Burden Calculation Tables

2442t04.xlsx

NSPS for New Residential Hydronic Heaters and Forced-Air Furnaces (40 CFR part 60, subpart QQQQ) (Renewal)

Burden Calculation Tables

OMB: 2060-0693

Document [xlsx]

Download: xlsx | pdf

Table 2 - Agency Burden

# Respondents

#Responses

Capital-Start-up

WoodHeater Database

Test Labs and Certifiers

Overview

Table 1 - Respondent BurdenTable 2 - Agency Burden

# Respondents

#Responses

Capital-Start-up

WoodHeater Database

Test Labs and Certifiers

Sheet 1: Table 1 - Respondent Burden

| Table 1: Annual Respondent Burden and Cost - NSPS for New Residential Hydronic Heaters and Forced-Air Furnaces (40 CFR Part 60, Subpart QQQQ) (Renewal) | |||||||||||||||||

| Burden Item | (A) Person-hours per occurrence |

(B) No. of occurrences per respondent per year |

(C) Person-hours per respondent (C=AxB) |

(D) Respondents per year a |

(E) Technical hours per year (E=CxD) |

(F) Management hours per year (F=Ex0.05) |

(G) Clerical person-hours per year (G=Ex0.1) |

(H) Total Cost per year ($) b |

|||||||||

| Reporting Requirements | |||||||||||||||||

| Manufacturers | |||||||||||||||||

| 1. Certification test notification (new model lines) c | 2 | 1 | 2 | 0 | 0 | 0 | 0 | $0 | |||||||||

| 2. Application for certification (new model lines) c | 8 | 1 | 8 | 0 | 0 | 0 | 0 | $0 | |||||||||

| 3. Application for recertification (existing model lines) d | 8 | 0.52 | 4.18 | 13 | 54.4 | 2.7 | 5.4 | $7,399.95 | Labor Rates | ||||||||

| 4. Biennial reporting e | 2 | 1.31 | 2.62 | 13 | 34.0 | 1.7 | 3.4 | $4,624.97 | Management | $153.55 | |||||||

| 5. Review annual QA program audit report f | 4 | 2.62 | 10.5 | 13 | 136 | 6.8 | 13.6 | $18,499.88 | Technical | $122.20 | |||||||

| 6. Review QA program performance test results g | 2 | 0.33 | 0.67 | 13 | 8.7 | 0.4 | 0.9 | $1,177.73 | Clerical | $61.51 | |||||||

| 7. Review EPA compliance audit testing h | 8 | 0.33 | 2.66 | 1 | 2.7 | 0.1 | 0.3 | $362.38 | |||||||||

| Test Laboratories | |||||||||||||||||

| 1. Application for test lab approval (new) i | |||||||||||||||||

| a. Already has ISO accreditation | 20 | 1 | 20 | 0 | 0 | 0 | 0 | $0 | |||||||||

| b. Needs to obtain ISO accreditation | 80 | 1 | 80 | 0 | 0 | 0 | 0 | $0 | |||||||||

| 2. Application for re-approval as a test lab j | 20 | 1 | 20 | 1.67 | 33 | 1.7 | 3.3 | $4,534.28 | |||||||||

| 3. EPA compliance audit testing k | 20 | 0.33 | 6.7 | 1 | 6.7 | 0.3 | 0.7 | $905.95 | |||||||||

| 4. Biennial proficiency testing and report development l | 150 | 0.50 | 75 | 8 | 600 | 30 | 60 | $81,617.10 | |||||||||

| Third-Party Certifier | |||||||||||||||||

| 1. Application for approval as a third-party certifier (new) m | |||||||||||||||||

| a. Already has ISO accreditation | 20 | 1 | 20 | 0 | 0 | 0 | 0 | $0 | |||||||||

| b. Needs to obtain ISO accreditation | 80 | 1 | 80 | 0 | 0 | 0 | 0 | $0 | |||||||||

| 2. Application for re-approval as a third-party certifier n | 20 | 1 | 20 | 1.33 | 27 | 1.3 | 2.7 | $3,627.43 | |||||||||

| 3. QA program annual audit reports o | 20 | 4.25 | 85 | 8 | 680 | 34 | 68 | $92,499.38 | |||||||||

| 4. Certification test p | 2 | 1 | 2 | 0 | 0 | 0 | 0 | $0 | |||||||||

| Subtotal for Reporting Requirements | 1,820 | $398,433.19 | |||||||||||||||

| Recordkeeping Requirements | |||||||||||||||||

| Manufacturers | |||||||||||||||||

| 1. Test and re-certification documentation q | 1 | 0.52 | 0.52 | 13 | 6.8 | 0.3 | 0.7 | $924.99 | |||||||||

| 2. QA parameter inspections r | 2 | 4 | 8 | 13 | 104 | 5 | 10 | $14,147 | |||||||||

