1100ss17

1100ss17.docx

NESHAP for Radionuclides (40 CFR Part 61, Subpart B, K, R, and W) (Renewal)

OMB: 2060-0191

ENVIRONMENTAL PROTECTION AGENCY

SUPPORTING STATEMENT

1. Identification of Information Collection

NESHAP for Radionuclides (40 CFR part 61, subparts B, K, R and W) (Renewal), EPA Number 1100.17 OMB Control Number 2060-0191

1(b) Short Characterization

On December 15, 1989, pursuant to Section 112 of the Clean Air Act, as amended in 1977 (42 USC 1857), the Environmental Protection Agency (EPA) promulgated National Emission Standards for Hazardous Air Pollutants (NESHAPs) to control radionuclide emissions from several source categories. The regulations were published in 54 FR 51653 and are codified at 40 CFR part 61. Of the subparts included in the 1989 rule, as currently amended, four apply to privately-operated facilities. In addition to requiring operational practices that limit emissions, subparts B, K, R, and W impose radionuclide dose and emission limits on source categories as listed in Table 1.

Table 1: Dose and Emissions Limits by Subpart

Subpart |

Source Category |

Dose or Release Limit |

B |

Underground Uranium Mines |

10 mrem/yr due to Radon-222 |

K |

Elemental Phosphorous Plants |

2 curies/yr of Polonium-210 |

R |

Phosphogypsum Stacks |

20 pCi/m2/s of Radon-222 |

W |

Uranium Mill Tailings |

20 pCi/m2/s of Radon-222 |

On January 17, 2017, the EPA issued final revisions to the radon emission standards for 40 CFR part 61, subpart W (82 FR 5142). Included in the revisions were additional requirements that owners and operators of uranium recovery facilities maintain specific records pertaining to the design, construction and operation of all uranium tailings impoundments, both conventional and non-conventional, and heap leach piles, and create written and digital photographic records showing compliance with the requirement to maintain liquid in non-conventional impoundments so that any solid materials in the impoundment are not visible above the liquid level. Because these requirements were not included in the existing information collection request (ICR) for radionuclide NESHAPs (EPA Number 1100.17, OMB Control Number 2060-0191) a new ICR was established specifically to address the information collection requirements created by the revisions to subpart W (EPA Number 2464.03, OMB Control Number 2060-0706). At the present time, the Agency seeks to consolidate these two ICRs, so that all the information collection requirements under 40 CFR part 61 subpart W are included in a single ICR, together with the information collection requirements of subparts B, K, and R, effectively consolidating all information collection for radionuclide NESHAPs into a single ICR. Following OMB approval, EPA ICR Number 2464.03, OMB Control Number 2060-0706, will be discontinued.

Information collected is used by the EPA to ensure that public health continues to be protected from the hazards of airborne radionuclides through compliance with these standards. Compliance is demonstrated through emissions testing and dose calculation when appropriate. Facilities are required to generate and maintain applicable records for 5 years, and to report results to the EPA.

2. Need and Use for the Collection

2(a) Need/Authority for the Collection

The Clean Air Act (42 USC 1857), Section 114 authorizes the Administrator of the EPA to require any person who owns or operates any emission source or who is subject to any requirements of the Act to establish and maintain records; make reports, install, use, and maintain monitoring equipment or methods; sample emissions in accordance with EPA‑prescribed locations, intervals and methods; and provide information as requested by the EPA Administrator or authorized representative.

2(b) Practical Utility/Users

The EPA uses the information collected to determine that public health continues to be protected through compliance with the health-based standards set by the radionuclide NESHAPs.

EPA's compliance monitoring activities vary widely. EPA could issue a letter requesting information about compliance or could conduct a full scale investigation if a compliance problem is identified, including on‑site inspections. When EPA first learns of a compliance problem, EPA attempts to work with the owner/operator to remedy the problem by holding informal discussions. If it is not possible to remedy the problem informally, formal action is taken. EPA's Clean Air Act Compliance Enforcement Guidance Manual identifies the Agency's informal and formal enforcement operating procedures.

3. NON DUPLICATION, CONSULTATIONS AND OTHER COLLECTION CRITERIA

3(a) Non duplication

The specific information collected under this ICR is not currently collected by any other office within the EPA or any other governmental agency.

3(b) Public Notice Required Prior to ICR Submission to OMB

The EPA requested comments on specific aspects of this proposed ICR renewal with a 60-day comment period which closed on Dec 3, 2021. The EPA will publish an FR notice opening an additional 30-day comment period on this ICR renewal concurrent with its submission to OMB.

3(c) Consultations

In the preparation of this ICR renewal, the EPA contacted representatives in each of its Regional Offices to update information on the operating and reporting status of affected facilities and updated the number of affected facilities based on this information. The Agency reached out directly to operators of uranium facilities to determine how many facilities were likely to monitor emissions and submit reports, particularly under Subpart B, for calendar year 2021, and to alert them to the pending opportunity to comment on the proposed ICR through a notice published in the Federal Register. Public comments on the proposed ICR renewal were requested via the Federal Register during a 60-day comment period beginning October 4, 2020 (86 FR 54691). No applicable comments were submitted to the docket during the comment period. One comment was received which was applicable to an EPA action unrelated to the radionuclide NESHAPs. Because no additional information was submitted during the comment period, no additional changes have been made to the proposed ICR renewal.

3(d) Effects of Less Frequent Collection

Generally, reporting under the radionuclide NESHAPs addressed in subparts B, K and R is required annually or less frequently than annually. Under subpart W, respondents are required to collect digital photographs of liquid levels in impoundments at least weekly and submit them to the Agency at least monthly. Extended periods of exposed uranium byproduct material could result in excessive emissions of radon to the atmosphere. In each case, the frequency of reporting is sufficient for the Agency to ensure that compliance is maintained, or that corrective actions can be taken in a timely manner.

3(e) General Guidelines

This ICR is consistent with OMB’s collection guidelines provided in 5 CFR Part 1320.5 and does not duplicate another collection.

3(f) Confidentiality

This section does not apply because this ICR does not request information of confidential nature.

3(g) Sensitive Questions

This section is not applicable because this ICR does not request sensitive information.

4. THE RESPONDENTS AND THE INFORMATION REQUESTED

4(a) Respondents/North American Industrial Classification System (NAICS) Codes

The North American Industry Classification System (NAICS) codes associated with the activities of the respondents are included in Table 2.

