FGIS-927 Testweight Checktest

Reporting and Recordkeeping Requirements (US Grain Standards Act and Agricultural Marketing Act of 1946)

FGIS 927 1.21 (508).xlsx

Reporting and Recordkeeping Requirements - State, Local, Tribal

OMB: 0581-0309

⚠️ Notice: This form may be outdated. More recent filings and information on OMB 0581-0309 can be found here:

Document [xlsx]

Download: xlsx | pdf

Example Form

Instructions

Overview

FGIS-927Example Form

Instructions

Sheet 1: FGIS-927

| UNITED STATES DEPARTMENT OF AGRICULTURE |

|

||||||||||||||

| FEDERAL GRAIN INSPECTION SERVICE | |||||||||||||||

| TESTWEIGHT CHECKTEST | |||||||||||||||

| NOTE: TEST UNIT OPERATOR FILL IN SHADED AREAS ONLY | |||||||||||||||

| DATE MAILED | FIELD OFFICE | AGENCY | LOCATION | ||||||||||||

| SCALE / BEAM TEST | |||||||||||||||

Before proceeding with test review Chapter 5 of the Equipment Handbook. Clean, level and balance the scale, filling apparatus, and kettle. Test weights must have a current Class F Report of Test. |

|||||||||||||||

| Scale Brand / Model / Serial No. / Date of Test | |||||||||||||||

| Scale Test for Electronic or Mechanical Grain Scales: This scale was tested in accordance with Chapter 2 of the Equipment Handbook and found to be within tolerance. | |||||||||||||||

| Beam Test: Complete test below. Tolerance is +/- 0.10 pound. | |||||||||||||||

| Load | Beam | Load | Beam | Load | Beam | Sensitivity | Beam Response | ||||||||

| g | lb | Reading |

Error | g | lb | Reading |

Error | g | lb | Reading |

Error | @ 60 lb/bu |

OK? |

||

| 0 | 0 | 142 | 10 | 850 | 60 | g | lb | YES | NO | ||||||

| 71 | 5 | 425 | 30 | 850+1 g | 60+1g | ||||||||||

| GRAIN TEST | |||||||||||||||

| Before the Grain Test, check alignment of the funnel and kettle. Record results to 0.00 pound for mechanical or electronic scales. For beams, the 0.1 pound graduations should be | |||||||||||||||

| estimated to ¼ graduations and recorded as 0.025, 0.050, 0.075, or 0.100 pounds. For each sample, strike the highest and lowest drops and average the remaining three results. | |||||||||||||||

| TEST UNIT Beam / Filler Brand & Serial No. | STANDARD UNIT Beam / Filler Brand & Serial No. | TEST SUMMARY | |||||||||||||

| Kettle Brand & Serial No. | Kettle Brand & Serial No. | ||||||||||||||

| Drop | Sample 1 | Sample 2 | Sample 3 | Drop | Sample 1 | Sample 2 | Sample 3 | Sample 1 | Sample 2 | Sample 3 | TOTAL | ||||

| 1 | 1 | TEST UNIT | 0.000 | 0.000 | 0.000 | 0.000 | |||||||||

| 2 | 2 | STD. UNIT | 0.000 | 0.000 | 0.000 | 0.000 | |||||||||

| 3 | 3 | DIFFERENCE | 0.000 | 0.000 | 0.000 | 0.000 | |||||||||

| 4 | 4 | Mean Deviation from Standard (Total Diff. 3) | |||||||||||||

| 5 | 5 | MDS Tolerance = 0.15 lb / bu | |||||||||||||

| AVERAGE | AVERAGE | OUT OF TOLERANCE | |||||||||||||

| Results By: | Date: | Results By: | Date: | Remarks | |||||||||||

| VOLUME TEST | |||||||||||||||

| Scale Used in Test / Brand / Model / Serial No. | Kettle Brand & Serial No. | Results By: / Date of Test: | |||||||||||||

| GROSS - TARE = NET WEIGHT (1,098.08 g at 68 °F) | OR Filled kettle ± 1.0 g of Standard counter weight. | ||||||||||||||

| Form FGIS-927 (01/21) Previous editions are obsolete. Expires XX-XX | |||||||||||||||

