49 Cfr 390-399

49 CFR 390-399.doc

Medical Qualification Requirements

49 CFR 390-399

OMB: 2126-0006

PART 390—FEDERAL MOTOR CARRIER SAFETY REGULATIONS; GENERAL

Section Contents Subpart A—General Applicability and Definitions

Subpart B—General Requirements and Information

Authority: 49 U.S.C. 508, 13301, 13902, 31133, 31136, 31502, 31504, and sec. 204, Pub. L. 104–88, 109 Stat. 803, 941 (49 U.S.C. 701 note); sec. 114, Pub. L. 103–311, 108 Stat. 1673, 1677; sec. 217, Pub. L. 106–159, 113 Stat. 1748, 1767; and 49 CFR 1.73. Source: 53 FR 18052, May 19, 1988, unless otherwise noted. Editorial Note: Nomenclature changes to part 390 appear at 66 FR 49873, Oct. 1, 2001. Subpart A—General Applicability and Definitions§ 390.1 Purpose.This part establishes general applicability, definitions, general requirements and information as they pertain to persons subject to this chapter. § 390.3 General applicability.(a) The rules in subchapter B of this chapter are applicable to all employers, employees, and commercial motor vehicles, which transport property or passengers in interstate commerce. (b) The rules in Part 383, Commercial Driver's License Standards; Requirements and Penalties, are applicable to every person who operates a commercial motor vehicle, as defined in §383.5 of this subchapter, in interstate or intrastate commerce and to all employers of such persons. (c) The rules in Part 387, Minimum Levels of Financial Responsibility for Motor Carriers, are applicable to motor carriers as provided in §387.3 or 387.27 of this subchapter. (d) Additional requirements. Nothing in subchapter B of this chapter shall be construed to prohibit an employer from requring and enforcing more stringent requirements relating to safety of operation and employee safety and health. (e) Knowledge of and compliance with the regulations. (1) Every employer shall be knowledgeable of and comply with all regulations contained in this subchapter which are applicable to that motor carrier's operations. (2) Every driver and employee shall be instructed regarding, and shall comply with, all applicable regulations contained in this subchapter. (3) All motor vehicle equipment and accessories required by this subchapter shall be maintained in compliance with all applicable performance and design criteria set forth in this subchapter. (f) Exceptions. Unless otherwise specifically provided, the rules in this subchapter do not apply to— (1) All school bus operations as defined in §390.5; (2) Transportation performed by the Federal government, a State, or any political subdivision of a State, or an agency established under a compact between States that has been approved by the Congress of the United States; (3) The occasional transportation of personal property by individuals not for compensation nor in the furtherance of a commercial enterprise; (4) The transportation of human corpses or sick and injured persons; (5) The operation of fire trucks and rescue vehicles while involved in emergency and related operations; (6)(i) The operation of commercial motor vehicles designed or used to transport between 9 and 15 passengers (including the driver), not for direct compensation, provided the vehicle does not otherwise meet the definition of a commercial motor vehicle, except that motor carriers operating such vehicles are required to comply with §§390.15, 390.19, and 390.21(a) and (b)(2). (ii) The operation of commercial motor vehicles designed or used to transport between 9 and 15 passengers (including the driver) for direct compensation, provided the vehicle is not being operated beyond a 75 air-mile radius (86.3 statute miles or 138.9 kilometers) from the driver's normal work-reporting location, and provided the vehicle does not otherwise meet the definition of a commercial motor vehicle, except that motor carriers operating such vehicles are required to comply with §§390.15, 390.19, and 390.21(a) and (b)(2). (g) Motor carriers that transport hazardous materials in intrastate commerce. The rules in the following provisions of subchapter B of this chapter apply to motor carriers that transport hazardous materials in intrastate commerce and to the motor vehicles that transport hazardous materials in intrastate commerce: (1) Part 385, subparts A and E, for carriers subject to the requirements of §385.403 of this chapter. (2) Part 386, Rules of practice for motor carrier, broker, freight forwarder, and hazardous materials proceedings, of this chapter. (3) Part 387, Minimum Levels of Financial Responsibility for Motor Carriers, to the extent provided in §387.3 of this chapter. (4) Section 390.19, Motor carrier identification report, and §390.21, Marking of CMVs, for carriers subject to the requirements of §385.403 of this chapter. Intrastate motor carriers operating prior to January 1, 2005, are excepted from §390.19(a)(1). [53 FR 18052, May 19, 1988, as amended at 54 FR 12202, Mar. 24, 1989; 58 FR 33776, June 21, 1993; 59 FR 8752, Feb. 23, 1994; 59 FR 67554, Dec. 29, 1994; 62 FR 1296, Jan. 9, 1997; 63 FR 33276, June 18, 1998; 64 FR 48516, Sept. 3, 1999; 66 FR 2766, Jan. 11, 2001; 68 FR 47875, Aug. 12, 2003; 69 FR 39372, June 30, 2004] § 390.5 Definitions.Unless specifically defined elsewhere, in this subchapter: Accident means— (1) Except as provided in paragraph (2) of this definition, an occurrence involving a commercial motor vehicle operating on a highway in interstate or intrastate commerce which results in: (i) A fatality; (ii) Bodily injury to a person who, as a result of the injury, immediately receives medical treatment away from the scene of the accident; or (iii) One or more motor vehicles incurring disabling damage as a result of the accident, requiring the motor vehicle(s) to be transported away from the scene by a tow truck or other motor vehicle. (2) The term accident does not include: (i) An occurrence involving only boarding and alighting from a stationary motor vehicle; or (ii) An occurrence involving only the loading or unloading of cargo. Alcohol concentration (AC) means the concentration of alcohol in a person's blood or breath. When expressed as a percentage it means grams of alcohol per 100 milliliters of blood or grams of alcohol per 210 liters of breath. Bus means any motor vehicle designed, constructed, and or used for the transportation of passengers, including taxicabs. Business district means the territory contiguous to and including a highway when within any 600 feet along such highway there are buildings in use for business or industrial purposes, including but not limited to hotels, banks, or office buildings which occupy at least 300 feet of frontage on one side or 300 feet collectively on both sides of the highway. Charter transportation of passengers means transportation, using a bus, of a group of persons who pursuant to a common purpose, under a single contract, at a fixed charge for the motor vehicle, have acquired the exclusive use of the motor vehicle to travel together under an itinerary either specified in advance or modified after having left the place of origin. Commercial motor vehicle means any self-propelled or towed motor vehicle used on a highway in interstate commerce to transport passengers or property when the vehicle— (1) Has a gross vehicle weight rating or gross combination weight rating, or gross vehicle weight or gross combination weight, of 4,536 kg (10,001 pounds) or more, whichever is greater; or (2) Is designed or used to transport more than 8 passengers (including the driver) for compensation; or (3) Is designed or used to transport more than 15 passengers, including the driver, and is not used to transport passengers for compensation; or (4) Is used in transporting material found by the Secretary of Transportation to be hazardous under 49 U.S.C. 5103 and transported in a quantity requiring placarding under regulations prescribed by the Secretary under 49 CFR, subtitle B, chapter I, subchapter C. Conviction means an unvacated adjudication of guilt, or a determination that a person has violated or failed to comply with the law in a court of original jurisdiction or by an authorized administrative tribunal, an unvacated forfeiture of bail or collateral deposited to secure the person's appearance in court, a plea of guilty or nolo contendere accepted by the court, the payment of a fine or court cost, or violation of a condition of release without bail, regardless of whether or not the penalty is rebated, suspended, or probated. Direct assistance means transportation and other relief services provided by a motor carrier or its driver(s) incident to the immediate restoration of essential services (such as, electricity, medial care, sewer, water, telecommunications, and telecommunication transmissions) or essential supplies (such as, food and fuel). It does not include transportation related to long-term rehabilitation of damaged physical infrastructure or routine commercial deliveries after the initial threat to life and property has passed. Direct compensation means payment made to the motor carrier by the passengers or a person acting on behalf of the passengers for the transportation services provided, and not included in a total package charge or other assessment for highway transportation services. Disabling damage means damage which precludes departure of a motor vehicle from the scene of the accident in its usual manner in daylight after simple repairs. (1) Inclusions. Damage to motor vehicles that could have been driven, but would have been further damaged if so driven. (2) Exclusions. (i) Damage which can be remedied temporarily at the scene of the accident without special tools or parts. (ii) Tire disablement without other damage even if no spare tire is available. (iii) Headlamp or taillight damage. (iv) Damage to turn signals, horn, or windshield wipers which makes them inoperative. Driveaway-towaway operation means an operation in which an empty or unladen motor vehicle with one or more sets of wheels on the surface of the roadway is being transported: (1) Between vehicle manufacturer's facilities; (2) Between a vehicle manufacturer and a dealership or purchaser; (3) Between a dealership, or other entity selling or leasing the vehicle, and a purchaser or lessee; (4) To a motor carrier's terminal or repair facility for the repair of disabling damage (as defined in §390.5) following a crash; or (5) To a motor carrier's terminal or repair facility for repairs associated with the failure of a vehicle component or system; or (6) By means of a saddle-mount or tow-bar. Driver means any person who operates any commercial motor vehicle. Driving a commercial motor vehicle while under the influence of alcohol means committing any one or more of the following acts in a CMV: Driving a CMV while the person's alcohol concentration is 0.04 or more; driving under the influence of alcohol, as prescribed by State law; or refusal to undergo such testing as is required by any State or jurisdiction in the enforcement of Table 1 to §383.51 or §392.5(a)(2) of this subchapter. Emergency means any hurricane, tornado, storm (e.g. thunderstorm, snowstorm, icestorm, blizzard, sandstorm, etc.), high water, wind-driven water, tidal wave, tsunami, earthquake, volcanic eruption, mud slide, drought, forest fire, explosion, blackout or other occurrence, natural or man-made, which interrupts the delivery of essential services (such as, electricity, medical care, sewer, water, telecommunications, and telecommunication transmissions) or essential supplies (such as, food and fuel) or otherwise immediately threatens human life or public welfare, provided such hurricane, tornado, or other event results in: (1) A declaration of an emergency by the President of the United States, the Governor of a State, or their authorized representatives having authority to declare emergencies; by the FMCSA Field Administrator for the geographical area in which the occurrence happens; or by other Federal, State or local government officials having authority to declare emergencies, or (2) A request by a police officer for tow trucks to move wrecked or disabled motor vehicles. Emergency relief means an operation in which a motor carrier or driver of a commercial motor vehicle is providing direct assistance to supplement State and local efforts and capabilities to save lives or property or to protect public health and safety as a result of an emergency as defined in this section. Employee means any individual, other than an employer, who is employed by an employer and who in the course of his or her employment directly affects commercial motor vehicle safety. Such term includes a driver of a commercial motor vehicle (including an independent contractor while in the course of operating a commercial motor vehicle), a mechanic, and a freight handler. Such term does not include an employee of the United States, any State, any political subdivision of a State, or any agency established under a compact between States and approved by the Congress of the United States who is acting within the course of such employment. Employer means any person engaged in a business affecting interstate commerce who owns or leases a commercial motor vehicle in connection with that business, or assigns employees to operate it, but such terms does not include the United States, any State, any political subdivision of a State, or an agency established under a compact between States approved by the Congress of the United States. Exempt intracity zone means the geographic area of a municipality or the commercial zone of that municipality described in appendix F to subchapter B of this chapter. The term “exempt intracity zone” does not include any municipality or commercial zone in the State of Hawaii. For purposes of §391.62, a driver may be considered to operate a commercial motor vehicle wholly within an exempt intracity zone notwithstanding any common control, management, or arrangement for a continuous carriage or shipment to or from a point without such zone. Exempt motor carrier means a person engaged in transportation exempt from economic regulation by the Federal Motor Carrier Safety Administration (FMCSA) under 49 U.S.C. 13506. “Exempt motor carriers” are subject to the safety regulations set forth in this subchapter. Farm vehicle driver means a person who drives only a commercial motor vehicle that is— (a) Controlled and operated by a farmer as a private motor carrier of property; (b) Being used to transport either— (1) Agricultural products, or (2) Farm machinery, farm supplies, or both, to or from a farm; (c) Not being used in the operation of a for-hire motor carrier; (d) Not carrying hazardous materials of a type or quantity that requires the commercial motor vehicle to be placarded in accordance with §177.823 of this subtitle; and (e) Being used within 150 air-miles of the farmer's farm. Farmer means any person who operates a farm or is directly involved in the cultivation of