Table 2: NAICS Codes of Respondents by Subpart

Subpart |

Source Category |

NAICS Code |

B |

Underground Uranium Mines |

212291: Uranium-Radium-Vanadium Ore Mining |

K |

Elemental Phosphorous |

325180: Other Basic Inorganic Chemical Manufacturing |

R |

Phosphogypsum Stacks |

212392: Phosphate Rock Mining |

W |

Uranium Mill Tailings |

212291: Uranium-Radium-Vanadium Ore Mining |

4(b) Information Requested

(i) Reporting

Descriptions of the reporting requirements are listed separately below for each subpart.

Subpart B: Underground Uranium Mines

Subpart B requires mines that are being actively ventilated to perform annual radon emissions measurements and public dose calculations using Appendix B, Method 115 of 40 CFR part 61 and the EPA computer program COMPLY-R, and to report the results to the EPA. The specific reporting requirements are found in Section 61.24(a):

“The mine owner or operator shall annually calculate and report the results of the compliance calculations and the input parameters used in making the calculation. This report shall cover the emissions of a calendar year and be sent to EPA by March 31 of the following year. Each report shall also include the following information:

(1) The name and location of the mine (including latitude and longitude).

(2) The name of the person responsible for the operation of the facility and the name of the person preparing the report (if different).

(3) The results of the emissions testing conducted and the dose calculated using the procedures in Section 61.23.

(4) A list of the stacks or vents or other points where radioactive materials are released to the atmosphere, including their location, diameter, flow rate, effluent temperature and release height.

(5) A description of the effluent controls that are used on each stack, vent, or other release point and the effluent controls used inside the mine, and an estimate of the efficiency of each control method or device.

(6) Distances from the points of release to the nearest residence, school, business or office and the nearest farms producing vegetables, milk and meat.

(7) The values used for all other user-supplied input parameters for the computer model (e.g., meteorological data) and the source of these data.

(8) Each report shall be signed and dated by a corporate officer in charge of the facility and contain the following declaration immediately above the signature line: ‘I certify under penalty of law that I have personally examined and am familiar with the information submitted herein and based on my inquiry of those individuals immediately responsible for obtaining the information, I believe that the submitted information is true, accurate and complete. I am aware that there are significant penalties for submitting false information including the possibility of fine and imprisonment. See 18 U.S.C. 1001.’"

Subpart K: Elemental Phosphorus Plants

Subpart K sets an annual emissions limit for polonium-210. Each owner or operator of an elemental phosphorus plant shall test emissions of polonium-210 from the plant annually according to the procedures in Section 61.123 and using the test methods in Section 61.125. The EPA requires that these results be reported annually. Specific compliance reporting requirements are included in Section 61.123(f):

“Each owner or operator of an elemental phosphorus plant shall furnish the EPA Administrator with a written report on the results of the emission test within 60 days of conducting the test. The report must provide the following information:

(1) The name and location of the facility (including latitude and longitude).

(2) The name of the person responsible for the operation of the facility and the name of the person preparing the report (if different).

(3) A description of the effluent controls that are used on each stack, vent or other release point and an estimate of the efficiency of each device.

(4) The results of the testing, including the results of each sampling run completed.

(5) The values used in calculating the emissions and the source of these data.

(6) Each report shall be signed and dated by a corporate officer in charge of the facility and contain the following declaration immediately above the signature line: ‘I certify under penalty of law that I have personally examined and am familiar with the information submitted herein and based on my inquiry of those individuals immediately responsible for obtaining the information, I believe that the submitted information is true, accurate and complete. I am aware that there are significant penalties for submitting false information including the possibility of fine and imprisonment. See, 18 U.S.C. 1001.’"

Subpart R: Phosphogypsum Stacks

Subpart R sets a limit for radon emissions from inactive stacks, defined in the rule as any stack which for two years has neither had phosphogypsum added nor has been used for water management. When a stack becomes inactive, testing and reporting is required, which is described in Section 61.203:

“(a)Within sixty days of the date on which a stack becomes an inactive stack…the owners or operators of the inactive phosphogypsum stack shall test the stack for radon-222 flux in accordance with the procedures described in 40 CFR part 61, appendix B, Method 115. EPA shall be notified at least 30 days prior to each such emission test so that EPA may, at its option, observe the test. If meteorological conditions are such that test cannot be properly conducted, then the owner of operator should notify EPA and test as soon as conditions permit.

(b)(1) Within ninety days after the testing is required, the owner or operator shall provide EPA with a report detailing the actions taken and the results of the radon-222 flux testing. Each report shall also include the following information:

(i) The name and location of the facility;

(ii) A list of the stacks at the facility including the size and dimensions of the stack;

(iii) The name of the person responsible for the operation of the facility and the name of the person preparing the report (if different);

(iv) A description of the control measures taken to decrease the radon flux from the source and any actions taken to insure the long-term effectiveness of the control measures; and

(v) The results of the testing conducted, including the results of each measurement.

(2) Each report shall be signed and dated by a corporate officer in charge of the facility and contain the following declaration immediately above the signature line: ‘I certify under penalty of law that I have personally examined and am familiar with the information submitted herein and based on my inquiry of those individuals immediately responsible for obtaining the information, I believe that the submitted information is true, accurate and complete. I am aware that there are significant penalties for submitting false information including the possibility of fine and imprisonment. See 18 U.S.C. 1001.’"

If a stack remains inactive, testing and reporting is only required once. Should the stack become active again for the purposes of phosphogypsum disposal or water management, the facility owner or operator must notify EPA, and radon flux measurement and reporting must be repeated when the stack again becomes inactive (see Section 61.203(d)).

Subpart R additionally defines certain scenarios in which removal of phosphogypsum from stacks is permitted. Within ninety days of phosphogypsum removal from an inactive stack, and at least once within each calendar year during which removal occurs, radon flux measurements and reporting must be repeated. Radon flux testing is not required for the removal of phosphogypsum from an active stack. Additionally, Section 61.207 sets forth requirements for measuring the radium-226 concentration at the location in the stack from which phosphogypsum is removed. The results of these analyses must be included in certification documents for the removed phosphogypsum required by Section 61.208(a)(1):

“The owner or operator of a stack from which phosphogypsum will be removed and distributed in commerce pursuant to Section 61.204, Section 61.205, or Section 61.206 shall prepare a certification document for each quantity of phosphogypsum distributed in commerce which includes:

(i) The name and address of the owner or operator;

(ii) The name and address of the purchaser or recipient of the phosphogypsum;

(iii) The quantity of phosphogypsum, in kilograms or pounds sold or transferred;

(iv) The date of sale or transfer;

(v) A description of the intended use for the phosphogypsum;

(vi) The average radium-226 concentration, in pCi/g (pCi/lb), of the phosphogypsum, as determined pursuant to §61.207; and

(vii) The signature of the person who prepared the certification.”

