FGIS-936 Sampler Condition Report

Reporting and Recordkeeping Requirements (US Grain Standards Act and Agricultural Marketing Act of 1946)

fgis-936.xls

Reporting and Recordkeeping Requirements - State, Local, Tribal

OMB: 0581-0309

⚠️ Notice: This form may be outdated. More recent filings and information on OMB 0581-0309 can be found here:

Document [xlsx]

Download: xlsx | pdf

Front Instructions

Back

Back Instructions

Overview

FrontFront Instructions

Back

Back Instructions

Sheet 1: Front

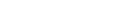

| OMB NO.: 0580-0013 | |||||||||||

| U.S. DEPARTMENT OF AGRICULTURE | (See reverse) | ||||||||||

| GRAIN INSPECTION, PACKERS AND STOCKYARDS ADMINISTRATION | |||||||||||

| FEDERAL GRAIN INSPECTION SERVICE | |||||||||||

| SAMPLER CONDITION REPORT | |||||||||||

| NAME OF ELEVATOR, CITY, AND STATE | DATE EXAMINED | FIELD OFFICE | |||||||||

| NAME OF OFFICIAL AGENCY | |||||||||||

| *INSTRUCTIONS TO EXAMINER: For a six month examination fill out the front of this form. For a complete grain test, including initial sampler test, fill out both sides of this form and send the original to the FGIS Field Office. Explain "FAIL" items in detail. If the sampler is not being used, indicate that fact under "Remarks" and prepare a report before the sampler is put into use. | |||||||||||

| PRIMARY SAMPLER | SECONDARY SAMPLERS | ||||||||||

| BRAND/MODEL | SERIAL NO. | BRAND/MODEL | SERIAL NO. | ||||||||

| GRAIN FLOW RATE (Past Sampler) | SAMPLING INTERVAL (Cycle Time) | BRAND/MODEL | SERIAL NO. | ||||||||

| SECTION 1 -- ALL SAMPLERS | SECTION 2 -- D/T SAMPLERS | ||||||||||

| ITEMS EXAMINED PASS / FAIL | ITEMS EXAMINED | PASS / FAIL | |||||||||

| Lighting around sampler | Pelican speed approx. 0.5 m/s | ||||||||||

| Safe access to areas | Pelican dust seals (interior) | ||||||||||

| Safe access to inside of devices | Pelican go-no-go gauge | ||||||||||

| Lockouts (safety switches) | Pelican cuts entire grain stream | ||||||||||

| Cleanliness of area | Condition of excess sample return leg or belt | ||||||||||

| Cleanliness of device | Timer set correctly | ||||||||||

| Lubrication (if required) | SECTION 3 -- TRUCK PROBES | ||||||||||

| Panel board indicator lights | ITEMS EXAMINED PASS / FAIL | ||||||||||

| Air or hydraulic pressure | Tip not bent/damaged | ||||||||||

| Delivery tube secure | Tip vacuum check with paper | ||||||||||

| Delivery tube air inlet secure | Hydraulic oil level OK | ||||||||||

| Collection box secure | Vacuum adjustments sealed | ||||||||||

| Collection box screen clean | Sample size | ||||||||||

| Sampler not modified or repaired | Collection box seal | ||||||||||

| Seals/padlocks in place | Delivery tube condition | ||||||||||

| Inspected By: (LI or ACG) | Vacuum pressure if known: | ||||||||||

| Reviewed By: (ACG) |

|||||||||||

| Form FGIS-936 (5-03) Previous editions are obsolete. Expires January 2015 | |||||||||||

Sheet 2: Front Instructions

|

||||||||||

| INSTRUCTIONS FOR COMPLETING | ||||||||||

| FORM FGIS-936, "SAMPLER CONDITION REPORT," (FRONT) | ||||||||||

| 1. Name of the elevator, city, and state. | ||||||||||

| 2. Date examination was done. | ||||||||||

| 3. Name of FGIS field office in charge of the circuit. | ||||||||||

| 4. Name of the official agency that does original inspections at the facility. | ||||||||||

| 5. Brand name and type of primary (diverter-type sampler) or probe-type sampler being | ||||||||||

| examined and tested. Are they of a type approved by FGIS? | ||||||||||

| 6. Serial number of primary diverter-type or probe-type sampler. | ||||||||||

| 7. Brand name of secondary sampler. | ||||||||||

| 8. Serial number of secondary sampler. | ||||||||||

| 9. Calculate the maximum flow of spout or belt on which the sampler is installed. | ||||||||||

| 10. Sampling Interval-Read from the timer. | ||||||||||

| 11. Type of carriers or lots the system will sample. | ||||||||||

| Section 1 – All Samplers | ||||||||||

| 12. Lighting should be approximately 30 footcandles (general task lighting). | ||||||||||

| 13. Safe access includes approved stairs, fixed ladders, platforms, and railings. | ||||||||||

| 14. Safe access to the inside of the housing or hood without endangering the examiner. | ||||||||||