land, crops, or livestock which— (a) Are owned by that person; or (b) Are under the direct control of that person. Fatality means any injury which results in the death of a person at the time of the motor vehicle accident or within 30 days of the accident. Federal Motor Carrier Safety Administrator means the chief executive of the Federal Motor Carrier Safety Administration, an agency within the Department of Transportation. For-hire motor carrier means a person engaged in the transportation of goods or passengers for compensation. Gross combination weight rating (GCWR) means the value specified by the manufacturer as the loaded weight of a combination (articulated) motor vehicle. In the absence of a value specified by the manufacturer, GCWR will be determined by adding the GVWR of the power unit and the total weight of the towed unit and any load thereon. Gross vehicle weight rating (GVWR) means the value specified by the manufacturer as the loaded weight of a single motor vehicle. Hazardous material means a substance or material which has been determined by the Secretary of Transportation to be capable of posing an unreasonable risk to health, safety, and property when transported in commerce, and which has been so designated. Hazardous substance means a material, and its mixtures or solutions, that is identified in the appendix to §172.101, List of Hazardous Substances and Reportable Quantities, of this title when offered for transportation in one package, or in one transport motor vehicle if not packaged, and when the quantity of the material therein equals or exceeds the reportable quantity (RQ). This definition does not apply to petroleum products that are lubricants or fuels, or to mixtures or solutions of hazardous substances if in a concentration less than that shown in the table in §171.8 of this title, based on the reportable quantity (RQ) specified for the materials listed in the appendix to §172.101. Hazardous waste means any material that is subject to the hazardous waste manifest requirements of the EPA specified in 40 CFR part 262 or would be subject to these requirements absent an interim authorization to a State under 40 CFR part 123, subpart F. Highway means any road, street, or way, whether on public or private property, open to public travel. “Open to public travel” means that the road section is available, except during scheduled periods, extreme weather or emergency conditions, passable by four-wheel standard passenger cars, and open to the general public for use without restrictive gates, prohibitive signs, or regulation other than restrictions based on size, weight, or class of registration. Toll plazas of public toll roads are not considered restrictive gates. Interstate commerce means trade, traffic, or transportation in the United States— (1) Between a place in a State and a place outside of such State (including a place outside of the United States); (2) Between two places in a State through another State or a place outside of the United States; or (3) Between two places in a State as part of trade, traffic, or transportation originating or terminating outside the State or the United States. Intrastate commerce means any trade, traffic, or transportation in any State which is not described in the term “interstate commerce.” Medical examiner means a person who is licensed, certified, and/or registered, in accordance with applicable State laws and regulations, to perform physical examinations. The term includes but is not limited to, doctors of medicine, doctors of osteopathy, physician assistants, advanced practice nurses, and doctors of chiropractic. Motor carrier means a for-hire motor carrier or a private motor carrier. The term includes a motor carrier's agents, officers and representatives as well as employees responsible for hiring, supervising, training, assigning, or dispatching of drivers and employees concerned with the installation, inspection, and maintenance of motor vehicle equipment and/or accessories. For purposes of subchapter B, this definition includes the terms employer, and exempt motor carrier. Motor vehicle means any vehicle, machine, tractor, trailer, or semitrailer propelled or drawn by mechanical power and used upon the highways in the transportation of passengers or property, or any combination thereof determined by the Federal Motor Carrier Safety Administration, but does not include any vehicle, locomotive, or car operated exclusively on a rail or rails, or a trolley bus operated by electric power derived from a fixed overhead wire, furnishing local passenger transportation similar to street-railway service. Multiple-employer driver means a driver, who in any period of 7 consecutive days, is employed or used as a driver by more than one motor carrier. Operating authority means the registration required by 49 U.S.C. 13902, 49 CFR part 365, 49 CFR part 368, and 49 CFR 392.9a. Operator—See driver. Other terms—Any other term used in this subchapter is used in its commonly accepted meaning, except where such other term has been defined elsewhere in this subchapter. In that event, the definition therein given shall apply. Out-of-service order means a declaration by an authorized enforcement officer of a Federal, State, Canadian, Mexican, or local jurisdiction that a driver, a commercial motor vehicle, or a motor carrier operation is out of service pursuant to 49 CFR 386.72, 392.5, 392.9a, 395.13, or 396.9, or compatible laws, or the North American Standard Out-of-Service Criteria. Person means any individual, partnership, association, corporation, business trust, or any other organized group of individuals. Previous employer means any DOT regulated person who employed the driver in the preceding 3 years, including any possible current employer. Principal place of business means the single location designated by the motor carrier, normally its headquarters, for purposes of identification under this subchapter. The motor carrier must make records required by parts 382, 387, 390, 391, 395, 396, and 397 of this subchapter available for inspection at this location within 48 hours (Saturdays, Sundays, and Federal holidays excluded) after a request has been made by a special agent or authorized representative of the Federal Motor Carrier Safety Administration. Private motor carrier means a person who provides transportation of property or passengers, by commercial motor vehicle, and is not a for-hire motor carrier. Private motor carrier of passengers (business) means a private motor carrier engaged in the interstate transportation of passengers which is provided in the furtherance of a commercial enterprise and is not available to the public at large. Private motor carrier of passengers (nonbusiness) means private motor carrier involved in the interstate transportation of passengers that does not otherwise meet the definition of a private motor carrier of passengers (business). Radar detector means any device or mechanism to detect the emission of radio microwaves, laser beams or any other future speed measurement technology employed by enforcement personnel to measure the speed of commercial motor vehicles upon public roads and highways for enforcement purposes. Excluded from this definition are radar detection devices that meet both of the following requirements: (1) Transported outside the driver's compartment of the commercial motor vehicle. For this purpose, the driver's compartment of a passenger-carrying CMV shall include all space designed to accommodate both the driver and the passengers; and (2) Completely inaccessible to, inoperable by, and imperceptible to the driver while operating the commercial motor vehicle. Regional Director of Motor Carriers means the Field Administrator, Federal Motor Carrier Safety Administration, for a given geographical area of the United States. Residential district means the territory adjacent to and including a highway which is not a business district and for a distance of 300 feet or more along the highway is primarily improved with residences. School bus means a passenger motor vehicle which is designed or used to carry more than 10 passengers in addition to the driver, and which the Secretary determines is likely to be significantly used for the purpose of transporting preprimary, primary, or secondary school students to such schools from home or from such schools to home. School bus operation means the use of a school bus to transport only school children and/or school personnel from home to school and from school to home. Secretary means the Secretary of Transportation. Single-employer driver means a driver who, in any period of 7 consecutive days, is employed or used as a driver solely by a single motor carrier. This term includes a driver who operates a commercial motor vehicle on an intermittent, casual, or occasional basis. Special agent See appendix B to subchapter B—Special agents. State means a State of the United States and the District of Columbia and includes a political subdivision of a State. Trailer includes: (a) Full trailer means any motor vehicle other than a pole trailer which is designed to be drawn by another motor vehicle and so constructed that no part of its weight, except for the towing device, rests upon the self-propelled towing motor vehicle. A semitrailer equipped with an auxiliary front axle (converter dolly) shall be considered a full trailer. (b) Pole trailer means any motor vehicle which is designed to be drawn by another motor vehicle and attached to the towing motor vehicle by means of a “reach” or “pole,” or by being “boomed” or otherwise secured to the towing motor vehicle, for transporting long or irregularly shaped loads such as poles, pipes, or structural members, which generally are capable of sustaining themselves as beams between the supporting connections. (c) Semitrailer means any motor vehicle, other than a pole trailer, which is designed to be drawn by another motor vehicle and is constructed so that some part of its weight rests upon the self-propelled towing motor vehicle. Truck means any self-propelled commercial motor vehicle except a truck tractor, designed and/or used for the transportation of property. Truck tractor means a self-propelled commercial motor vehicle designed and/or used primarily for drawing other vehicles. United States means the 50 States and the District of Columbia. [53 FR 18052, May 19, 1988] Editorial Note: For Federal Register citations affecting §390.5, see the List of CFR Sections Affected, which appears in the Finding Aids section of the printed volume and on GPO Access. § 390.7 Rules of construction.(a) In part 325 of subchapter A and in this subchapter, unless the context requires otherwise: (1) Words imparting the singular include the plural; (2) Words imparting the plural include the singular; (3) Words imparting the present tense include the future tense. (b) In this subchapter the word— (1) Officer includes any person authorized by law to perform the duties of the office; (2) Writing includes printing and typewriting; (3) Shall is used in an imperative sense; (4) Must is used in an imperative sense; (5) Should is used in a recommendatory sense; (6) May is used in a permissive sense; and (7) Includes is used as a word of inclusion, not limitation. [53 FR 18052, May 19, 1988, as amended at 60 FR 38744, July 28, 1995] Subpart B—General Requirements and Information§ 390.9 State and local laws, effect on.Except as otherwise specifically indicated, subchapter B of this chapter is not intended to preclude States or subdivisions thereof from establishing or enforcing State or local laws relating to safety, the compliance with which would not prevent full compliance with these regulations by the person subject thereto. § 390.11 Motor carrier to require observance of driver regulations.Whenever in part 325 of subchapter A or in this subchapter a duty is prescribed for a driver or a prohibition is imposed upon the driver, it shall be the duty of the motor carrier to require observance of such duty or prohibition. If the motor carrier is a driver, the driver shall likewise be bound. § 390.13 Aiding or abetting violations.No person shall aid, abet, encourage, or require a motor carrier or its employees to violate the rules of this chapter. § 390.15 Assistance in investigations and special studies.(a) A motor carrier must make all records and information pertaining to an accident available to an authorized representative or special agent of the Federal Motor Carrier Safety Administration, an authorized State or local enforcement agency representative or authorized third party representative, upon request or as part of any investigation within such time as the request or investigation may specify. A motor carrier shall give an authorized representative all reasonable assistance in the investigation of any accident including providing a full, true and correct response to any question of the inquiry. (b) For accidents that occur after April 29, 2003, motor carriers must maintain an accident register for three years after the date of each accident. For accidents that occurred on or prior to April 29, 2003, motor carriers must maintain an accident register for a period of one year after the date of each accident. Information placed in the accident register must contain at least the following: (1) A list of accidents as defined at §390.5 of this chapter containing for each accident: (i) Date of accident. (ii) City or town, or most near, where the accident occurred and the State where the accident occurred. (iii) Driver Name. (iv) Number of injuries. (v) Number of fatalities. (vi) Whether hazardous materials, other than fuel spilled from the fuel tanks of motor vehicle involved in the accident, were released. (2) Copies of all accident reports required by State or other governmental entities or insurers. (Approved by the Office of Management and Budget under control number 2126–0009) [69 FR 16719, Mar. 30, 2004] § 390.16 [Reserved]§ 390.17 Additional equipment and accessories.Nothing in this subchapter shall be construed to prohibit the use of additional equipment and accessories, not inconsistent with or prohibited by this subchapter, provided such equipment and accessories do not decrease the safety of operation of the commercial motor vehicles on which they are used. [53 FR 18052, May 19, 1988, as amended at 60 FR 38744, July 28, 1995. Redesignated at 65 FR 35296, June 2, 2000] § 390.19 Motor carrier identification report.(a) Each motor carrier that conducts operations in interstate commerce (or intrastate commerce if the carrier requires a Safety Permit as per §385.400 of this chapter) must file a Motor Carrier Identification Report, Form MCS–150, or the Combined Motor Carrier Identification Report and HM Permit Application, Form MCS–150B for permitted carriers, at the following times: (1) Before it begins operations; and (2) Every 24 months, according to the following schedule: |