Section 61.208 (b) requires a certification document with the same content to be prepared by “each distributor, retailer, or reseller who purchases or receives phosphogypsum for subsequent resale or transfer.” Submission of certification documents to EPA is not a requirement, but the documents must be retained according to recordkeeping requirements as discussed below.

Subpart W: Uranium Mill Tailings

Subpart W limits radon flux from operating uranium mill tailing impoundments. The EPA requires reports to be submitted annually. The requirements for those reports are included in Section 61.254:

“The owners or operators of operating existing mill impoundments shall perform radon measurements and compliance calculations as required in §61.253. The input parameters and results of the calculation for each calendar year shall be sent to EPA by March 31 of the following year. Each report shall also include the following information:

(1) The name and location of the mill.

(2) The name of the person responsible for the operation of the facility and the name of the person preparing the report (if different).

(3) The results of the testing conducted, including the results of each measurement.

(4) Each report shall be signed and dated by a corporate officer in charge of the facility and contain the following declaration immediately above the signature line: ‘I certify under penalty of law that I have personally examined and am familiar with the information submitted herein and based on my inquiry of those individuals immediately responsible for obtaining the information, I believe that the submitted information is true, accurate and complete. I am aware that there are significant penalties for submitting false information including the possibility of fine and imprisonment. See 18 U.S.C. 1001.’"

EPA amended subpart W on January 17, 2017 (82 FR 5142). The amendments clarified the distinction between “conventional” impoundments, which are used to manage the mostly solid wastes from uranium milling, and “non-conventional” impoundments, which are used to manage liquid process effluents. Non-conventional impoundments are also known as evaporation or holding ponds. The amendments also clarified the applicability of subpart W to non-conventional impoundments, without changing the radon monitoring requirements for conventional impoundments constructed prior to December 15, 1989 (“existing conventional impoundments”). The owners or operators of operating non-conventional impoundments are required to submit digital photographs collected during compliance inspections to the Subpart W Impoundment Photographic Reporting system (SWIPR) under Section 61.255. Digital photographs documenting the presence of liquids in non-conventional impoundments such that solid materials are not visible above the liquid level are to be collected at least weekly and uploaded to SWIPR at least monthly. Daily inspections of impoundments are required by the Nuclear Regulatory Commission. Written observations and digital photographs documenting liquid levels can be collected in conjunction with these customary and usual business practices.

(ii) Recordkeeping

The record keeping requirements of all the subparts are similar. The owner or operator of the facility must maintain records documenting the results of all measurements, the calculations and/or analytical methods used to derive values for input parameters, and the procedures used to determine compliance. In the case of uranium recovery facilities, the owner or operator must maintain records that confirm the approved design and operating procedures for conventional impoundments, non-conventional impoundments and heap leach piles, including the results of liner compatibility tests, and written and digital photographic records confirming that liquid has been maintained in non-conventional impoundments such that no solid material is visible above the liquid level. This documentation should be sufficient to allow an independent auditor to verify the accuracy of the determination made concerning the facility's compliance with the standard. Records must be kept at the facility for the lifetime of the facility and, upon request, be made available for inspection by the EPA Administrator, or his/her authorized representative.

5. The Information Collected—Agency Activities, Collection Methodology, and Information Management

5(a) Agency Activities

The information collected under this ICR is used to demonstrate compliance with Federal regulations. The EPA’s activities consist of reviewing reports and photographic submissions, taking further actions if needed to verify compliance, and maintaining files.

5(b) Collection Methodology and Management

The EPA Regional Offices review facility reports to determine compliance with the regulatory standards. The EPA may recalculate reported doses using computer models, conduct site inspections, or witness emission tests, as deemed necessary. The Office of Radiation and Indoor Air and the EPA Regional Offices have planned and allocated resources for the efficient and effective management and use of this information. EPA may perform periodic on-site inspections to determine if compliance with the regulatory standards is being maintained, including review of records.

5(c) Small Entity Flexibility

The rule does not define small entities for the affected source categories, nor does it identify exemptions to compliance or reporting requirements that are specific to small businesses. Of the 17 respondents identified by this ICR renewal, many likely meet the Small Business Administration’s definition of Small Business. Most of the burden placed on respondents is due to emissions testing and analyses, which are necessary to determine compliance with a health-based standard. Reporting the results of emissions testing to the EPA is comparatively small burden. Respondents are explicitly allowed, under Section 61.13, to propose alternate compliance methods for EPA approval, or to request a waiver from reporting requirements. As discussed in Section 6, one facility successfully obtained a waiver for testing and reporting in 2017.

In the case of subpart W facilities, a small entity is defined as: (1) a small business whose company has less than 250 employees and is primarily engaged in leaching or beneficiation of uranium, radium or vanadium ores as defined by NAICS code 212291; (2) a small governmental jurisdiction that is a government of a city, county, town, school district or special district with a population of less than 50,000; and (3) a small organization that is any not-for-profit enterprise, which is independently owned and operated and is not dominant in its field. Of nine facilities identified, five are owned by small businesses. Three of the six facilities that have been documenting the liquid level in non-conventional impoundments are owned by small businesses. Regulated entities create and store records of inspections to determine the liquid retention requirement for non-conventional impoundments during the daily inspections of the tailings and waste retention systems already required by the Nuclear Regulatory Commission (and Agreement States) under 10 CFR 40, Appendix A, Criterion 8A, resulting in a small additional burden. Therefore, no small organizations or small governmental entities have been identified that would be adversely impacted by the information collection requirements under subpart W.

5(d) Collection Schedule

The reporting schedule is set by the regulation. Collection of the information required will begin when the facility enters operational status, with the documentation of design and construction of impoundments. Under subparts B, K and conventional impoundments under subpart W, annual reports are required to provide yearly certification of compliance with a health-based emissions standard, unless the EPA has granted a waiver. For subpart R, it was determined during rulemaking that less frequent reports are adequate to protect public health. Under the amendments to subpart W, inspections and recordkeeping of impoundment liquid levels shall begin when non-conventional impoundments are first used to manage uranium byproduct material or tailings and shall be performed daily during the inspections required by 10 CFR Part 40, Appendix A, Criterion 8A. Digital photographs to document the liquid level in non-conventional impoundments are to be taken at least weekly. Monthly submission of digital photographs to the SWIPR system is required; if the SWIPR system is not available, photographs must be maintained at the facility and made available upon request.

