Ethylene Oxide (EtO) Commercial Sterilization Main

Ethylene Oxide Commercial Sterilization Facilities National Emission Standards for Hazardous Air Pollutants (NESHAP) Technology Review (New)

EtO_114ICR_Main.xlsx

Ethylene Oxide Commercial Sterilization Facilities

OMB: 2060-0733

Document [xlsx]

Download: xlsx | pdf

Terms

Facility Details

Room Area

EtO & EG Storage

Sterilizer Chambers

Aeration

APCD Summary

APCD Details

EtO Monitoring

Miscellaneous

Additional Info

Documents

Certification

Overview

IntroductionTerms

Facility Details

Room Area

EtO & EG Storage

Sterilizer Chambers

Aeration

APCD Summary

APCD Details

EtO Monitoring

Miscellaneous

Additional Info

Documents

Certification

Sheet 1: Introduction

| Ethylene Oxide (EtO) Commercial Sterilization | OMB Control No. 2060-NEW | |||||||

| CAA Section 114 Information Collection Request (ICR) | Approval Expires mm/dd/yyyy | |||||||

| Paperwork Reduction Act Burden Statement | ||||||||

| This collection of information is approved by OMB under the Paperwork Reduction Act, 44 U.S.C. 3501 et seq. (OMB Control No. 2060-NEW). Responses to this collection of information mandatory under section 114(a) of Clean Air Act. An agency may not conduct or sponsor, and a person is not required to respond to, a collection of information unless it displays a currently valid OMB control number. The average public reporting and recordkeeping burden for this collection of information is estimated to be proximately 108 hours per response. Send comments on the Agency’s need for this information, the accuracy of the provided burden estimates and any suggested methods for minimizing respondent burden to the Regulatory Support Division Director, U.S. Environmental Protection Agency (2821T), 1200 Pennsylvania Ave., NW, Washington, D.C. 20460. Include the OMB control number in any correspondence. Do not send the completed form to this address. | ||||||||

| Introduction | ||||||||

| The U.S. Environmental Protection Agency (EPA) is requesting facility data and information to inform the Technology Review project for 40 CFR part 63, subpart O, Ethylene Oxide (EtO) Commercial Sterilization source category. The purpose of this ICR is to enable facilities to submit accurate facility information. For more detailed instructions on how to fill out, name and submit the main questionnaire, supplements and additional documents, refer to the Instructions Document for the Ethylene Oxide Commercial Sterilization Section 114 ICR at: https://www.epa.gov/stationary-sources-air-pollution/ethylene-oxide-emissions-standards-sterilization-facilities (click to visit). | ||||||||

| About the Main Questionnaire | ||||||||

| This main questionnaire contains worksheets and data fields shaded in different colors: | ||||||||

| Worksheets and data fields shaded in green indicate that facility shall provide inputs according to the corresponding instructions | ||||||||

| Worksheets and data fields shaded in gold contain instructions and supporting information that help facility with this questionnaire | ||||||||

| Data fields shaded in gray indicate that these either do not need to be filled out or will be automatically filled out based on facility's inputs in relevant fields | ||||||||

| Data fields shaded in red by facility indicate that these fields contain confidential business information (CBI), and relevant data needs special handling * | ||||||||

| "Certification" worksheet in blue must be completed by facility before submission | ||||||||

| If any information entered contains CBI, be sure to select “Yes” in the designated cell (Cell N2) on each worksheet, shade all cells with CBI in red, then follow the instructions specified on each worksheet or in Section IV of the Instructions Document. | ||||||||

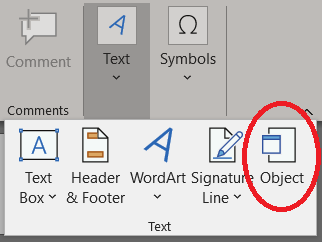

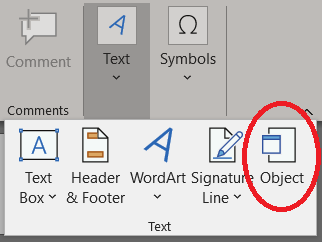

| This main questionnaire contains the following worksheets (you may click on the links below to visit each individual worksheet): | ||||||||

| Introduction (this worksheet) | Introduction and instructions for completing and submitting this questionnaire | |||||||

| Terms (link) | Definitions or explanations of certain technical terms that are mentioned throughout this questionnaire | |||||||

| Facility Details (link) | Information about facility registration, ownership, general characteristics, facility-level data, legal documents, etc. | |||||||

| Room Area (link) | Characteristics, inventory of components and control of individual room areas where EtO is used or emitted | |||||||

| EtO & EG Storage (link) | Questions regarding EtO storage in drums and containers, and ethylene glycol (EG) tanks | |||||||

| Sterilizer Chambers (link) | Operation, monitoring and control characteristics of sterilizer chambers | |||||||

| Aeration (link) | Details of aeration equipment | |||||||

| APCD Summary (link) | Information about all air pollution control devices operated by facility | |||||||

| APCD Details (link) | Details regarding air pollution control devices such as scrubbers, catalytic oxidizers, thermal oxidizers, and others | |||||||

| EtO Monitoring (link) | Information about workspace monitoring, personal monitoring, room monitoring, etc. conducted by facility | |||||||

| Miscellaneous (link) | Questions regarding facility's wastewater treatment and other items of EtO commercial sterilization operation | |||||||

| Additional Info (link) | Use this worksheet if you need extra space to provide any additional information requested within this questionnaire | |||||||

| Documents (link) | Designated space to attach documents requested throughout this questionnaire | |||||||

| Certification (link) | Reporter's information and certification for completing and submitting this questionnaire | |||||||

| About the Supplements | ||||||||

| There are 3 supplements to this main questionnaire, including: Supplement 1 for Section B, Table 3 Supplement 2 for Section B, Table 4 Supplement 3 for Section I, Table 1 The supplements may be used should you need more space than what is available in the original tables to provide the data requested. If you prefer to fill out any supplement in lieu of the original table, please leave the original table blank in the main questionnaire. Be sure to select “Yes” in the designated cell above each original table where a supplement will be used, and the data fields will be automatically shaded in gray. |

||||||||

Sheet 2: Terms

| Ethylene Oxide (EtO) Commercial Sterilization | |||||||

| CAA Section 114 Information Collection Request (ICR) | |||||||

| Click here to go to "Introduction" | |||||||

| 1. Definitions | |||||||

| Term | Definition | ||||||

| Accelerated aeration | Aeration conducted in a heated aeration chamber or cell, not an aeration room, combined with: (1) use of vacuum cycles, and/or (2) high turbulence air created by multiple inlet ports along the length of the aeration cell and multiple outlet points along the top of the cell to provide even distribution of air flow | ||||||

| Aeration cell/chamber | Any vessel that is used to facilitate off-gassing of ethylene oxide at a sterilization facility. If single-item sterilization occurs, the vessel is classified as a sterilization chamber | ||||||

| Aeration room | Any vessel or room that is used to facilitate off-gassing of ethylene oxide at a sterilization facility. If single-item sterilization occurs, the vessel or room is classified as a sterilization chamber | ||||||

| Aeration room vent (ARV) | The point(s) through which the evacuation of ethylene oxide-laden air from an aeration room occurs | ||||||