------------------------------------------------------------------------

USDOT Number ending in Must file by last day of;

------------------------------------------------------------------------

1......................................... January

2......................................... February

3......................................... March

4......................................... April

5......................................... May

6......................................... June

7......................................... July

8......................................... August

9......................................... September

0......................................... October

------------------------------------------------------------------------

------------------------------------------------------------------------

Service center Territory included Location of office

------------------------------------------------------------------------

Eastern............. CT, DC, DE, MA, MD, ME, City Crescent Building,

NJ, NH, NY, PA, PR, RI, #10 South Howard

VA, VT, Virgin Islands, Street, Suite 4000,

WV. Baltimore, MD 21201-

2819.

Midwestern.......... IA, IL, IN, KS, MI, MO, 19900 Governors Drive,

MN, NE, OH, WI. Suite 210, Olympia

Fields, IL 60461-1021.

Southern............ AL, AR, FL, GA, KY, LA, 61 Forsyth Street, SW,

MS, NC, NM, OK, SC, TN, Suite 17T75, Atlanta,

TX. GA 30303-3104.

Western............. American Samoa, AK, AZ, 201 Mission Street,

CA, CO, Guam, HI, ID, Suite 2100, San

Mariana Islands, MT, Francisco, CA 94105-

ND, NV, OR, SD, UT, WA, 1838.

WY.

