1684ss20

1684ss20.docx

Emissions Certification and Compliance Requirements for Nonroad Compression-ignition Engines and On-highway Heavy Duty Engines (Renewal)

OMB: 2060-0287

Supporting Statement

for

Information Collection Request

Emissions Certification and Compliance Requirements for

Nonroad Compression-ignition Engines and On-highway Heavy Duty Engines

(Revision)

EPA ICR Number 1684.20 OMB Control Number 2060-0287

42 USC 7521 § 206 (b)(1)

42 USC 7521 § 207(b)

42 USC 7521 § 213(d)

42 USC 7521 § 217

40 CFR Parts 85-86, 89 and 94

40 CFR Part 1027, 1033

40 CFR Parts 1036-1037

40 CFR Part 1039

40 CFR Part 1042-1043

40 CFR Part 1045

40 CFR Part 1060

40 CFR Part 1065-1066

40 CFR Part 1068

49 CFR 535

August 2018

Certification and Compliance Division

Office of Transportation and Air Quality

Office of Air and Radiation

U.S. Environmental Protection Agency

1. Identification of the Information Collection

1(a) Title and Number of the Information Collection

Emissions Certification and Compliance Requirements for Nonroad Compression-ignition Engines and On-highway Heavy Duty Engines (Revision); EPA ICR Number 1684.20; OMB Control Number 2060-0287

1(b) Short Characterization

With this supporting statement, EPA requests the revision with a three-year extension of an existing Information Collection Request (ICR). The requirements described in this statement apply to emissions certification and compliance programs for:

Nonroad (NR) compression-ignition (CI) engines and equipment, e.g. diesel:

NRCI engines are used primarily for agriculture and construction equipment and as auxiliary engines on other applications such as marine vessels and locomotives; and

NRCI Equipment manufactured under the Transition Program for Equipment Manufacturers (TPEM);

Category 1 and Category 2 marine CI engines which provide propulsion power on marine vessels; and,

On-highway heavy-duty (HD) vehicles/trucks and engines, both gasoline and diesel, including HD alternative fuel conversions.

` This supporting statement also consolidates into it the existing ICRs listed in Table 1.

Table 1

List of ICRs Consolidated into ICR 1684.20

ICR Information |

Industries covered |

Reason for Consolidation |

Consolidated Portion |

Control of Emissions from New Marine Compression-Ignition Engines at or Above 30 Liters per Cylinder, EPA No. 2345.03; OMB No. 2060-0641; expiring March 31, 2020 |

Category 3 Marine Engines |

Categories 1 & 2 are already included in 1684. |

Incorporated in its entirety |

Engine Emission Defect Information Reports and Voluntary Emission Recall Reports, EPA No. 0282.17; OMB No. 2060-0048; expiring on November 30, 2020 |

All heavy-duty, spark ignition and compression ignition engines |

Defect reporting stems from certification; same respondents as 1684. |

Portion related to HD and NR compression ignition industries only |

Emissions Certification and Compliance Requirements for Locomotives and Locomotive Engines, EPA No. 1800.07; OMB No. 2060-0392; expiring July 31, 2018 (in process) |

Locomotives, locomotive engines and remanufacturing kits |

Same programs as those already included in 1684. Some of the same respondents. |

Incorporated in its entirety |

Certification and Compliance Requirements for Medium- and Heavy-Duty Engines and Vehicles, EPA No. 2394.03; OMB No. 2060-0678; expiring on April 30, 2018 (in process) |

Medium-heavy duty engines and vehicles |

Certification programs for HD engines already in 1684. Some of the same respondents. |

Incorporated in its entirety |

This action is undertaken to consolidate information requirements for the HD & NRCI engine and equipment industries into one ICR for simplification and to eliminate duplicity. All ICRs address related sets of respondents. Many manufacturers responded to more than one of these ICRs.

Under Title II of the Clean Air Act (42 U.S.C. 7521 et seq.; CAA), EPA is charged with issuing certificates of conformity for engine prototypes that comply with applicable emission standards. Such a certificate must be issued before engines produced after these prototypes may be legally introduced into commerce. Table 2 below lists EPA regulations pertaining to the industries covered by this ICR.

Table 2

Nonroad CI and Heavy-duty Emissions Regulations

Industry |

40 CFR1 Part |

Nonroad Compression-Ignition (NRCI) Engines and Equipment |

89*2, 1039* |

Marine Compression-Ignition Engines (Marine CI) |

94*, 1042*, 1043* |

Locomotives, locomotive engines and remanufacturing kits |

92*, 1033* |

Heavy-Duty (HD) Engines |

85*, 86 |

Greenhouse Gas Requirements for HD Engines |

1036* |

Greenhouse Gas Requirements for HD Vehicles |

1037* |

Evaporative Requirements |

1060 |

Testing Provisions |

1065 |

General Provisions – apply to most nonroad categories |

1068 |

Fees, as applicable to the above industries |

1027 |

Each model year, engine and vehicle manufacturers wishing to sell their products in the US must obtain a certificate of conformity with criteria pollutant3 standards. HD engines and vehicles also need to comply with evaporative, greenhouse gas (GHG) emissions4 and fuel economy standards. The fuel economy data is shared with the National Highway Transportation Safety Agency, which administers the program. There are also recordkeeping requirements. To apply, manufacturers submit descriptions of their planned production engines, detailed descriptions of emission control systems and test data. This information is organized by "engine family" groups expected to have similar emission characteristics.

Engine manufacturers electing to participate in the Average, Banking and Trading (AB&T) Program must submit information regarding the calculation, actual generation and usage of credits in an initial report, end-of-the-year report and final report. These reports are used for certification and enforcement purposes. Manufacturers must also maintain records for eight years on the engine families included in the program.

The Act also mandates EPA to verify that engine manufacturers have successfully translated their certified prototypes into mass produced engines, and that these engines comply with emission standards throughout their useful lives. Some respondents are required to test a sample of engines as they leave the assembly line. The Production Line Testing (PLT) Program is a self-audit program that allows manufacturers to monitor compliance with statistical certainty while minimizing the cost of correcting errors through early detection. Through Selective Enforcement Audits (SEAs) or similar programs, EPA verifies that test data submitted by manufacturers is reliable and that testing is performed according to EPA regulations. Compliance with emission regulations throughout the useful life of an engine is verified through the In-use Testing (In-use) Programs under which engines are tested after they have served a portion of their useful lives. Not all programs apply to all industries included in this collection.

Engine and equipment manufacturers who chose to participate in TPEM must submit annual reports and keep records. Equipment manufacturers must also notify EPA of their intent to participate prior to introducing any TPEM engines/equipment into the US market.

This information is collected by the Compliance Division (CD) within the Office of Transportation and Air Quality, Office of Air and Radiation, U.S. Environmental Protection Agency (EPA). HD certification and fuel economy data is collected in conjunction with and shared with the National Highway Transportation Administration (NHTSA) for use in their fuel economy programs. All information collected could be used by the Office of Enforcement and Compliance Assurance (OECA) and the Department of Justice for enforcement purposes. Non-confidential portions of the applications are disclosed in EPA’s website and may be used by trade associations, environmental groups, and the public. The information is usually submitted in an electronic format and it is stored in CD's databases.

It has been estimated that a total of 468 engine, vehicle and equipment manufacturers will respond to this collection with an approximate cost of $25,797,805. Please note that some burden and cost tables referenced in this document are found in the accompanying Excel file.

