repair (suggested topics, complete relevant ones) |

Installation of leak detection systems |

We are installing better leak sensors in the machine rooms in an additional 600 stores (new leak detectors installed in 600 stores in every year from 2006-2015). |

Leak prevention or charge reducing system components |

|

Regular leak prevention maintenance program |

|

Use of GreenChill’s Leak Prevention and Repair Guideline |

|

Use of GreenChill’s Maintenance for Leak Prevention Fact Sheet |

|

Rapid leak response protocol |

We have a rapid response system that ensures that a technician responds to a leak in any stores within 7 minutes of the notification. |

Leak repair verification requirements |

We require verification from our service technicians that every leak was fixed and then require re-verification after 30 minutes of regular system operation. |

Other notes |

|

C. Store Remodels or Retrofits (suggested topics, complete relevant ones) |

Number of remodels or retrofits planned |

Curly-Cue Supermarkets has discontinued our R-22 store retrofits to HFC refrigerants. All stores have been converted. |

Refrigerants involved (e.g., retrofitted in and out) |

|

Systems involved (e.g., retrofitted in and out) |

|

Use of GreenChill’s Installation Leak Tightness Guidelines or GreenChill’s Retrofit Guidelines |

|

Remodeled or retrofitted system design features (e.g., for reduced charge and leak potential) |

|

Estimated charge size for remodeled or retrofitted systems |

|

Estimated leak rate for remodeled or retrofitted systems |

|

Other notes |

|

D. Newly Designed Stores (suggested topics, complete relevant ones) |

Number of new stores opening |

We are opening 20 new stores throughout 2016. All new stores will use non-ODS refrigerants for A/C, commercial refrigeration, and self-contained equipment. |

Refrigerants involved |

We are considering adopting a policy of using only climate-friendly refrigerants in all new stores. |

Refrigeration systems involved |

|

New system design features (e.g., for reduced charge and leak potential) |

We will achieve lower refrigerant charges by using:

When building new stores, we ensure reduced leak potential by planning:

|

Use of GreenChill’s Installation Leak Tightness Guidelines |

All new stores will GreenChill’s installation leak tightness standards as described in the GreenChill Leak Tightness Installation Guideline. The refrigeration systems for all new DX stores are currently tested for leak tightness at installation. We have adopted GreenChill’s Installation Leak Tightness Best Practices Guidelines as our company spec, and all service technicians are required to follow the Guidelines and have the results of the GreenChill Leak Tightness Testing verified by a Supervisory Maintenance Manager before declaring the work complete. |

Estimated charge size for new systems |

New DX Stores Curly-Cue’s goal is to reduce the refrigerant charge in all new DX stores from an average of 4500 lbs. of refrigerant to 3000 lbs of refrigerant.

New Secondary Loop stores Our goal is to reduce our refrigerant charge in all new secondary loop stores down to an average of 1000 lbs. per store, vs. 3000-4500 lbs in our DX systems.

New Distributed System stores The stores that use distributed systems will have a refrigerant charge of 2000 lbs., as opposed to our DX stores that have a charge that ranges from 3000-4500 lbs of refrigerant.

|

Estimated leak rate for new systems |

New DX Stores In the 800 new DX stores we built from 2006-2015 using these steps, we have consistently achieved and maintained annual leak rates below 10%.

New Secondary Loop stores We estimate that our stores that use secondary loop systems will have leak rates of less than 5%.

New Distributed System stores We estimate that our stores that use a distributed refrigeration system will have leak rates of less than 10%.

|

Other notes |

|

E. GreenChill Certification (suggested topics, complete relevant ones) |

Plans for achieving certification or re-certification in existing stores |

|

Plans for achieving certification in new/future stores |

|

Other notes |

|

F. Store Turnover (suggested topics, complete relevant ones) |

Number of stores to be acquired |

|

Refrigerants and systems used in stores to be acquired |

|

Number of stores to be closed |

|

Refrigerants and systems used in stores to be closed |

|

Other notes |

|

G. Technician and Contractor Coordination (suggested topics, complete relevant ones) |

Technician training on leak prevention and refrigerant management |

|

Technician/contractor performance tracking and incentive programs |

|

Contract specifications for GreenChill best practices |

|

Other notes |

|

H. Refrigerant Use Tracking (suggested topics, complete relevant ones) |

Refrigerant tracking tools/software |

|

Refrigerant banking |

|

Other notes |

|

I. Evaluation and Communications (suggested topics, complete relevant ones) |

Estimating impacts of refrigerant leaks (e.g., using GreenChill’s Financial Impact Calculator) |

|

Communicating to management about importance of leak prevention and refrigerant management |

|

Other notes |

|

GreenChill Supermarket Corporate Refrigerant Management Plan

Annual Reporting for Partners [Form]