6. ESTIMATING THE BURDEN AND COST OF THE COLLECTION

6(a) Estimating Respondent Burden, and

6(b) Estimating Respondent Cost

First, the EPA combined the two existing ICRs. Then, the EPA updated the number of facilities that are currently active, and therefore subject to monitoring and reporting requirements under 40 CFR part 61. In July 2018, when this ICR was last reviewed, there were no active subpart B facilities, one active subpart K facility, thirteen active subpart R and three subpart W facilities with conventional impoundments that were currently active. The subpart K facility had been granted a permanent waiver from radionuclide testing and reporting from EPA Region 10 in 2017. In 2020, when the ICR for the amended subpart W was reviewed, the EPA identified nine total facilities which were affected by the general record keeping requirements, and six facilities with non-conventional impoundments which were required to inspect and report on water levels in the impoundments. By reaching out directly to facility operators, the EPA has learned that although no subpart B uranium mines are currently producing ore, two are likely to vent for maintenance operations in 2021, which would require them to monitor emissions and submit a report. The EPA confirmed that there were no changes in the number of facilities or operating status for the other subparts since the last renewals. Finally, burden and costs estimates were recalculated for each subpart using updated labor rates obtained from the U.S. Department of Labor, Bureau of Labor Statistics (BLS), following the same process as in past renewals. The mean hourly rates for three labor categories -- management, technical, and clerical -- were obtained from the published 2020 Occupational Employment Statistics for NAICS codes 212200 (Mining [except Oil and Gas]) and 325100 (Basic Chemical Manufacturing). Management rates were given. Technical rates were based on the mean salary for “all production operations” in the mining sector which includes mining engineers, environmental engineers, and geologists. Clerical rates were based on the hourly labor rates for secretary and information clerk in the mining sector in the 2020 BLS data. Loaded hourly labor rates were calculated by multiplying the base salary rates by a factor of 1.5 to account for overhead expenses. Finally, the loaded hourly labor rate for 2020 then was increased by a factor of 1.035 to account for inflation between June 2020 and the present. In previous renewals, this information was obtained from the Consumer Price Index Inflation Calculator. In this renewal, the BLS Employment Cost Index Summary was consulted, which showed private industry wages to have risen by 3.5% during the period from June 2020 to June 2021 (https://www.bls.gov/news.release/eci.nr0.htm). The resulting loaded labor rates were $115.50 per hour for management, $74.00 per hour for technical, and $34.00 per hour for clerical labor. The compliance and reporting activities anticipated are listed below for each subpart.

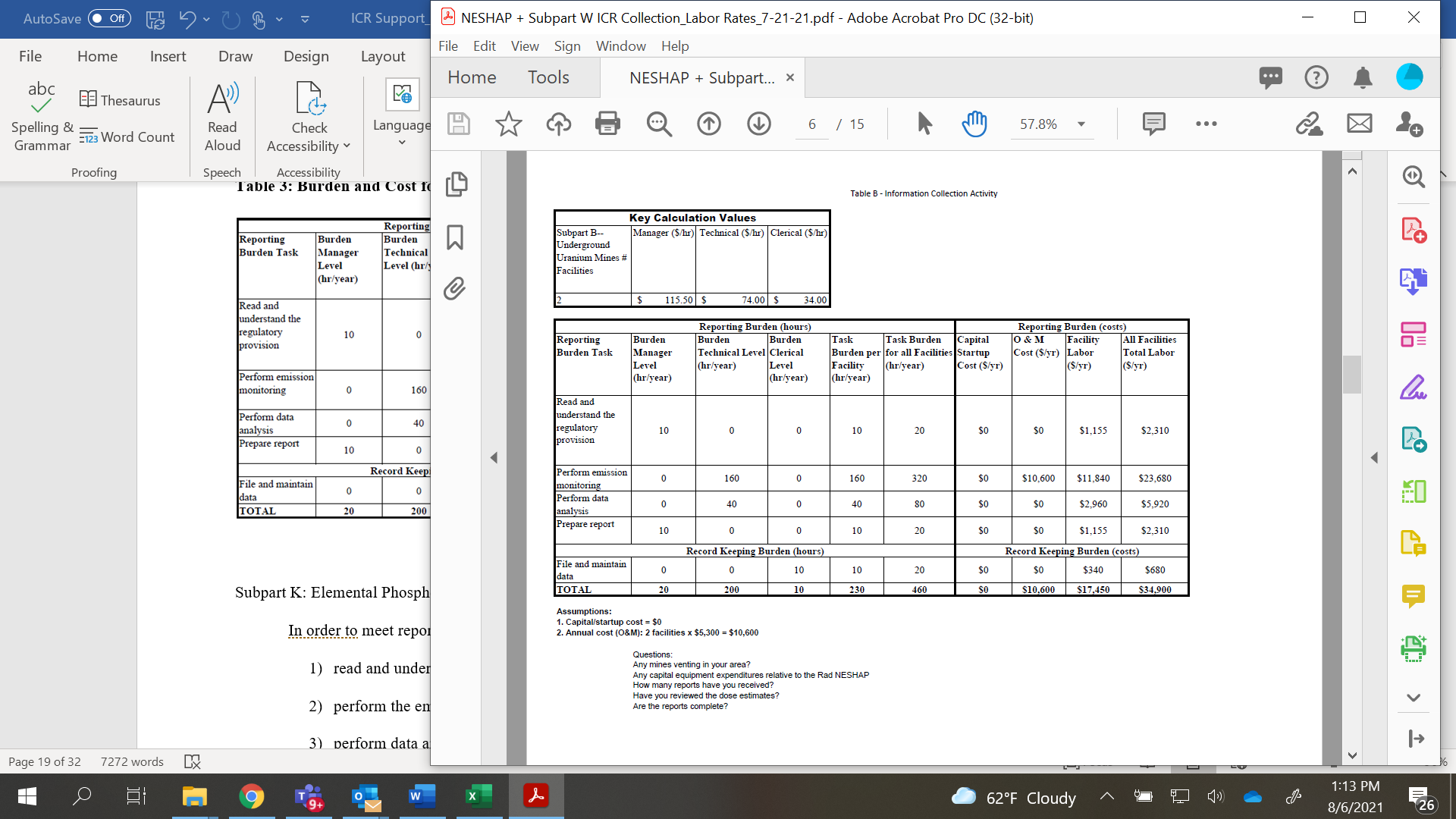

Subpart B: Underground Uranium Mines

To meet reporting requirements for subpart B, respondents are expected to:

read and understand the regulatory provision,

perform radon-222 emission measurements as required in 40 CFR part 61, Appendix B, Method 115,

perform data analysis, including Method 115 source term calculations and dose calculation using an approved model for concentration calculations,

prepare and submit the report.