| 15. Lockout switches must be present and meet requirements. | ||||||||||

| 16. Cleanliness of the area-overhead, floor, stairs. | ||||||||||

| 17. Cleanliness/condition of primary-check for plugs, leaks, dust, sprouted grain, broken | ||||||||||

| hasps/hinges, wiring. | ||||||||||

| 18. Lubrication-Grease or oil leaks. | ||||||||||

| 19. Panel lights-Use radio or phone (if needed) to ensure that the power and traverse lights work | ||||||||||

| properly. Have any changes been made in the wiring? | ||||||||||

| 20. Air or hydraulic pressure-Is there enough? Record the gage pressure, if available. | ||||||||||

| 21. Delivery tube must be secure from loss or introduction of material. | ||||||||||

| 22. Delivery tube-Pneumatic systems must have a guard over the air supply inlet. | ||||||||||

| 23. Collection box-If not continuously attended, must be secure at inlet and outlet. | ||||||||||

| 24. Collection boxes that have a screen must be maintained in a clean condition. | ||||||||||

| 25. Sampler not Modified-For this check, good installation records are essential. | ||||||||||

| 26. Seals-Were the security seals on inspection doors found intact? Was the delivery tube found | ||||||||||

| secure? | ||||||||||

| Section 2 – D/T Samplers | ||||||||||

| 27. Pelican speed must be uniform with no slow spots. Speed can be estimated. | ||||||||||

| 28. Pelican dust seals-Must be present, not torn, and must seal-off the pelican, no air gap. | ||||||||||

| 29. Pelican Go-no-go Gauge-Use it to ensure the opening is between 3/4 and 7/8 inch wide | ||||||||||

| along its entire length. | ||||||||||

| 3 The reverse of Form FGIS-936 is used for performing a test (grain test). Instructions for completing the reverse | ||||||||||

| are contained in Chapter 5, Tests. | ||||||||||

| 30. Pelican cuts stream-If practical, observe a cut to see that the pelican is sampling the entire | ||||||||||

| stream, and that it does not back up from excess grain. | ||||||||||

| 31. Condition of excess sample return-Check if it is leaking, infested, or backing up. | ||||||||||

| 32. Timer-Does the timer setting match the documented setting (required). Use a stopwatch or | ||||||||||

| read the timer; do not rely on posted signs or old records. | ||||||||||

| Section 3 – Truck Probes | ||||||||||

| 33. Probe tip must be in good condition. | ||||||||||

| 34. For core-type probes, a small piece of paper is placed over the tip to check the air | ||||||||||

| supply/vacuum balance. The paper should not fall off or be sucked into the tip. | ||||||||||

| 35. Check levels if possible. | ||||||||||

| 36. After adjustment, air supply/vacuum balance should not be changed. If it is possible to seal | ||||||||||

| them or record settings, this provides assurance that they remain correctly adjusted. | ||||||||||

| 37. Is the sample size adequate? Has it changed? | ||||||||||

| 38. If the collection box has a gasket, is it in good condition with no air leaks. | ||||||||||

| 39. Is the delivery tube in good condition, | ||||||||||

| 40. If a gage reading is available, it can indicate leaks or misadjustment. | ||||||||||

| Name of Inspector | ||||||||||

| 41. Show the name of the inspector who completed the examination. If any item is | ||||||||||

| unsatisfactory, the sampler is not acceptable. Keep the not acceptable Form FGIS-936 as a | ||||||||||

| record. Even if the facility brings the sampler into compliance immediately, complete | ||||||||||

| another form. | ||||||||||

| 42. An ACG should review some forms for correctness when possible. Any questionable | ||||||||||

| information or remarks must be verified to be accurate. | ||||||||||

Sheet 3: Back

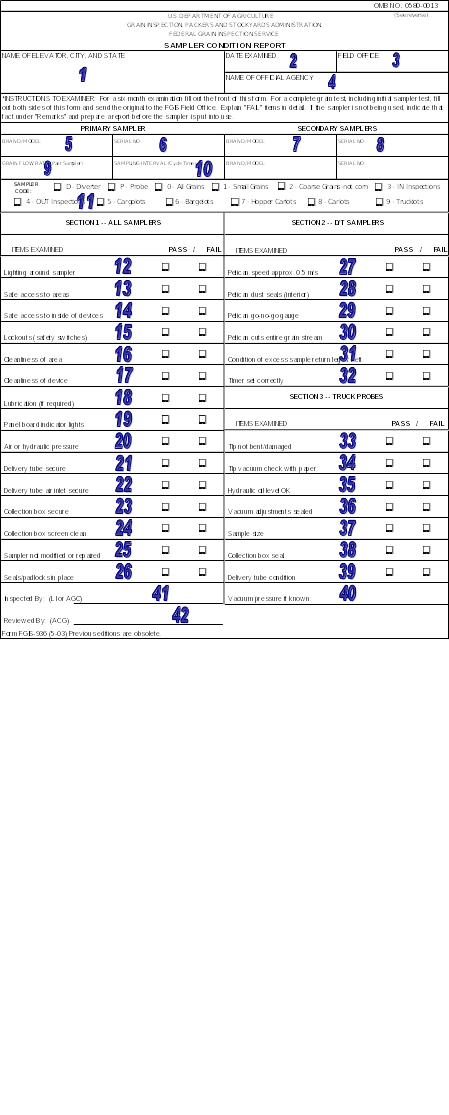

| According to the Paperwork Reduction Act of 1995, an agency may not conduct or sponsor, and a person is not required to respond to a collection of information unless it displays a valid OMB control number. The valid OMB control number for this information collection is 0580-0013. The time required to complete this information collection is estimated to average 45 minutes per response, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information. | |||||||||||