| Balancer/abator system | An air pollution control device (APCD) that consists of a combination of a water balancer and a catalytic oxidizer | ||||||

| Cascading air | Ventilation air removed from one room area or process, with a lower EtO concentration, is vented as the input ventilation air or intake ventilation air directly to another room area or process (e.g., ventilation air from a warehouse is used as intake air to the aeration room or aeration cell). Ventilation air removed from one room area or process must have an equivalent or lower EtO concentration than the room air concentration or process concentration of the room area or process in which it is reused | ||||||

| Chamber exhaust vent (CEV) | The point(s) through which ethylene oxide-laden gas is removed from the sterilization chamber during chamber unloading, following the completion of sterilization and associated air washes. Also known as "back vent" | ||||||

| Combination-chamber sterilizer | Any enclosed vessel in which both the sterilization process and the aeration process occur within the same vessel, e.g., the vessel is filled with ethylene oxide gas or an ethylene oxide/inert gas mixture for the purpose of sterilizing and is followed by off-gassing of ethylene oxide | ||||||

| Dwell period | The length of time that the product is exposed to ethylene oxide in sterilizer chamber for the purpose of sterilizing or fumigating the product | ||||||

| Engineering test | A test that measures the amount of pollutants being emitted, demonstrates the capture efficiency, or determines the destruction or removal efficiency of a control device used to reduce emissions at a facility. This testing is not related to compliance or regulatory requirements | ||||||

| Ethylene oxide (EtO) service | A piece of equipment either contains or contacts ethylene oxide as a liquid or gas at any concentration | ||||||

| Fugitive emissions | Emissions (of ethylene oxide) which are not routed through the existing control equipment | ||||||

| Natural draft opening (NDO) | Any permanent opening in the enclosure that remains open during operation of the facility and is not connected to a duct in which a fan is installed | ||||||

| Non-colocated warehouse/distribution center | A warehouse or distribution center, used to store products that are sterilized with ethylene oxide, that is not part of a facility subject to the ethylene oxide commercial sterilizer rule under 40 CFR part 63, subpart O | ||||||

| Performance test | A test that measures the amount of pollutants being emitted, demonstrates the capture efficiency, or determines the destruction or removal efficiency of a control device used to reduce emissions at a facility. Used to determine a facility’s compliance with an emission limit, capture efficiency, or control efficiency requirement | ||||||

| Research and laboratory facility | Any stationary source whose primary purpose is to conduct research and development into new processes and products, where such source is operated under the close supervision of technically trained personnel and is not engaged in the manufacturer of products for commercial sale in commerce, except in a de minimis manner | ||||||

| Single-item sterilizer | Any enclosed vessel in which sealed pouches containing product and ethylene oxide gas for the purpose of sterilizing are placed, and the ethylene oxide sterilizes and aerates | ||||||

| Sterilization chamber vent (SCV) | The point (prior to vacuum pump) through which the evacuation of ethylene oxide from the sterilizer chamber occurs following sterilization or fumigation, including any subsequent air washes | ||||||

| Sterilization facility | Any stationary source where ethylene oxide is used in the sterilization or fumigation of materials | ||||||

| Sterilization operation | Any time when ethylene oxide is removed from the sterilization chamber through the sterilization chamber vent or the chamber exhaust vent or when ethylene oxide is removed from the aeration room through the aeration room vent | ||||||

| Sterilizer chamber | Any enclosed vessel or room that is filled with ethylene oxide gas, or an ethylene oxide/inert gas mixture, for the purpose of sterilizing and/or fumigating at a sterilization facility. Includes any vessels or rooms where both ethylene oxide sterilization and aeration occur within one chamber | ||||||

| 2. Acronyms | |||||||

| Acronym | Term | Acronym | Term | ||||

| APCD | air pollution control device | ID | identifier | ||||

| ARV | Aeration room vent | in. H2O | inches of water | ||||

| CAA | Clean Air Act | kWh | kilowatt hour | ||||

| CBI | Confidential business information | LEL | lower explosive limit | ||||

| CEMS | Continuous emissions monitoring system | mg/L | milligrams per liter | ||||

| CEV | Chamber exhaust vent | NAICS | North American Industrial Classification System | ||||

| cfm | Cubic feet per minute | NDO | natural draft opening | ||||

| CFR | Code of Federal Regulations | ppmv | parts per million, volume | ||||

| EG | ethylene glycol | psig | pressure per square inch, gauge | ||||

| EIS | Emission Inventory System | QA | quality assurance | ||||

| EPA | Environmental Protection Agency | QC | quality control | ||||

| EtO | ethylene oxide | R&D | research and development | ||||

| ICR | information collection request | SCV | sterilization chamber vent | ||||

Sheet 3: Facility Details

| Ethylene Oxide (EtO) Commercial Sterilization | Does any information entered on this worksheet contain confidential business information (CBI)? Specify in Cell N2 on the right → Be sure to shade each cell that contains CBI in red Before saving the non-CBI version of your response, select and copy the Sample CBI Cell (Cell O2), and paste directly into each cell that contains CBI. Make sure that all "CBI" cells are shaded in red |

CBI | EIS ID (Auto-populated) |

||||||||||||||||

| CAA Section 114 Information Collection Request (ICR) | Sample CBI Cell (above) |

||||||||||||||||||

| Click here to go to "Introduction" | Click here to go to "Terms" | Click here to go to "Additional Info" | |||||||||||||||||

| A. Facility Details | |||||||||||||||||||

| Table 1. Facility Information | |||||||||||||||||||

| Field # | A-1 | A-2 | A-3 | A-4 | A-5 | A-6 | A-7 | A-8 | A-9 | A-10 | A-11 | A-12 | |||||||

| Data | Primary NAICS code | EIS ID | Facility name | Facility address | Facility city | Facility state | Facility zip code | Phone number | Number of employees at facility | Operating status in current year | Comments | Operating hours | Is there a plan to expand/modify/close this facility in the near future? | ||||||

| Instruction | Enter the primary NAICS code for the facility 1 | Enter EIS ID for the facility | Enter facility name | Enter the street address of facility verified by U.S. Postal Service (USPS). Do not include P.O. box in this field | Enter facility city | Select from the dropdown menu in this column | Enter facility zip code verified by U.S. Postal Service (USPS) | Provide a contact phone number at the facility | Select from the dropdown menu. Full-time, part-time, and temporary employees should be counted equally |