| 3. Retained (sealed) stoves s | 1 | 0 | 0 | 13 | 0 | 0 | 0 | $0 | |||||||||

| Test Laboratories | |||||||||||||||||

| 1. Certification test, proficiency test, and audit test results t | 2 | 12 | 24 | 8 | 192 | 9.6 | 19.2 | $26,117.47 | |||||||||

| Third-Party Certifier | |||||||||||||||||

| 1. Certification test, QA program inspection and audit tests u | 2 | 12 | 24 | 8 | 192 | 9.6 | 19.2 | $26,117.47 | |||||||||

| Subtotal for Recordkeeping Requirements | 569 | $67,307.00 | |||||||||||||||

| Total Labor Burden and Costs (rounded) v | 2,390 | $466,000 | |||||||||||||||

| Total Capital and O&M Cost (rounded) v | $484,000 | ||||||||||||||||

| GRAND TOTAL (rounded) v | $950,000 | ||||||||||||||||

| Assumptions | |||||||||||||||||

| a We assume there are 10 hydronic heater manufacturers with 31 model lines and 3 forced-air furnace manufacturers with 3 model lines. We assume no new manufacturers and no new model lines during the three-year period of this ICR. We assume there are 11 laboratories with 8 acting as testing labs and 8 acting as third-party certifiers. | |||||||||||||||||

| b This ICR uses the following labor rates: Managerial $153.55 ($73.12+ 110%); Technical $122.20 ($58.19 + 110%); and Clerical $61.51 ($29.29 + 110%). These rates are from the United States Department of Labor, Bureau of Labor Statistics, March 2021, “Table 2. Civilian Workers, by occupational and industry group.” The rates are from column 1, “Total compensation.” The rates have been increased by 110 percent to account for the benefit packages available to those employed by private industry. Management person-hours and clerical person-hours are assumed to be 5 percent and 10 percent of technical person-hours, respectively. | |||||||||||||||||

| c We assume that no manufacturers will certify new model lines during the three-year period of this ICR. | |||||||||||||||||

| d All 34 existing certified model lines must be re-certified every five years. We assume that, for all model lines that require re-certification during the three-year period of this ICR, that manufacturers will choose to renew the certification of their currently-certified models without testing by affirming that the central heaters are similar in all respects to the representative central heater submitted for testing and requesting a waiver from certification testing. (34 model lines/5 years/13 manufacturers = 0.52 model lines recertified each year per manufacturer). | |||||||||||||||||

| e Manufacturers are required to submit a report every two years following issuance of a certification of compliance for each model line. (34 model lines/13 manufacturers/2 years = 1.31 reports/manufacturer/year). | |||||||||||||||||

| f Manufacturers must conduct a quality assurance program for each certified model line. The quality assurance plan is audited annually by the third-party certifier. After receiving each audit report, the manufacturer must report to the third-party certifier and to the Administrator its corrective actions and responses to any deficiencies identified in the audit report. (34 model lines/13 manufacturers/audited once per year = 2.62 audit report responses/manufacturer/year). | |||||||||||||||||

| g We assume that each manufacturer will perform a quality assurance performance test on one model line under the quality assurance program during the three-year period. | |||||||||||||||||

| h EPA may require a manufacturer to perform compliance audit testing on a manufacturer's model line(s). We assume one model gets audited by EPA in the three-year period of this ICR. | |||||||||||||||||

| i We assume no new laboratories will apply for approval from EPA to perform testing under this program during the three-year period of this ICR. | |||||||||||||||||

| j All 8 testing labs are currently accredited under ISO-IEC Standard 17025 to perform testing and are approved by EPA to perform testing under this rule. Five test labs will require ISO re-accreditation and EPA approval during the three-year period of this ICR. (5 testing labs/3 years = 1.67 testing labs/year). | |||||||||||||||||

| k EPA may require a manufacturer to perform compliance audit testing on a manufacturer's model line(s). We assume one model gets audited by EPA in the three-year period of this ICR. The testing lab performing this test is required to submit a report containing all documentation pertaining to the test to both the manufacturer and the Administrator. | |||||||||||||||||

| l Assume 8 testing labs participate in proficiency testing every 2 years. 40 CFR 5479(b) requires that each approved test laboratory submit accreditation credentials and all proficiency test results to the Administrator. | |||||||||||||||||

| m We assume no new laboratories will apply for approval from EPA to act as third-party certifiers under this program during the three-year period of this ICR. | |||||||||||||||||

| n All 8 third-party certifiers are ISO accredited and approved by EPA. Four third-party certifiers will require ISO re-accreditation and EPA approval during the three-year period of this ICR. Each third-party certifier must submit ISO-IEC accreditation credentials to the Administrator. (4 third-party certifiers/3 years = 1.33 third-party certifiers/year). | |||||||||||||||||

| o Manufacturers must contract with third-party certifiers to conduct annual audits on the quality assurance program for each model line. The third-party certifier is required to submit a report of these audits to the Administrator and the manufacturer identifying any deviations and specifying corrective actions that need to be taken. (34 model lines/8 third-party certifiers/once per year audits = 4.25 audit reports/certifier/year). | |||||||||||||||||