2. Need for and Use of the Collection

2(a) Need/Authority for the Collection

EPA's emission programs are statutorily mandated; the agency does not have discretion to cease these functions. The data required is necessary to comply with Title II of the Clean Air Act (42 U.S.C. 7521 et seq.; “CAA” or “the Act”), as amended. The Act charges EPA with developing standards for compounds deemed ‘pollutants’ as defined by the CAA itself, and issue certificates of conformity for those engines and motor vehicle designs that comply with those standards. Such a certificate must be issued before engines and vehicles may be legally introduced into commerce. Section 206(a) of the CAA (42 USC 7521) states:

"The Administrator shall test, or require to be tested in such manner as he deems appropriate, any new motor vehicle or new motor vehicle engine submitted by a manufacturer to determine whether such vehicle or engine conforms with the regulations prescribed under §202 of this Act. If such vehicle or engine conforms to such regulations, the Administrator shall issue a certificate of conformity upon such terms, and for such period (not in excess of one year) as he may prescribe."

This charge also applies to nonroad engines and equipment, pursuant to §213(d) of the CAA. The Supreme Court’s decision in Massachusetts v. Environmental Protection Agency, 549 U.S. 497 (2007), extended it to greenhouse gases (GHGs) when it ruled that GHGs are in fact pollutants under the CAA.

Therefore, engine and vehicle manufacturers may not legally introduce their product into U.S. commerce unless EPA has certified that their vehicles and engines comply with applicable emission standards. To ensure compliance with the CAA, EPA reviews product information and manufacturers' test results. The agency may also test some vehicles and engines to verify data provided by manufacturers at certification. There are also some regulatory requirements for nonroad equipment manufacturers.

Section 206(b)(1) of the Act authorizes EPA to inspect and require testing of new vehicles and engines to: (1) verify that a manufacturer's final products comply with EPA standards; (2) assure that the correct parts are installed correctly in each engine; and (3) audit the manufacturer's testing process to ensure testing is being done correctly. The PLT and SEA Programs fulfill these requirements by inspecting and testing engines taken directly from the assembly line and/or existing fleets, and by auditing the engine manufacturer's testing procedures and facilities. Section 207(b) of the CAA mandates the establishment of methods and testing procedures to ascertain whether certified engines in actual use in fact comply with applicable emission standards throughout their useful lives. The In-Use Testing and similar programs are implemented in response to that mandate.

49 USC 32902 requires the National Highway Traffic Safety Administration (NHTSA), in consultation with the Department of Energy and the EPA, to prescribe each model year average fuel economy standards. Under 49 USC 32907, manufacturers are required to submit reports to both NHTSA and EPA demonstrating how they plan to comply with applicable average fuel economy standards.

2(b) Practical Utility/Users of the Data

EPA uses the information requested under this collection to implement a three-stage compliance assurance system established by the CAA; and for enforcement purposes. First, certification information is needed to verify that the proper prototype engines have been selected to represent each engine/vehicle family (group of engines/vehicles expected to have similar emission characteristics), and that the necessary testing has been performed. Based on this information, EPA issues a certificate of conformity. However, prototypes are often hand-built and not typical of assembly line engines. Information collected under the PLT and similar programs is used to verify that manufacturers have successfully translated their prototypes into mass-produced engines. Engines are taken directly from the assembly line and tested. Lastly, in-use testing is designed to determine if engines and vehicles maintained in accordance with the manufacturer's instructions still emit at acceptable levels after a prescribed number of years of actual use. If a family of engines or vehicles is found not to comply, manufacturers are required to recall the family.

Flexibility programs such as AB&T and TPEM ease the burden of EPA regulations on regulated parties who choose to participate.

The information will be received and used by various divisions within CD and NHTSA. In instances of noncompliance, the information may be used by the EPA’s and NHTSA’s enforcement offices and the Department of Justice. Non-confidential portions of the information submitted to CD are available to and used by importers, environmental groups, members of the public and state and local government organizations.

3. Nonduplication, Consultations and Other Collection Criteria

3(a) Nonduplication

The information requested under this ICR is required by statute. Because of its specialized nature, and the fact that most of it must be submitted to EPA before engines and vehicles can be sold, the information collected is not available from any other source. Furthermore, some of the data requested, such as sales volumes or certain engine designs, may be proprietary in nature, and thus claimed as confidential business information (CBI) by manufacturers. Therefore, EPA can only obtain the information if it is submitted by its owners.

3(b) Public Notice Required Prior to ICR Submission to OMB

An announcement of the public comment period for this ICR revision was published in the Federal Register (83 FR 24992) on May 31, 2018 which can be accessed through the Federal Register's website at http://www.gpoaccess.gov/fr/index.html. Two anonymous comments were received in response to this ICR revision, which can be read by accessing this ICR’s docket at https://www.regulations.gov/document?D=EPA-HQ-OAR-2007-1182-0005.

One comment was unfortunately not within the scope of this ICR, as it asked EPA to regulate human waste on the streets. The second comment, which was also submitted verbatim in response to a prior FR notice, states: “Just think of the Billions that could be saved from unfair Regulations and spend on Schools, Healthcare, Budget. American has Good Air and Good Water, please stop beating on this same subject day after day;” and proceeds to quote average pollution statistics from the World Health Organization for 3 American cities during one month in 2018. While we appreciate this concern, we’d like to point out that, while the direct costs of some of the measures called for in the 1990 amendments to the Clean Air Act (not counting the implementation of the original 1970 CAA) have been assessed at $65 Billion by 2020; its direct benefits at $2 Trillion, a 31:1 ratio. The World Health Organization (organization cited by the commenter)’s own report Cost of the Health Impact of Air Pollution in Europe – Clean Air, Health and Wealth available at cites those figures on page 345.

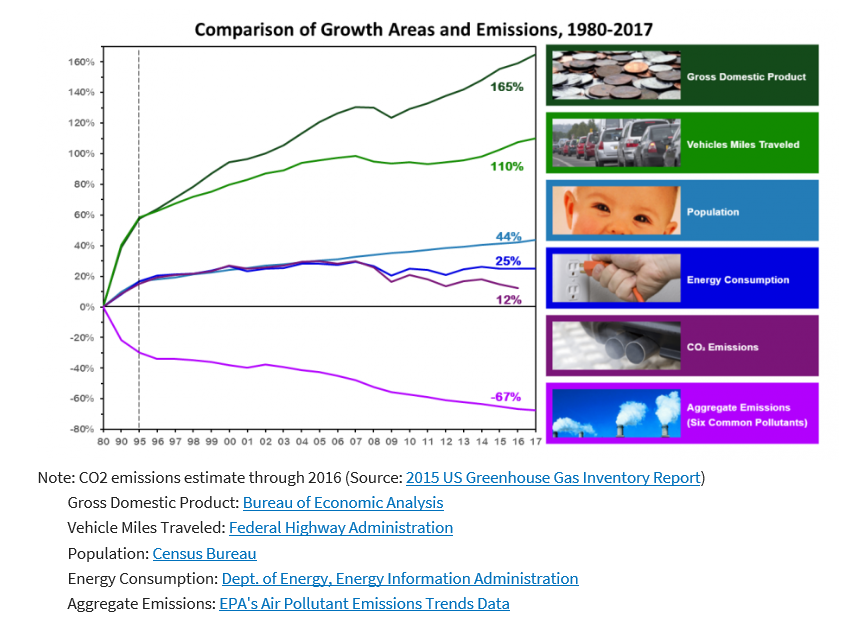

Furthermore, the chart Comparison of Growth Areas and Emissions, 1980-2017 from EPA’s 2017 Air Trends Report6 shows that “between 1980 and 2017, gross domestic product increased 165 percent, vehicle miles traveled increased 110 percent, energy consumption increased 25 percent, and U.S. population grew by 44 percent. During the same time period, total emissions of the six principal air pollutants dropped by 67 percent. The graph also shows that between 1980 and 2016, CO2 emissions increased by 12 percent. Despite great progress in air quality improvement, approximately 111 million people nationwide lived in counties with pollution levels above the primary [National Ambient Air Quality Standards, NAAQS] in 2017.” While we are happy to see that long term efforts by people in all levels of government, industry, nonprofit organizations, and private individuals are already paying off for some areas of the country, the fact remains that the Clean Air Act mandates EPA not to forget Americans who still pay for unhealthy air quality with increased health care costs, lost productivity, lost quality of life and premature deaths. Those costs are perhaps less noticeable in the short term for the individual observer and more difficult to quantify, but they exact a great toll on the US economy as well. “By 2030, EPA air quality emissions standards for vehicles are projected to annually prevent 40,000 premature deaths, 34,000 avoided hospitalizations, 4.8 million work days lost.”7 As reductions in air pollutants are achieved over time, we believe that “the associated air quality benefits will lead to improved health, longevity, and quality of life for all Americans.8” For more information about how pollution from engines, vehicles and equipment affect human health, see https://www.epa.gov/mobile-source-pollution/how-mobile-source-pollution-affects-your-health.