------------------------------------------------------------------------

Note 1: Canadian carriers, for information regarding proper service center, contact a FMCSA division (State) office in AK, ME, MI, MT, NY, ND, VT, or WA. Note 2: Mexican carriers, for information regarding proper service center, contact a FMCSA division (State) office in AZ, CA, NM, or TX. [65 FR 35297, June 2, 2000, as amended at 67 FR 61824, Oct. 2, 2002; 67 FR 63019, Oct. 9, 2002] § 390.29 Location of records or documents.(a) A motor carrier with multiple offices or terminals may maintain the records and documents required by this subchapter at its principal place of business, a regional office, or driver work-reporting location unless otherwise specified in this subchapter. (b) All records and documents required by this subchapter which are maintained at a regional office or driver work-reporting location shall be made available for inspection upon request by a special agent or authorized representative of the Federal Motor Carrier Safety Administration at the motor carrier's principal place of business or other location specified by the agent or representative within 48 hours after a request is made. Saturdays, Sundays, and Federal holidays are excluded from the computation of the 48-hour period of time. [63 FR 33276, June 18, 1998] § 390.31 Copies of records or documents.(a) All records and documents required to be maintained under this subchapter must be preserved in their original form for the periods specified, unless the records and documents are suitably photographed and the microfilm is retained in lieu of the original record for the required retention period. (b) To be acceptable in lieu of original records, photographic copies of records must meet the following minimum requirements: (1) Photographic copies shall be no less readily accessible than the original record or document as normally filed or preserved would be and suitable means or facilities shall be available to locate, identify, read, and reproduce such photographic copies. (2) Any significant characteristic, feature or other attribute of the original record or document, which photography in black and white will not preserve, shall be clearly indicated before the photograph is made. (3) The reverse side of printed forms need not be copied if nothing has been added to the printed matter common to all such forms, but an identified specimen of each form shall be on the film for reference. (4) Film used for photographing copies shall be of permanent record-type meeting in all respects the minimum specifications of the National Bureau of Standards, and all processes recommended by the manufacturer shall be observed to protect it from deterioration or accidental destruction. (5) Each roll of film shall include a microfilm of a certificate or certificates stating that the photographs are direct or facsimile reproductions of the original records. Such certificate(s) shall be executed by a person or persons having personal knowledge of the material covered thereby. (c) All records and documents required to be maintained under this subchapter may be destroyed after they have been suitably photographed for preservation. (d) Exception. All records except those requiring a signature may be maintained through the use of computer technology provided the motor carrier can produce, upon demand, a computer printout of the required data. § 390.33 Commercial motor vehicles used for purposes other than defined.Whenever a commercial motor vehicle of one type is used to perform the functions normally performed by a commercial motor vehicle of another type, the requirements of this subchapter and part 325 of subchapter A shall apply to the commercial motor vehicle and to its operation in the same manner as though the commercial motor vehicle were actually a commercial motor vehicle of the latter type. Example: If a commercial motor vehicle other than a bus is used to perform the functions normally performed by a bus, the regulations pertaining to buses and to the transportation of passengers shall apply to that commercial motor vehicle. [53 FR 18052, May 19, 1988, as amended at 60 FR 38744, July 28, 1995] § 390.35 Certificates, reports, and records: Falsification, reproduction, or alteration.No motor carrier, its agents, officers, representatives, or employees shall make or cause to make— (a) A fraudulent or intentionally false statement on any application, certificate, report, or record required by part 325 of subchapter A or this subchapter; (b) A fraudulent or intentionally false entry on any application, certificate, report, or record required to be used, completed, or retained, to comply with any requirement of this subchapter or part 325 of subchapter A; or (c) A reproduction, for fraudulent purposes, of any application, certificate, report, or record required by this subchapter or part 325 of subchapter A. § 390.37 Violation and penalty.Any person who violates the rules set forth in this subchapter or part 325 of subchapter A may be subject to civil or criminal penalties. Subpart C [Reserved]

For

questions or comments regarding e-CFR editorial content, features,

or design, email [email protected]. Last updated: August 7, 2006

|

Title 49: Transportation

PART 391—QUALIFICATIONS OF DRIVERS AND LONGER COMBINATION VEHICLE (LCV) DRIVER INSTRUCTORS

![]()

Section Contents

§ 391.1 Scope

of the rules in this part; additional qualifications; duties of

carrier-drivers.

§ 391.2 General

exemptions.

Subpart B—Qualification and Disqualification of Drivers

§ 391.11 General

qualifications of drivers.

§ 391.13 Responsibilities

of drivers.

§ 391.15 Disqualification

of drivers.

Subpart C—Background and Character

§ 391.21 Application

for employment.

§ 391.23 Investigation

and inquiries.

§ 391.25 Annual

inquiry and review of driving record.

§ 391.27 Record

of violations.

§ 391.31 Road

test.

§ 391.33 Equivalent

of road test.

Subpart E—Physical Qualifications and Examinations

§ 391.41 Physical

qualifications for drivers.

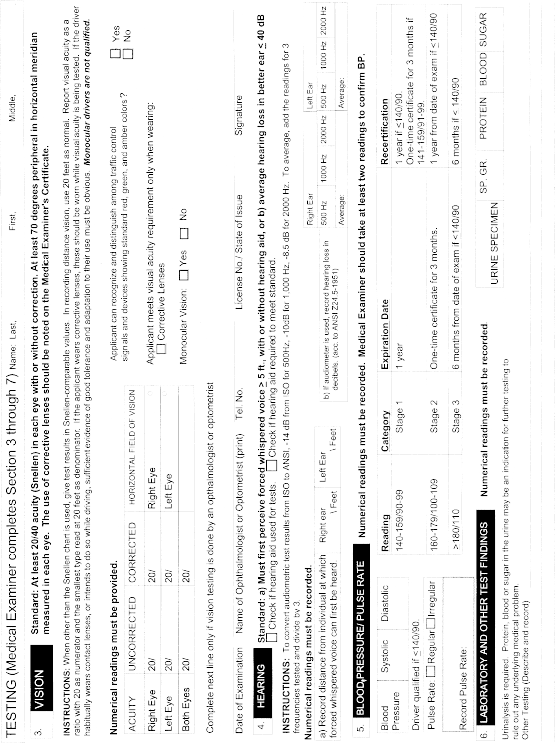

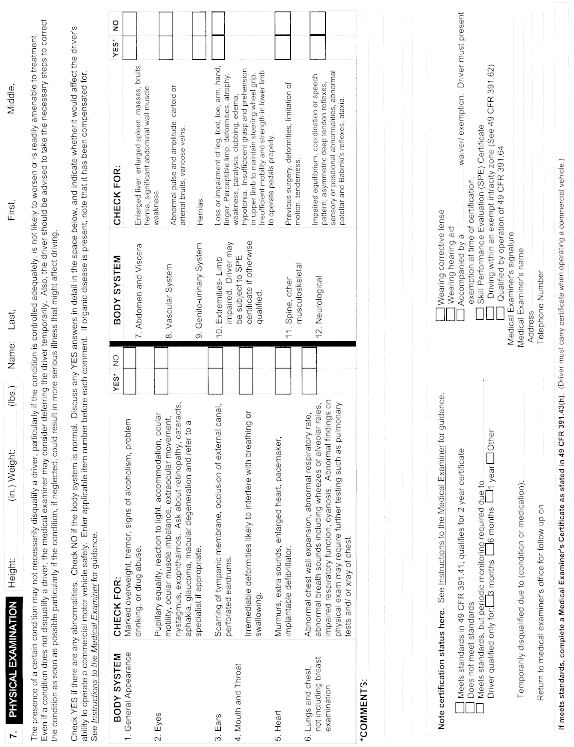

§ 391.43 Medical

examination; certificate of physical examination.

§ 391.45 Persons

who must be medically examined and certified.

§ 391.47 Resolution

of conflicts of medical evaluation.

§ 391.49 Alternative

physical qualification standards for the loss or impairment of limbs.

§ 391.51 General

requirements for driver qualification files.

§ 391.53 Driver

investigation history file.

§ 391.55 LCV

Driver-Instructor qualification files.

§ 391.61 Drivers

who were regularly employed before January 1,

1971.

§ 391.62 Limited

exemptions for intra-city zone drivers.

§ 391.63 Multiple-employer

drivers.

§ 391.64 Grandfathering

for certain drivers participating in vision and diabetes waiver study

programs.

§ 391.65 Drivers

furnished by other motor carriers.

§ 391.67 Farm

vehicle drivers of articulated commercial motor

vehicles.

§ 391.68 Private

motor carrier of passengers (nonbusiness).

§ 391.69 Private

motor carrier of passengers (business).

§ 391.71 [Reserved]

![]()

Authority: 49 U.S.C. 322, 504, 508, 31133, 31136 and 31502; Sec. 4007(b) of Pub. L. 102–240 (105 Stat. 2152); Sec. 114, Pub. L. 103–311 (108 Stat. 1673, 1677); and 49 CFR 1.73.

Source: 35 FR 6460, Apr. 22, 1970, unless otherwise noted.

Editorial Note: Nomenclature changes to part 391 appear at 66 FR 49873, Oct. 1, 2001.

Subpart A—General

§ 391.1 Scope of the rules in this part; additional qualifications; duties of carrier-drivers.

(a) The rules in this part establish minimum qualifications for persons who drive commercial motor vehicles as, for, or on behalf of motor carriers. The rules in this part also establish minimum duties of motor carriers with respect to the qualifications of their drivers.

(b) A motor carrier who employs himself/herself as a driver must comply with both the rules in this part that apply to motor carriers and the rules in this part that apply to drivers.