Introduction to Store Certification Program [Instructional/Information]

Store Certification Criteria [Instructional/Information]

Store Certification Guidance [Informational/Instruction]

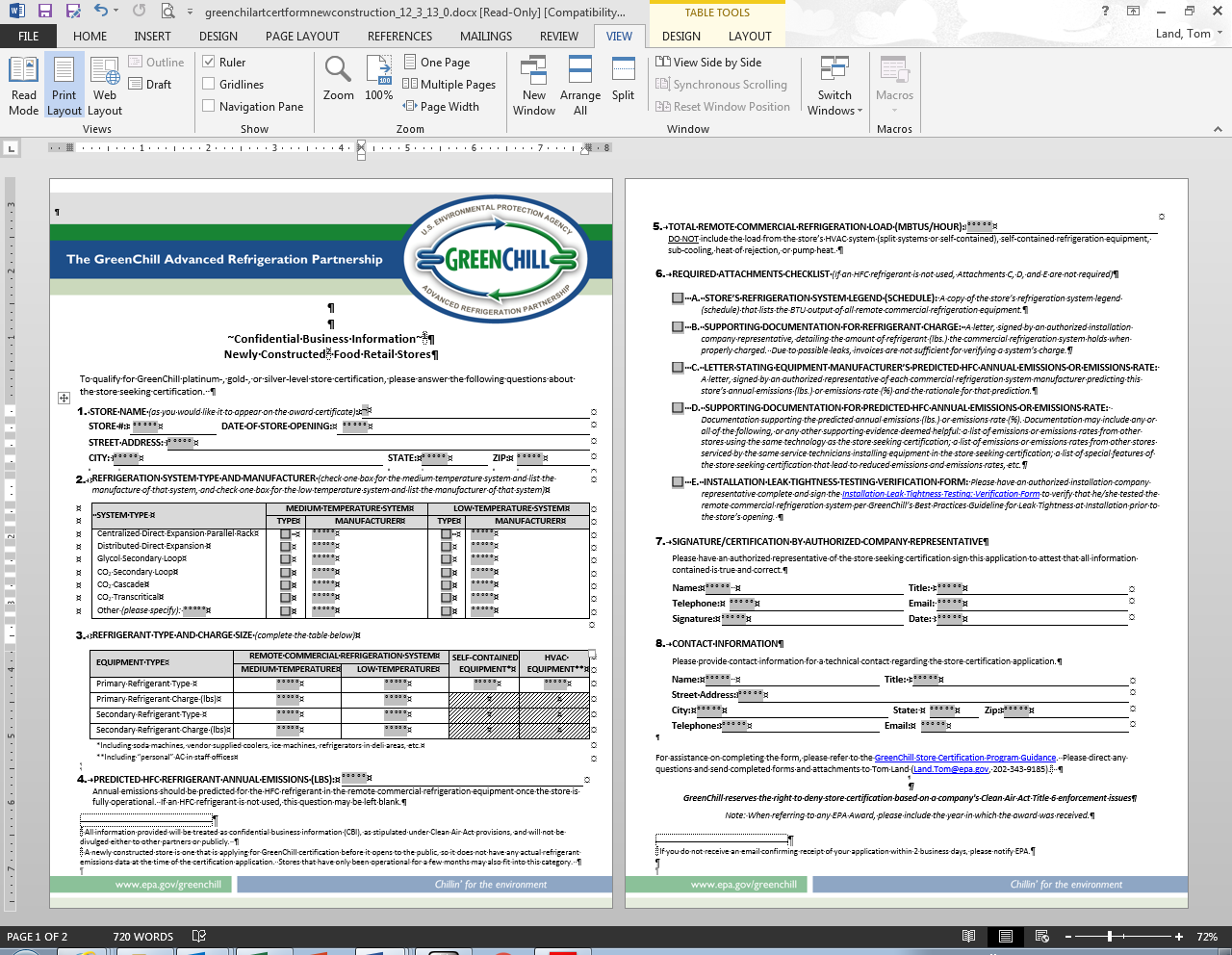

