FGIS 965 Scale Test Report (Hopper)

Reporting and Recordkeeping Requirements (US Grain Standards Act and Agricultural Marketing Act of 1946)

FGIS 965 1.21 (508).xlsx

Reporting and Recordkeeping Requirements - Private Sector

OMB: 0581-0309

⚠️ Notice: This form may be outdated. More recent filings and information on OMB 0581-0309 can be found here:

Document [xlsx]

Download: xlsx | pdf

Sample Form

Instructions

Contact and Distribution

Overview

FGIS 965Sample Form

Instructions

Contact and Distribution

Sheet 1: FGIS 965

| OMB Approved: 0581-0309 | |||||||||||

| U.S. DEPARTMENT OF AGRICULTURE | LAST DATE TESTED | TEST DATE | PAGE | OF | |||||||

| AGRICULTUAL MARKETING SERVICE | |||||||||||

| FEDERAL GRAIN INSPECTION SERVICE | |||||||||||

| FIELD MANAGEMENT DIVISION | MANUFACTURER | MODEL OF SCALE | SCALE CODE NO. | ||||||||

| SCALE TEST REPORT - GRAIN HOPPER | |||||||||||

| TESTING AGENCY (Inspector's Name, Address) | SCALE CAPACITY | MINIMUM DIVISION | SERIAL NO. | ||||||||

| SCALE TYPE | SCALE NO. | ||||||||||

| FIELD OFFICE LOCATION | |||||||||||

| Contact: | |||||||||||

| Fax Number: | |||||||||||

| SCALE OWNER | TYPE AND MFG. | NUMBER OF WEIGHTS | |||||||||

| SCALE LOCATION (ADDRESS) | LAST REVERIFICATION DATE | TOTAL WEIGHT | |||||||||

| TEST RESULTS | |||||||||||

| SENSITIVITY | DISCRIMINATION | ||||||||||

| ZERO | CAP. | ZERO | CAP. | ||||||||

| CORNER TEST | INCREASING LOAD TEST (CONT'D) | ||||||||||

| TEST | WEIGHT | ERROR | BALANCE | TEST | WEIGHT | ERROR | |||||

| BALANCE | WEIGHT | INDICATION | WTS. Lbs | ERROR | GRAIN | WEIGHTS | WEIGHTS | INDICATION | WTS lbs | ERROR | |

| Corner 1 | |||||||||||

| Corner 2 | |||||||||||

| Corner 3 | |||||||||||

| Corner 4 | |||||||||||

| INCREASING LOAD TEST | |||||||||||

| BAL. | TEST | WEIGHT | ERROR | ||||||||

| GRAIN | WTS. | WEIGHTS | INDICATION | WTS lbs | ERROR | ||||||

| ZERO BALANCE CHANGE DURING TEST: | lbs. | ||||||||||

| THE ERRORS IN THIS SCALE AS INDICATED ABOVE | |||||||||||

| WITHIN THE ACCURACY REQUIREMENTS PRESCRIBED BY THE FEDERAL GRAIN INSPECTION SERVICE | |||||||||||

| REPAIRS, ADJUSTMENTS, MODIFICATIONS OR RECOMMENDATIONS MADE AT THIS TIME: | |||||||||||

| Return completed form to the above Field Office. | |||||||||||

| NEXT TEST IN: | |||||||||||

| APPLICABLE TOLERANCE ( "x" one) | |||||||||||

| FGIS WITNESS (Signature) | |||||||||||

|

|

||||||||||

Sheet 2: Sample Form

|

|

Sheet 3: Instructions

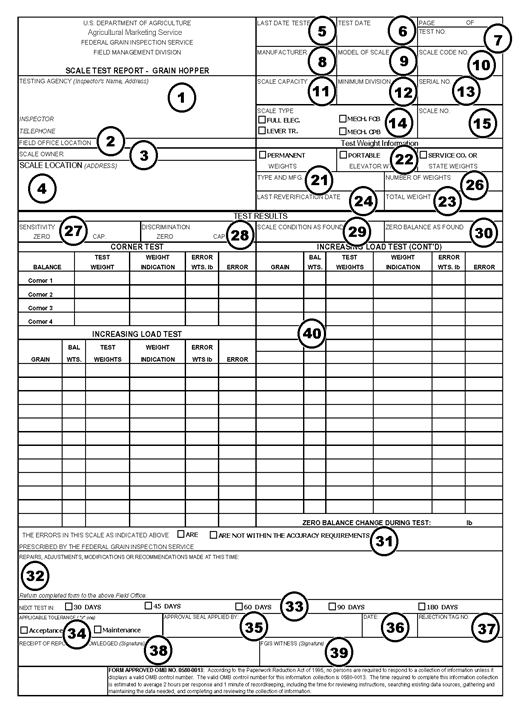

| Instructions for Completing FGIS-965 | |

| 1 | Testing Agency. The name of the organization, name of the person testing, address, and telephone number. |

| 2 | Field Office Location. The city and state of the field office which has jurisdiction for the scale being tested. |

| 3 | Scale Owner. Facility name and designation; i.e., Mid-South Grain, House A. |