| p Third-party certifiers are required to submit certification tests to the Administrator. No new models are expected to be tested/certified during the three-year period of this ICR. | |||||||||||||||||

| q Assumes that manufacturers will spend one hour per certification test and recertification to keep the required records. | |||||||||||||||||

| r Quality parameter inspections are part of the existing safety inspections program. Assume that all manufacturers (13) will spend 2 hours per quarter to document results for each certified model. | |||||||||||||||||

| s Assumes that one stove is sealed and retained for each certification test. Assumes all stoves certified to 2020 standard are stored for the 3-year period. | |||||||||||||||||

| t Proficiency testing is required every two years for each lab. Assume that test laboratories will spend 2 hours per month to maintain the required records. | |||||||||||||||||

| u Quality assurance program inspections are performed annually for each certified model. Assume that third-party certifiers will spend 2 hours per month to maintain the required records. | |||||||||||||||||

| v Totals have been rounded to three significant values. Figures may not add exactly due to rounding. | |||||||||||||||||

Sheet 2: Table 2 - Agency Burden

| Table 2: Average Annual EPA Burden and Cost - NSPS for New Residential Hydronic Heaters and Forced-Air Furnaces (40 CFR Part 60, Subpart QQQQ) (Renewal) | |||||||||||

| Burden Activity | (A) EPA person-hours per occurrence |

(B) No. of occurrences per year |

(C) EPA person-hours per year (C=AxB) |

(D) Respondents per year a |

(E) Technical person-hours per year (E=CxD) |

(F) Management person-hours per year (F=Ex0.05) |

(G) Clerical person-hours per year (G=Ex0.1) |

(H) Total Cost per year ($) b |

|||

| 1. Review certification test notification (new model lines) c | 0.5 | 1 | 0.5 | 0 | 0 | 0 | 0 | $0 | Labor Rates | ||

| 2. Observe certification test (new model lines) c, d | 20 | 0.2 | 4 | 0 | 0 | 0 | 0 | $0 | Management | $69.04 | |

| 3. Review performance test report and application for certification (new model line) c | 8 | 1 | 8 | 0 | 0 | 0 | 0 | $0 | Technical | $51.23 | |

| 4. Review application for recertification of model line e | 8 | 0.52 | 4.2 | 13 | 54.4 | 2.7 | 5.4 | $3,125.55 | Clerical | $27.73 | |

| 5. Review biennial reporting for certified models f | 1 | 1.31 | 1.31 | 13 | 17.0 | 0.9 | 1.7 | $976.74 | |||

| 6. Review QA performance test results g | 2 | 0.33 | 0.67 | 13 | 8.7 | 0.4 | 0.9 | $497.45 | |||

| 7. Review and approval of test lab credentials h | 4 | 1 | 4 | 1.67 | 6.7 | 0.3 | 0.7 | $383.03 | |||

| 8. Review EPA Compliance Audit results i | 40 | 0.33 | 13.3 | 1 | 13.3 | 0.7 | 1.3 | $765.30 | |||

| 9. Review test lab biennial proficiency test reports j | 10 | 0.5 | 5 | 8 | 40.0 | 2.0 | 4.0 | $2,298.20 | |||

| 10. Review and approval of third-party certifier credentials k | 8 | 1 | 8 | 1.33 | 10.7 | 0.5 | 1.1 | $613 | |||

| 11. Review QA audit report l | 2 | 4.25 | 8.5 | 8 | 68.0 | 3.4 | 6.8 | $3,906.94 | |||

| TOTAL (rounded) m | 252 | $12,600 | |||||||||

| Assumptions: | |||||||||||

| a We assume there are 10 hydronic heater manufacturers with 31 model lines and 3 forced-air furnace manufacturers with 3 model lines. We assume no new manufacturers. We assume no new model lines will be tested/certified during the three-year period of this ICR. We assume there are 11 laboratories with 8 acting as testing labs and 8 acting as third-party certifiers. | |||||||||||

| b This cost is based on the average hourly labor rate as follows: Managerial $69.04 (GS-13, Step 5, $43.15 + 60%); Technical $51.23 (GS-12, Step 1, $32.02 + 60%); and Clerical $27.73 (GS-6, Step 3, $17.33 + 60%). This ICR assumes that Managerial hours are 5 percent of Technical hours, and Clerical hours are 10 percent of Technical hours. These rates are from the Office of Personnel Management (OPM), 2021 General Schedule, which excludes locality, rates of pay. The rates have been increased by 60 percent to account for the benefit packages available to government employees. Management person-hours and clerical person-hours are assumed to be 5 percent and 10 percent of technical person-hours, respectively. | |||||||||||

| c We assume no new manufacturers. We assume no new model lines will be tested/certified during the three-year period of this ICR. | |||||||||||

| d Assumes that EPA will observe 20 percent of certification tests. | |||||||||||