Select from the dropdown menu in this column | If you choose an option other than "operating" in the previous column, please add a brief comment in this column | Enter the daily operating hours on average of the facility (hours) | Enter the annual operating hours on average of the facility (hours) | Select from the dropdown menu in this column | Provide a short explanation if you select "Yes" on the left | ||||

| Response | |||||||||||||||||||

| 1 For assistance in determining your facility’s NAICS code, see the website for the North American Industry Classification System (NAICS), maintained by the U.S. Census Bureau: https://www.census.gov/eos/www/naics/. (click to visit) | |||||||||||||||||||

| Table 2. Parent Company Information | |||||||||||||||||||

| Field # | A-13 | A-14 | A-15 | A-16 | A-17 | A-18 | A-19 | A-20 | |||||||||||

| Data | Parent company | Parent company address | Parent company city | Parent company state | Parent company zip code | Phone number | Is parent company a small business? | Number of employees at parent company | |||||||||||

| Instruction | Enter parent company name | Enter the street address of parent company verified by U.S. Postal Service (USPS). Do not include P.O. box in this field | Enter parent company city | Select from the dropdown menu in this column | Enter parent company zip code verified by U.S. Postal Service (USPS) | Provide a contact phone number at the parent company | Select from the dropdown menu in this column 2 | Select from the dropdown menu in this column | |||||||||||

| Response | |||||||||||||||||||

| 2 To determine the employee threshold for a small business, you may look up the small business size standard using six-digit NAICS codes. The size standards used to define Small Businesses are provided in 13 CFR 121, Small Business Size Regulations. See §121.201, "What size standards has SBA identified by North American Industry Classification System codes?", table “Small Business Size Standards by NAICS Industry”, column “Size standards in number of employees”. | |||||||||||||||||||

| Website for the Small Business Administration: https://www.sba.gov/. (click to visit) | |||||||||||||||||||

| Code of Federal Regulations (CFR), part 121: https://www.ecfr.gov/cgi-bin/text-idx?SID=85df5b1185a8b127a9b324c6583f72c6&mc=true&node=pt13.1.121&rgn=div5. (click to visit) | |||||||||||||||||||

| Table 3. Facility Documents | |||||||||||||||||||

| Field # | A-21 | A-22 | A-23 | A-24 | A-25 | ||||||||||||||

| Data | Facility diagrams | Process flow diagrams | Most recent air permit(s) | Application documents for the most recent air permit(s) | Startup, shutdown and malfunction (SSM) plan | ||||||||||||||

| Instruction | Provide diagrams of your facility indicating all rooms, primary EtO emission points (e.g., regulated emission points), and secondary EtO emission points (e.g., fugitive emission points). Ensure that all NDOs are adequately labeled | Provide process flow diagrams of the EtO processes at your facility | Provide the most recent air permit(s) approved for your facility | Provide the application documents for the most recent air permit(s) approved for your facility | Provide the startup, shutdown and malfunction (SSM) plan approved for your facility | ||||||||||||||

| Response | See instructions in "Documents" worksheet | See instructions in "Documents" worksheet | See instructions in "Documents" worksheet | See instructions in "Documents" worksheet | See instructions in "Documents" worksheet | ||||||||||||||

| Table 4. Facility Buildings | |||||||||||||||||||

| Field # | A-26 | A-27 | A-28 | A-29 | A-30 | A-31 | A-32 | A-33 | A-34 | A-35 | |||||||||

| Data | Building ID | Building height | Building corner 1 | Building corner 2 | Building corner 3 | Building corner 4 (if any) | Building corner 5 (if any) | Building corner 6 (if any) | Building corner 7 (if any) | Additional comments | |||||||||

| Instruction | Enter from permit description, if available. Otherwise, use a unique identifier for each building | Enter the (average) height of the building (feet) |

Enter the latitude of this building corner. Specify to the 6th decimal point | Enter the longitude of this building corner. Specify to the 6th decimal point | Enter the latitude of this building corner. Specify to the 6th decimal point | Enter the longitude of this building corner. Specify to the 6th decimal point | Enter the latitude of this building corner. Specify to the 6th decimal point | Enter the longitude of this building corner. Specify to the 6th decimal point | Enter the latitude of this building corner. Specify to the 6th decimal point | Enter the longitude of this building corner. Specify to the 6th decimal point | Enter the latitude of this building corner. Specify to the 6th decimal point | Enter the longitude of this building corner. Specify to the 6th decimal point | Enter the latitude of this building corner. Specify to the 6th decimal point | Enter the longitude of this building corner. Specify to the 6th decimal point | Enter the latitude of this building corner. Specify to the 6th decimal point | Enter the longitude of this building corner. Specify to the 6th decimal point | Enter any additional comments that you may have regarding the information provided in this table about buildings and building corners | ||

| Response | |||||||||||||||||||

| Table 5. Facility-level Data | |||||||||||||||||||

| Field # | A-36 | A-40 | A-41 | A-42 | A-43 | A-44 | A-45 | A-46 | A-47 | ||||||||||

| Data | EtO usage at your facility for the last 5 calendar years | Annual EtO stack emissions of facility for the last 5 years | Annual EtO fugitive emissions of facility for the last 5 years | Documentation for annual EtO emissions calculations | Average annual energy cost of facility operation (include the last 5 years in the average) | Average annual growth rate in revenues from EtO sterilization services for the last 5 years | Size category of facility with respect to hazardous air pollutant (HAP) emissions | As a percentage of all products sterilized at your facility, what is the percentage of products sterilized with EtO? | As a percentage of all products sterilized at your facility, what is the percentage of products sterilized using non-EtO techniques or approaches? | ||||||||||

| Instruction | Specify the calendar year. Select from the dropdown menu in this column | Enter the corresponding EtO usage in this column (pounds) |

Specify the calendar year. Select from the dropdown menu in this column | Enter the value of annual EtO emissions in this column (pounds) |

Specify the calendar year. Select from the dropdown menu in this column | Enter the value of annual EtO emissions in this column (pounds) |

Provide calculations and supporting documentation for both stack emissions and fugitive emissions, including all emission factors used to determine the annual EtO emissions | Enter the dollar amount in this column | Specify the dollar year in this column | Enter the amount in this column (dollars/year) |

Specify the dollar year in this column | Select from the dropdown menu in this column 3 | Specify the percentage of products sterilized with EtO, based on all products sterilized at your facility, including both EtO sterilization and non-EtO sterilization. Note that the values entered in this field and Field A-47 should sum to 100% (%) |

Specify the percentage of products sterilized with non-EtO approaches, based on all products sterilized at your facility, including both EtO sterilization and non-EtO sterilization. Note that the values entered in this field and Field A-46 should sum to 100% (%) |

|||||

| Response | See instructions in "Documents" worksheet | ||||||||||||||||||

| 3 For definitions of major source and area source, see section 112, Hazardous Air Pollutants, paragraph (a)(1) and (2), respectively: https://www3.epa.gov/ttn/atw/112a_def.html. (click to visit) | |||||||||||||||||||

| “Synthetic minor” for HAP means a source that otherwise has the potential to emit HAPs in amounts that are at or above those for major sources of HAP in 40 CFR 63.2, but that have taken a restriction so that its potential to emit (PTE) is less than such amounts for major sources. Such restrictions must be enforceable as a practical matter. See 40 CFR 63.2, Definitions for the definition of federally enforceable: https://www.ecfr.gov/cgi-bin/text-idx?SID=e4db7138e51ff76ffa723d3162b8169d&mc=true&node=se40.11.63_12&rgn=div8. (click to visit) | |||||||||||||||||||

| Table 6. Materials Sterilized with EtO | |||||||||||||||||||

| Field # | A-37 | A-38 | A-39 | A-39.1 | A-39.2 | ||||||||||||||

| Data | Materials sterilized with EtO (e.g., medical products, pharmaceutical products, spices, etc.) at your facility in 2019 | Percentage of each type of materials sterilized with EtO in 2019 based on volume of throughput | Percentage of each type of materials sterilized with EtO in 2019 based on dollar amount | Packaging material used for products sterilized with EtO | Pallet material used for products sterilized with EtO | ||||||||||||||

| Instruction | List all types of materials sterilized with EtO at your facility in 2019. Enter one type in each cell. If you have more than 10 types, enter "Other materials sterilized with EtO" in Cell C89, then specify. For example: "Other materials sterilized with EtO (Type 10, Type 11, Type 12, etc.)" | Provide the approximate percentage of each type of materials sterilized with EtO in 2019 based on volume of material throughput (%) |