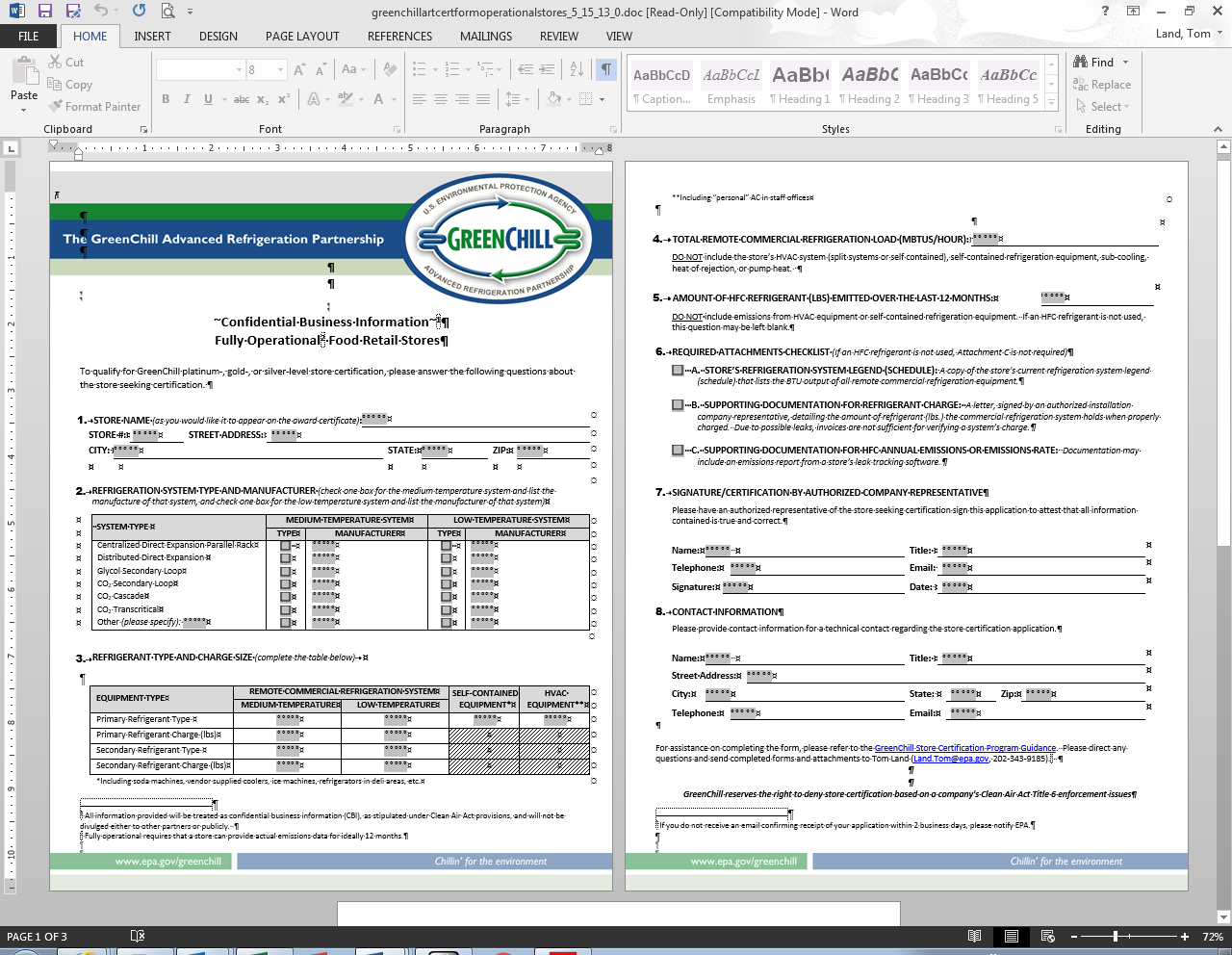

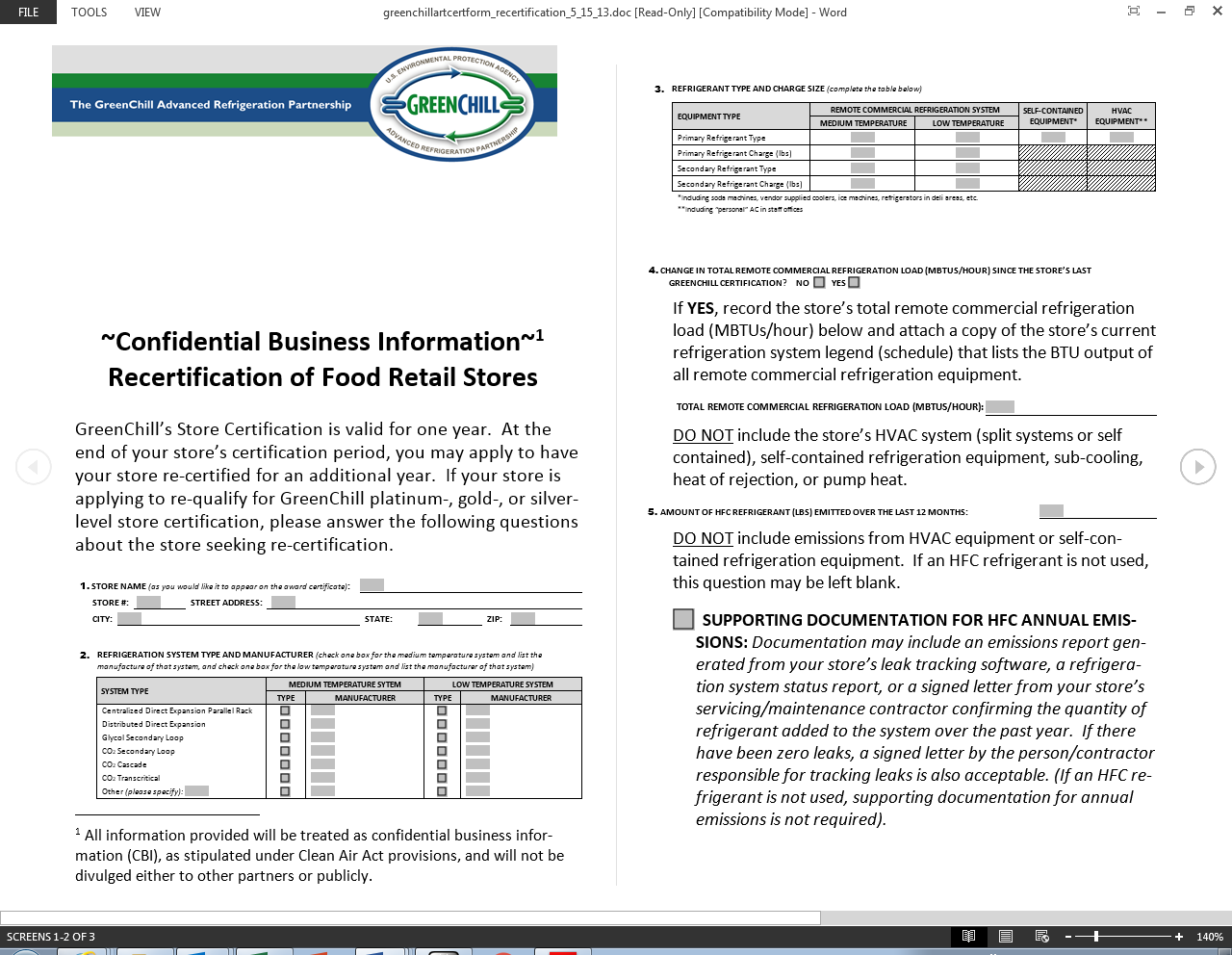

Store Certification Applications [Forms – Newly Constructed, Operational, and Recertification]

Further guidance and instructions for the GreenChill program can be found at: http://www.epa.gov/greenchill

| File Type | application/vnd.openxmlformats-officedocument.wordprocessingml.document |

| File Modified | 0000-00-00 |

| File Created | 0000-00-00 |

© 2026 OMB.report | Privacy Policy