| e We assume there are 10 hydronic heater manufacturers with 31 model lines and 3 forced-air furnace manufacturers with 3 model lines. We assume that manufacturers will apply for recertification of all model lines whose certification expires during the three-year period of this ICR. (34 model lines/5 years/13 manufacturers = 0.52 model lines recertified each year per manufacturer). | |||||||||||

| f We assume that the EPA will review biennial reports for each of the certified model lines over the 3-year ICR period. (34 model lines/13 manufacturers/2 years = 1.31 reports/manufacturer/year). | |||||||||||

| g We assume that there will be one QA audit performance test per manufacturer under the QA program during the 3-year period. | |||||||||||

| h All 8 testing labs are currently ISO accredited and are approved by EPA to perform testing under this rule. Five test labs will require ISO re-accreditation and EPA approval during the three-year period of this ICR. (5 testing labs/3 years = 1.67 testing labs/year). | |||||||||||

| i We assume that one model line for one of the manufacturers will be audited by the EPA during the ICR three-year period of this ICR. | |||||||||||

| j We assume that each testing lab conducts a laboratory proficiency test every two years. | |||||||||||

| k All 8 third-party certifiers are currently ISO accredited and approved by EPA. Four certifiers will require ISO re-accreditation and EPA approval during the three-year period of this ICR. (4 third-party certifiers/3 years = 1.33 third-party certifiers/year). | |||||||||||

| l We assume that EPA will review the annual QA audits performed by the third-party certifiers on each certified model line over the three-year ICR period. (34 model lines/8 third-party certifiers/once per year audits = 4.25 audit reports/certifier/year). | |||||||||||

| m Totals have been rounded to three significant values. Figures may not add exactly due to rounding. |

|||||||||||

Sheet 3: # Respondents

| NSPS for New Residential Hydronic Heaters and Forced-Air Furnaces (40 CFR Part 60, Subpart QQQQ) (Renewal) | |||||||||

| Number of Respondents That are Manufacturers | |||||||||

| Respondents That Submit Reports | Respondents That Do Not Submit Any Reports | ||||||||

| (A) | (B) | (C) | (D) | (E) | |||||

| Year | Number of New Respondents | Number of Existing Respondents a | Number of Existing Respondents that keep records but do not submit reports | Number of Existing Respondents That Are Also New Respondents | Number of Respondents (E=A+B+C-D) |

||||

| 1 | 0 | 24 | 0 | 0 | 24 | ||||

| 2 | 0 | 24 | 0 | 0 | 24 | ||||

| 3 | 0 | 24 | 0 | 0 | 24 | ||||

| Average | 0 | 24 | 0 | 0 | 24 | ||||

| Assumptions | |||||||||

| a Assumes there are 10 hydronic heater manufacturers with 31 model lines, 3 forced-air furnace manufacturers with 3 model lines, and 11 laboratories acting as testing labs and/or third-party certifiers. | |||||||||

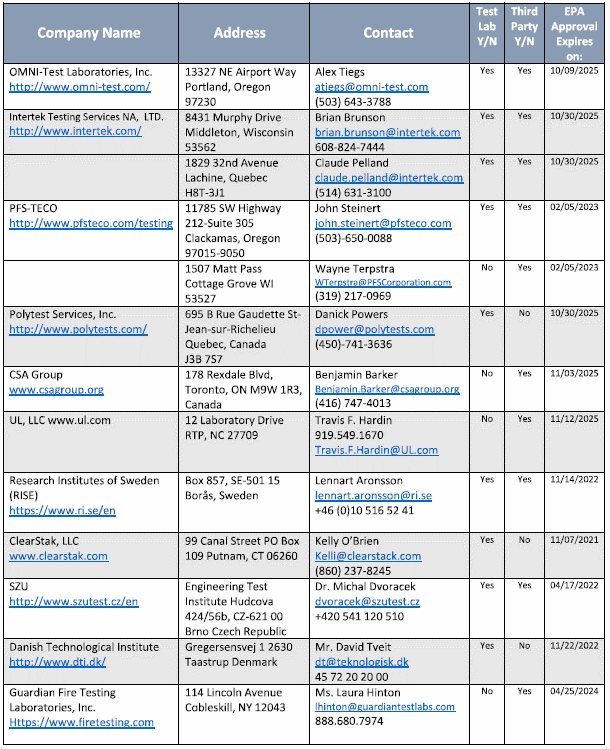

| EPA-approved Test Labs and Third-party Certifying Entities for 2015 Residential Wood Heaters NSPS | |||||||||

| Name | EPA-approved Test Lab | EPA-approved Third-Party Certifier | Expiration Date of EPA Aproval | ||||||

| Wood Stove | Forced Air Furnace | Hydronic Heater | Wood Stove | Forced Air Furnace | Hydronic Heater | ||||

| PFS-TECO | Yes | Yes | Yes | Yes | Yes | Yes | 2/5/2023 | <will need to obtain reapproval as test lab | <will need to obtain reapproval as certifier |