| GRAIN TEST DATA | |||||||||||

| SAMPLING METHOD USED FOR STANDARD: | for Mechanical Truck Probes only | ||||||||||

| Date | Sample No. | Type | DKG | BCFM | |||||||

| COMMODITY: | Test Unit | ||||||||||

| 6 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 7 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 8 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 9 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 10 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 11 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| 12 | Standard | ||||||||||

| HP | |||||||||||

| Date | Sample No. | Type | DKG | BCFM | Test Unit | ||||||

| Test Unit | 13 | Standard | |||||||||

| 1 | Standard | HP | |||||||||

| Test Unit | |||||||||||

| Difference | 14 | Standard | |||||||||

| Tolerance | HP | ||||||||||

| Result - One test lot | Test Unit | ||||||||||

| 15 | Standard | ||||||||||

| HP | |||||||||||

| Test Unit | |||||||||||

| Date | Sample No. | Type | DKG | BCFM | 16 | Standard | |||||

| Test Unit | HP | ||||||||||

| 2 | Standard | Test Unit | |||||||||

| 17 | Standard | ||||||||||

| Test Unit | HP | ||||||||||

| 3 | Standard | Test Unit | |||||||||

| 18 | Standard | ||||||||||

| Test Unit | HP | ||||||||||

| 4 | Standard | Test Unit | |||||||||

| 19 | Standard | ||||||||||

| Test Unit | HP | ||||||||||

| 5 | Standard | Test Unit | |||||||||

| 20 | Standard | ||||||||||

| Test Unit MDS* | HP | ||||||||||

| Tolerance | Test Unit MDS* | ||||||||||

| Result - Five test lots | Hand Probe MDS* | ||||||||||

| Regression or T-test | |||||||||||

| *Mean Deviation from Standard | |||||||||||

| Form FGIS-936 (5-03) Previous editions are obsolete. | |||||||||||

Sheet 4: Back Instructions

|

INSTRUCTIONS FOR COMPLETING | |||||||||

| FORM FGIS-936, "SAMPLER CONDITION REPORT," | ||||||||||

| (REVERSE) | ||||||||||

| Use the reverse of Form FGIS-936 for testing (grain test). Always precede a test with an | ||||||||||

| examination, documented on the front of the form. If the examination and the test are not | ||||||||||

| recorded on the same sheet, properly identify the test by filling in the Name of Elevator, etc., | ||||||||||

| Items 1 through 11, 41 and 42 on the front as described in Chapter 4, Examinations. | ||||||||||

| 1. Method of sampling-What was the standard? If a special location or procedure was used, | ||||||||||

| explain in remarks. | ||||||||||

| 2. Specify grain. | ||||||||||

| 3. Remarks-Summary of important observations on the sampling system and testing | ||||||||||

| information. Was the test run at normal load-out speed, air pressure, belt depth, etc.? Was | ||||||||||

| dust collection turned on? Shipping bins checked? | ||||||||||

| 4. Enter date sampled. | ||||||||||

| 5. One factor is required, but additional factors may be tested. If necessary, the field office | ||||||||||

| manager shall decide the appropriate factors. Test weight is not to be used as the only factor. | ||||||||||

| Report percentages to 2 decimal places. | ||||||||||

| 6. Mathematical average of the mechanical sampler results, average of the standard results, | ||||||||||

| average of other results. Round percentages to 2 places. | ||||||||||

| 7. Tolerance or allowable deviation = 0.10 x (standard average). | ||||||||||

| 8. Mark the appropriate box for each factor tested. If more than one factor was tested, each of | ||||||||||

| them must be within tolerance for a pass. A factor is considered within tolerance when the | ||||||||||

| mean deviation from the standard is less than or equal to the allowable deviation for the | ||||||||||

| applicable factor(s). | ||||||||||

| 9. If 5 test lots are to be evaluated, continue entering sample data. | ||||||||||

| 10. If testing a mechanical truck probe, continue entering sample data for 20 test lots. | ||||||||||

| 11. Truck probe performance is evaluated against a standard and a hand probe, using either a | ||||||||||

| regression or a T-test. Technical Service Division provides support for the analysis. | ||||||||||

| File Type | application/vnd.ms-excel |

| File Title | Sampler Condition Report |

| Subject | MSSH |

| Author | PHadyka |

| Last Modified By | ASGreenfield |

| File Modified | 2011-04-22 |

| File Created | 2001-02-10 |

© 2026 OMB.report | Privacy Policy