3(c) Consultations

In updating the information collections in this request, EPA contacted fewer than 10 past respondents. Some did not provide comments. Below is a list of those contacted as well as industry representatives who have provided input through past interactions, such as providing input during the development of templates/forms used to collect information. EPA also used data generated during past consultations with the regulated industry for similar programs.

Mr. Mark Siddall,

Hino Motors Ltd.

Dave Gardner

Navistar Vehicles

Mr. Dan Kieffer

Director of Emissions Compliance

PACCAR Inc.

Email: [email protected]

Mr. Scott Crafard

Senior Vehicle Compliance Engineer

Isuzu Motors Limited

Contact: Members of EMA

Company: Engine Manufacturers Association (EMA)

Phone: (312) 929-1974 – contact Roger Gault

3(d) Effects of Less Frequent Collection

The CAA states that emission certification must be done on a yearly basis (CAA 206(a)(1)), coinciding with the industry's 'model year.' Major product changes typically occur at the start of a model year. For these reasons, a collection frequency of less than a model year is not possible. However, when an engine design is "carried over" to a subsequent model year, the amount of new information required is substantially reduced.

For practical reasons, PLT reports are submitted on a quarterly basis. Manufacturers are required to test up to one percent of their production at random to ensure that mass produced engines comply with emission requirements. If a problem is found, manufacturers must correct it and might need to recall engines that have already been sold. Engine manufacturing companies update their internal production volume reports every quarter. By conducting this quality control testing also on a quarterly basis, manufacturers are able to learn about and address any problems early, before the start of the next quarter's production, thus minimizing costs.

In-use testing and SEA information is collected on occasion, when EPA orders testing of a particular engine or audits a particular manufacturer.

AB&T and TPEM data is collected annually, once manufacturers elect to participate in those programs, also to correspond with manufacturing cycles and to make data collection and compliance verification more manageable for both EPA and respondents.

3(e) General Guidelines

Certification, ABT, and end-of-the-year report related records must be maintained for eight years. Note that respondents may “store these records in any format and on any media, as long as [respondents] can promptly send us organized, written records in English if we ask for them" [for example in 1039.250(d), 1042.250(d)]. For HD engines, "records may be retained as hard copy or reduced to microfilm, ADP film, etc., depending on the manufacturer's record retention procedure, provided that in every case all the information contained in the hard copy is retained" [(86.000-7(a)(3)]. These recordkeeping requirements stem, in large part, from the statutory requirement to warrant some items for long periods of time. In addition, the manufacturers must comply with requirements to recall vehicles and engines failing to meet emission standards during their useful lives. However, data related to routine testing such as test cell temperatures and relative humidity readings, must only be kept for one year after a certificate of conformity is issued.

Manufacturers are required to submit confidential business information such as sales projections and certain sensitive technical descriptions (Please see section 4(b)(i) for reference). This information is kept confidential in accordance with the Freedom of Information Act, EPA regulations at 40 CFR Part 2, and class determinations issued by EPA's Office of General Counsel. Also, non-proprietary information submitted by manufacturers is held as confidential until the specific vehicle or engine to which it pertains is available for purchase.

For practical reasons, PLT reports are submitted on a quarterly basis. Manufacturers are required to test a number of engines at random to ensure that mass produced engines comply with emission requirements. If a problem is found, manufacturers must correct it and might need to recall engines that have already been sold. Engine manufacturing companies update their internal production volume reports every quarter. By conducting this quality control testing also on a quarterly basis, manufacturers are able to learn about and address any problems early, before the start of the next quarter's production, thus minimizing costs.

Under an SEA, manufacturers are required to submit test results and information within five working days after all engines ordered to be tested have been tested. The items requested are all readily available or generated during the SEA. For nonroad engines, a report on the test results must be submitted within 30 days (see Section 1068.450). The information is requested in less than thirty days so that EPA can verify the accuracy and validity of the emission data and expeditiously reach a conclusive audit decision. An expeditious audit decision allows the manufacturer to quickly release the tested vehicles or engines for introduction into commerce.

No other general guideline is exceeded by this information collection.

3(f) Confidentiality

Manufacturers are allowed to assert a claim of confidentiality over information provided to EPA. Confidentiality is provided in accordance with the Freedom of Information Act and EPA regulations at 40 CFR Part 2. For further detail, refer to section 3(e).

3(g) Sensitive Questions

No sensitive questions are asked in this information collection.

4. Respondents and Information Requested

4(a) Respondents/SIC Codes

Respondents are manufacturers of heavy-duty and non-road engines, vehicles and equipment within various North American Industry Classification System (NAICS) codes. Respondents to NRCI, locomotive, and marine CI requirements fall in the following categories:

333618 Other Engine Equipment Manufacturing

333111 Farm Machinery and Equipment Manufacturing

333112 Lawn and Garden Tractor Manufacturing

333120 Construction Machinery Manufacturing

336312 Gasoline Engine and Engine Parts Manufacturing

336611 Manufacturers of Marine Vessels;

811310 Engine Repair and Maintenance

Companies responding to HD requirements are “companies that manufacture, sell, or import into the United States new heavy-duty engines and new Class 2b through 8 trucks, including combination tractors, all types of buses, vocational vehicles including municipal, commercial, recreational vehicles, and commercial trailers as well as 3/4-ton and 1-ton pickup trucks and vans. The heavy-duty category incorporates all motor vehicles with a gross vehicle weight rating of 8,500 lbs. or greater, and the engines that power them, except for medium-duty passenger vehicles already covered by the greenhouse gas standards and corporate average fuel economy standards issued for light-duty model year 2017-2025 vehicles.”9 Regulated categories and entities include the following” North American Industry Classification System (NAICS) codes as published in the Federal Register, 81 FR 73478:

Table 3

HD Respondents NAICS Codes

Category |

NAICS code |

Examples of potentially affected entities |

Industry |

336111 |

Motor Vehicle Manufacturers, Engine Manufacturers, Truck Manufacturers, Truck Trailer Manufacturers. |

|

336112 |

|

|

333618 |

|

|

336120 |

|

|

336212 |

|

Industry |

541514 |

Commercial Importers of Vehicles and Vehicle Components. |

|

811112 |

|

|

811198 |

|

Industry |

336111 |

Alternative Fuel Vehicle Converters. |

|

336112 |

|

|

422720 |

|

|

454312 |

|

|

541514 |

|

|

541690 |

|

|

811198 |

|

4(b) Information Requested

This section summarizes the various programs included in this collection and their reporting and recordkeeping requirements as well as the tools used to collect that information. It includes many regulatory references or citations. When a requirement is found in multiple regulations covered in this request, we provide several of the citations. Please note that in those cases, the list of citations is not meant to be exhaustive.

This information collection implements a three-stage process envisioned in the Clean Air Act with regards emissions from mobile sources: engines, vehicles and equipment. The three-stage process starts with the certification program, where EPA issues certificates of conformity to those engines/vehicles that meet emissions requirements. Programs such as AB&T provide manufacturers with flexibility to meet those requirements. To apply for a certificate, manufacturers must describe prototypes of their products and supply test data to demonstrate compliance with applicable standards. This information is organized by engine or vehicle groups called “families” and by model year. Engines or vehicles that are subject to multiple regulations may need to obtain more than one certificate.