[35 FR 6460, Apr. 22, 1970, as amended at 53 FR 18057, May 19, 1988; 60 FR 38744, July 28, 1995]

§ 391.2 General exemptions.

(a) Farm custom operation. The rules in this part do not apply to a driver who drives a commercial motor vehicle controlled and operated by a person engaged in custom-harvesting operations, if the commercial motor vehicle is used to—

(1) Transport farm machinery, supplies, or both, to or from a farm for custom-harvesting operations on a farm; or

(2) Transport custom-harvested crops to storage or market.

(b) Apiarian industries. The rules in this part do not apply to a driver who is operating a commercial motor vehicle controlled and operated by a beekeeper engaged in the seasonal transportation of bees.

(c) Certain farm vehicle drivers. The rules in this part do not apply to a farm vehicle driver except a farm vehicle driver who drives an articulated (combination) commercial motor vehicle, as defined in §390.5. (For limited exemptions for farm vehicle drivers of articulated commercial motor vehicles, see §391.67.)

[36 FR 24219, Dec. 22, 1971, as amended at 37 FR 26112, Dec. 8, 1972; 54 FR 12202, Mar. 24, 1989; 60 FR 38745, July 28, 1995; 61 FR 13346, Mar. 26, 1996; 61 FR 17253, Apr. 19, 1996]

Subpart B—Qualification and Disqualification of Drivers

§ 391.11 General qualifications of drivers.

(a) A person shall not drive a commercial motor vehicle unless he/she is qualified to drive a commercial motor vehicle. Except as provided in §391.63, a motor carrier shall not require or permit a person to drive a commercial motor vehicle unless that person is qualified to drive a commercial motor vehicle.

(b) Except as provided in subpart G of this part, a person is qualified to drive a motor vehicle if he/she—

(1) Is at least 21 years old;

(2) Can read and speak the English language sufficiently to converse with the general public, to understand highway traffic signs and signals in the English language, to respond to official inquiries, and to make entries on reports and records;

(3) Can, by reason of experience, training, or both, safely operate the type of commercial motor vehicle he/she drives;

(4) Is physically qualified to drive a commercial motor vehicle in accordance with subpart E—Physical Qualifications and Examinations of this part;

(5) Has a currently valid commercial motor vehicle operator's license issued only by one State or jurisdiction;

(6) Has prepared and furnished the motor carrier that employs him/her with the list of violations or the certificate as required by §391.27;

(7) Is not disqualified to drive a commercial motor vehicle under the rules in §391.15; and

(8) Has successfully completed a driver's road test and has been issued a certificate of driver's road test in accordance with §391.31, or has presented an operator's license or a certificate of road test which the motor carrier that employs him/her has accepted as equivalent to a road test in accordance with §391.33.

[35 FR 6460, Apr. 22, 1970, as amended at 35 FR 17420, Nov. 13, 1970; 35 FR 19181, Dec. 18, 1970; 36 FR 222, Jan. 7, 1971, 36 FR 24220, Dec. 22, 1971; 45 FR 46424, July 10, 1980; 52 FR 20589, June 1, 1987; 59 FR 60323, Nov. 23, 1994; 60 FR 38744, 38745, July 28, 1995; 63 FR 33276, June 18, 1998]

§ 391.13 Responsibilities of drivers.

In order to comply with the requirements of §392.9(a) and §393.9 of this subchapter, a motor carrier shall not require or permit a person to drive a commercial motor vehicle unless the person—

(a) Can, by reason of experience, training, or both, determine whether the cargo he/she transports (including baggage in a passenger-carrying commercial motor vehicle) has been properly located, distributed, and secured in or on the commercial motor vehicle he/she drives;

(b) Is familiar with methods and procedures for securing cargo in or on the commercial motor vehicle he/she drives.

[63 FR 33277, June 18, 1998]

§ 391.15 Disqualification of drivers.

(a) General. A driver who is disqualified shall not drive a commercial motor vehicle. A motor carrier shall not require or permit a driver who is disqualified to drive a commercial motor vehicle.

(b) Disqualification for loss of driving privileges. (1) A driver is disqualified for the duration of the driver's loss of his/her privilege to operate a commercial motor vehicle on public highways, either temporarily or permanently, by reason of the revocation, suspension, withdrawal, or denial of an operator's license, permit, or privilege, until that operator's license, permit, or privilege is restored by the authority that revoked, suspended, withdrew, or denied it.

(2) A driver who receives a notice that his/her license, permit, or privilege to operate a commercial motor vehicle has been revoked, suspended, or withdrawn shall notify the motor carrier that employs him/her of the contents of the notice before the end of the business day following the day the driver received it.

(c) Disqualification for criminal and other offenses—(1) General rule. A driver who is convicted of (or forfeits bond or collateral upon a charge of) a disqualifying offense specified in paragraph (c)(2) of this section is disqualified for the period of time specified in paragraph (c)(3) of this section, if—

(i) The offense was committed during on-duty time as defined in §395.2(a) of this subchapter or as otherwise specified; and

(ii) The driver is employed by a motor carrier or is engaged in activities that are in furtherance of a commercial enterprise in interstate, intrastate, or foreign commerce;

(2) Disqualifying offenses. The following offenses are disqualifying offenses:

(i) Driving a commercial motor vehicle while under the influence of alcohol. This shall include:

(A) Driving a commercial motor vehicle while the person's alcohol concentration is 0.04 percent or more;

(B) Driving under the influence of alcohol, as prescribed by State law; or

(C) Refusal to undergo such testing as is required by any State or jurisdiction in the enforcement of §391.15(c)(2)(i) (A) or (B), or §392.5(a)(2).

(ii) Driving a commercial motor vehicle under the influence of a 21 CFR 1308.11 Schedule I identified controlled substance, an amphetamine, a narcotic drug, a formulation of an amphetamine, or a derivative of a narcotic drug;

(iii) Transportation, possession, or unlawful use of a 21 CFR 1308.11 Schedule I identified controlled substance, amphetamines, narcotic drugs, formulations of an amphetamine, or derivatives of narcotic drugs while the driver is on duty, as the term on-duty time is defined in §395.2 of this subchapter;

(iv) Leaving the scene of an accident while operating a commercial motor vehicle; or

(v) A felony involving the use of a commercial motor vehicle.

(3) Duration of disqualification—(i) First offenders. A driver is disqualified for 1 year after the date of conviction or forfeiture of bond or collateral if, during the 3 years preceding that date, the driver was not convicted of, or did not forfeit bond or collateral upon a charge of an offense that would disqualify the driver under the rules of this section. Exemption. The period of disqualification is 6 months if the conviction or forfeiture of bond or collateral soley concerned the transportation or possession of substances named in paragraph (c)(2)(iii) of this section.

(ii) Subsequent offenders. A driver is disqualified for 3 years after the date of his/her conviction or forfeiture of bond or collateral if, during the 3 years preceding that date, he/she was convicted of, or forfeited bond or collateral upon a charge of, an offense that would disqualify him/her under the rules in this section.

(d) Disqualification for violation of out-of-service orders—(1) General rule. A driver who is convicted of violating an out-of-service order is disqualified for the period of time specified in paragraph (d)(2) of this section.

(2) Duration of disqualification for violation of out-of-service orders—(i) First violation. A driver is disqualified for not less than 90 days nor more than one year if the driver is convicted of a first violation of an out-of-service order.

(ii) Second violation. A driver is disqualified for not less than one year nor more than five years if, during any 10-year period, the driver is convicted of two violations of out-of-service orders in separate incidents.

(iii) Third or subsequent violation. A driver is disqualified for not less than three years nor more than five years if, during any 10-year period, the driver is convicted of three or more violations of out-of-service orders in separate incidents.

(iv) Special rule for hazardous materials and passenger offenses. A driver is disqualified for a period of not less than 180 days nor more than two years if the driver is convicted of a first violation of an out-of-service order while transporting hazardous materials required to be placarded under the Hazardous Materials Transportation Act (49 U.S.C. 5101 et seq.), or while operating commercial motor vehicles designed to transport more than 15 passengers, including the driver. A driver is disqualified for a period of not less than three years nor more than five years if, during any 10-year period, the driver is convicted of any subsequent violations of out-of-service orders, in separate incidents, while transporting hazardous materials required to be placarded under the Hazardous Materials Transportation Act, or while operating commercial motor vehicles designed to transport more than 15 passengers, including the driver.

[37 FR 24902, Nov. 23, 1972, as amended at 49 FR 44215, Nov. 5, 1984; 51 FR 8200, Mar. 10, 1986; 53 FR 18057, May 19, 1988; 53 FR 39051, Oct. 4, 1988; 54 FR 40788, Oct. 3, 1989; 59 FR 26028, May 18, 1994; 60 FR 38744, 38745, July 28, 1995; 62 FR 37152, July 11, 1997; 63 FR 33277, June 18, 1998]

Subpart C—Background and Character

§ 391.21 Application for employment.