Table 3 includes the estimated annual burden to understand regulatory provisions, perform Method 115 radon testing, perform data analysis, prepare a report, and manage records. One mine submitted an annual report in 2021 for calendar year 2020. Based on conversations with mine operators, up to three mines are likely to vent in 2021 and submit a report in 2022.

Table 3: Burden and Cost for Subpart B Uranium Mines

Subpart K: Elemental Phosphorus Plants

To meet reporting requirements for subpart K, respondents are expected to:

read and understand the regulatory provision,

perform the emission monitoring and test procedures in Section 61.125,

perform data analysis, including calculation of annual emission rate,

prepare and submit the report to EPA.

The only operating subpart K facility sought and obtained a waiver from EPA for testing and reporting and is therefore exempt from reporting requirements. Twenty hours of burden per year are assumed for the facility to remain cognizant of the regulatory requirements and conditions of the waiver. This burden and the associated costs are reflected in Table 4.

Table 4: Burden and Cost for Subpart K Elemental Phosphorus Plants

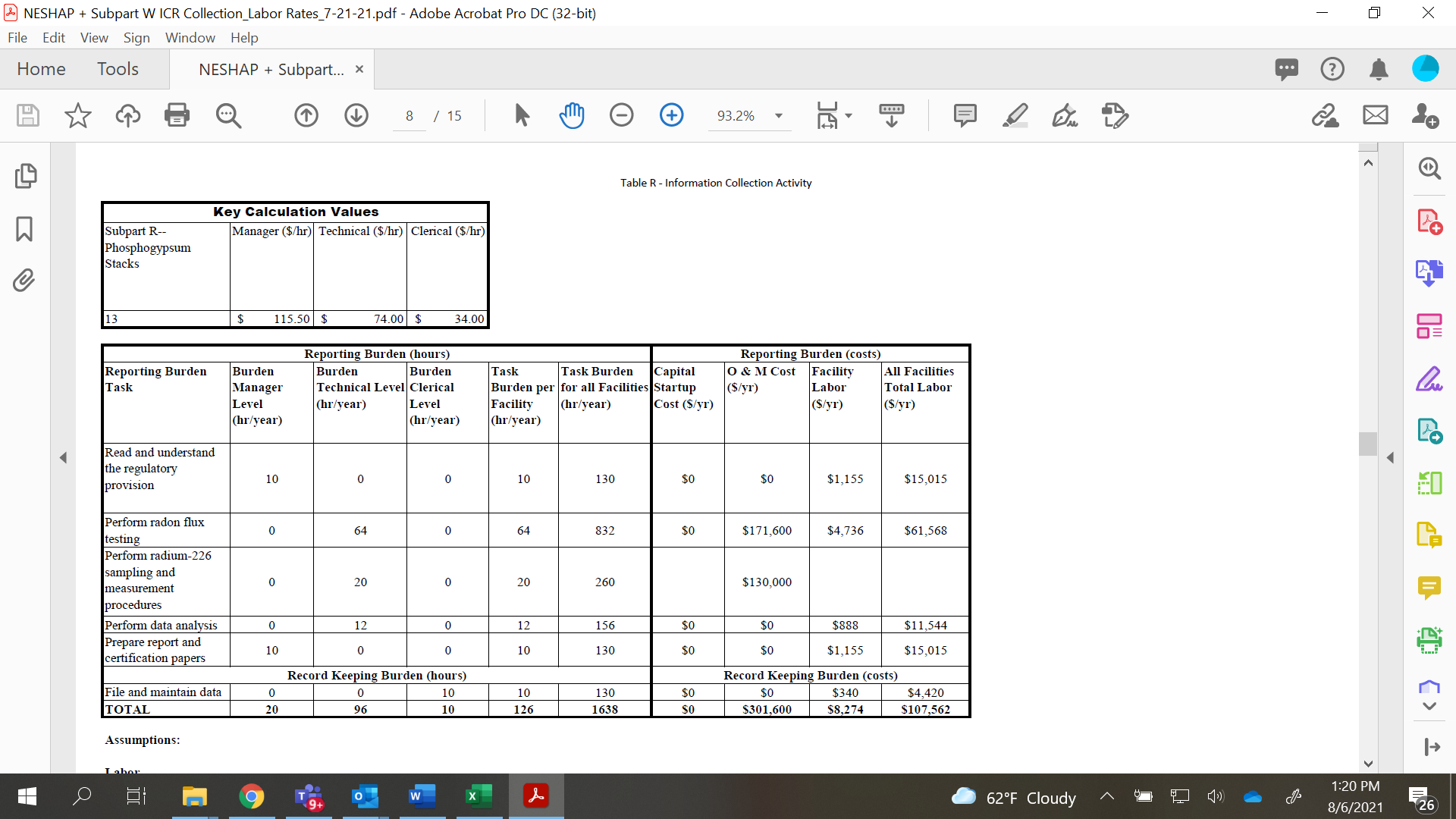

Subpart R: Phosphogypsum Stacks

To meet reporting requirements for subpart R, respondents are expected to:

read and understand the regulatory provision,

perform radon flux testing as directed in Section 61.203,

perform radium-226 sampling and measurement procedures in Section 61.207 (if required),

perform data analysis including Method 115 radon flux or radium-226,

prepare and submit the report and/or certification documents.

Table 5 includes the following expenses for respondents:

It is estimated that the testing materials for 300 flux measurements and the analysis are obtained from a contract source at a cost of $44/measurement.

It is estimated that it will take four days for two people to place, collect and ship 300 samples to a testing lab.

It is estimated that that the thirteen stacks that have not closed yet must complete this one-time report.

It is likewise estimated that all thirteen currently active phosphogypsum stacks will remove material, and therefore be required to measure the radium-226 concentration of the removed material to be included in certification papers.

Testing and reporting under subpart R is required only when facilities close active stacks or remove phosphogypsum. Rather than predict the exact number of facilities per year that will undertake these activities, the EPA has chosen estimates which represent an upper bound of the potential burden due to testing and reporting. It is unlikely that in a given year all active stacks will take actions requiring testing and reporting, as is assumed, and possible that no stacks will take such actions. The Agency will continue to observe the actual activities of facilities to refine these estimates for future ICRs.