Obtaining a certificate of conformity, however, is not the end of the road; but the beginning. The Clean Air Act requires EPA to verify that the manufacturer successfully translated their prototypes into mass-produced engines or vehicles and that those engines/vehicles comply with standards throughout their useful life. Programs such as Production Line Testing (PLT), In-use Testing and Selective Enforcement Audits (SEAs) accomplish that as described in this section. Not all programs apply to all industries and specific requirements vary depending on the characteristics of each engine/vehicle family.

Most of the information in this request is collected electronically through EPA’s Engines and Vehicles Compliance Information System (EV-CIS), formerly known as VERIFY, as described in Section 5(b) of this document. EV-CIS has different components or modules to house and manage the data. Certification and defects data is collected using webforms (screens). TPEM, AB&T and other compliance programs data is collected through Excel-based templates that are then uploaded into the Compliance Database. Table 4 below provides a list of forms used in this collection which are available at https://www.epa.gov/vehicle-and-engine-certification/certification-and-compliance-nonroad-vehicles-and-engines.

Forms Related to ICR 1684.20

Form |

Number |

HD/NR Engine Manufacturer Annual Production Report |

5900-90 |

AB&T Report for Nonroad Compression Ignition Engines |

5900-125 |

AB&T Report for Heavy-duty On-highway Engines |

5900-134 |

AB&T Report for Locomotives |

5900-274 |

AB&T Report for Marine Compression-ignition Engines |

5900-125 |

PLT Report for Marine CI CumSum |

5900-297 |

PLT Report for Marine CI Non-CumSum |

5900-298 |

PLT Report for Locomotives |

5900-135 |

Locomotive Installation Audit Report |

5900-273 |

In-use Testing for Locomotives |

5900-93 |

In-use Testing for Non-Road Engines |

5900-93 |

Replacement Engine Exemption Report |

6900-5414 |

HD Defect Information Reports |

5900-301 |

HD Voluntary Emissions Recall Reports VERRs |

5900-300 |

HD VER Quarterly Reports |

5900-302 |

HD Alternative Fuel Conversions of Intermediate Age |

5900-338 |

HD Alternative Fuel Conversions Outside of Useful Life |

5900-259 |

TPEM Equipment Manufacturer Notification |

5900-242 |

TPEM Equipment Manufacturer Report |

5900-240 |

TPEM Engine Manufacturer Report |

5900-241 |

TPEM Importers Notification |

In process |

TPEM Importers Annual Report |

In process |

TPEM Statement to Comply |

In process |

TPEM Bond Worksheet |

5900-239 |

TPEM Hardship Relief Application Questionnaire |

5900-465 |

TPEM Hardship Relief Prescreening Questionnaire |

Reporting and recordkeeping requirements vary according to the characteristics of the engine/vehicle being certified and the programs manufacturers elect to participate in. However, the data requested and recordkeeping timelines are very similar across industries. Some of the data items are only required to be kept in records and submitted upon request.

EPA may deny an application, revoke, suspend or void a certificate for an engine family for which the manufacturer [1039.255(c) and 1042.255(c), 1068.601]:

Refuses to comply with any testing or reporting requirement

Submits false or incomplete information

Submits inaccurate test data

Fails to update an application to include all engine models being produced,

Fails to supply information requested by the agency

Fails to keep records or does not produce them when asked by EPA

Should EPA deny or revoke a certificate, the affected manufacturer may request a hearing within 30 days of the EPA's decision. The request must be in writing, include a description of the manufacturer's objections and data to support the objections. Hearings will be conducted using the procedures specified in 40 CFR Part 1068, Subpart G.

(4)(b)(i) Data Items

(4)(b)(i)(1) Pre-model year reports – HD GHG Engines and Vehicles Only

NHTSA’s regulations at 49 CFR 535.8(b) require

manufacturers of HD pickups and vans subject to fuel economy

standards to provide pre-model year reports prior to submitting

their first application for certification. The information can be

submitted during a voluntary annual certification preview meeting

with EPA and NHTSA. Pre-model year reports providing “early

estimates demonstrating how [a manufacturer’s] fleet(s) would

comply with GHG emissions and fuel consumption standards.” The

information is needed to help construct an annual testing plan. Each

pre-model report must include the following:

Make and model designations and attribute-based values of each unique vehicle subconfiguration in the manufacturer’s fleet

Emission and fuel consumption fleet average for each configuration

Estimated production volumes by vehicle configuration, test group and fleet

Expected emissions and fuel consumption test results and fleet average performance

The list of Class 2b-3 cab-complete vehicles and the method used to certify them

The list of Class 4 and 5 incomplete and complete vehicles and the method used to certify them

List of loose engines included in the heavy-duty pickup and van category and the list of vehicles used to derive target standards

Copy of any notices sent to the engine manufacturer about using their compliant engines in excluded vehicles

An AB&T plan including plans to resolve any credit deficit that may occur. AB&T is described in section (4)(b)(i)(3) below.

(4)(b)(i)(2) Certification – All Industries

To apply for a certificate, manufacturers must describe prototypes of their products and supply test data to demonstrate compliance with applicable standards. This information is organized by "engine or vehicle family." An engine or vehicle family is a group of engines/vehicles expected to have similar emission characteristics. Specific criteria for establishing these families, sometimes referred to as test groups, is outlined in each industry’s standard setting part.10 For example, for HD GHG engines and vehicles, the criteria are found in §1036.230 (engines) and §1037.230 (vehicles). Vehicle families may be further subdivided in sub-families and configurations. Each manufacturer identifies the worst-case scenario among its families and test groups and selects them for actual testing.

Certificates are issued on a “model year” (MY) basis. A model year refers to the manufacturers' annual production period, or a calendar year if the manufacturer does not have a model year. Engine families need to be certified each model year. Manufacturers must indicate whether they are applying for a “50-state” certificate, a “49-state” certificate (engines/vehicles are don’t comply with California’s emissions requirements) or a “California-only” certificate (for engine families that are to be sold only in California).

In some industries, there are more than one type of manufacturer. For example, in the locomotive industry manufacturers of locomotives, locomotive engines and locomotive remanufacturers must obtain certificates of conformity with emission standards. As appropriate, we’ve highlighted the most important differences in reporting and recordkeeping requirements for each category.

Most engine families are only certified for emissions of criteria pollutants such as carbon monoxide, nitrogen oxides, hydrocarbons, and particulate matter. However, certain HD engines, nonroad CI and marine CI engine families that will be fueled with volatile liquid fuels other than conventional diesel must obtain two certificates of conformity: (1) an Exhaust Emissions (criteria pollutants) Certificate under the applicable standard setting part; and (2) an Evaporative Certificate11 under Part 1060. Medium- and Heavy-duty engines and vehicles (collectively referred to in this document as HD GHG engines/vehicles) are also subject to fuel consumption and GHG emissions standards for carbon dioxide (CO2), nitrous oxides (N2O), hydrofluorocarbons (HFC) and methane (CH4). Manufacturers of HD GHG engines regulated under Part 1036 obtain (1) a certificate of conformity with GHG emissions requirements, (2) an Exhaust Emissions Certificate under Part 85, and (3) comply with NHTSA’s fuel economy requirements. HD GHG Vehicle manufacturers must obtain a HD GHG certificate under Part 1037 and comply with fuel economy requirements.

For Marine CI Category 3 engines, reporting and recordkeeping requirements vary according to its characteristics as well as the vessel in which the engine is installed. Based on those characteristics, engine or vessel manufacturers may need to obtain between one and three certificates of conformity:

Exhaust Emissions Certificate under 40 CFR 1042 – all engines sold or installed in vessels that navigate US waters must be covered by a Part 1042 certificate. Must be obtained annually.