| Intertek | Yes | Yes | Yes | Yes | Yes | Yes | 10/30/2025 | ||

| OMNI | Yes | Yes | Yes | Yes | Yes | Yes | 10/9/2025 | ||

| Polytests Inc. | Yes | Yes | Yes | No | No | No | 10/30/2025 | ||

| CSA Group | No | No | No | Yes | Yes | Yes | 11/3/2025 | ||

| UL, LLC | No | No | No | Yes | Yes | Yes | 11/12/2025 | ||

| Research Institutes of Sweden (RISE) | Yes | Yes | Yes | Yes | Yes | Yes | 11/14/2022 | <will need to obtain reapproval as test lab | <will need to obtain reapproval as certifier |

| ClearStak, LLC | Yes | Yes | Yes | No | No | No | 11/7/2021 | <will need to obtain reapproval as test lab | |

| SZU | Yes | Yes | Yes | Yes | Yes | Yes | 4/17/2022 | <will need to obtain reapproval as test lab | <will need to obtain reapproval as certifier |

| Danish Technological Institute | Yes | Yes | Yes | No | No | No | 11/22/2022 | <will need to obtain reapproval as test lab | |

| Guardian Fire Testing Laboratories, Inc. | No | No | No | Yes | Yes | Yes | 4/25/2024 | <will need to obtain reapproval as certifier | |

| Source: U.S. Environmental Protection Agency. (April 2021). EPA-approved Test Labs and Third-Party Certifiers for Residential Wood Heaters. Accessed November 8, 2021. Retrieved from https://www.epa.gov/sites/default/files/2021-04/documents/epa_approved_test_labs_and_third_party_certifiers_april_2021.pdf. "EPA Approved Test Labs and Third Party Certifiers April 07,2021 (pdf) (04/07/2021) " | |||||||||

Sheet 4: #Responses

| NSPS for New Residential Hydronic Heaters and Forced-Air Furnaces (40 CFR Part 60, Subpart QQQQ) (Renewal) | |||||||

| Total Annual Responses | |||||||

| (A) | (B) | (C) | (D) | (E) | |||

| Information Collection Activity | Number of Respondents | Number of Responses | Number of Existing Respondents That Keep Records But Do Not Submit Reports | Total Annual Responses E=(BxC)+D |

Rule Citation | ||

| Manufacturers a | |||||||

| Certification test notification (new model lines) b | 0 | 1 | N/A | 0 | § 60.5476(h) | ||

| Application for certification (new model lines) b | 0 | 1 | N/A | 0 | § 60.5475 (a), (b), (f) | ||

| Application for re-certification (existing model lines) c | 13 | 0.52 | N/A | 6.8 | § 60.5475(i) | ||

| Biennial reporting d | 13 | 1.31 | N/A | 17 | § 60.5479 (d) | ||

| Review annual QA program audit report e | 13 | 2.62 | N/A | 34 | § 60.5479 (m) | ||

| Review QA program performance test results f | 13 | 0.33 | N/A | 4.33 | § 60.5478 (a)(5)(iii) and § 60.5478 (b) | ||

| Review EPA compliance audit testing g | 1 | 0.33 | N/A | 0.33 | |||

| Test Laboratories a | |||||||

| New application for test lab approval - needs to obtain ISO accreditation h | 0 | 1 | N/A | 0 | § 60.5477 (a), § 60.5479 (b) | ||

| New application for test lab approval - already has ISO accreditation h | 0 | 1 | N/A | 0 | |||

| Re-application for test lab approval i | 1.67 | 1 | N/A | 1.67 | § 60.5477 (a), § 60.5479 (b) | ||

| EPA compliance audit testing j | 1 | 0.33 | N/A | 0.33 | § 60.5475 (n) | ||

| Biennial proficiency testing and report development k | 8 | 0.5 | N/A | 4 | § 60.5477 (a) | ||

| Third-Party Certifiers a | |||||||

| New application for approval as a third-party certifier - needs to obtain ISO accreditation l | 0 | 1 | N/A | 0 | § 60.5477 (d), § 60.5479 (b) | ||

| New application for approval as a third-party certifier - already has ISO accreditation l | 0 | 1 | N/A | 0 | § 60.5477 (d), § 60.5479 (b) | ||

| Re-application for approval as a third-party certifier m | 1.33 | 1 | N/A | 1.33 | |||

| QA program annual audit reports n | 8 | 4.25 | N/A | 34 | 40 CFR 60.5479(f) | ||

| Certification test o | 0 | 1 | N/A | 0 | § 60.5479 (b) | ||

| Total | 104 | ||||||

| hrs/response: | 23 | ||||||

| Assumptions: | |||||||

| a We assume there are 10 hydronic heater manufacturers with 31 model lines and 3 forced-air furnace manufacturers with 3 model lines. We assume there are 11 laboratories with 8 acting as testing labs and 8 acting as third-party certifiers. | |||||||

| b We assume that no manufacturers will certify new models during the three-year period of this ICR. 40 CFR 60.5476(h) requires manufacturers to notify EPA in advance of a certification test. | |||||||