Section 61.207 requires a minimum of 30 samples from each area where phosphogypsum is being removed from the stack, with additional sampling required where the concentrations approach 10 pCi/g of radium-226. It is estimated that 100 samples per stack will be necessary to document radium concentrations and that radium analysis will be performed for $100 per sample by a contract laboratory. It is estimated that sample collection and preparation occur at a rate of five samples per hour. The total burden estimated for subpart R facilities is shown in Table 5.

Table 5: Burden and Cost for Subpart R Phosphogypsum Stacks

Subpart W: Uranium Mill Tailings

Maintaining design/construction records

To meet the requirements of subpart W, as amended in 2017, all facilities subject to subpart W must maintain design and construction documentation for all impoundments. Design and construction records are required as part of the application for construction/modification required under subpart A of 40 CFR part 61. A startup cost of $100 per facility is assumed for establishing appropriate storage for existing impoundment design and construction records. Afterwards, there are no O&M costs associated with maintaining these records, only annual labor costs to do so. It is estimated that two hours of management time per facility will be required annually to retain familiarity with the regulatory provision, and that ten hours of clerical time per facility per year will be sufficient to store and maintain the records at the facility so that they are accessible. All nine facilities that are subject to subpart W will maintain these records. Burden and cost are shown in Table 6, Burden and Cost to Meet Design and Construction Record Requirements for All Impoundments.

Table 6: Burden and Cost to Meet Design and Construction Record Requirements for All Impoundments

Subpart W-- Uranium Mill Tailings |

Manager ($/hr) |

Technical ($/hr) |

Clerical ($/hr) |

Respond (hrs/yr) |

Labor cost/ yr |

Capital/ Startup cost |

O & M Cost |

Number of Respond |

Total hours/yr |

Total Labor cost/yr |

Read and understand the regulatory provision (Mgmt) |

2 |

|

|

2 |

$231 |

|

|

9 |

18 |

$2,079 |

Record Keeping |

||||||||||

File and maintain data (Clerical) |

|

|

10 |

10 |

$340 |

$100 |

|

9 |

90 |

$3,060 |

TOTAL |

2 |

0 |

10 |

12 |

$571 |

$100 |

|

9 |

108 |

$5,139 |

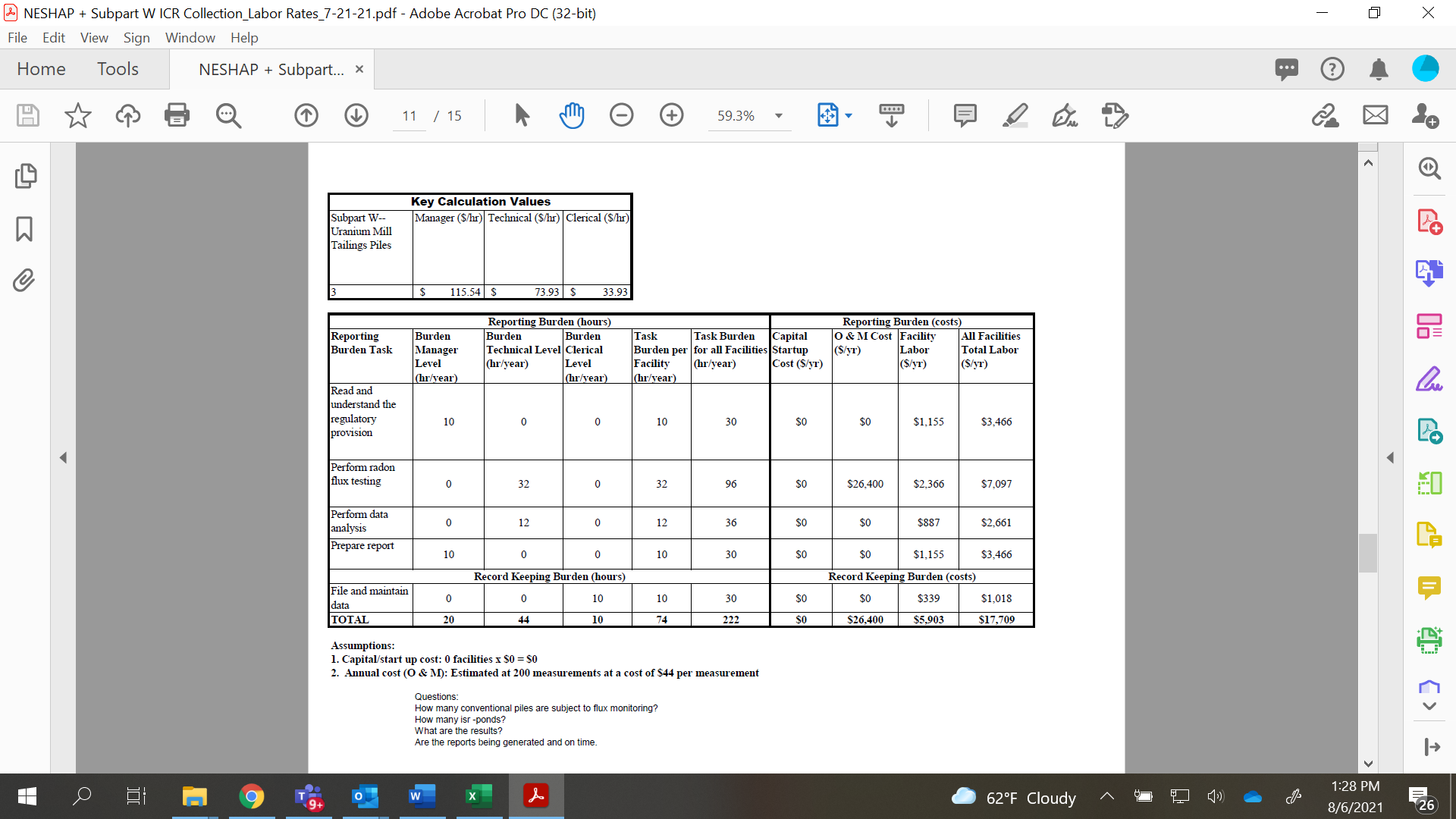

To meet reporting requirements for conventional impoundments under subpart W, respondents are expected to:

read and understand the regulatory provision,

perform radon flux testing required in 40 CFR part 61, Appendix B, Method 115,

perform data analysis including Method 115 radon flux calculations,

prepare and submit the report to EPA.

Table 7 includes the following expenses for respondents:

It is estimated that the testing materials for 200 measurements and the analysis is obtained from a contract source at a cost of $44/measurement.

It is estimated that it will take one day for two people to place the test canisters and one day for two people to collect the canisters and ship them to a testing lab.