Provide the approximate percentage of each type of materials sterilized with EtO in 2019 based on dollar amount (%) |

Specify the packaging material used for products sterilized with EtO at your facility | Enter the percent by volume of product sterilized with EtO that uses this packaging material (%) |

Specify the pallet materials used in EtO sterilizer chambers | Enter the percent by volume of each type of pallet material used for EtO sterilization (%) |

||||||||||||

| Response | |||||||||||||||||||

| Table 7. Materials Sterilized with Non-EtO Techniques and Approaches | |||||||||||||||||||

| Field # | A-48 | A-49 | A-50 | A-51 | |||||||||||||||

| Data | Materials sterilized with non-EtO approaches (e.g., medical products, pharmaceutical products, spices, etc.) at your facility in 2019 | Percentage of each type of material sterilized with non-EtO approaches in 2019 based on volume of throughput | Percentage of each type of material sterilized with non-EtO approaches in 2019 based on dollar amount | Packaging material used for products sterilized with non-EtO approaches | |||||||||||||||

| Instruction | List all types of materials sterilized with non-EtO approaches at your facility in 2019. Enter one type in each cell. If you have more than 10 types, enter "Other materials sterilized with non-EtO" in Cell C105, then specify. For example: "Other materials sterilized with non-EtO (Type 10, Type 11, Type 12, etc.)" | Provide the approximate percentage of each type of material sterilized with non-EtO approaches in 2019 based on volume of material throughput (%) |

Provide the approximate percentage of each type of material sterilized with non-EtO approaches in 2019 based on dollar amount (%) |

Specify the packaging material used for products sterilized with non-EtO approaches at your facility | Enter the percent by volume of product sterilized with non-EtO approaches that uses this packaging material (%) |

||||||||||||||

| Response | |||||||||||||||||||

Sheet 4: Room Area

| Ethylene Oxide (EtO) Commercial Sterilization | Does any information entered on this worksheet contain confidential business information (CBI)? Specify in Cell N2 on the right → Be sure to shade each cell that contains CBI in red Before saving the non-CBI version of your response, select and copy the Sample CBI Cell (Cell O2), and paste directly into each cell that contains CBI. Make sure that all "CBI" cells are shaded in red |

CBI | EIS ID (Auto-populated) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| CAA Section 114 Information Collection Request (ICR) | Sample CBI Cell (above) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Click here to go to "Introduction" | Click here to go to "Terms" | Click here to go to "Additional Info" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B. Individual Room Area (All Areas where EtO is Used or Emitted) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table 1. Characteristics of Room Areas | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Field # | B-1 | B-2 | B-3 | B-4 | B-5 | B-6 | B-7 | B-8 | B-9 | B-10 | B-11 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Data | Room area ID for all rooms and areas where EtO is used or emitted | Category of room area | Activities conducted in room area | Floor area | Room height | Temperature | Relative humidity | Pressure drop | Air flow (ventilation) | Air flow (conditioned) | Number of air changes per hour | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Instruction | Enter from permit description, if available. Otherwise, use a unique identifier for each room | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your room area)" |

Provide a brief explanation of the activities conducted in each room area | (square feet) | (feet) | Enter temperature set point or range for summer in this column (Fahrenheit) |

Enter temperature set point or range for winter in this column (Fahrenheit) |

Enter temperature set point or range for intermediate seasons in this column (Fahrenheit) |

Enter average or range of relative humidity (percent) |

Enter the pressure drop across room area (inch H2O) |

Specify definition of pressure drop, or locations based on which pressure drop is measured (e.g., farthest point to control device inlet) | Enter average or range of ventilation air flow (actual cubic feet per minute, acfm) |

Enter average or range of conditioned air flow (actual cubic feet per minute, acfm) |

Enter average or range of number of air changes per hour | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Response | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table 2. Natural Draft Openings (NDO) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Field # | B-1 | B-12 | B-13 | B-14 | B-15 | B-16 | B-17 | B-18 | B-19 | B-20 | B-21 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Data | Room area ID for all rooms and areas where EtO is used or emitted | Natural draft opening (NDO) 1 (if any) | Natural draft opening (NDO) 2 (if any) | Natural draft opening (NDO) 3 (if any) | Natural draft opening (NDO) 4 (if any) | Natural draft opening (NDO) 5 (if any) | Natural draft opening (NDO) 6 (if any) | Natural draft opening (NDO) 7 (if any) | Natural draft opening (NDO) 8 (if any) | Natural draft opening (NDO) 9 (if any) | Natural draft opening (NDO) 10 (if any) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Instruction | This column will be auto-populated based on your entries in the previous fields | NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

NDO ID. Enter from permit description, if available. Otherwise, use a unique identifier for each NDO | Type. Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your NDO)" |

Orientation. Select from the dropdown menu in this column | Latitude. Specify to the 6th decimal point | Longitude. Specify to the 6th decimal point | Cross-sectional area (square feet) |

Height above the ground (feet) |

Is air forced out of this NDO? Select from the dropdown menu in this column | Air velocity (feet/minute) |

| Response | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table 3. Leak Checks of Components in EtO Service | No (default) | ← Switch to "Yes" in Cell F82 on the left if Supplement 1 is used in lieu of this table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| If leak checks are performed on multiple types of components in a room area, use another row in this table, repeat your entries in Fields B-1 and B-22, then fill out the other fields as necessary | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| *** Note: If you need to enter more than 30 rows of data, please select "Yes" in Cell F82 above, leave this table below BLANK, then fill out SUPPLEMENT 1 to the Section 114 ICR. Refer to the Instructions Document for more details *** | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Field # | B-1 | B-22 | B-23 | B-24 | B-25 | B-26 | B-27 | B-28 | B-29 | B-30 | B-31 | B-32 | B-33 | B-34 | B-35 | B-36 | B-37 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Data | Room area ID for all rooms and areas where EtO is used or emitted | Are leak checks performed in the room area? | Component type | Total component count | What is the percentage of components that are included in regular leak checks? | Frequency of leak checks | Average length of time to perform leak checks | Instrument and standard method for leak checks | Leak check procedure | Average cost per inspection | Average percentage of leaking components identified | Definition of leak | Applicable state/local regulations | Repair method/procedure for the leaks identified | Average cost per repair for leaks identified | Are there any specialty components that are not readily available on site and that need to be ordered in the event of a component replacement? | Are there any other impediments that would prevent immediate repair of leaks? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Instruction | Select from the dropdown menu. Scroll up to see options that are auto-populated based on your entries in the previous fields | Select from the dropdown menu in this column | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your component)" |

Specify the total number of component of this type | Specify the percentage of components that are included in regular leak checks (percent) |

Specify how often leak checks are performed | Enter average length of time to perform leak checks per component type, per inspection (hours) |