| c 40 CFR 60.5475(i) requires that existing certified model lines be re-certified every five years. We assume that, for all model lines that require re-certification during the three-year period of this ICR, that manufacturers will choose to renew the certification of their currently-certified models without testing by affirming that the central heaters are similar in all respects to the representative central heater submitted for testing and requesting a waiver from certification testing. (34 model lines/5 years/13 manufacturers = 0.52 model lines recertified each year per manufacturer). | |||||||

| d 40 CFR 60.5479(d) requires manufacturers to submit a report every two years following issuance of a certification of compliance for each model line. (34 model lines/13 manufacturers/2 years = 1.31 reports/manufacturer/year). | |||||||

| e Under 40 CFR 60.5479(m), manufacturers must conduct a quality assurance program for each certified model line. The quality assurance plan is audited annually by the third-party certifier. After receiving each audit report, the manufacturer must report to the third-party certifier and to the Administrator its corrective actions and responses to any deficiencies identified in the audit report. (34 model lines/13 manufacturers/audited once per year = 2.62 audit report responses/manufacturer/year). | |||||||

| f We assume that each manufacturer will perform a quality assurance performance test on one model line under the quality assurance program during the three-year period. | |||||||

| g Under 40 CFR 60.5475(n), EPA may require a manufacturer to perform compliance audit testing on a manufacturer's model line(s). We assume one model gets audited by EPA in the three-year period of this ICR. | |||||||

| h We assume no new laboratories will apply for approval from EPA to perform testing under this program during the three-year period of this ICR. | |||||||

| i All 8 testing labs are ISO accredited and approved by EPA to perform testing. Five test labs will require ISO re-accreditation and EPA approval during the three-year period of this ICR. (5 testing labs/3 years = 1.67 testing labs/year). | |||||||

| j Under 40 CFR 60.5475(n), EPA may require a manufacturer to perform compliance audit testing on a manufacturer's model line(s). We assume one model gets audited by EPA in the three-year period of this ICR. The testing lab performing this test is required to submit a report containing all documentation pertaining to the test to both the manufacturer and the Administrator. | |||||||

| k Under 40 CFR 60.5477(a), all 8 testing labs participate in a proficiency testing program every 2 years. | |||||||

| l We assume no new laboratories will apply for approval from EPA to act as third-party certifiers under this program during the three-year period of this ICR. | |||||||

| m All 8 third-party certifiers are ISO accredited and approved by EPA. Four certifiers will require ISO re-accreditation and EPA approval during the three-year period of this ICR. Each third-party certifier must submit ISO-IEC accreditation credentials to the Administrator. (4 third-party certifiers/3 years = 1.33 third-party certifiers/year). | |||||||

| n Under 40 CFR 60.5479(f), manufacturers must contract with third-party certifiers to conduct annual audits on the quality assurance program for each model line. The third-party certifier is required to submit a report of these audits to the Administrator and the manufacturer identifying any deviations and specifying corrective actions that need to be taken. (34 model lines/8 third-party certifiers/once per year audits = 4.25 audit reports/certifier/year). | |||||||

| o Third-party certifiers are required to submit certification tests to the Administrator. No new models are expected to be tested/certified during the three-year period of this ICR. | |||||||

Sheet 5: Capital-Start-up

| NSPS for New Residential Hydronic Heaters and Forced-Air Furnaces (40 CFR Part 60, Subpart QQQQ) (Renewal) | |||

| Capital/Startup Costs | |||

| (A) | (B) | (C) | (D) |

| Data Collection Device | Capital/Start-Up for One Respondent/Unit | Number of New Respondents/Models per Year | Total Capital/Start-Up Cost (B x C) |

| Certification Test a, b | $55,000 | 0 models | $0 |

| Cost of Permanent Label b | $1,250 | 0 models | $0 |

| QA Performance Test c | $55,000 | 4.33 models | $238,095 |

| EPA Compliance Audit Test d | $63,564 per model | 0.33 models | $21,167 |

| Owner's Manual e | $3,750 | 0 models | $0 |

| ISO Accreditation-Test Laboratories f | $75,000 per respondent | 1.67 respondents | $125,000 |

| ISO Accreditation-Third-Party Certifiers g | $75,000 per respondent | 1.33 respondents | $100,000 |

| Annual Totals (rounded) h | $484,000 | ||

| a We assume that, for all model lines that require re-certification during the three-year period of this ICR, that manufacturers will choose to renew the certification of their currently-certified models without testing by affirming that the central heaters are similar in all respects to the representative central heater submitted for testing and requesting a waiver from certification testing. | |||

| b The cost of certification testing is $55,000 per test (includes EPA testing ($30,000), confirmation safety testing or full safety testing ($22,500), and shipping of prototype(s)($2,500) costs)). Total costs of permanent labels are estimated to be $1,250 per model. | |||