IMO Certificate – demonstrates compliance with international standards, codified for the US at 40 CFR Part 1043. Required for commercial engines/vessels which travel beyond US territorial waters. Must be obtained at least once. Recertification is only necessary if the engine design undergoes changes that affect emissions.

Evaporative Certificate – required for engines that will be fueled with volatile liquid fuels other than conventional diesel. Must be obtained annually.

The burden associated with certifying a given engine or vehicle family is usually reduced after the first production year (model year), because certification data and information from previous years can be "carried over" if no significant changes have occurred. For instance, an engine family certified in MY 2018 can be certified in MY 2019 and subsequent years by "carrying over" the test data used in the 2018 application if no significant emissions-related changes have occurred to the engine family between model years. EPA may also allow manufacturers to "carry across" data from HD certification to NRCI certification and vice-versa for engine families they produce for both markets if there are no significant differences between the HD and NRCI versions of the engine family. Allowing manufacturers to "carry-over" and "carry across" data saves manufacturers the cost of testing both families.

Manufacturers may make changes to one or more engine/vehicle models within a family at any time during the model year (‘running changes’). These running changes may significantly affect the engine models, and therefore, the engine family's emission levels. For this reason, all engine emissions compliance programs run on a model year basis.

Engine manufacturers must label all engines. The label must identify each engine and state the engine family name, the fuel(s) the engine is certified to run on, the engine useful life and category, if applicable. Other language applies if the engine is being certified under a special provision or exempted under any of the programs discussed here. Under certain circumstances, nonroad equipment or vessels must also be labeled. Manufacturers are also required to provide warranties and owner’s manuals to consumers.

An application fee must be paid per engine family per model year. This fee, which is recalculated every year, is requested under the authority of Section 217 of the CAA and the Independent Offices Appropriation Act (31 U.S.C. 9701) to ensure that the motor vehicle emissions compliance program is self-sustaining to the extent possible. Fees are collected electronically at www.pay.gov or by mail using the Nonroad Fee Filing Form, Form 3520-29. The fee filing form is covered under ICR 2080.05, OMB Control Number 2060-0545. Additional information is available at https://www.epa.gov/vehicle-and-engine-certification/fees-information-motor-vehicle-and-engine-compliance-program-mvecp and in section 6(b)(ii) of this supporting statement.

The following is a summary of data items requested for certification-related activities and recordkeeping. Other data items may be listed in the regulations. EPA regulations provide that the Agency may also require additional information as needed to evaluate the application for certification and determine compliance with various requirements.

Statement of compliance

Identification and description of the basic engine design including, but not limited to, the engine family specifications (fuel, cooling medium, etc.)

Explanation of how the emission control system operates

Fuel System Type and Components

Useful Life Period.

Deterioration Factors

Intended Service Class

Projected Sales

Estimated Production Period

Sales Area

Plant Contact and Location

Program Information

Family Emission Limits

Nonroad Engine Equipment Types

Detailed description and justification of each auxiliary emission control device (AECD), and how they affect emissions

Description of all adjustable parameters, their adjustable ranges and methods employed to prevent tampering, etc.

Detailed drawings and descriptions of the various emissions-related components

Description of the test equipment and fuel to be used

Description of the test procedures to be used to establish the durability data or the exhaust emission deterioration factors

All test data obtained by the manufacturer on each test engine

Statement of the useful life

Statement of the alternative useful-life period and a brief synopsis of the justification, if applicable

Maintenance information

Description of the provisions taken to prevent tampering with emission control computer instructions

Proposed test fleet selection and the rationale for the test fleet selection

Special or alternate test procedures, if applicable

Period of operation necessary to accumulate service hours on test engines and stabilize emission levels

Fee Filing Form

If EPA submits a written request for an explanation of good engineering judgment, manufacturers must provide a written description of the judgment in question within 15 working days, unless otherwise specified

Additional information may be submitted is the manufacturer requests a special provision

For Heavy-duty engines only [Exhaust emissions certification – for GHG and fuel economy requirements, see section (4)(b)(i)(2)(A) below]:

For evaporative families: a description of any unique procedures required to perform evaporative and/or refueling tests, and a description of the method used to develop those unique procedures

Canister working capacity, canister bed volume, and fuel temperature profile for the running loss test

Maximum nominal fuel tank capacity

Certification standard

Weight category

Identification of those families that will not comply with cold temperature CO standards

For families incorporating an emission control diagnostic system: a full and detailed description of its functional characteristics, the method of detecting malfunctions, and provisions taken to prevent tampering

For methanol-fueled vehicles: whether the vehicle is flexible or dedicated, and the fuel for which the vehicle was designed

For Marine CI engines only:

All information required for EPA to interpret all messages and parameters broadcast on an engine's controller area network

Information about the engine family's compliance with the Not-to-Exceed (NTE) Standards

Manufacturers who wish to “dress” or “marinize” a land-based engine for use as a propulsion engine on a vessel must label the marinized engine (1042.605(e)). If an original engine manufacturer marinizes its own engines, it must notify EPA in the certification application (1042.605(g)(1)). An original engine manufacturer may be required to submit emissions data on engines marinized by someone else [1042.605(g)(2)]

For branded engines, the company whose trademark the applicant will use. (1042.640(2)(b))

If the respondent modifies its own engines for use on a vessel, it must notify us in the certification application (1042.605(g)(1))

For Locomotives only:

|

||

|

||

|

|

|

|

|

|

|

|

|

Running Changes:

Manufacturers may make changes to a certified engine, or add an engine model to an already certified engine family, which are referred to as running changes. Running changes are submitted using the same electronic format used to apply for a certificate and include:

● Notification of changes made to the application and/or request for amendment of the application

● Full description of the change to be made

● Engineering evaluations or data showing that engines as modified or added will comply with all applicable emission standards

● Determination of whether the original test fleet selection is still appropriate, and proposed new test fleet selections, if applicable

● Upon request, test data on the engine changed or added

● Supporting documentation, test data and engineering evaluations as appropriate to demonstrate that all affected engines will still meet applicable emission standards

Certification Recordkeeping:

Manufacturers must keep the following certification-related records for eight years [86.094-7(a)(3), 89.124-96(b), 1039.250(c) and 94.215(a)(3)] except routine emission records. Manufacturers must keep routine emission records for only one year.

General records:

● Identification and description of all engines for which testing is required

● Description of emission control systems

● Description of test procedures

Individual Family Records:

● Copies of all the applications submitted

● Brief history of all test engines and running changes

● Complete records of all emission tests performed

● Description of service accumulation, including dates and number of hours/mileage accumulated

● Record and description of all maintenance and other servicing performed

● Record and description of each test performed to diagnose engine or emission control system performance

● Brief description of any significant events affecting the vehicle

● Production figures for each engine family by assembly plant (Nonroad CI)

● List of engine identification numbers for all engines produced (Nonroad CI)

● Actual U.S. sales volume

● Routine emission test data.

HD GHG Manufacturers must keep copies of all the applications, application supporting information required to be kept but not submitted (1036.205), and any other information sent to us for eight years [1036.250(d) and 1037.250(d)]. Routine emission records must be kept for only one year [1036.250(c) and 1037.250(c)].

(4)(b)(i)(2)(A) HD GHG Engine & Vehicle Manufacturers

Manufacturers that must comply with HD GHG and fuel economy requirements have additional certification data requirements found at 1036.205 and 1037.205. In general terms, the requested data items provide a complete description of the engine/vehicle family to be certified, its emissions profile and methods used/requested for demonstrating compliance, whether the engine/vehicle family is participating in ABT, etc. Some items are unique to certain types of engines or vehicles. GHG and fuel economy data is collected through EV-CIS and shared. Some respondents may elect to submit some fuel economy data through NHTSA’s CAFÉ database or in writing [535.8(a)(6)].