Briefly describe the instrument and standard method used for leak checks | Describe the leak check procedure for each room area. Specifically, provide any action levels | Enter the dollar amount in this column | Specify the dollar year in this column | Enter average percentage of leaking components identified during each leak check (percent) |

If applicable, specify the definition or criteria of leak in the state/local regulations that require leak checks, or the definition that facility refers to | Specify any state/local regulations applicable to your facility for leak checks | Provide a brief description of the repair method/procedure for the leaks identified | Enter the dollar amount in this column | Specify the dollar year in this column | Select from the dropdown menu in this column | How long does it take, on average, for the facility to receive the components? (days) (if you select "Yes" on the left) |

Select from the dropdown menu in this column | List the impediments that would prevent immediate repair of leaks (if you select "Yes" on the left) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Response | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table 4. Room Area Controls | No (default) | ← Switch to "Yes" in Cell F120 on the left if Supplement 2 is used in lieu of this table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| If any of your room area is routed to more than 3 APCDs or more than 1 stack, use another row in this table, repeat the room area ID in Field B-1, then fill out the other fields as necessary | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| *** Note: If you need to enter more than 30 rows of data, please select "Yes" in Cell F120 above, leave this table below BLANK, then fill out SUPPLEMENT 2 to the Section 114 ICR. Refer to the Instructions Document for more details *** | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Field # | B-1 | B-38 | B-39 | B-40 | B-41 | B-42 | B-43 | B-44 | B-45 | B-46 | B-47 | B-48 | B-49 | B-50 | B-51 | B-52 | B-53 | B-54 | B-55 | B-56 | B-57 | B-58 | B-59 | B-60 | B-60.1 | B-61 | B-62 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Data | Room area ID for all rooms and areas where EtO is used or emitted | Is air from the room area vented to an APCD, used as cascading air, vented to the atmosphere, or handled in any other ways? | APCD 1 for room area | APCD 2 for room area (if any) | APCD 3 for room area (if any) | Material of duct work for room area venting | Total length of duct work for room area venting | Average thickness of duct work for room area venting | Is the cross section of duct work for room area venting circular or rectangular? | Diameter of duct work (For circular duct work only) |

Cross-sectional height of duct work (For rectangular duct work only) |

Cross-sectional width of duct work (For rectangular duct work only) |

Are the dimensions of duct work constant throughout? | Diameter of duct work (For circular duct work only) |

Cross-sectional height of duct work (For rectangular duct work only) |

Cross-sectional width of duct work (For rectangular duct work only) |

Installation year of duct work | Lifetime of duct work | Capital cost of duct work for room area venting (estimated or actual) | Installation cost of duct work for room area venting (estimated or actual) | Room area air used as cascading air for reuse in another room or unit (For cascading only) |

Stack ID to which the uncontrolled room area vents (For room area vented to the atmosphere only) |

Stack parameter (For room area vented to the atmosphere only) |

Stack coordinates (For room area vented to the atmosphere only) |

Distance from room area outlet to stack (For room area vented to the atmosphere only) |

Other handling of air from room area | Room Air Capture | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Instruction | Select from the dropdown menu. Scroll up to see options that are auto-populated based on your entries in the previous fields | Select from the dropdown menu in this column | APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the room to this APCD (actual cubic feet per minute, acfm) |

APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the room to this APCD (actual cubic feet per minute, acfm) |

APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the room to this APCD (actual cubic feet per minute, acfm) |

Specify the material of duct work | Enter the total length of duct work (feet) |

Enter the average thickness of duct work (inches) |

Select from the dropdown menu in this column | Enter the average diameter of duct work (feet) |

Enter the average cross-sectional height of duct work (feet) |

Enter the average cross-sectional width of duct work (feet) |

Select from the dropdown menu in this column | Enter the maximum diameter of duct work (feet) |

Enter the minimum diameter of duct work (feet) |

Enter the maximum cross-sectional height of duct work (feet) |

Enter the minimum cross-sectional height of duct work (feet) |

Enter the maximum cross-sectional width of duct work (feet) |

Enter the minimum cross-sectional width of duct work (feet) |

Enter the calendar year in which duct work was installed | Enter the expected lifetime of duct work (years) |

Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Specify the room area ID or unit ID the air is vented to if the room area air is used as cascading air for reuse in another room or unit (i.e., vented as the input air to another area). If multiple room areas/units are involved, list all the IDs and separate by commas (,). Ensure that any room area ID entered in this field is consistent with your entries in Field B-1 of this worksheet, and that any unit ID is consistent with your entries elsewhere in this questionnaire | Enter from permit description, if available. Otherwise, use a unique identifier for each stack | Enter the stack height (feet) |

Enter the stack diameter (feet) |

Enter the temperature at stack outlet (Fahrenheit) |

Enter the exhaust velocity at stack outlet (feet/second) |

Enter the volumetric flow rate for this emission source at stack outlet (cubic feet per minute) |

Enter the latitude of stack. Specify to the 6th decimal point | Enter the longitude of stack. Specify to the 6th decimal point | Enter the distance from outlet of the room area to the stack (feet) |

Provide a brief description of any air pollution control or handling procedure if air from this room area is not: vented to an APCD; used as cascading air; or vented to the atmosphere | Is there a structure or approach to capture the air emitted from the room area? Select from the dropdown menu in this column | If yes, specify the capture efficiency for this room area (%) |

If yes, specify the structure type or approach used to capture the room area (e.g., permanent total enclosure) | If yes, specify the method(s) used to verify the capture efficiency of room air (e.g., Method 204) | |||||||||||||||||||||||||||||||||||||||||||||

| Response | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sheet 5: EtO & EG Storage

| Ethylene Oxide (EtO) Commercial Sterilization | Does any information entered on this worksheet contain confidential business information (CBI)? Specify in Cell N2 on the right → Be sure to shade each cell that contains CBI in red Before saving the non-CBI version of your response, select and copy the Sample CBI Cell (Cell O2), and paste directly into each cell that contains CBI. Make sure that all "CBI" cells are shaded in red |

CBI | EIS ID (Auto-populated) |

|||||||||||||||||||||||||||||||||||||||||||||||

| CAA Section 114 Information Collection Request (ICR) | Sample CBI Cell (above) |

|||||||||||||||||||||||||||||||||||||||||||||||||

| Click here to go to "Introduction" | Click here to go to "Terms" | Click here to go to "Additional Info" | ||||||||||||||||||||||||||||||||||||||||||||||||

| C. EtO Drum and Container Storage | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Field # | Data | Instruction | Response | |||||||||||||||||||||||||||||||||||||||||||||||

| C-0 | What companies supply EtO drums or cartridges to your facility? Specify the name and percent (%) by weight for each company | Separate data for each company by commas (,). For example: Company 1 - 70%, Company 2 - 30% | ||||||||||||||||||||||||||||||||||||||||||||||||

| C-1 | How many EtO drums and/or containers are typically stored at the facility at once? | |||||||||||||||||||||||||||||||||||||||||||||||||

| C-2 | Permitted amount of EtO storage | (pounds) | ||||||||||||||||||||||||||||||||||||||||||||||||

| C-3 | Is there a designated area for storing EtO drums and/or containers? | Select from the dropdown menu | ||||||||||||||||||||||||||||||||||||||||||||||||

