FGIS-904 Laboratory Scale Test

Reporting and Recordkeeping Requirements (US Grain Standards Act and Agricultural Marketing Act of 1946)

FGIS 904 1.21 (508).xlsx

Reporting and Recordkeeping Requirements - State, Local, Tribal

OMB: 0581-0309

⚠️ Notice: This form may be outdated. More recent filings and information on OMB 0581-0309 can be found here:

Document [xlsx]

Download: xlsx | pdf

Form Example

Instructions

Overview

FGIS-904Form Example

Instructions

Sheet 1: FGIS-904

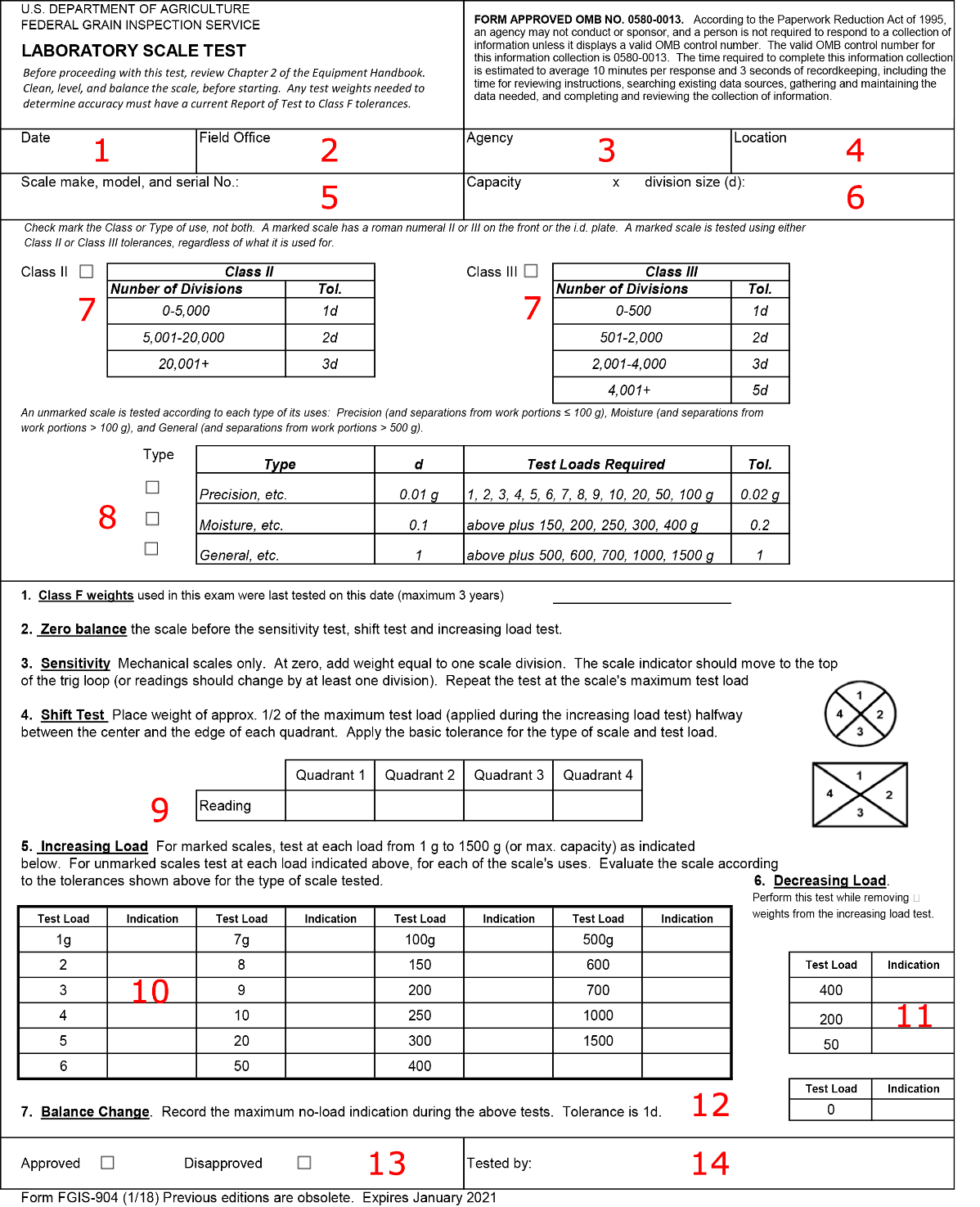

| U.S. DEPARTMENT OF AGRICULTURE |

|

||||||||||||

| FEDERAL GRAIN INSPECTION SERVICE | |||||||||||||

| LABORATORY SCALE TEST | |||||||||||||

| Date | Field Office | Agency | Location | ||||||||||

| Scale make, model, and serial No.: | Capacity x | division size (d): | |||||||||||

| Check mark the Class or Type of use, not both. A marked scale has a roman numeral II or III on the front or the i.d. plate. A marked scale is tested using either | |||||||||||||

| Class II or Class III tolerances, regardless of what it is used for. | |||||||||||||