(a) Except as provided in subpart G of this part, a person shall not drive a commercial motor vehicle unless he/she has completed and furnished the motor carrier that employs him/her with an application for employment that meets the requirements of paragraph (b) of this section.

(b) The application for employment shall be made on a form furnished by the motor carrier. Each application form must be completed by the applicant, must be signed by him/her, and must contain the following information:

(1) The name and address of the employing motor carrier;

(2) The applicant's name, address, date of birth, and social security number;

(3) The addresses at which the applicant has resided during the 3 years preceding the date on which the application is submitted;

(4) The date on which the application is submitted;

(5) The issuing State, number, and expiration date of each unexpired commercial motor vehicle operator's license or permit that has been issued to the applicant;

(6) The nature and extent of the applicant's experience in the operation of motor vehicles, including the type of equipment (such as buses, trucks, truck tractors, semitrailers, full trailers, and pole trailers) which he/she has operated;

(7) A list of all motor vehicle accidents in which the applicant was involved during the 3 years preceding the date the application is submitted, specifying the date and nature of each accident and any fatalities or personal injuries it caused;

(8) A list of all violations of motor vehicle laws or ordinances (other than violations involving only parking) of which the applicant was convicted or forfeited bond or collateral during the 3 years preceding the date the application is submitted;

(9) A statement setting forth in detail the facts and circumstances of any denial, revocation, or suspension of any license, permit, or privilege to operate a motor vehicle that has been issued to the applicant, or a statement that no such denial, revocation, or suspension has occurred;

(10)(i) A list of the names and addresses of the applicant's employers during the 3 years preceding the date the application is submitted,

(ii) The dates he or she was employed by that employer,

(iii) The reason for leaving the employ of that employer,

(iv) After October 29, 2004, whether the (A) Applicant was subject to the FMCSRs while employed by that previous employer,

(B) Job was designated as a safety sensitive function in any DOT regulated mode subject to alcohol and controlled substances testing requirements as required by 49 CFR part 40;

(11) For those drivers applying to operate a commercial motor vehicle as defined by Part 383 of this subchapter, a list of the names and addresses of the applicant's employers during the 7-year period preceding the 3 years contained in paragraph (b)(10) of this section for which the applicant was an operator of a commercial motor vehicle, together with the dates of employment and the reasons for leaving such employment; and

(12) The following certification and signature line, which must appear at the end of the application form and be signed by the applicant:

This certifies that this application was completed by me, and that all entries on it and information in it are true and complete to the best of my knowledge.

(Date) (Applicant's signature)

(c) A motor carrier may require an applicant to provide information in addition to the information required by paragraph (b) of this section on the application form.

(d) Before an application is submitted, the motor carrier must inform the applicant that the information he/she provides in accordance with paragraph (b)(10) of this section may be used, and the applicant's previous employers will be contacted, for the purpose of investigating the applicant's safety performance history information as required by paragraphs (d) and (e) of §391.23. The prospective employer must also notify the driver in writing of his/her due process rights as specified in §391.23(i) regarding information received as a result of these investigations.

[35 FR 6460, Apr. 22, 1970, as amended at 35 FR 17420, Nov. 13, 1970; 52 FR 20589, June 1, 1987; 60 FR 38744, July 28, 1995; 69 FR 16719, Mar. 30, 2004]

§ 391.23 Investigation and inquiries.

(a) Except as provided in subpart G of this part, each motor carrier shall make the following investigations and inquiries with respect to each driver it employs, other than a person who has been a regularly employed driver of the motor carrier for a continuous period which began before January 1, 1971:

(1) An inquiry into the driver's driving record during the preceding 3 years to the appropriate agency of every State in which the driver held a motor vehicle operator's license or permit during those 3 years; and

(2) An investigation of the driver's safety performance history with Department of Transportation regulated employers during the preceding three years.

(b) A copy of the driver record(s) obtained in response to the inquiry or inquiries to each State driver record agency required by paragraph (a)(1) of this section must be placed in the driver qualification file within 30 days of the date the driver's employment begins and be retained in compliance with §391.51. If no driving record exists from the State or States, the motor carrier must document a good faith effort to obtain such information, and certify that no record exists for that driver in that State. The inquiry to the State driver record agencies must be made in the form and manner each agency prescribes.

(c)(1) Replies to the investigations of the driver's safety performance history required by paragraph (a)(2) of this section, or documentation of good faith efforts to obtain the investigation data, must be placed in the driver investigation history file, after October 29, 2004, within 30 days of the date the driver's employment begins. Any period of time required to exercise the driver's due process rights to review the information received, request a previous employer to correct or include a rebuttal, is separate and apart from this 30-day requirement to document investigation of the driver safety performance history data.

(2) The investigation may consist of personal interviews, telephone interviews, letters, or any other method for investigating that the carrier deems appropriate. Each motor carrier must make a written record with respect to each previous employer contacted, or good faith efforts to do so. The record must include the previous employer's name and address, the date the previous employer was contacted, or the attempts made, and the information received about the driver from the previous employer. Failures to contact a previous employer, or of them to provide the required safety performance history information, must be documented. The record must be maintained pursuant to §391.53.

(3) Prospective employers should report failures of previous employers to respond to an investigation to the FMCSA following procedures specified at §386.12 of this chapter and keep a copy of such reports in the Driver Investigation file as part of documenting a good faith effort to obtain the required information.

(4) Exception. For a drivers with no previous employment experience working for a DOT regulated employer during the preceding three years, documentation that no investigation was possible must be placed in the driver history investigation file, after October 29, 2004, within the required 30 days of the date the driver's employment begins.

(d) The prospective motor carrier must investigate, at a minimum, the information listed in this paragraph from all previous employers of the applicant that employed the driver to operate a CMV within the previous three years. The investigation request must contain specific contact information on where the previous motor carrier employers should send the information requested.

(1) General driver identification and employment verification information.

(2) The data elements as specified in §390.15(b)(1) of this chapter for accidents involving the driver that occurred in the three-year period preceding the date of the employment application.

(i) Any accidents as defined by §390.5 of this chapter.

(ii) Any accidents the previous employer may wish to provide that are retained pursuant to §390.15(b)(2), or pursuant to the employer's internal policies for retaining more detailed minor accident information.

(e) In addition to the investigations required by paragraph (d) of this section, the prospective motor carrier employers must investigate the information listed below in this paragraph from all previous DOT regulated employers that employed the driver within the previous three years from the date of the employment application, in a safety-sensitive function that required alcohol and controlled substance testing specified by 49 CFR part 40.

(1) Whether, within the previous three years, the driver had violated the alcohol and controlled substances prohibitions under subpart B of part 382 of this chapter, or 49 CFR part 40.

(2) Whether the driver failed to undertake or complete a rehabilitation program prescribed by a substance abuse professional (SAP) pursuant to §382.605 of this chapter, or 49 CFR part 40, subpart O. If the previous employer does not know this information (e.g., an employer that terminated an employee who tested positive on a drug test), the prospective motor carrier must obtain documentation of the driver's successful completion of the SAP's referral directly from the driver.

(3) For a driver who had successfully completed a SAP's rehabilitation referral, and remained in the employ of the referring employer, information on whether the driver had the following testing violations subsequent to completion of a §382.605 or 49 CFR part 40, subpart O referral:

(i) Alcohol tests with a result of 0.04 or higher alcohol concentration;

(ii) Verified positive drug tests;

(iii) Refusals to be tested (including verified adulterated or substituted drug test results).

(f) A prospective motor carrier employer must provide to the previous employer the driver's written consent meeting the requirements of §40.321(b) for the release of the information in paragraph (e) of this section. If the driver refuses to provide this written consent, the prospective motor carrier employer must not permit the driver to operate a commercial motor vehicle for that motor carrier.

(g) After October 29, 2004, previous employers must:

(1) Respond to each request for the DOT defined information in paragraphs (d) and (e) of this section within 30 days after the request is received. If there is no safety performance history information to report for that driver, previous motor carrier employers are nonetheless required to send a response confirming the non-existence of any such data, including the driver identification information and dates of employment.

(2) Take all precautions reasonably necessary to ensure the accuracy of the records.

(3) Provide specific contact information in case a driver chooses to contact the previous employer regarding correction or rebuttal of the data.

(4) Keep a record of each request and the response for one year, including the date, the party to whom it was released, and a summary identifying what was provided.

(5) Exception. Until May 1, 2006, carriers need only provide information for accidents that occurred after April 29, 2003.

(h) The release of information under this section may take any form that reasonably ensures confidentiality, including letter, facsimile, or e-mail. The previous employer and its agents and insurers must take all precautions reasonably necessary to protect the driver safety performance history records from disclosure to any person not directly involved in forwarding the records, except the previous employer's insurer, except that the previous employer may not provide any alcohol or controlled substances information to the previous employer's insurer.