Under 1036.210, 1037.210 and 1037.211, manufacturers may seek a preliminary approval or determination by submitting a draft application. They may also amend their applications, even after a certificate has been issued, to include new or modified engine configurations and for other reasons (1036.225 and 1037.225).

HD GHG Engine Certification (1036.2015):

Description of the engine family specifications and basic emission control parameters

Description of test equipment and procedures

Emission-related installation instructions

Description of the engine emissions label

Information about family emissions limits for GHG emissions

Deterioration factors

Emissions test data to show compliance

Statement of Compliance

Other applicable information, such as request for exemptions

For imported engines/equipment:

A description of normal imports practices

Identity of agents authorized to import

The location of a US test facility where SEAs could be conducted

Information related to vehicle certification under Part 1037, if application

Per NHTSA requirements, equivalent fuel consumption values from CO2 emissions test results

Some additional information required by other subparts, such as declaring whether the company is a small business

HD GHG Vehicle certification (1036.2015):

Description of the vehicle family specifications and basic emission control parameters

Explanation of how the emission control system operates, including but not limited to auxiliary emission control devices, fuel components

Describe modeling inputs such as speed limiters and automatic engine shutdown systems

Descriptions of:

Engineering analysis related to air compressor compliance

Idle-reduction technology

Configuration and basic design of hybrid systems

Test equipment and procedures used

The emissions control label

Adjustable parameters

If power train testing was performed, report CO2 and NOx emission levels

Identify, if applicable:

Engine family name of any auxiliary power units in tractors

Useful life

Emission standards/FEL used

Certain information for vehicles subject to air conditioning standards

Test fuel specs, if applicable

Maintenance instructions and warranty

Projected production

An agent of service in the US

Some additional information required by other subparts and/or for specific types of vehicles, such as declaring whether the company is a small business

(4)(b)(i)(2)(B) Rebuilders & Aftermarket Part Manufacturers

Manufacturers or rebuilders of aftermarket engine parts for nonroad CI engines are not required to apply for certificates of conformity, but must keep information that shows how their parts or service affect emissions. EPA may test engines and equipment to investigate potential defeat devices or may require the manufacturer to complete this testing. Manufacturers may need to provide information regarding test programs, engineering evaluations, design specifications, calibrations, on-board computer algorithms, and design strategies. (see Section 1068.110)

The following records must be kept for at least two years after rebuilding an engine, and must be accessible for EPA's review. Records may be based on engine families rather than individual engines if that is a normal business practice.

● Hours of operation (or mileage, as appropriate) at the time of the rebuild

● Work completed on the engine or any emission-related control components, including a listing of parts and components used

● Engine parameter adjustments

● Emission-related codes or signals responded to and rests

(4)(b)(i)(2)(C) Alternative Fuel Converters

Aftermarket fuel conversion systems allow gasoline or diesel vehicles to operate on alternative fuels such as natural gas, propane, alcohol, or electricity. Use of clean alternative fuels opens new fuel supply choices and can help consumers address concerns about fuel costs, energy security, and emissions. EPA is responsible for ensuring that all vehicles and engines sold in the United States, including aftermarket conversions, meet emission standards. Regulations pertaining to alternative fuel conversions are codified at 40 CFR Part 85, Subpart F. Engines can be converted when they are new or nearly new (beginning of useful life), sometime between the second year of use and the end of their useful life (intermediate age) or after their intended useful lives has ended (outside of useful life).

Alternative fuel converters must obtain certificates of conformity with emission standards. However, the amount of information collected from beginning-of-useful-life converters is reduced as converters may group multiple engine families into a larger one. Engine families must share certain characteristics before they can be combined. Converters of new engines submit their certification applications through EC-VIS in the same manner as other HD engine manufacturers. They must also comply with HD GHG requirements and evaporative requirements, as applicable. Those programs are addressed in earlier in this section.

The burden for converters of intermediate age engines is even lower. Instead of testing their converted engines, they can submit a simplified On-Board Diagnostics testing demonstration instead of a full certification application. Converters of engines outside their useful life also benefit from a reduced burden. Converters can simply submit an On-Board Diagnostics (OBD) scan tool test report and a detailed technical description of the conversion system sufficient in detail for EPA to confirm the conversion system’s ability to maintain or improve on emission levels in the converted engine. EPA has developed Forms 5900-338 and 5900-259 for converters of intermediate age and outside-of-useful-life engines use EPA, respectively, to submit their applications.

Summary of data items:

For all engine conversions:

Expanded conversion engine families

New engine label requirement describing OEM engine family, mileage, and date

For intermediate-age and outside useful-life age vehicles (25%):

Online notification and test result report rather than application for certification

A engineering judgement “demonstration” for intermediate age and outside useful life conversions

OBD scan tool report showing results of an OBD scan tool test procedure

A statement that the OBD system remains fully functional in the converted engine.

Intermediate age and outside useful life engine families will not be required to pay a certification fee.

(4)(b)(i)(2)(D) Confirmatory Testing

From time to time, EPA may conduct confirmatory testing. When there is reason to believe that a compliance issue may exist with the emissions data submitted at certification, EPA may, at its own expense, purchase or rent engines/vehicles and test them. Manufacturers may be notified about this testing in advance and may be required to explain discrepancies found between EPA test data and data submitted by the manufacturer.

(4)(b)(i)(3) Production Reports

Most manufacturers must submit an Annual Production Report identifying the number of engines or vehicles produced by engine family, by gross power, by displacement, by fuel system, or by other categories. For all industries except HD GHG engines and vehicles, the report is due within 45 days after the end of the model year and must be submitted using Form 5900-90. The data is then electronically uploaded into the Compliance Database. HD GHG manufacturers’ deadline is 90 days after the end of the model year. Production is reported by serial number/vehicle identification number and engine/vehicle configuration. Vehicle manufacturers must include subfamily identifiers and must report uncertified vehicles sold to secondary vehicle manufacturers. We may waive this requirement for small engine manufacturers, while small vehicle manufacturers may omit this requirement altogether. Engine manufacturers may combine this report with their AB&T reports. HD GHG reports are submitted directly to EC-VIS’ HD GHG module.

(4)(b)(i)(4) Averaging, Banking and Trading (AB&T)

AB&T is a tool allow HD engine and vehicle manufacturers to introduce into the US market engines that emit above emissions limits provided other cleaner engines compensate for the additional emissions. Engine manufacturers may earn positive credits for engine families that emit below an established family emissions limit and then use those credits to obtain certification for engine families that emit above the limits. The overall credit balance, also called ‘average’, is calculated based on credit generation/usage by engine family and how many units of each engine model were sold during the year. That average must be zero or above at the end of the year, meaning that the participant’s overall production meets or exceeds the emissions limits. Credits may be banked for use in subsequent years or traded among participants. Credits must be calculated by pollutant and by type of engine and vehicle, among other criteria. Participation in AB&T is voluntary.

Participants must indicate in each engine family’s certification application whether that family is participating in AB&T. Then, the following year, they must submit two reports which include all the participating engine families: an end-of-the-year report (draft report due by March 31) and a final report (due by September 30). AB&T reports provide data on the number of credits used or generated by each engine family; and verify that participants have a zero or above credit balance at the end of each model year. Manufacturers have 270 days after the end of the model year to correct any mistakes found in the credit balance calculations. If the initial report shows a negative balance, EPA may disallow the correction [(1036.730(f)(2), 1037.730(f)(2), etc.]. If credits are sold or purchased, a trade report must be submitted within 90 days of the transaction [(1036.730(d) and 1037.730(d)].

Since all new locomotives and locomotive engines are required to meet both the line-haul and switch duty-cycle standards, manufacturers and remanufacturers can participate in separate line-haul and switch ABT programs. They cannot, however, use credits generated under one program to satisfy the requirements of the other. Credits can only be generated for NOx and PM. Only manufacturers and remanufacturers of new locomotives and new locomotive engines manufactured or remanufactured in the 1999 model year or later can participate.