| Class II | Class II | Class III | Class III | ||||||||||

| Nunber of Divisions | Tol. | Nunber of Divisions | Tol. | ||||||||||

| 0-5,000 | 1d | 0-500 | 1d | ||||||||||

| 5,001-20,000 | 2d | 501-2,000 | 2d | ||||||||||

| 20,001+ | 3d | 2,001-4,000 | 3d | ||||||||||

| 4,001+ | 5d | ||||||||||||

| An unmarked scale is tested according to each type of its uses: Precision (and separations from work portions ≤ 100 g), Moisture (and separations from | |||||||||||||

| work portions > 100 g), and General (and separations from work portions > 500 g). | |||||||||||||

| Type | Type | d | Test Loads Required | Tol. | |||||||||

| Precision, etc. | 0.01 g | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 20, 50, 100 g | 0.02 g | ||||||||||

| Moisture, etc. | 0.1 | above plus 150, 200, 250, 300, 400 g | 0.2 | ||||||||||

| General, etc. | 1 | above plus 500, 600, 700, 1000, 1500 g | 1 | ||||||||||

| 1. Class F weights used in this exam were last tested on this date (maximum 3 years) | |||||||||||||

| 2. Zero balance the scale before the sensitivity test, shift test and increasing load test. | |||||||||||||

| 3. Sensitivity Mechanical scales only. At zero, add weight equal to one scale division. The scale indicator should move to the top | |||||||||||||

| of the trig loop (or readings should change by at least one division). Repeat the test at the scale's maximum test load |

|

||||||||||||

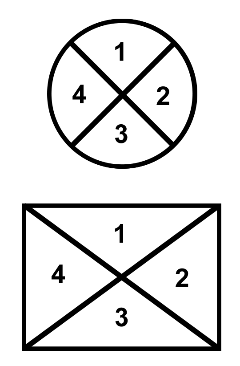

| 4. Shift Test Place weight of approx. 1/2 of the maximum test load (applied during the increasing load test) halfway | |||||||||||||

| between the center and the edge of each quadrant. Apply the basic tolerance for the type of scale and test load. | |||||||||||||

| Quadrant 1 | Quadrant 2 | Quadrant 3 | Quadrant 4 | ||||||||||

| Reading | |||||||||||||

| 5. Increasing Load For marked scales, test at each load from 1 g to 1500 g (or max. capacity) as indicated | |||||||||||||

| below. For unmarked scales test at each load indicated above, for each of the scale's uses. Evaluate the scale according | |||||||||||||

| to the tolerances shown above for the type of scale tested. | 6. Decreasing Load. | ||||||||||||

| Perform this test while removing |

|||||||||||||

| Test Load | Indication | Test Load | Indication | Test Load | Indication | Test Load | Indication | weights from the increasing load test. | |||||

| 1g | 7g | 100g | 500g | ||||||||||

| 2 | 8 | 150 | 600 | Test Load | Indication | ||||||||

| 3 | 9 | 200 | 700 | 400 | |||||||||

| 4 | 10 | 250 | 1000 | 200 | |||||||||

| 5 | 20 | 300 | 1500 | 50 | |||||||||

| 6 | 50 | 400 | |||||||||||

| Test Load | Indication | ||||||||||||

| 7. Balance Change. Record the maximum no-load indication during the above tests. Tolerance is 1d. | 0 | ||||||||||||

| Approved Disapproved | Tested by: | ||||||||||||

| Form FGIS-904 (1/21) Previous editions are obsolete. Expires XX-XX | |||||||||||||

Sheet 2: Form Example

|

||||||||

Sheet 3: Instructions

| Instructins for Completeing FGIS-904 |

| 1. Date the test was performed. |

| 2. Field office that performed or supervised the performance of the test. |

| 3. Agency that performed the test, when applicable. |

| 4. Location of the field office or agency that performed the test. |

| 5. Name of the manufacturer, model number, and scale serial number. |

| 6. Maximum rated scale capacity and the minimum scale division size. |

| 7. Indicate with a check mark if the scale is marked with an accuracy class, such as Class II. |

| 8. Indicate with one or more check marks the application of the unmarked scale; precision, |

| moisture, or general. |

| 9. Record scale indications from the shift test. |

| 10. Increasing Load Test - Test marked scales at each test load indicated up to 1,500 g or |

| capacity, whichever is less. Test unmarked scales at each test load shown in the table checked off in |

| item 8, above. |

| 11. Decreasing Load Test - Test marked scales at each load indicated, as appropriate. Test |

| unmarked scales at approximately ½ the maximum test load used in the increasing load test. |

| If the scale is mechanical, do not perform the test or complete this portion. |

| 12. Balance Change - Scale indication with zero load at completion of testing must be £ 1 division. |

| 13. Has the scale met all requirements of the pre-test inspection as well as each (all) of the |

| accuracy tests? |

| 14. Name of the person who performed this test. |

| Return Form To: |

| FGIS, Field Management Division |

| FAX Number (202) 720-1015 |

| Retain in official file. |

| Any Questions Call: Local FGIS field Office. |

| File Type | application/vnd.openxmlformats-officedocument.spreadsheetml.sheet |

| File Modified | 0000-00-00 |

| File Created | 0000-00-00 |

© 2026 OMB.report | Privacy Policy