(i)(1) The prospective employer must expressly notify drivers with Department of Transportation regulated employment during the preceding three years—via the application form or other written document prior to any hiring decision—that he or she has the following rights regarding the investigative information that will be provided to the prospective employer pursuant to paragraphs (d) and (e) of this section:

(i) The right to review information provided by previous employers;

(ii) The right to have errors in the information corrected by the previous employer and for that previous employer to re-send the corrected information to the prospective employer;

(iii) The right to have a rebuttal statement attached to the alleged erroneous information, if the previous employer and the driver cannot agree on the accuracy of the information.

(2) Drivers who have previous Department of Transportation regulated employment history in the preceding three years, and wish to review previous employer-provided investigative information must submit a written request to the prospective employer, which may be done at any time, including when applying, or as late as 30 days after being employed or being notified of denial of employment. The prospective employer must provide this information to the applicant within five (5) business days of receiving the written request. If the prospective employer has not yet received the requested information from the previous employer(s), then the five-business days deadline will begin when the prospective employer receives the requested safety performance history information. If the driver has not arranged to pick up or receive the requested records within thirty (30) days of the prospective employer making them available, the prospective motor carrier may consider the driver to have waived his/her request to review the records.

(j)(1) Drivers wishing to request correction of erroneous information in records received pursuant to paragraph (i) of this section must send the request for the correction to the previous employer that provided the records to the prospective employer.

(2) After October 29, 2004, the previous employer must either correct and forward the information to the prospective motor carrier employer, or notify the driver within 15 days of receiving a driver's request to correct the data that it does not agree to correct the data. If the previous employer corrects and forwards the data as requested, that employer must also retain the corrected information as part of the driver's safety performance history record and provide it to subsequent prospective employers when requests for this information are received. If the previous employer corrects the data and forwards it to the prospective motor carrier employer, there is no need to notify the driver.

(3) Drivers wishing to rebut information in records received pursuant to paragraph (i) of this section must send the rebuttal to the previous employer with instructions to include the rebuttal in that driver's safety performance history.

(4) After October 29, 2004, within five business days of receiving a rebuttal from a driver, the previous employer must:

(i) Forward a copy of the rebuttal to the prospective motor carrier employer;

(ii) Append the rebuttal to the driver's information in the carrier's appropriate file, to be included as part of the response for any subsequent investigating prospective employers for the duration of the three-year data retention requirement.

(5) The driver may submit a rebuttal initially without a request for correction, or subsequent to a request for correction.

(6) The driver may report failures of previous employers to correct information or include the driver's rebuttal as part of the safety performance information, to the FMCSA following procedures specified at §386.12.

(k)(1) The prospective motor carrier employer must use the information described in paragraphs (d) and (e) of this section only as part of deciding whether to hire the driver.

(2) The prospective motor carrier employer, its agents and insurers must take all precautions reasonably necessary to protect the records from disclosure to any person not directly involved in deciding whether to hire the driver. The prospective motor carrier employer may not provide any alcohol or controlled substances information to the prospective motor carrier employer's insurer.

(l)(1) No action or proceeding for defamation, invasion of privacy, or interference with a contract that is based on the furnishing or use of information in accordance with this section may be brought against—

(i) A motor carrier investigating the information, described in paragraphs (d) and (e) of this section, of an individual under consideration for employment as a commercial motor vehicle driver,

(ii) A person who has provided such information; or

(iii) The agents or insurers of a person described in paragraph (l)(1)(i) or (ii) of this section, except insurers are not granted a limitation on liability for any alcohol and controlled substance information.

(2) The protections in paragraph (l)(1) of this section do not apply to persons who knowingly furnish false information, or who are not in compliance with the procedures specified for these investigations.

(Approved by the Office of Management and Budget under control number 2126–0004)

[35 FR 6460, Apr. 22, 1970, as amended at 35 FR 17420, Nov. 13, 1970; 69 FR 16720, Mar. 30, 2004]

§ 391.25 Annual inquiry and review of driving record.

(a) Except as provided in subpart G of this part, each motor carrier shall, at least once every 12 months, make an inquiry into the driving record of each driver it employs, covering at least the preceding 12 months, to the appropriate agency of every State in which the driver held a commercial motor vehicle operator's license or permit during the time period.

(b) Except as provided in subpart G of this part, each motor carrier shall, at least once every 12 months, review the driving record of each driver it employs to determine whether that driver meets minimum requirements for safe driving or is disqualified to drive a commercial motor vehicle pursuant to §391.15.

(1) The motor carrier must consider any evidence that the driver has violated any applicable Federal Motor Carrier Safety Regulations in this subchapter or Hazardous Materials Regulations (49 CFR chapter I, subchapter C).

(2) The motor carrier must consider the driver's accident record and any evidence that the driver has violated laws governing the operation of motor vehicles, and must give great weight to violations, such as speeding, reckless driving, and operating while under the influence of alcohol or drugs, that indicate that the driver has exhibited a disregard for the safety of the public.

(c) Recordkeeping. (1) A copy of the response from each State agency to the inquiry required by paragraph (a) of this section shall be maintained in the driver's qualification file.

(2) A note, including the name of the person who performed the review of the driving record required by paragraph (b) of this section and the date of such review, shall be maintained in the driver's qualification file.

[63 FR 33277, June 18, 1998]

§ 391.27 Record of violations.

(a) Except as provided in subpart G of this part, each motor carrier shall, at least once every 12 months, require each driver it employs to prepare and furnish it with a list of all violations of motor vehicle traffic laws and ordinances (other than violations involving only parking) of which the driver has been convicted or on account of which he/she has forfeited bond or collateral during the preceding 12 months.

(b) Each driver shall furnish the list required in accordance with paragraph (a) of this section. If the driver has not been convicted of, or forfeited bond or collateral on account of, any violation which must be listed, he/she shall so certify.

(c) The form of the driver's list or certification shall be prescribed by the motor carrier. The following form may be used to comply with this section:

Driver's Certification

I certify that the following is a true and complete list of traffic violations (other than parking violations) for which I have been convicted or forfeited bond or collateral during the past 12 months.

Date of conviction Offense

Location Type of motor vehicle operated

If no violations are listed above, I certify that I have not been convicted or forfeited bond or collateral on account of any violation required to be listed during the past 12 months.

(Date of certification) (Driver's signature)

(Motor carrier's name)

(Motor carrier's address)

(Reviewed by: Signature) (Title) ____________________________________

(d) The motor carrier shall retain the list or certificate required by this section, or a copy of it, in its files as part of the driver's qualification file.

(e) Drivers who have provided information required by §383.31 of this subchapter need not repeat that information in the annual list of violations required by this section.

[35 FR 6460, Apr. 22, 1970, as amended at 35 FR 17420, Nov. 13, 1970; 52 FR 20589, June 1, 1987; 60 FR 38745, July 28, 1995]

Subpart D—Tests

§ 391.31 Road test.

(a) Except as provided in subpart G, a person shall not drive a commercial motor vehicle unless he/she has first successfully completed a road test and has been issued a certificate of driver's road test in accordance with this section.

(b) The road test shall be given by the motor carrier or a person designated by it. However, a driver who is a motor carrier must be given the test by a person other than himself/herself. The test shall be given by a person who is competent to evaluate and determine whether the person who takes the test has demonstrated that he/she is capable of operating the commercial motor vehicle, and associated equipment, that the motor carrier intends to assign him/her.

(c) The road test must be of sufficient duration to enable the person who gives it to evaluate the skill of the person who takes it at handling the commercial motor vehicle, and associated equipment, that the motor carriers intends to assign to him/her. As a minimum, the person who takes the test must be tested, while operating the type of commercial motor vehicle the motor carrier intends to assign him/her, on his/her skill at performing each of the following operations:

(1) The pretrip inspection required by §392.7 of this subchapter;

(2) Coupling and uncoupling of combination units, if the equipment he/she may drive includes combination units;

(3) Placing the commercial motor vehicle in operation;

(4) Use of the commercial motor vehicle's controls and emergency equipment;

(5) Operating the commercial motor vehicle in traffic and while passing other motor vehicles;

(6) Turning the commercial motor vehicle;

(7) Braking, and slowing the commercial motor vehicle by means other than braking; and

(8) Backing and parking the commercial motor vehicle.

(d) The motor carrier shall provide a road test form on which the person who gives the test shall rate the performance of the person who takes it at each operation or activity which is a part of the test. After he/she completes the form, the person who gave the test shall sign it.

(e) If the road test is successfully completed, the person who gave it shall complete a certificate of driver's road test in substantially the form prescribed in paragraph (f) of this section.