| C-4 | Describe the designated area for EtO drum and/or container storage | |||||||||||||||||||||||||||||||||||||||||||||||||

| C-5 | Describe the storage location for full and empty storage media (e.g., indoors in an enclosed room) | |||||||||||||||||||||||||||||||||||||||||||||||||

| C-6 | Specify the maximum number of full EtO storage media (e.g., twelve 55-gallon drums) kept at the facility in the last 12 months | |||||||||||||||||||||||||||||||||||||||||||||||||

| C-7 | Is the ambient air in the storage areas continually monitored for ethylene oxide? | Select from the dropdown menu | ||||||||||||||||||||||||||||||||||||||||||||||||

| C-8 | Describe the make/model and range of the instrumentation used for continuous monitoring of the storage areas | |||||||||||||||||||||||||||||||||||||||||||||||||

| C-9 | How often are new drums or containers delivered to facility and empty drums or containers picked up and sent offsite? | |||||||||||||||||||||||||||||||||||||||||||||||||

| C-10 | What is the procedure for checking drums or containers before accepting them onsite? If drums or containers do not meet the requirements, what corrective actions are taken, and how many drums or containers per year are the corrective actions performed on? | |||||||||||||||||||||||||||||||||||||||||||||||||

| C-11 | Are drums or containers placed next to sterilizer chambers when they are in use? | Select from the dropdown menu | ||||||||||||||||||||||||||||||||||||||||||||||||

| C-12 | Describe how EtO is charged to the sterilizer chamber | |||||||||||||||||||||||||||||||||||||||||||||||||

| D. Ethylene Glycol (EG) Tanks | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Field # | D-1 | D-2 | D-3 | D-4 | D-5 | D-6 | D-7 | D-8 | D-9 | D-10 | D-11 | D-12 | D-13 | D-14 | D-15 | D-16 | D-17 | D-18 | D-19 | D-20 | D-21 | D-22 | D-23 | D-24 | D-25 | D-26 | D-27 | D-28 | D-29 | D-30 | D-31 | |||||||||||||||||||

| Data | Ethylene glycol (EG) tank ID | Material of EG tank | Capacity of EG tank | Throughput of EG tank | Installation year of EG tank | Expected lifetime of EG tank | Capital cost of EG tank | Installation cost of EG tank | Annual cost of EG tank | Is the EG tank routed to any control device? | APCD 1 for EG tank | APCD 2 for EG tank (if any) | Material of duct work for EG tank | Total length of duct work for EG tank | Average thickness of duct work for EG tank | Is the cross section of duct work for EG tank circular or rectangular? | Diameter of duct work (For circular duct work only) |

Cross-sectional height of duct work (For rectangular duct work only) |

Cross-sectional width of duct work (For rectangular duct work only) |

Are the dimensions of duct work constant throughout? | Diameter of duct work (For circular duct work only) |

Cross-sectional height of duct work (For rectangular duct work only) |

Cross-sectional width of duct work (For rectangular duct work only) |

Installation year of duct work | Lifetime of duct work | Capital cost of duct work for EG tank (estimated or actual) | Installation cost of duct work for EG tank (estimated or actual) | Stack ID to which the uncontrolled EG tank vents (For uncontrolled EG tank only) |

Stack parameter (For uncontrolled EG tank only) |

Stack coordinates (For uncontrolled EG tank only) |

Distance from EG tank outlet to stack (For uncontrolled EG tank only) |

|||||||||||||||||||

| Instruction | Enter from permit description, if available. Otherwise, use a unique identifier for each EG tank | Specify the material of EG tank | Enter the capacity of EG tank (gallons) |

Enter the average daily throughput of EG tank (gallons per day) |

Enter the calendar year in which EG tank was installed | Enter the expected lifetime of EG tank (years) |

Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Select from the dropdown menu in this column | APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the tank to this APCD (actual cubic feet per minute, acfm) |

APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the tank to this APCD (actual cubic feet per minute, acfm) |

Specify the material of duct work | Enter the total length of duct work (feet) |

Enter the average thickness of duct work (inches) |

Select from the dropdown menu in this column | Enter the average diameter of duct work (feet) |

Enter the average cross-sectional height of duct work (feet) |

Enter the average cross-sectional width of duct work (feet) |

Select from the dropdown menu in this column | Enter the maximum diameter of duct work (feet) |

Enter the minimum diameter of duct work (feet) |

Enter the maximum cross-sectional height of duct work (feet) |

Enter the minimum cross-sectional height of duct work (feet) |

Enter the maximum cross-sectional width of duct work (feet) |

Enter the minimum cross-sectional width of duct work (feet) |

Enter the calendar year in which duct work was installed | Enter the expected lifetime of duct work (years) |

Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Enter from permit description, if available. Otherwise, use a unique identifier for each stack | Enter the stack height (feet) |

Enter the stack diameter (feet) |

Enter the temperature at stack outlet (Fahrenheit) |

Enter the exhaust velocity at stack outlet (feet/second) |

Enter the volumetric flow rate for this emission source at stack outlet (cubic feet per minute) |

Enter the latitude of stack. Specify to the 6th decimal point | Enter the longitude of stack. Specify to the 6th decimal point | Enter the distance from outlet of the uncontrolled EG tank to the stack (feet) |

||

| Response | ||||||||||||||||||||||||||||||||||||||||||||||||||

Sheet 6: Sterilizer Chambers

| Ethylene Oxide (EtO) Commercial Sterilization | Does any information entered on this worksheet contain confidential business information (CBI)? Specify in Cell N2 on the right → Be sure to shade each cell that contains CBI in red Before saving the non-CBI version of your response, select and copy the Sample CBI Cell (Cell O2), and paste directly into each cell that contains CBI. Make sure that all "CBI" cells are shaded in red |

CBI | EIS ID (Auto-populated) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| CAA Section 114 Information Collection Request (ICR) | Sample CBI Cell (above) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Click here to go to "Introduction" | Click here to go to "Terms" | Click here to go to "Additional Info" | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E. Sterilization Chambers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table 1. Summary for Sterilizer Chambers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Field # | Data | Response | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E-0 | Enter the total number of sterilizer chambers at your facility | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table 2. Sterilizer Chamber Operation and Monitoring Characteristics | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Field # | E-1 | B-1 | E-2 | E-3 | E-4 | E-5 | E-6 | E-7 | E-8 | E-9 | E-10 | E-11 | E-12 | E-13 | E-14 | E-15 | E-16 | E-17 | E-18 | E-19 | E-20 | E-21 | E-22 | E-23 | E-24 | E-25 | E-26 | E-27 | E-28 | E-29 | E-30 | E-31 | E-32 | E-33 | E-34 | E-35 | E-36 | E-37 | E-38 | E-39 | E-40 | E-41 | E-42 | E-43 | E-44 | E-45 | E-46 | E-47 | E-48 | E-49 | E-50 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Data | Sterilizer unit ID | Room area in which sterilizer unit is located | Associated EIS release point ID | Is this an R&D chamber (under the definition of research and laboratory facility)? | Does aeration of the sterilized product occur in the same sterilizer chamber? | Is this a single-item chamber? | Volume of sterilizer chamber | How many cycles per year are conducted in sterilizer chamber in total? | Temperature (For combination sterilizers, enter temperature for sterilization mode only) |