Reports are submitted through EV-CIS using the following forms:

|

|

|

|

Summary of AB&T data items:

With application for certification:

Intent to include this specific engine family in the ABT program

Declaration that participation in this program will not cause the applicable emission standard to be exceeded (have negative credit balance)

Family emission limit

Projected applicable production volumes for the model year

Reports:

Values required to calculate credits

Projected number of credits generated/used

If credits are generated, the designated use of the credits involved or if credits are used, the source of those credits

Trade Reports [example: 1036.730 (d) and 1037.730(d)]:

The identity of the traders and brokers

Copy of the trade contracts

How the credits will be used

AB&T Recordkeeping:

ABT records are to be kept for eight years [86.094-7(c)(3), 89.210-96(d), 1039.735(b), 94.308(d), 1033.735(b), 1036.735, 1037.735, and 1042.735(b)]:

● EPA Engine Family

● Engine Identification Number

● Engine build date and model year

● Power Rating

● Purchaser and Destination

● Assembly Plant

● Family Emission Limit

● Useful Life

● Projected and actual production model

For families (other than HD GHG engines/vehicles) participating in trading, the following records must be kept quarterly.

● Actual quarterly and cumulative applicable production/sales volume

● Value required to calculate credits

● Resulting type and number of credits generated/required

● How and where credit surpluses are dispersed

● How and through what means credit deficits are met

For HD GHG families, manufacturers may not use credits if the following information is not kept. Records can be stored in any format as long as they are readily available for inspection upon request.

EPA Engine Family

Copies of all reports submitted

FELs and a list of engine identification numbers those FELs apply to

Engine/vehicle purchasers and destination

(4)(b)(i)(5) Production-Line Testing (PLT) and Product Verification

Of the industries covered under this ICR, only Marine CI engines, evaporative families and locomotives are subject to PLT or similar programs. PLT requires engine manufacturers to test a sample of production engines to ensure that they in fact have the same emissions profile as the prototype tested for certification.

(4)(b)(i)(5)(A) Marine CI PLT

Under Part 1042, marine CI engine manufacturers must test “one engine or one percent of the projected US-directed production volume for all their Category 1 or Category 2 engine families” [1042.310(a)(1) and (2)]. Manufacturers may request a reduced rate for carryover engines families which have consistently passed PLT testing on each of the preceding two years. Small volume manufacturers and engine families with projected productions of less than 100 units may be exempted from PLT [1042.301 (a)(1) and (2)].

For category 1 and 2 engines, PLT testing is conducted quarterly, and respondents must report their PLT results within 45 days after the end of each quarter (1042.345(a)). Every Category 3 engine must be tested for NOx emissions either at its vessel’s sea trial or within the first 300 hours of operation, whichever comes first. This is due to the low volume of Category 3 engine families (most consist of between one and four engines). If an engine fails PLT or the manufacturer fails to comply with reporting requirements, EPA may revoke or suspend that engine family’s certificate [1042.301(b), 1042.302(a)]. Manufacturers may request alternative testing methods for PLT under 1042.301(d)(3) or 1042.302(e).

EPA may audit engine manufacturers' PLT testing procedures. During an audit, manufacturers are required to allow EPA officials to enter into facilities where engines are being manufactured, stored, or tested and where records may be located. Manufacturers are also expected to afford reasonable assistance (such as clerical or translation services, photocopying, etc.) to EPA personnel conducting the audit. PLT audit failures and hearing requests are handled in the same manner as SEAs failures and hearings.

Information requested under the PLT testing program consists mainly of test results, a description of the engines tested and the conditions under which the tests took place. PLT Reports are submitted electronically using Forms 5900-297 (CumSum) or Form 5900-298 (non-CumSum). Records must be kept for 8 years [1042.350(b)].

(4)(b)(i)(5)(B) Evaporative Family Product Verification

Evaporative families are subject to Product Verification under Part 1060, Subpart D. Manufacturers are required to use good engineering judgement to verify compliance, which may include testing. While there are no reporting requirements, manufacturers must make the information available [1060.301(b)] and provide samples for testing (1060.310) upon request from EPA.

(4)(b)(i)(5)(C) Locomotive PLT

Only manufacturers of freshly manufactured locomotive engines are subject to PLT testing requirements. Remanufacturers, however, must conduct audits under 1033.335. However, if EPA has reason to believe that there are problems with a remanufacturer's production, the Agency can extend PLT testing requirement to that remanufacturer.

Under PLT, each calendar quarter, manufacturers must conduct testing on a sample of locomotives or locomotive engines taken directly from the assembly line. The required sample size for an engine family (as long as there are no failures), is the lesser of 5 tests per year or one percent of the projected annual production [1033.310(b)]. Two additional tests must be performed for each failed test. Respondents may request a reduction in sample size for carry-over families that have successfully completed PLT in the two previous years. Some engine families may not have production in some quarters or the sample size may be reached before the end of the year, so some respondents may submit less than four reports per engine family per year.

Per 1033.320(e), within 45 days of the end of each quarter, manufacturers must report the information listed below using form 5900-135. Locomotive PLT reports are submitted using the PLT Report for Locomotives, EPA Form Number 5900-135.

Records, also listed below, must be kept for eight years after completion of all testing [1033.325(b)]. Under 1033.325(d), EPA may require manufacturers and remanufacturers to submit or retain additional information not specifically listed here.

The location and description of the test facilities where testing was conducted.

Total production and sample size for each engine family.

Applicable standards and/or FELs.

A description of the test locomotives or locomotive engines.

For each test conducted:

Description of the test locomotive or locomotive engine, including engine family and configuration, year, make, built date, engine ID number, etc.;

Location(s) where service accumulation was conducted and description of accumulation procedure and schedule, if applicable;

Test number, date, test procedure used, initial test results before and after rounding, final test results, etc.;

Complete description of any adjustment, modification, repair, preparation, maintenance, and testing which was performed on the test locomotive or locomotive engine; and

Any other information the Administrator may request.

For each failed locomotive or locomotive engine, a description of the remedy and test results for all retests.

The date of the end of the locomotive or locomotive engine manufacturer's model year production for each engine family tested.

A statement of compliance, found at 1033.320(e)(7) signed and endorsement by an authorized representative of the manufacturer or remanufacturer.

Upon request, manufacturers must also submit:

Projected production for each configuration within each engine family for which certification has been requested and/or approved; and/or

Number of locomotives or engines, by configuration and assembly plant, scheduled for production.

Recordkeeping requirements for the PLT Program:

A description of all testing equipment used or can be used for PLT

For each PLT conducted: date, time, and location of each test or audit.

The method by which the green engine factor was calculated or the number of hours of service accumulated

The names of all supervisory personnel involved

A record and description of any adjustment, repair, preparation or modification performed on test locomotives or locomotive engines

Shipping information including dates and locations, if applicable

A complete record of all emission tests or audits performed (except tests performed directly by EPA)

A brief description of any significant events during testing not otherwise described, including engine damage during shipment.

(4)(b)(i)(5)(C)(i) Remanufacturer Installation Audit Program

Each calendar quarter, remanufacturers must audit the installation of locomotives covered by its certificate(s) of conformity for proper components, component settings, and component installations on randomly chosen locomotives in an engine family. Within 45 days of the end of each quarter, remanufacturers must report the following information [1033.335(g)] using the Locomotive Installation Audit Report, EPA Form Number 5900-273:

|

|

|

|

|

|

(4)(b)(i)(5)(C)(ii) Failed PLT Testing

When a locomotive or locomotive engine fails PLT or an audit, the certificate of conformity issued to that locomotive or locomotive engine family is suspended, effective from the time the testing of that locomotive or locomotive engine is completed. The affected manufacturer or remanufacturer must then remedy the nonconformity, retest or re-audit, and submit reports with the following information:

A description of the remedy and new test or audits results.