| c Assumes each of the manufacturers will be required to test one of their models under their QA program during the three-year period covered by this ICR (2022-2025) at $55,000 per test ( includes EPA testing ($30,000), confirmation safety testing or full safety testing ($22,500), and shipping of prototype(s)($2,500) costs) (13 manufacturers * 1 model tested / 3 years = 4.33 models tested/year). | |||

| d Assumes one model line will be audited by EPA during the three-year ICR period (2022 – 2025). Costs assume the cost of one appliance (based on the average cost of three appliances: 1 outdoor ($11,571) and 1 indoor ($11,543) hydronic heater and 1 forced-air furnace ($2,579)) plus the cost of testing at $55,000 (assumes EPA testing costs of $30,000, full safety cost of $22,500 and $2,500 in shipping costs). | |||

| e Assumes an average fixed cost of $3,750 for owner's manual (revised or new, possibly bilingual) per model certified. | |||

| f 8 testing labs are ISO accredited and these 8 labs are currently certified by EPA. 5 testing labs will require ISO re-accreditation and EPA recertification during the three-year period of this ICR. We assume an average cost to obtain ISO accreditation is $75,000 based on cost estimates provided by manufacturers. (5 testing labs/3 years = 1.67 labs/year). | |||

| g 8 third-party certifiers are ISO accredited and these 8 third-party certifiers are currently certified by EPA. 4 third-party certifiers will require ISO re-accreditation and EPA recertification during the three-year period of this ICR. We assume an average cost to obtain ISO accreditation is $75,000 based on cost estimates provided by manufacturers. (4 third-party certifiers/3 years = 1.33 third-party certifiers/year). | |||

| h Totals have been rounded to 3 significant figures. Figures may not add exactly due to rounding. | |||

Sheet 6: WoodHeater Database

| EPA-Certified Wood Stove Database, https://www.epa.gov/burnwise and https://cfpub.epa.gov/oarweb/woodstove/index.cfm?fuseaction=app.about , accessed October 21, 2021 | |||||||||||||||||

| New | Model | Manufacturer | Firebox Volume | Emission Rate Annual Average (lb/mmBTU) | Heat Output Maximum (BTUs) | Efficiency | Type | Subtype | Fuel Type | Test Method | CO | NSPS Compliance 2020 | Certification Date | Renewal Date | |||

| Classic Edge 760 | Central Boiler | 0.1 | 0.1 | 235938 | 83 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 5.553 | Yes | 01/01/2020 | 12/30/2024 | 1 | ||||

| Classic Edge 560 | Central Boiler | 0.14 | 0.14 | 194724 | 84 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 3.25 | Yes | 01/01/2020 | 12/30/2024 | 1 | ||||

| Classic Edge 360 | Central Boiler | 0.12 | 0.12 | 148625 | 82 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 4.35 | Yes | 03/19/2020 | 3/18/2025 | 1 | ||||

| S3 Turbo 50 | Fröling Heizkessel und Behälterbau Ges.m.b.H | 0.12 | 0.12 | 83097 | 73 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | Yes | 09/23/2016 | 9/22/2021 | ||||||

| PE1 Pellet 20 | Fröling Heizkessel und Behälterbau Ges.m.b.H | 0.05 | 0.05 | 67744 | 78 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.73 | Yes | 02/09/2018 | 2/8/2023 | 1 | ||||

| PE1 Pellet 35 | Fröling Heizkessel und Behälterbau Ges.m.b.H | 0.05 | 0.05 | 121300 | 80 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.74 | Yes | 02/15/2018 | 2/14/2023 | 1 | ||||

| Crown Royal Stoves 7300E | Greentech Manufacturing Inc. | 0.08 | 0.08 | 199000 | 75 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 3.1 | Yes | 04/25/2020 | 4/24/2025 | 1 | ||||

| Crown Royal Stoves 7400E | Greentech Manufacturing Inc. | 0.06 | 0.06 | 325000 | 83 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 3.5 | Yes | 09/04/2020 | 9/3/2025 | |||||

| Crown Royal Stoves 7200E | Greentech Manufacturing Inc. | 0.08 | 0.08 | 125000 | 77 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 2.8 | Yes | 10/14/2020 | 10/13/2025 | |||||

| ECO-HK 70 Multifuel | Hargassner GmbH | 0.07 | 0.07 | 239000 | 87 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.09 | Yes | 04/06/2020 | 4/5/2025 | 1 | ||||

| ECO-HK 120 Multifuel | Hargassner GmbH | 0.04 | 0.04 | 409500 | 88 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.031 | Yes | 04/24/2020 | 4/23/2025 | 1 | ||||

| Pellematic Smart XS (Condensing Mode) | Maine Energy Systems, LLC | 0.05 | 0.05 | 90 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.027 | Yes | 04/04/2019 | 4/2/2024 | 1 | |||||

| Pellematic 20 | Maine Energy Systems, LLC | 0.02 | 0.02 | 68300 | 77 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.025 | Yes | 05/17/2020 | 5/16/2025 | 1 | ||||