Relative humidity | Pressure | Does the sterilizer chamber have positive pressure cycles? | EtO dose per cycle | Number of nitrogen washes per cycle | Nitrogen used for washes during each cycle | Annual cost of nitrogen washes | Number of air washes per cycle | Air used for washes during each cycle | Annual cost of air washes | Average electricity used per gas wash (nitrogen washes and air washes combined) | Annual cost of electricity for gas washes (nitrogen washes and air washes combined) | Are leak checks performed on sterilizer chamber? | Frequency of leak checks for sterilizer chamber | Average length of time to perform a leak check | Leak check procedure(s) for sterilizer chamber | Annual cost of leak checks for sterilizer chamber | Average quantity of leaks identified per year | Repair method/procedure for the leaks identified | Average cost per repair for the leaks identified | Is an EtO concentration monitor used within this sterilizer chamber? | Description of the EtO concentration monitor used within this sterilizer chamber | Installation year of EtO concentration monitor | Expected lifetime of EtO concentration monitor | Capital cost of the EtO concentration monitor used within this sterilizer chamber | Installation cost of the EtO concentration monitor used within this sterilizer chamber | Annual cost of the EtO concentration monitor used within this sterilizer chamber | Standards or work practices followed for the EtO concentration monitor used within this sterilizer chamber | Duration of product dwell time within the chamber at EtO dosing concentration | Total duration of time product stays within the sterilizer chamber before it is moved out | Concentration that EtO is reduced to before moving the product out of this sterilizer chamber | Is EtO from sterilizer captured for re-use? | Is water used during this process? | Amount of water disposed annually | Method of water disposal | Annual costs associated with water disposal | What is the percentage of EtO recovered by this system? | Year in which the EtO recovery system was installed | Expected lifetime of the EtO recovery system | Capital cost of the EtO recovery system used with this sterilizer chamber | Installation cost of the EtO recovery system used with this sterilizer chamber | Annual cost of the EtO recovery system used with this sterilizer chamber (excluding costs associated with wastewater treatment and disposal) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Instruction | Enter from permit description, if available. Otherwise, use a unique identifier for each sterilizer | Select from the dropdown menu. Scroll up to see options that are auto-populated based on your entries in the previous fields | Enter the EIS release point ID associated with the sterilizer unit, if any | Select from the dropdown menu in this column | Select from the dropdown menu in this column (If you select "Yes" for any sterilizer, fill out Table 3 on "Aeration" worksheet) |

Select from the dropdown menu in this column | (cubic feet) | Enter the total number of cycles conducted in the sterilizer chamber each year | Enter the average temperature of sterilizer chamber when in operation (Fahrenheit) | Enter the maximum temperature of sterilizer chamber when in operation (Fahrenheit) |

Enter the minimum temperature of sterilizer chamber when in operation (Fahrenheit) |

Enter the average relative humidity within sterilizer chamber when in operation (percent) | Enter the maximum relative humidity within sterilizer chamber when in operation (percent) |

Enter the minimum relative humidity within sterilizer chamber when in operation (percent) |

Enter the average pressure within the chamber during EtO dwell period (psig) |

Enter the magnitude of vacuum on average that is applied during evacuation (psig) |

Select from the dropdown menu in this column | Enter the average EtO dose per cycle (mg/L) |

Enter the maximum EtO dose per cycle (mg/L) |

Enter the minimum EtO dose per cycle (mg/L) |

Enter the average number of nitrogen washes per cycle | Enter the maximum number of nitrogen washes per cycle | Enter the minimum number of nitrogen washes per cycle | Enter the average amount of nitrogen used during each cycle (pounds) |

Enter the maximum amount of nitrogen used during each cycle (pounds) |

Enter the minimum amount of nitrogen used during each cycle (pounds) |

Enter the dollar amount in this column | Specify the dollar year in this column | Enter the average number of air washes per cycle | Enter the maximum number of air washes per cycle | Enter the minimum number of air washes per cycle | Enter the average amount of air used during each cycle (pounds) |

Enter the maximum amount of air used during each cycle (pounds) |

Enter the minimum amount of air used during each cycle (pounds) |

Enter the dollar amount in this column | Specify the dollar year in this column | (kWh) | Enter the dollar amount in this column | Specify the dollar year in this column | Select from the dropdown menu in this column | Specify the frequency of leak checks for sterilizer chamber | Enter average length of time to perform a leak check (minutes) |

Provide a brief description of the leak check procedure(s) for sterilizer chamber | Enter the dollar amount in this column | Specify the dollar year in this column | Enter average quantity of leaks found per year | Provide a brief description of the repair method/procedure for the leaks identified | Enter the dollar amount in this column | Specify the dollar year in this column | Select from the dropdown menu in this column | Enter the type of EtO concentration monitor | Enter the manufacturer of EtO concentration monitor | Enter the model of EtO concentration monitor | Specify the method of detection of EtO concentration monitor | Enter the value of detection level of EtO concentration monitor | Specify the unit of detection level of EtO concentration monitor | Enter the calendar year in which the EtO concentration monitor was installed | Enter the expected lifetime of the EtO concentration monitor (years) |

Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Provide a brief description of any standards or work practices followed for the EtO concentration monitor used within the chamber | Enter the average duration (hours) |

Enter the maximum duration (hours) |

Enter the minimum duration (hours) |

Enter the average duration (hours) |

Enter the maximum duration (hours) |

Enter the minimum duration (hours) |

Specify the unit of concentration. Select from the dropdown menu in this column |

Enter the average concentration that EtO is reduced to (ppm or % LEL) |

Enter the maximum concentration that EtO is reduced to (ppm or % LEL) |

Enter the minimum concentration that EtO is reduced to (ppm or % LEL) |

Select from the dropdown menu in this column | Select from the dropdown menu in this column | (gallons) | Provide a brief description about how water is disposed after being used to capture EtO for re-use | Enter the dollar amount in this column | Specify the dollar year in this column | (percent) | Enter the calendar year | Enter the expected lifetime of the EtO recovery system (years) |

Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | ||||||||||||||||||||||||

| Response | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Table 3. Control Characteristics for Sterilizer Chambers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Field # | E-1 | E-51 | E-52 | E-53 | E-54 | E-55 | E-56 | E-57 | E-58 | E-59 | E-60 | E-61 | E-62 | E-63 | E-64 | E-65 | E-66 | E-67 | E-68 | E-69 | E-70 | E-71 | E-72 | E-72.1 | E-73 | E-74 | E-74.1 | E-74.2 | E-75 | E-76 | E-77 | E-78 | E-79 | E-80 | E-81 | E-82 | E-83 | E-84 | E-85 | E-86 | E-87 | E-88 | E-89 | E-90 | E-91 | E-92 | E-93 | E-94 | E-95 | E-96 | E-97 | E-98 | E-99 | E-100 | E-101 | E-102 | E-103 | E-104 | E-105 | E-106 | E-107 | E-108 | E-109 | E-110 | E-110.1 | |||||||||||||||||||||||||||||||||||||||||||||||||

| Data | Sterilizer unit ID | Is the sterilizer chamber vent (SCV) routed to any control device? | APCD 1 for sterilizer chamber vent (SCV) | APCD 2 for sterilizer chamber vent (SCV) (if any) | APCD 3 for sterilizer chamber vent (SCV) (if any) | Material of duct work for sterilizer chamber vent (SCV) | Total length of duct work for sterilizer chamber vent (SCV) | Average thickness of duct work for sterilizer chamber vent (SCV) | Is the cross section of duct work for sterilizer chamber vent (SCV) circular or rectangular? | Diameter of duct work (For circular duct work only) |