The reason for the failure, the remedies and the date when the remedies will be implemented.

A demonstration that the failed engine family does in fact conform.

Manufacturers and remanufacturers may request a hearing.

Within 30 days, the interested party must file two copies of their written request, which must include:

A statement as to which configuration(s) within a family is to be the subject of the hearing.

A concise statement of the issues to be raised by the manufacturer or remanufacturer at the hearing.

A statement specifying reasons why the manufacturer or remanufacturer believes it will prevail on the merits of each of the issues raised.

A summary of the evidence which supports the manufacturer's or remanufacturer's position on each of the issues raised.

(4)(b)(i)(6) In-Use Testing

The In-use Program seeks to verify that engines comply with emission standards throughout their useful lives, as mandated in the CAA. There are two types of in-use testing programs: (1) Manufacturer-run testing, where EPA orders engine manufacturers to in-use test certain engine families at their expense; and (2) EPA-run testing where the agency locates and tests engines at its own expense.

(4)(b)(i)(6)(A) Manufacturer-run In-Use Testing

Of the industries covered by this ICR, this program only applies to HD and locomotives. Per 40 CFR Part 86, Subsection T, every year EPA issues in-use test orders to several HD manufacturers and engine families. A minimum of five engines/vehicles per engine family are tested. Once manufacturers have collected test data, HD manufacturers submit data (criteria pollutants only) via EV-CIS.

Manufacturers and remanufacturers must test, each year, a sample of used locomotives from one of their certified locomotive engine families previously chosen by EPA. If one manufacturer holds certificates for both freshly manufactured engine families and remanufactured engine families, EPA can request the manufacturer to test one engine family of each category [1033.405(a)(1)]. EPA may request a manufacturer to test more than one engine family if it has reason to believe that engines in an engine family do not comply with in-use standards. Engine families of less than ten locomotives per year do not need to participate in in-use testing [1033.405(a)(1)]. Within 90 days of completing their in-use testing program, locomotive manufacturers submit the date using EPA Form Number 5900-93.

(4)(b)(i)(6)(B) EPA-run In-Use Testing

EPA may also run in-use testing programs, at its own expense. For industries under an EPA-run In-use Testing Program, there is no specific requirement for manufacturers to conduct in-use testing, submit information or keep in-use records. However, EPA may perform in-use testing on any marine CI engine (Part 1042, Subpart E), evaporative family (Part 1060, Subpart E) or any HD GHG engine (Part 1036, Subpart E) or vehicle (Part 1037, Subpart E).

HD engine manufacturers may request that the EPA use a higher FEL for in-use testing, subject to the rules governing FEL changes (1036.625). This option is not available to HD vehicle manufacturers.

EPA-run in-use testing programs are conducted at the National Vehicle and Fuel Emissions Laboratory (NVFEL). Engines or vehicles obtained by EPA for in-use testing purposes are leased from businesses or other government entities which EPA locates through either: (1) potential fleet owners/lessees in registration lists; (2) engine manufacturer-supplied customer lists; and/or (3) existing contacts that have provided EPA with valuable information in the past.

EPA contracts out most of the work related to finding the necessary vehicles/engines. EPA staff directs a contractor to locate heavy-duty vehicles with specific engine families. The contractor then calls fleet facilities to locate vehicles that meet the criteria and specifications outlined by EPA staff. Once potential sources are identified and leased for EPA’s in-use testing program, EPA staff install a mobile emission measurement equipment. On-road testing is conducted with the contractor assistance onsite at NVFEL. Within a typical year, about 200 vehicles/engines from different industries are leased and tested. Testing for each one of those vehicles/engines lasts about 2 weeks (8 hours per day). The driving conditions and information gathered may vary depending on the issues relevant to the type of heavy-duty vehicle selected and tested. After testing, the emissions measurement equipment is removed and the vehicle is returned to the owner.

While EPA contacts fleet owners to locate vehicles/engines, in most cases there is no communication with the engine/equipment manufacturer unless a compliance issue is found. Since EPA compensates the fleet owners for the use of their vehicles/engines as any other customer would, the activities associated with this program are considered customary business practices.

(4)(b)(i)(7) Selective Enforcement Audits (SEAs)

During an SEA, EPA visits the facilities where a manufacturer’s testing is conducted. The primary purpose of a SEAs is to verify that the laboratory’s testing methods comply with EPA regulations. Only Nonroad CI, HD engine and HD vehicle manufacturers’ laboratories are subject to SEAs. Marine CI engine manufactures are not since they are subject to a robust PLT program.

EPA collects the information needed for SEAs in two stages: First, a limited number of manufacturers are asked to submit their production plans for a specified period of time, as described below. EPA uses this "pre-audit" information to efficiently determine which manufacturers and engine models to audit. After a manufacturer has been chosen, EPA issues a test order specifying which engine models and configurations will be tested. Testing is then performed on engines coming out of the assembly line under the observation of EPA staff. When all required testing is completed, manufacturers submit a report containing all testing results. This "audit" information is then used to determine compliance with applicable emission standards.

Per 89.505 (d), 86.1005-90(d), and 1068.450, EPA can request manufacturers to submit additional SEA information or keep records not specifically listed in this section. SEA data requirements can be found at Part 1068 Subpart E for nonroad CI engines and Part 86 Subpart K for HD Engines.

Upon EPA's request, engine manufacturers must submit the following information regarding engine production. This information is used by EPA as pre-audit data under the SEA Program to determine which engines will be audited.

● Projected U.S. sales data for each engine configuration and engine family

● Number of engines, by configuration and assembly plant, scheduled for production within the time period designated by EPA

● Number of engines, by configuration and assembly plant, storage facility or port facility, scheduled to be stored during the time period designated by EPA

● Number of engines, by configuration and assembly plant, produced during the designated period that are complete for introduction into commerce

Within 30 days after all tests ordered by EPA are completed, manufacturers must submit a report with the following information:

● Testing facilities' location and description

● Applicable standards or compliance levels against which the engines were tested

● Deterioration factors for the selected configurations

● Description of the engine and the method used to select its emission-related components.

For each test conducted:

● Test engine description

● Location where service accumulation was conducted and a description of the procedure

● Test information, raw results, which includes emission figures for all measured pollutants, for both valid and invalid test results

● A complete description of any modification, repair, preparation, maintenance and/or testing performed on the engine not previously reported. This must include the results of any emission measurements, regardless of the procedure or type of equipment

● If an engine was deleted from the test sequence by authorization of EPA, the reason to delete it

● Brake-specific fuel consumption values for all valid and invalid tests

● Any other information requested by EPA

● Statement of compliance and endorsement

● For nonroad CI engines, a report on each failed engine

● Request for re-testing of failed engines, if applicable

● For nonroad CI engines, an authorized representative of the company must sign the statement under Section 1068.450(c) to accompany reports.

Recordkeeping

Records must be kept for one year after all ordered tests have been completed. Records may be kept in any media, according to the manufacturer's procedures, provided that in every case all the information contained in the hard copy is kept. Note that EPA may review manufacturer records at any time.

General records: a description of all test equipment used, including the information submitted with the audit report described above.

Individual records for each audit:

● If a nonroad CI engine was shipped for testing, the date of shipping, the associated storage or port facility, and the date the engine arrived at the testing facility

● Date, time and location of each test

● Any records related to an audit that are not in the written report for nonroad CI engines

● Number of hours accumulated in each engine when testing began

● Names of all supervisory personnel involved

● Detail records of all repairs performed prior/after EPA's authorization

● Date engine was shipped and date it was received

● Complete record of all tests performed including worksheets and other documentation

● Brief description of any significant event that occurred during the audit

● For nonroad CI engines, a manufacturer must be able to provide projected or actual production for an engine family, which includes each assembly plant

● Copy of the trace for each test

● Description of the equipment in each test cell that can be used to perform SEA testing