| Pellematic 56 | Maine Energy Systems, LLC | 0.05 | 0.05 | 191000 | 86 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.027 | Yes | 05/17/2020 | 5/16/2025 | 1 | ||||

| Pellematic 32 | Maine Energy Systems, LLC | 0.02 | 0.02 | 109000 | 77 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.025 | Yes | 05/22/2020 | 5/21/2025 | 1 | ||||

| G-Class G2Plus | Polar Furnace Manufacturing Inc. | 0.07 | 0.07 | 183307 | 73 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 1.7 | Yes | 11/21/2016 | 11/20/2021 | |||||

| G Class G3 | Polar Furnace Manufacturing Inc. | 0.06 | 0.06 | 77 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 3.288 | Yes | 12/15/2020 | 12/14/2025 | ||||||

| G Series G7000 | Steel Tech, Inc. | 0.11 | 0.11 | 200000 | 70 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 2.179 | Yes | 06/13/2020 | 6/12/2025 | |||||

| G Series G4000 | Steel Tech, Inc. | 0.09 | 0.09 | 110000 | 82 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 1.648 | Yes | 01/22/2021 | 1/21/2026 | |||||

| Vedolux 350 | Varmebaronen AB | 0.08 | 0.08 | 118724 | 74 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 0.07 | Yes | |||||||

| Vedolux 37 | Varmebaronen AB | 0.11 | 0.11 | 132119 | 69 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 0.1 | Yes | |||||||

| Vedolux 450 | Varmebaronen AB | 0.04 | 0.04 | 130731 | 75 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 0.04 | Yes | |||||||

| Vedolux 55 | Varmebaronen AB | 0.11 | 0.11 | 170418 | 67 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 0.12 | Yes | |||||||

| Vedolux 650 | Varmebaronen AB | 0.08 | 0.08 | 201743 | 73 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 0.46 | Yes | |||||||

| BioWIN 152 | Windhager Zentralheizung Technik GmbH | 0.04 | 0.04 | 51200 | 65 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.03 | Yes | 08/21/2020 | 8/20/2025 | |||||

| BioWIN 212 | Windhager Zentralheizung Technik GmbH | 0.06 | 0.06 | 71700 | 58 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.04 | Yes | 08/21/2020 | 8/20/2025 | |||||

| BioWIN 262 | Windhager Zentralheizung Technik GmbH | 0.04 | 0.04 | 88400 | 71 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.04 | Yes | 08/21/2020 | 8/20/2025 | |||||

| BioWIN 332 | Windhager Zentralheizung Technik GmbH | 0.04 | 0.04 | 110900 | 71 | Hydronic Heater | Non-Catalytic Stove | Wood Pellets | 0.04 | Yes | 08/21/2020 | 8/20/2025 | |||||

| CleanFire 700 | WoodMaster Inc. | 0.1 | 0.1 | 235938 | 83 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 5.553 | Yes | 01/31/2020 | 1/29/2025 | 1 | ||||

| CleanFire 500 | WoodMaster Inc. | 0.14 | 0.14 | 194724 | 84 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 3.25 | Yes | 01/31/2020 | 1/29/2025 | 1 | ||||

| CleanFire 300 | WoodMaster Inc. | 0.12 | 0.12 | 148625 | 82 | Hydronic Heater | Non-Catalytic Stove | Cord Wood | 4.35 | Yes | 03/19/2020 | 3/18/2025 | 1 | ||||

| SF1000E, FC1000E, X1020, L1020 | HY-C Company, LLC | 0.14 | 0.14 | 70 | Forced Air Furnace | Non-Catalytic Stove | Cord Wood | 1.73 | Yes | 01/04/2021 | 1/3/2026 | ||||||

| Vapor Fire 100 (VF100) | Lamppa Manufacturing, Inc. | 0.09 | 0.09 | 79 | Forced Air Furnace | Non-Catalytic Stove | Cord Wood | 0.82 | Yes | 08/16/2017 | 8/15/2022 | 1 | |||||

| SR-3.6 Series Heat Commander, Caddy Advanced, Caddy Advanced CR | Stove Builder International, Inc. | 0.1 | 0.1 | 77 | Forced Air Furnace | Non-Catalytic Stove | Cord Wood | 1.54 | Yes | 10/07/2020 | 10/6/2025 | ||||||

| 16 | 0.551724137931034 | 19 |

Sheet 7: Test Labs and Certifiers

| EPA Test Lab and Thid Party Certifiers data. EPA Approved Test Labs and Third Party Certifiers April 07,2021 (pdf) (04/07/2021) | ||||||||||||

| https://www.epa.gov/sites/default/files/2021-04/documents/epa_approved_test_labs_and_third_party_certifiers_april_2021.pdf | ||||||||||||

|

||||||||||||

| File Type | application/vnd.openxmlformats-officedocument.spreadsheetml.sheet |

| File Modified | 0000-00-00 |

| File Created | 0000-00-00 |

© 2026 OMB.report | Privacy Policy