FGIS 998 Questionnaire for Proposed Dioverter Type Mechanical Sam

Reporting and Recordkeeping Requirements (US Grain Standards Act and Agricultural Marketing Act of 1946)

fgis-998.xls

Reporting and Recordkeeping Requirements - Private Sector

OMB: 0581-0309

⚠️ Notice: This form may be outdated. More recent filings and information on OMB 0581-0309 can be found here:

Document [xlsx]

Download: xlsx | pdf

Instructions

Overview

FGIS-998Instructions

Sheet 1: FGIS-998

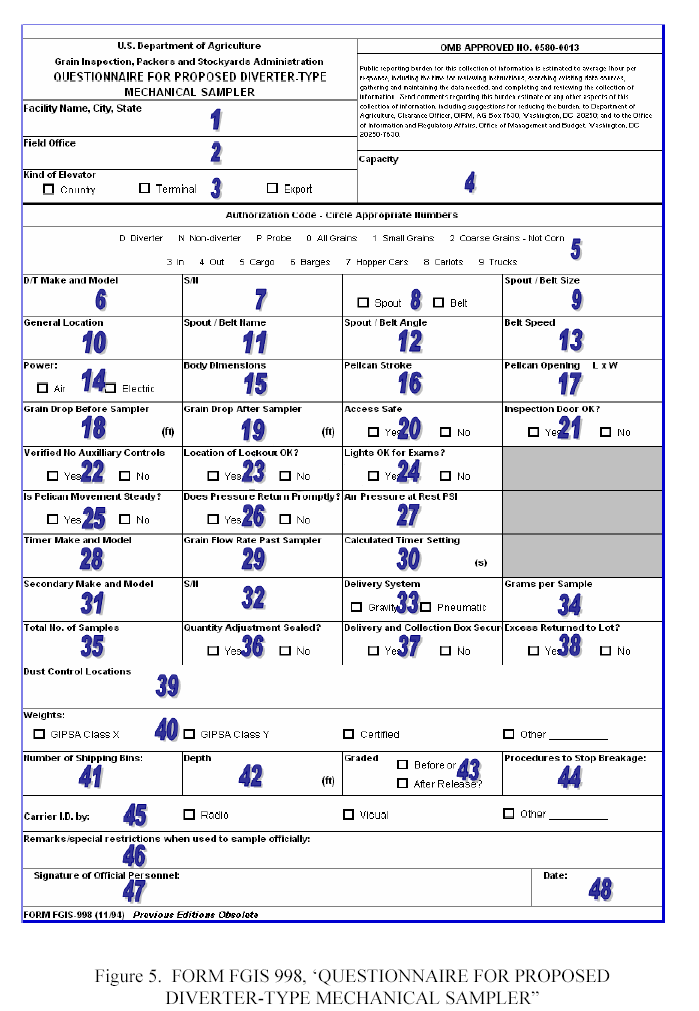

| U.S. Department of Agriculture | OMB APPROVED NO. 0580-0013 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Grain Inspection, Packers and Stockyards Administration |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| QUESTIONNAIRE FOR PROPOSED DIVERTER-TYPE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| MECHANICAL SAMPLER | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Facility Name, City, State | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Field Office | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Kind of Elevator | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Authorization Code - Circle Appropriate Numbers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D Diverter N Non-diverter P Probe 0 All Grains 1 Small Grains 2 Coarse Grains - Not Corn | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 In 4 Out 5 Cargo 6 Barges 7 Hopper Cars 8 Carlots 9 Trucks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D/T Make and Model | S/N | Spout / Belt Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| General Location | Spout / Belt Name | Spout / Belt Angle | Belt Speed | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Power: | Body Dimensions | Pelican Stroke | Pelican Opening L x W | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Grain Drop Before Sampler | Grain Drop After Sampler | Access Safe | Inspection Door OK? | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| (ft) | (ft) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Verified No Auxilliary Controls | Location of Lockout OK? | Lights OK for Exams? | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Is Pelican Movement Steady? | Does Pressure Return Promptly? | Air Pressure at Rest PSI | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Timer Make and Model | Grain Flow Rate Past Sampler | Calculated Timer Setting | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| (s) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Secondary Make and Model | S/N | Delivery System | Grams per Sample | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Total No. of Samples | Quantity Adjustment Sealed? | Delivery and Collection Box Secure? | Excess Returned to Lot? | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dust Control Locations | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Weights: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| NO SCALE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Number of Shipping Bins: | Depth | Graded | Procedures to Stop Breakage: | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| (ft) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Remarks/special restrictions when used to sample officially: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Signature of Official Personnel: | Date: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FORM FGIS-998 (7/04) Previous edition may be used. Expires January 2015 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sheet 2: Instructions

|

||||||||||||

| DIRECTIONS FOR COMPLETING QUESTIONNAIRE | ||||||||||||

| 1. Facility name, city, and state. | ||||||||||||

| 2. Name of FGIS field office. | ||||||||||||

| 3. Check the box indicating kind of elevator. | ||||||||||||

| 4. Storage capacity of elevator. | ||||||||||||

| 5. Authorization Code-circle the numbers that apply to the intended sampler use. | ||||||||||||