It is estimated that 3 facilities will file a report annually.

Table 7: Burden and Cost for Subpart W Uranium Mill Tailings

Maintaining

liquid in non-conventional impoundment

Maintaining

liquid in non-conventional impoundment

To meet the reporting requirements for non-conventional impoundments in subpart W, as amended in 2017, facilities must perform daily inspections of liquid levels in those impoundments and submit photographs to the Agency. It is estimated that management will spend two hours annually to remain familiarity with the regulatory provision, and five hours per year to acquire any necessary equipment. It is estimated that it will take one technical staff person one day to be trained to record the required information, and one person to provide training. The Agency estimates that it will take one hour to perform the inspection and record the required information, and inspections will be conducted on 240 workdays per year. It is estimated that it will take clerical staff 20 hours per year to submit digital photographs and maintain written and digital photographic records. The Agency confirmed that six facilities currently generate and submit these records through SWIPR. It is estimated that the equipment required for documenting the liquid level through digital photographic records will cost $300 for each facility. Afterwards, there are no O&M costs associated with conducting these inspections and submitting reports. The estimated burden is included in Table 8, Burden and Cost to Meet Liquid Retention Requirement for Non-conventional Impoundments.

Table 8: Burden and Cost to Meet Liquid Retention Requirement for Non-conventional Impoundments

Subpart W-- Uranium Mill Tailings |

Manager ($/hr) |

Technical ($/hr) |

Clerical ($/hr) |

Respond (hrs/yr) |

Labor cost/ yr |

Capital/ Startup cost |

O&M Cost |

Number of Respond |

Total hours/yr |

Total Labor cost/yr |

$ 115.50 |

$ 74.00 |

$ 34.00 |

|

|

|

|

|

|

|

|

Read and understand the regulatory provision (Mgmt) |

2 |

|

|

2 |

$231 |

|

|

6 |

12 |

$1,386 |

Acquire Instrumentation (Mgmt) |

5 |

|

|

5 |

$578 |

$300 |

|

6 |

30 |

$3,465 |

Train technician to perform inspection (Mgmt./Tech) |

8 |

8 |

|

16 |

$1,516 |

|

|

6 |

96 |

$9,096 |

Perform inspection to determine presence of liquid (Tech.) |

|

240 |

|

240 |

$17,760 |

|

|

6 |

1440 |

$106,560 |

Record Keeping |

||||||||||

File and maintain data (Clerical/Tech) |

|

10 |

10 |

20 |

$1,080 |

|

|

6 |

120 |

$6,480 |

TOTAL |

15 |

258 |

10 |

283 |

$21,165 |

$300 |

|

6 |

1698 |

$126,987 |

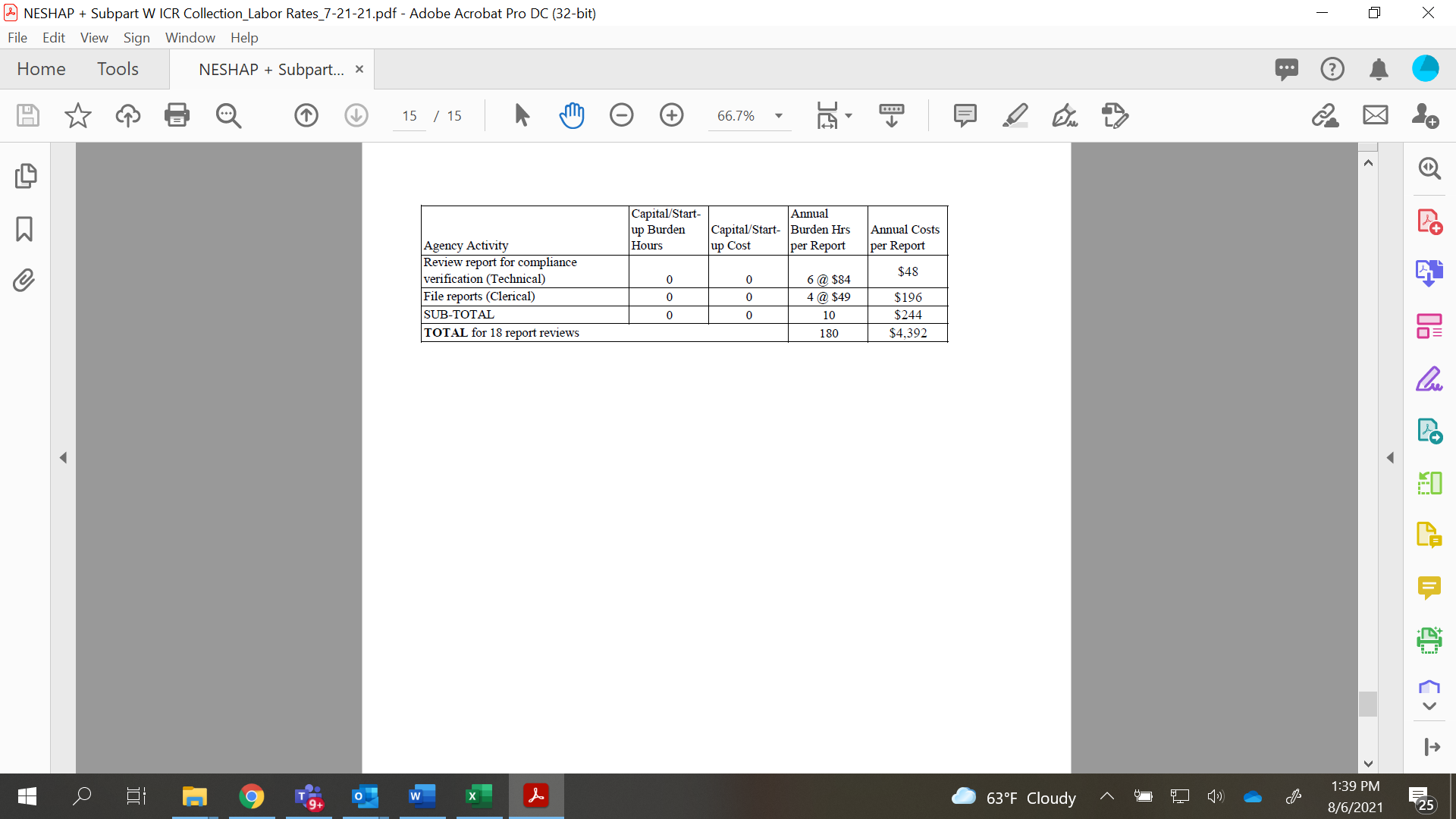

6(c) ESTIMATED AGENCY BURDEN AND COST

The burden to the EPA is from the review of the information submitted by the regulated community to ensure that emissions and dose are within the limits set by the regulations, and record keeping. The Agency burden and costs are estimated below in Table 9. Two separate calculations are included; one for the review of reports submitted under subparts B, K, R, and subpart W conventional impoundments, and the other for receiving and reviewing electronic reports for subpart W nonconventional impoundments. The breakdown of General Schedule levels and steps were different for the two activities in past ICRs, and those different levels have been maintained in this combined ICR. All Agency salaries were found in 2020 General Schedule salary tables.