Cross-sectional height of duct work (For rectangular duct work only) |

Cross-sectional width of duct work (For rectangular duct work only) |

Are the dimensions of duct work constant throughout? | Diameter of duct work (For circular duct work only) |

Cross-sectional height of duct work (For rectangular duct work only) |

Cross-sectional width of duct work (For rectangular duct work only) |

Installation year of duct work | Lifetime of duct work | Capital cost of duct work for sterilizer chamber vent (SCV) (estimated or actual) | Installation cost of duct work for sterilizer chamber vent (SCV) (estimated or actual) | Stack ID to which the uncontrolled sterilizer chamber vent (SCV) vents (For uncontrolled SCV only) |

Stack parameter (For uncontrolled SCV only) |

Stack coordinates (For uncontrolled SCV only) |

Distance from SCV to stack (For uncontrolled SCV only) |

Is there a chamber exhaust vent (CEV)? | Is there a target EtO concentration that is reached before activation of the CEV? | Duration of CEV operation in each sterilization cycle | Average EtO concentration during CEV operation | Is an interlock system present that prevents activation of the CEV and opening of the sterilizer door until a set EtO concentration is reached? | Installation year of interlock system | Expected lifetime of interlock system | Capital cost of interlock system | Annual cost of interlock system | Standards or work practices followed for interlock system | Is the chamber exhaust vent (CEV) routed to any control device? | APCD 1 for chamber exhaust vent (CEV) | APCD 2 for chamber exhaust vent (CEV) (if any) | APCD 3 for chamber exhaust vent (CEV) (if any) | Material of duct work for chamber exhaust vent (CEV) | Total length of duct work for chamber exhaust vent (CEV) | Average thickness of duct work for chamber exhaust vent (CEV) | Is the cross section of duct work for chamber exhaust vent (CEV) circular or rectangular? | Diameter of duct work (For circular duct work only) |

Cross-sectional height of duct work (For rectangular duct work only) |

Cross-sectional width of duct work (For rectangular duct work only) |

Are the dimensions of duct work constant throughout? | Diameter of duct work (For circular duct work only) |

Cross-sectional height of duct work (For rectangular duct work only) |

Cross-sectional width of duct work (For rectangular duct work only) |

Installation year of duct work | Lifetime of duct work | Capital cost of duct work for chamber exhaust vent (CEV) (estimated or actual) | Installation cost of duct work for chamber exhaust vent (CEV) (estimated or actual) | Is any APCD installed solely for the purpose of controlling emissions from the CEV? | If not, was a damper system installed for the purpose of adjusting the flow rate to the control device upon CEV activation? | Year in which the damper system was installed | Expected lifetime of the damper system | Capital cost of the damper system | Installation cost of the damper system | Annual cost of the damper system | APCD installed solely for the purpose of controlling emissions from the CEV | Stack ID to which the uncontrolled chamber exhaust vent (CEV) vents (For uncontrolled CEV only) |

Stack parameter (For uncontrolled CEV only) |

Stack coordinates (For uncontrolled CEV only) |

Distance from CEV to stack (For uncontrolled CEV only) |

|||||||||||||||||||||||||||||||||||||||||||||||||

| Instruction | This column will be auto-populated based on your entries in the previous fields | Select from the dropdown menu in this column | APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the vent to this APCD (actual cubic feet per minute, acfm) |

APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the vent to this APCD (actual cubic feet per minute, acfm) |

APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the vent to this APCD (actual cubic feet per minute, acfm) |

Specify the material of duct work | Enter the total length of duct work (feet) |

Enter the average thickness of duct work (inches) |

Select from the dropdown menu in this column | Enter the average diameter of duct work (feet) |

Enter the average cross-sectional height of duct work (feet) |

Enter the average cross-sectional width of duct work (feet) |

Select from the dropdown menu in this column | Enter the maximum diameter of duct work (feet) |

Enter the minimum diameter of duct work (feet) |

Enter the maximum cross-sectional height of duct work (feet) |

Enter the minimum cross-sectional height of duct work (feet) |

Enter the maximum cross-sectional width of duct work (feet) |

Enter the minimum cross-sectional width of duct work (feet) |

Enter the calendar year in which duct work was installed | Enter the expected lifetime of duct work (years) |

Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Enter from permit description, if available. Otherwise, use a unique identifier for each stack | Enter the stack height (feet) |

Enter the stack diameter (feet) |

Enter the temperature at stack outlet (Fahrenheit) |

Enter the exhaust velocity at stack outlet (feet/second) |

Enter the volumetric flow rate for this emission source at stack outlet (cubic feet per minute) |

Enter the latitude of stack. Specify to the 6th decimal point | Enter the longitude of stack. Specify to the 6th decimal point | Enter the distance from the uncontrolled SCV to the stack (feet) |

Select from the dropdown menu in this column | Select from the dropdown menu in this column | Enter the value if you select "Yes" on the left (ppm) |

Enter the time that the CEV is in operation for each sterilization cycle (minutes) |

Enter the average EtO concentration over the duration of the CEV operation, if available. This should NOT be the EtO concentration at the start of operation (ppm) |

Select from the dropdown menu in this column | Enter the calendar year in which the interlock system was installed | Enter the expected lifetime of the interlock system (years) |

Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Provide a brief description of any standards or work practices followed for interlock system that prevents activation of the CEV until a set concentration is reached | Select from the dropdown menu in this column | APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the vent to this APCD (actual cubic feet per minute, acfm) |

APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the vent to this APCD (actual cubic feet per minute, acfm) |

APCD ID. Enter from permit description, if available. Otherwise, use a unique identifier for each APCD | Select from the dropdown menu in this column If you select "Other (double click and type here)", be sure to enter your response between the parentheses Example: "Other (your APCD)" |

Enter the average air flow routed from the vent to this APCD (actual cubic feet per minute, acfm) |

Specify the material of duct work | Enter the total length of duct work (feet) |

Enter the average thickness of duct work (inches) |

Select from the dropdown menu in this column | Enter the average diameter of duct work (feet) |

Enter the average cross-sectional height of duct work (feet) |

Enter the average cross-sectional width of duct work (feet) |

Select from the dropdown menu in this column | Enter the maximum diameter of duct work (feet) |

Enter the minimum diameter of duct work (feet) |

Enter the maximum cross-sectional height of duct work (feet) |

Enter the minimum cross-sectional height of duct work (feet) |

Enter the maximum cross-sectional width of duct work (feet) |

Enter the minimum cross-sectional width of duct work (feet) |

Enter the calendar year in which duct work was installed | Enter the expected lifetime of duct work (years) |

Enter the dollar amount in this column | Specify the dollar year in this column | Enter the dollar amount in this column | Specify the dollar year in this column | Select from the dropdown menu in this column | Select from the dropdown menu in this column | Enter the calendar year | Enter the expected lifetime of the damper system (years) |