FGIS-904 Laboratory Scale Test

Reporting and Recordkeeping Requirements (US Grain Standards Act and Agricultural Marketing Act of 1946)

fgis-904.xls

Reporting and Recordkeeping Requirements - State, Local, Tribal

OMB: 0581-0309

⚠️ Notice: This form may be outdated. More recent filings and information on OMB 0581-0309 can be found here:

Document [xlsx]

Download: xlsx | pdf

Instructions

Overview

FGIS-904Instructions

Sheet 1: FGIS-904

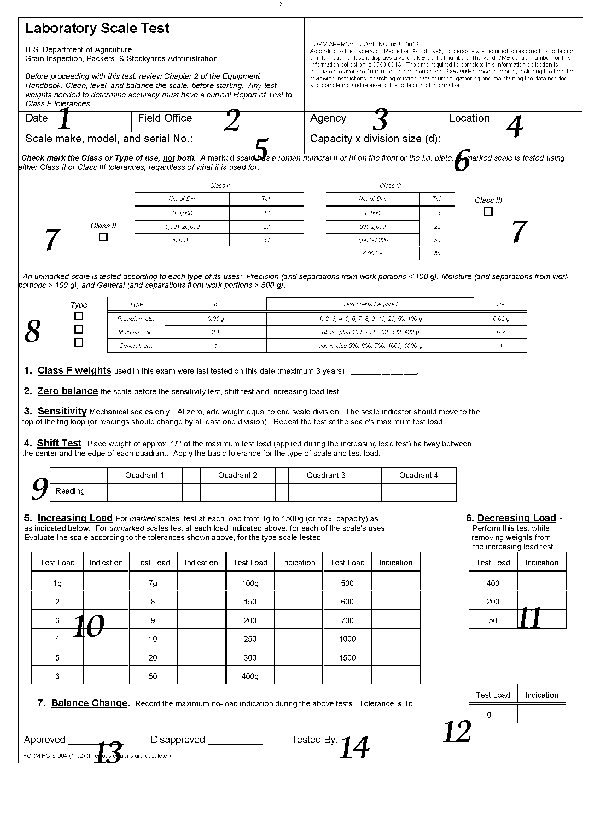

| Laboratory Scale Test | ||||||||||||||||||||||||||||||||||||||||||||

| U.S. Department of Agriculture | ||||||||||||||||||||||||||||||||||||||||||||

| Grain Inspection, Packers & Stockyards Administration | ||||||||||||||||||||||||||||||||||||||||||||

| Before proceeding with this test, review Chapter 2 of the Equipment Handbook. Clean, level, and balance the scale, before starting. Any test weights needed to determine accuracy must have a current Report of Test to Class F tolerances. | ||||||||||||||||||||||||||||||||||||||||||||

| Date | Field Office | Agency | Location | |||||||||||||||||||||||||||||||||||||||||

| Scale make, model, and serial No.: | Capacity x | division size (d): | ||||||||||||||||||||||||||||||||||||||||||

| Check mark the Class or Type of use, not both. A marked scale has a roman numeral II or III on the front or the i.d. plate. A marked scale is tested using either Class II or Class III tolerances, regardless of what it is used for. | ||||||||||||||||||||||||||||||||||||||||||||

| Class II | Class III | |||||||||||||||||||||||||||||||||||||||||||

| No. of Div. | Tol. | No. of Div. | Tol. | |||||||||||||||||||||||||||||||||||||||||

| Class II | 0-5,000 | 1d | 0-500 | 1d | Class III | |||||||||||||||||||||||||||||||||||||||

| 5,001-20,000 | 2d | 501-2,000 | 2d | |||||||||||||||||||||||||||||||||||||||||

| 20,001+ | 3d | 2,001-4,000 | 3d | |||||||||||||||||||||||||||||||||||||||||

| 4,001+ | 5d | |||||||||||||||||||||||||||||||||||||||||||

| An unmarked scale is tested according to each type of its uses: Precision (and separations from work portions ≤ 100 g), Moisture (and separations from work portions > 100 g), and General (and separations from work portions > 500 g). | ||||||||||||||||||||||||||||||||||||||||||||

| Type | d | Test Loads Required | Tol. | |||||||||||||||||||||||||||||||||||||||||

| Precision, etc. | 0.01 g | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 20, 50, 100 g | 0.02 g | |||||||||||||||||||||||||||||||||||||||||

| Moisture, etc. | 0.1 | above plus 150, 200, 250, 300, 400 g | 0.2 | |||||||||||||||||||||||||||||||||||||||||

| General, etc. | 1 | above plus 500, 600, 700, 1000, 1500 g | 1 | |||||||||||||||||||||||||||||||||||||||||

| 1. Class F weights used in this exam were last tested on this date (maximum 3 years) | ||||||||||||||||||||||||||||||||||||||||||||

| 2. Zero balance the scale before the sensitivity test, shift test and increasing load test. | ||||||||||||||||||||||||||||||||||||||||||||