| 6. Sampler Make & Model; e.g., Gamet 6800S. | ||||||||||||

| 7. Sampler Serial Number. | ||||||||||||

| 8. Is the sampler in a spout or on a belt end? For spout samplers-diameter or length x width | ||||||||||||

| cross sectional measurements or; | ||||||||||||

| 9. Belt Size-width and depth of grain carried. | ||||||||||||

| 10. General location of sampler; e.g., Headhouse 6th Floor; or Gallery. | ||||||||||||

| 11. Spout/belt name; e.g., Scale #1 lower garner. | ||||||||||||

| 12. Spout angle-90_ is vertical. Belt Angle-0_ is horizontal. Show normal angle and max/min | ||||||||||||

| limits of travel, if angle can be varied. | ||||||||||||

| 13. Belt speed-measure with belt loaded. | ||||||||||||

| 14. Check the box showing type of power. | ||||||||||||

| 15. Body dimensions for the sampler. | ||||||||||||

| 16. Pelican stroke is the distance traveled from one side to the other. | ||||||||||||

| 17. Length and width of the pelican opening. | ||||||||||||

| 18. Distance in feet from release point. | ||||||||||||

| 19. Distance grain falls is used to estimate impact and breakage. For example, measure from | ||||||||||||

| sampler to bin bottom. | ||||||||||||

| 20. Is access to the sampler by approved ladder or stairs, and does the platform have an | ||||||||||||

| approved railing? | ||||||||||||

| 21. Are the inspection doors properly located on the sampler? Do they have appropriate seal | ||||||||||||

| hasps and hinges? | ||||||||||||

| 22. Check verified after you determine that the system controls have no bypasses, dump | ||||||||||||

| counters, timer interrupts, or programmable controllers. | ||||||||||||

| 23. Location of lockout ok-does the lockout provided meet FGIS requirements? | ||||||||||||

| 24. Light for examinations-can all exterior examination checks be made with lighting supplied? | ||||||||||||

| 25. For pneumatic/hydraulic samplers-is pressure sufficient to move the pelican across the | ||||||||||||

| stream of grain evenly, without lagging or slowing down. | ||||||||||||

| 26. For pneumatic/hydraulic samplers-pressure returns to maximum before next cut is initiated. | ||||||||||||

| 27. For pneumatic samplers-gauge pressure at rest. Maximum reached when no cuts are | ||||||||||||

| initiated. | ||||||||||||

| 28. Timer Make & Model; e.g., Eagle HP5 Model 9. | ||||||||||||

| 29. Flow past sampler should be figured out by timing a known amount, such as one scale draft, | ||||||||||||

| as it passes the sampler. | ||||||||||||

| 30. Calculate the timer setting in seconds based on grain flow rate past sampler. Also show | ||||||||||||

| whether this is based on a 200, 350, or 500 bushel sampling rate. | ||||||||||||

| 31. Secondary Sampler (divider) Make & Model; e.g., InterSystems MD300. | ||||||||||||

| 32. Secondary Sampler Serial Number. | ||||||||||||

| 33. Check box indicating type of sample delivery system. | ||||||||||||

| 34. Weight in grams received for the official sample. | ||||||||||||

| 35. Total number of samples needed for all interested parties. | ||||||||||||

| 36. Are the quantity adjustment features on secondary sampler fixed or sealed in place? | ||||||||||||

| 37. Is the sample delivery system secure from the air inlet to the collection box? | ||||||||||||

| 38. Is excess grain automatically returned from the secondary to the lot from which the sample | ||||||||||||

| was taken? | ||||||||||||

| 39. Location of dust collection ducts-are they located where they can affect the sample | ||||||||||||

| constituents? The measurements will serve as a record of approved duct work. | ||||||||||||

| 40. Weights-are weights official; i.e., supervised under the USGSA as Class X or Y-are weights | ||||||||||||

| Certified; i.e., supervised unofficially by a local organization-or are weights unofficial and | ||||||||||||

| not supervised, or not provided? | ||||||||||||

| 41. Shipping bins-number used. | ||||||||||||

| 42. Shipping bin depth(s). | ||||||||||||

| 43. Grading-will bin be held for grade or factor results before being released? | ||||||||||||

| 44. Procedures to stop breakage-will the bins require use of cushion level indicators, grain | ||||||||||||

| ladders, or baffles to reduce impact of grain and resulting breakage? | ||||||||||||

| 45. Carrier identification or stowage locations. | ||||||||||||

| 46. Special restrictions-any special procedural restrictions; e.g., weighback belt must be sealed, | ||||||||||||

| turnhead must be locked in position, cushion must be maintained in shipping bin, etc. | ||||||||||||

| 47. Name or signature of the official personnel who filled out the questionnaire. | ||||||||||||

| 48. Date information obtained. | ||||||||||||

| File Type | application/vnd.ms-excel |

| File Title | Questionnaire for Proposed... |

| Subject | EqHb |

| Author | phadyka |

| Last Modified By | ASGreenfield |

| File Modified | 2011-03-16 |

| File Created | 2003-06-19 |

© 2026 OMB.report | Privacy Policy