For reviewing reports submitted by subpart B, K, R, and conventional subpart W facilities, Agency burden is based on the salary for a GS-13, step 5 technical employee, with a multiplier of 1.6 to include overhead; this resulted in a loaded rate of $84 per hour. For the Clerical category, the salary scale for a GS-11, step 10 was used with a multiplier of 1.6 to account for overhead; this resulted in $53 per hour. The multiplier of 1.6 was obtained from the Agency’s ICR Handbook. A total of 16 report reviews are used for this calculation, because one of the 17 respondents has obtained a permanent waiver from annual reporting.

For nonconventional subpart W facilities, burden to the EPA is due to both reviewing submissions by the regulated community to ensure that they meet the requirements of the regulations, as well as continuing maintenance of the SWIPR system for electronic submittal of digital photographs documenting the liquid level in non-conventional impoundments. Since the Agency reviews the design and construction records of impoundments at the time of the initial application, the Agency does not revisit those records routinely and there is no annual burden to the Agency associated with those records being maintained at the facility.

Uranium recovery facilities in the respondent universe are in EPA Regions 7 and 8, so the average locality pay for those locations was used (Lenexa, KS and Denver, CO). The data for review of reports for compliance was based on the salary scale for GS-13, step 5, with a multiplier of 1.6 to include overhead; this resulted in $85/hr. For the Clerical category, the salary scale for a GS-9, step 5 was used with a multiplier of 1.6 to account for overhead; this resulted in $48/hr. In addition, development and maintenance of the system for electronic submittal of digital photographs is estimated to involve a GS-14, step 1, using locality pay for Washington, D.C. Using the 1.6 multiplier, this resulted in $93/hr. There is an O&M burden of 50 hours of Agency staff time and 47 hours of contractor time to maintain the electronic reporting system used by facilities to submit digital photographs from their daily inspections. Maintenance of this system is independent of the number of respondents. It is estimated that 6 hours of Agency technical staff time and 4 hours of Agency clerical staff time are required per reporting facility annually to review submitted reports. This information is submitted monthly by the six facilities with non-conventional impoundments.

Table 9: Burden and Cost to the Agency

Subparts B, R and W (conventional)

Subparts W (nonconventional)

6(d) Estimating the Respondent Universe and Total Burden and Costs, and

6(e) Bottom-Line Burden Hours and Cost Tables

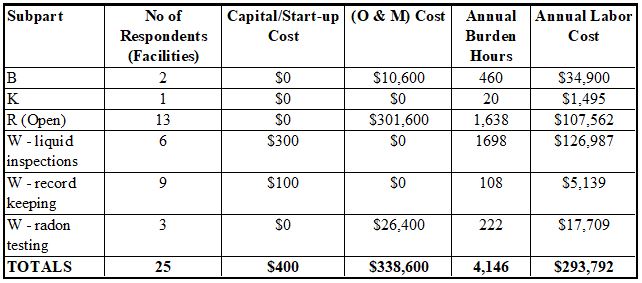

The total estimated annual burden for respondents affected by all four subparts is estimated below, in Table 10:

Table 10: Summary of Burden Estimate for Respondents

* Assumes that all operational stacks both remove phosphogypsum, requiring analyses for radium-226, and that these facilities all require radon flux measurements. This is a conservative assumption – see Section 6(b).

6(f) Reasons for Change in Burden

The greatest reason for the change in burden for this ICR is its combination with the ICR for the amendments to subpart W – that is, the addition of the burden of complying with requirements for all subpart W facilities to maintain design records, and the requirement for nonconventional impoundments to photograph liquid levels and submit those photographs (see 86 FR 1965, January 11, 2021 for more information). For subparts K, R, and W, there were no changes to the number of respondents, the annual time burden, or the annual non-labor cost compared to the most recent renewals of these ICRs: the total respondents and burden requested at this time is simply the sum of the two ICRs. In the case of subpart B, based on conversations with mine operators, the Agency identified two respondents that are likely to submit annual reports in 2021. No subpart B facilities were reporting at the time of the last renewal in 2018. Two responses were added to the ICR, adding 460 hours of labor and $10,600 of non-labor cost. These changes are shown in Table 11.

Table 11: Combining Burden from ICRs 2060-0109 and 2060-0706

|

Total Annual Responses |

Annual Time Burden (Hours) |

Annual Non-labor Cost ($) |

ICR 2060-0191 (approved in 2019) |

16 |

1,880 |

328,000 |

ICR 2060-0706 (approved in 2021) |

72 |

1,806 |

0 |

Sum of previously approved/submitted ICRs |

88 |

3,686 |

328,000 |

Changes made in 2021 (2 Subpart B facilities added) |

2 |

460 |

10,600 |

Total combined burden for 2022 |

90 |

4,146 |

338,600 |

6(g) Burden Statement

The annual public reporting and record keeping burden for this collection of information is estimated to average 46 hours per response. Burden means the total time, effort, or financial resources expended by persons to generate, maintain, retain, or disclose or provide information to or for a Federal agency. This includes the time needed to review instructions; develop, acquire, install, and utilize technology and systems for the purposes of collecting, validating, and verifying information, processing and maintaining information, and disclosing and providing information; adjust the existing ways to comply with any previously applicable instructions and requirements; train personnel to be able to respond to a collection of information; search data sources; complete and review the collection of information; and transmit or otherwise disclose the information. An agency may not conduct or sponsor, and a person is not required to respond to, a collection of information unless it displays a currently valid OMB control number. The OMB control numbers for EPA's regulations are listed in 40 CFR part 9 and 48 CFR chapter 15.

| File Type | application/vnd.openxmlformats-officedocument.wordprocessingml.document |

| File Title | SUPPORTING STATEMENT |

| Author | Joglekar, Rajani |

| File Modified | 0000-00-00 |

| File Created | 2022-03-28 |

© 2026 OMB.report | Privacy Policy