| 3. Sensitivity Mechanical scales only. At zero, add weight equal to one scale division. The scale indicator should move to the top of the trig loop (or readings should change by at least one division). Repeat the test at the scale's maximum test load | ||||||||||||||||||||||||||||||||||||||||||||

| 1 | ||||||||||||||||||||||||||||||||||||||||||||

| 4. Shift Test Place weight of approx. 1/2 of the maximum test load (applied during the increasing load test) halfway between the center and the edge of each quadrant. Apply the basic tolerance for the type of scale and test load. | 4 | 2 | ||||||||||||||||||||||||||||||||||||||||||

| 3 | ||||||||||||||||||||||||||||||||||||||||||||

| Quadrant 1 | Quadrant 2 | Quadrant 3 | Quadrant 4 | 1 | ||||||||||||||||||||||||||||||||||||||||

| Reading | 4 | 2 | ||||||||||||||||||||||||||||||||||||||||||

| 3 | ||||||||||||||||||||||||||||||||||||||||||||

| 5. Increasing Load For marked scales, test at each load from 1 g to 1500 g (or max. capacity) as indicated below. For unmarked scales test at each load indicated above, for each of the scale's uses. Evaluate the scale according |

||||||||||||||||||||||||||||||||||||||||||||

| to the tolerances shown above for the type of scale tested. |

|

|||||||||||||||||||||||||||||||||||||||||||

| Test Load | Indication | Test Load | Indication | Test Load | Indication | Test Load | Indication | |||||||||||||||||||||||||||||||||||||

| 1g | 7g | 100g | 500 | |||||||||||||||||||||||||||||||||||||||||

| 2 | 8 | 150 | 600 | Test Load | Indication | |||||||||||||||||||||||||||||||||||||||

| 3 | 9 | 200 | 700 | 400 | ||||||||||||||||||||||||||||||||||||||||

| 4 | 10 | 250 | 1000 | 200 | ||||||||||||||||||||||||||||||||||||||||

| 5 | 20 | 300 | 1500 | 50 | ||||||||||||||||||||||||||||||||||||||||

| 6 | 50 | 400 | ||||||||||||||||||||||||||||||||||||||||||

| Test Load | Indication | |||||||||||||||||||||||||||||||||||||||||||

| 7. Balance Change. Record the maximum no-load indication during the above tests. Tolerance is 1d. | 0 | |||||||||||||||||||||||||||||||||||||||||||

| Approved Disapproved | Tested by: | |||||||||||||||||||||||||||||||||||||||||||

| Form FGIS-904 (1-02) (Previous editions are obsolete.) | Expires January 2015 | |||||||||||||||||||||||||||||||||||||||||||

Sheet 2: Instructions

|

INSTRUCTIONS FOR COMPLETING FORM FGIS-904, | |||||||||||

| "LABORATORY SCALE TEST" | ||||||||||||

| 1. Date the test was performed. | ||||||||||||

| 2. Field office that performed or supervised the performance of the test. | ||||||||||||

| 3. Agency that performed the test, when applicable. | ||||||||||||

| 4. Location of the field office or agency that performed the test. | ||||||||||||

| 5. Name of the manufacturer, model number, and scale serial number. | ||||||||||||

| 6. Maximum rated scale capacity and the minimum scale division size. | ||||||||||||

| 7. Indicate with a check mark if the scale is marked with an accuracy class, such as Class II. | ||||||||||||

| 8. Indicate with one or more check marks the application of the unmarked scale; precision, | ||||||||||||

| moisture, or general. | ||||||||||||

| 9. Record scale indications from the shift test. | ||||||||||||

| 10. Increasing Load Test - Test marked scales at each test load indicated up to 1,500 g or | ||||||||||||

| capacity, whichever is less. Test unmarked scales at each test load shown in the table checked off in item 8, above. | ||||||||||||

| 11. Decreasing Load Test - Test marked scales at each load indicated, as appropriate. Test | ||||||||||||

| unmarked scales at approximately ½ the maximum test load used in the increasing load test. | ||||||||||||

| If the scale is mechanical, do not perform the test or complete this portion. | ||||||||||||

| 12. Balance Change - Scale indication with zero load at completion of testing must be £ 1 division. | ||||||||||||

| 13. Has the scale met all requirements of the pre-test inspection as well as each (all) of the | ||||||||||||

| accuracy tests? | ||||||||||||

| 14. Name of the person who performed this test. | ||||||||||||

| FAX Number (202) 720-1015 | ||||||||||||

| GIPSA, Field Management Division | ||||||||||||

| Return Form To: Retain in official file. | ||||||||||||

| Any Questions Call: Local GIPSA field Office. | ||||||||||||

| File Type | application/vnd.ms-excel |

| File Title | Laboratory Scale Test |

| Subject | EqHB |

| Author | Phadyka |

| Last Modified By | ASGreenfield |

| File Modified | 2011-04-22 |

| File Created | 2003-05-01 |

© 2026 OMB.report | Privacy Policy