(f) The form for the certificate of driver's road test is substantially as follows:

Certification of Road Test

Driver's

name____________________

Social

Security No____________________

Operator's

or Chauffeur's License

No____________________

State____________________

Type

of power unit ______ Type of trailer(s)____________________

If

passenger carrier, type of bus __________________________

This is to certify that the above-named driver was given a road test under my supervision on ______, 20__, consisting of approximately ___ miles of driving.

It is my considered opinion that this driver possesses sufficient driving skill to operate safely the type of commercial motor vehicle listed above.

(Signature of examiner) (Title) ____________________________________ (Organization and address of examiner)

(g) A copy of the certificate required by paragraph (e) of this section shall be given to the person who was examined. The motor carrier shall retain in the driver qualification file of the person who was examined—

(1) The original of the signed road test form required by paragraph (d) of this section; and

(2) The original, or a copy of, the certificate required by paragraph (e) of this section.

[35 FR 6460, Apr. 22, 1970, as amended at 36 FR 223, Jan. 7, 1971; 59 FR 8752, Feb. 23, 1994; 60 FR 38744, July 28, 1995]

§ 391.33 Equivalent of road test.

(a) In place of, and as equivalent to, the road test required by §391.31, a person who seeks to drive a commercial motor vehicle may present, and a motor carrier may accept—

(1) A valid Commercial Driver's License as defined in §383.5 of this subchapter, but not including double/triple trailer or tank vehicle endorsements, which has been issued to him/her to operate specific categories of commercial motor vehicles and which, under the laws of that State, licenses him/her after successful completion of a road test in a commercial motor vehicle of the type the motor carrier intends to assign to him/her; or

(2) A copy of a valid certificate of driver's road test issued to him/her pursuant to §391.31 within the preceding 3 years.

(b) If a driver presents, and a motor carrier accepts, a license or certificate as equivalent to the road test, the motor carrier shall retain a legible copy of the license or certificate in its files as part of the driver's qualification file.

(c) A motor carrier may require any person who presents a license or certificate as equivalent to the road test to take a road test or any other test of his/her driving skill as a condition to his/her employment as a driver.

[35 FR 6460, Apr. 22, 1970, as amended at 60 FR 38744, July 28, 1995; 63 FR 33277, June 18, 1998]

Subpart E—Physical Qualifications and Examinations

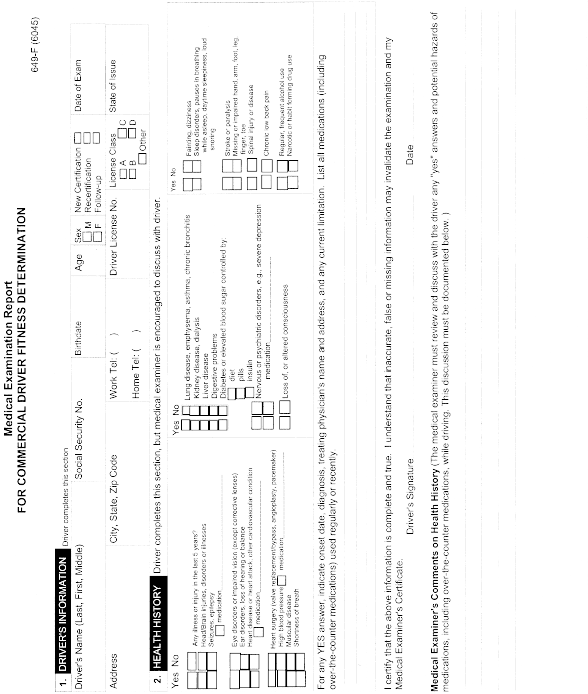

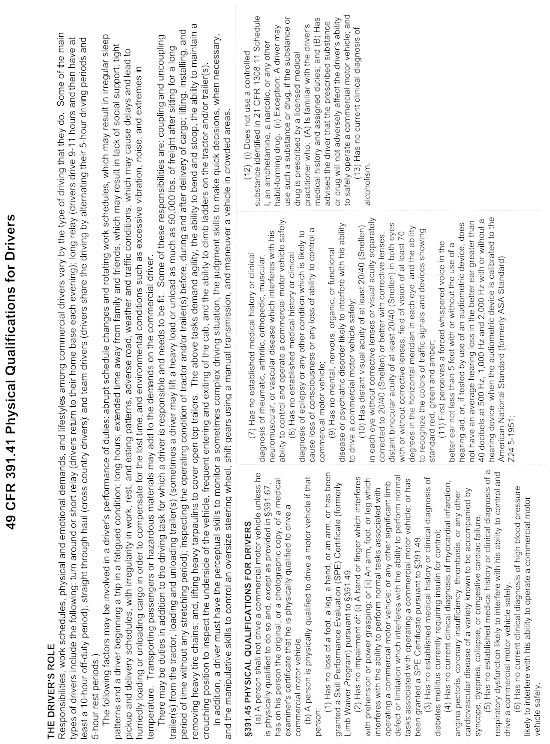

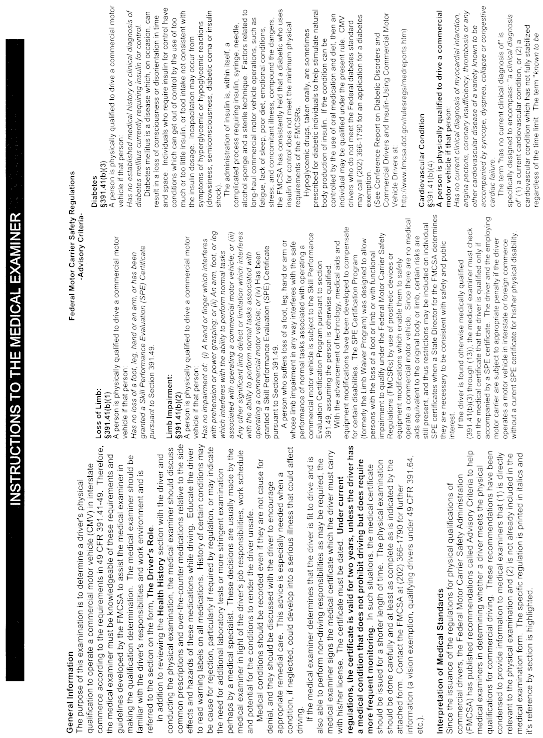

§ 391.41 Physical qualifications for drivers.

(a) A person shall not drive a commercial motor vehicle unless he/she is physically qualified to do so and, except as provided in §391.67, has on his/her person the original, or a photographic copy, of a medical examiner's certificate that he/she is physically qualified to drive a commercial motor vehicle.

The United States and Canada entered into a Reciprocity Agreement, effective March 30, 1999, recognizing that a Canadian commercial driver's license is proof of medical fitness to drive. Therefore, Canadian commercial motor vehicle (CMV) drivers are no longer required to have in their possession a medical examiner's certificate if the driver has been issued, and possesses, a valid commercial driver's license issued by a Canadian Province or Territory. However, Canadian drivers who are insulin-using diabetics, who have epilepsy, or who are hearing impaired as defined in §391.41(b)(11) are not qualified to drive CMVs in the United States. Furthermore, Canadian drivers who do not meet the medical fitness provisions of the Canadian National Safety Code for Motor Carriers but who have been issued a waiver by one of the Canadian Provinces or Territories are not qualified to drive CMVs in the United States.

(b) A person is physically qualified to drive a commercial motor vehicle if that person—

(1) Has no loss of a foot, a leg, a hand, or an arm, or has been granted a skill performance evaluation certificate pursuant to §391.49;

(2) Has no impairment of:

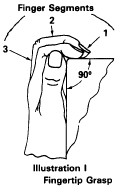

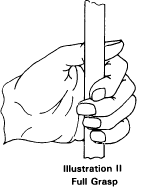

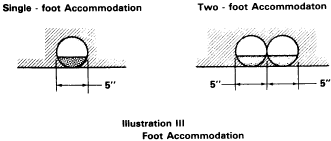

(i) A hand or finger which interferes with prehension or power grasping; or

(ii) An arm, foot, or leg which interferes with the ability to perform normal tasks associated with operating a commercial motor vehicle; or any other significant limb defect or limitation which interferes with the ability to perform normal tasks associated with operating a commercial motor vehicle; or has been granted a skill performance evaluation certificate pursuant to §391.49.

(3) Has no established medical history or clinical diagnosis of diabetes mellitus currently requiring insulin for control;

(4) Has no current clinical diagnosis of myocardial infarction, angina pectoris, coronary insufficiency, thrombosis, or any other cardiovascular disease of a variety known to be accompanied by syncope, dyspnea, collapse, or congestive cardiac failure.

(5) Has no established medical history or clinical diagnosis of a respiratory dysfunction likely to interfere with his/her ability to control and drive a commercial motor vehicle safely;