| 4 | Scale Location. The street address of the elevator. |

| 5 | Last Date Tested. Date of the last test. |

| 6 | Test Date. The month, day, and year of the test. |

| 7 | Test No. Inspector’s assigned serial number, plus consecutive test number for the fiscal year. Cary Brown’s assigned serial (which is 1000), the first test of FY 2004, would be: "1001-04", the second would "1002-04", and so forth. In order of testing, regardless whether a hopper, vehicle, or railway track scale test. |

| 8 | Manufacturer. The name of the company, corporation, person, etc., who manufactured the indicating element. |

| 9 | Model of scale. The model name, number, or designation which has been assigned by the manufacturer. |

| 10 | Scale Code No. The code number of the scale which was assigned by the FGIS Policies and Procedures Branch for use in the ADP Scale Test Monitoring System. |

| 11 | Scale Capacity. The maximum gross load that can be accepted for official weight certification as determined by an official scale inspector. |

| 12 | Minimum Division. The value of the smallest unit that can be indicated on the primary indicating element during normal weighing. |

| 13 | Serial No. The nonrepetitive number which was assigned by the manufacturer and affixed to the indicating element or beam. |

| 14 | Scale Type. Check the appropriate box to indicate whether the scale is full electronic, levertronic, a full capacity beam (FCB) mechanical scale, or a counterpoise (CPB) mechanical scale. |

| 15 | Scale No. The number assigned to the scale by the owner which usually includes S and/ or R designations to differentiate between shipping and receiving. |

| 16 | Sectional Capacity. The maximum gross load that can be applied to any one section of the scale without causing structural deflections affecting the accuracy of the scale. |

| 17 | Platform Size. The length and width of the vehicle scale platform. |

| 18 | Scale Length. The length of the live track on a railroad track scale. |

| 19 | Load Cell Capacity. The manufacturer's rated capacity of one of the load cells in the scale system. |

| 20 | Sectional Test Load. The maximum amount of test standards applied to any one section of a railroad track or vehicle scale. |

| 21 | Type and Mfg. For vehicle and hopper scales indicate the type of test weights; i.e., fab, basket, cast, etc., and the manufacturer. For railroad track scales check the appropriate box. |

| 22 | Test Weight Owner. Indicate the test weight owner. |

| 23 | Total Weight. The total amount of the test weights combined. |

| 24 | Last Reverification Date. Indicate the month and year of the latest test weight reverification. |

| 25 | I.D. No. The identification of the test car. |

| 26 | Number of Weights. The total number of individual weights. |

| 27 | Sensitivity. The results of the sensitivity check in number of divisions at zero and at capacity. |

| 28 | Discrimination. The results of the discrimination check in number of divisions at ZERO and at CAPACITY. |

| 29 | Scale Condition as Found. Indicate the condition of the scale as found. (i.e., water in pit, dirty platform, etc.) |

| 30 | Zero Balance as Found. The weight indication on the primary indicating element with no load on the load receiving element at the time of starting the official inspection and test. |

| 31 | Results. Check appropriate box; /x/ ARE‑for scales that are within tolerance or have been adjusted to be within tolerance, /x/ ARE NOT‑for a scale that cannot be used for official weight certification because it cannot be adjusted or fixed and is consequently REJECTED. |

| 32 | Remarks. Indicate any repairs, adjustments, modifications, or recommendations. (i.e., scale serviced before test, load cell #2 replaced, A/D converter replaced.) |

| 33 | Next Test In. Check the appropriate box to indicate approximately when the next test is due. |

| 34 | Applicable Tolerance. ("X" one.) Indicate which tolerance is to be applied. |

| 35 | Approval Seal Applied. Indicate the name of the inspector who applied the FGIS Approved Label for Inspected Machinery. If the person is the same as the FGIS witness, just initial. |

| 36 | Date. Indicate the date of approval. |

| 37 | Rejection Tag No. Indicate the number of the rejection tag, if applicable. |

| 38 | Receipt of Report Acknowledged. Signature of the scale owner's representative. |

| 39 | FGIS Witness. FGIS or delegated official who observed the testing and approval of the scale. |

| 40 | Test Procedures. See test procedures for hopper scales in Chapter 3 of the FGIS Weighing Handbook. |

Sheet 4: Contact and Distribution

| Distribution of FGIS-965 | |

| FGIS 965 original and copies shall be distributed as follows: | |

| 1 | Original shall be retained in a separate file at the office (FGIS or State) to which the responsibility for the scale is assigned. The hard copy printed record of the test indications shall be attached to the original. |

| 2 | First Copy shall be given or sent to the owner/operator of the scale for their information and records. |

| 3 | Second Copy shall be sent to the FGIS, Policies and Procedures Branch by the FGIS scale specialist responsible for the scale. |

| 4 | Third Copy shall be sent to the FGIS field office, which is responsible for the area in which the scale is located. |

| 5 | Fourth Copy is an extra copy available for an interested party (e.g., State Weights and Measures supervisor or scale service company). |

| For questions concerning this form contact: | |

| Joseph Han | |

| Field Management Division | |

| Policy and Procedures Branch | |

| Email: [email protected] |

| File Type | application/vnd.openxmlformats-officedocument.spreadsheetml.sheet |

| File Modified | 0000-00-00 |

| File Created | 0000-00-00 |

© 2026 OMB.report | Privacy Policy