Sheet 2: Example Form

| UNITED STATES DEPARTMENT OF AGRICULTURE |

|

||||||||||||||

| FEDERAL GRAIN INSPECTION SERVICE | |||||||||||||||

| TESTWEIGHT CHECKTEST | |||||||||||||||

| NOTE: TEST UNIT OPERATOR FILL IN SHADED AREAS ONLY | |||||||||||||||

| DATE MAILED | FIELD OFFICE | AGENCY | LOCATION | ||||||||||||

| 1 | 2 | 3 | 4 | ||||||||||||

| SCALE / BEAM TEST | |||||||||||||||

Before proceeding with test review Chapter 5 of the Equipment Handbook. Clean, level and balance the scale, filling apparatus, and kettle. Test weights must have a current Class F Report of Test. |

|||||||||||||||

| Scale Brand / Model / Serial No. / Date of Test | |||||||||||||||

| 5a | |||||||||||||||

| Scale Test for Electronic or Mechanical Grain Scales: This scale was tested in accordance with Chapter 2 of the Equipment Handbook and found to be within tolerance. | |||||||||||||||

| Beam Test: Complete test below. Tolerance is +/- 0.10 pound. | |||||||||||||||

| Load | Beam | 5b | Load | Beam | Load | Beam | Sensitivity | Beam Response | |||||||

| g | lb | Reading |

Error | g | lb | Reading |

Error | g | lb | Reading |

Error | @ 60 lb/bu |

OK? |

||

| 0 | 0 | 142 | 10 | 850 | 60 | g | lb | YES | NO | ||||||

| 71 | 5 | 425 | 30 | 850+1 g | 60+1g | ||||||||||

| GRAIN TEST | |||||||||||||||

| Before the Grain Test, check alignment of the funnel and kettle. Record results to 0.00 pound for mechanical or electronic scales. For beams, the 0.1 pound graduations should be | |||||||||||||||

| estimated to ¼ graduations and recorded as 0.025, 0.050, 0.075, or 0.100 pounds. For each sample, strike the highest and lowest drops and average the remaining three results. | |||||||||||||||

| TEST UNIT Beam / Filler Brand & Serial No. | STANDARD UNIT Beam / Filler Brand & Serial No. | TEST SUMMARY | |||||||||||||

| 6a | 6d | ||||||||||||||

| Kettle Brand & Serial No. | Kettle Brand & Serial No. | ||||||||||||||

| Drop | Sample 1 | Sample 2 | Sample 3 | Drop | Sample 1 | Sample 2 | Sample 3 | Sample 1 | Sample 2 | Sample 3 | TOTAL | ||||

| 1 | 6b | 1 | 6e | TEST UNIT | 6c | 0.000 | 0.000 | 0.000 | |||||||

| 2 | 2 | STD. UNIT | 0.000 | 0.000 | 0.000 | 0.000 | |||||||||

| 3 | 3 | DIFFERENCE | #VALUE! | 0.000 | 0.000 | 0.000 | |||||||||

| 4 | 4 | Mean Deviation from Standard (Total Diff. 3) | |||||||||||||

| 5 | 5 | MDS Tolerance = 0.15 lb / bu | |||||||||||||

| AVERAGE | 6c | AVERAGE | OUT OF TOLERANCE | ||||||||||||

| Results By: | Date: | Results By: | Date: | Remarks | |||||||||||

| 7 | |||||||||||||||

| VOLUME TEST | |||||||||||||||

| Scale Used in Test / Brand / Model / Serial No. | Kettle Brand & Serial No. | Results By: / Date of Test: | |||||||||||||

| 8a | 8b | 8c | |||||||||||||

| GROSS - TARE = NET WEIGHT (1,098.08 g at 68 °F) | 8d | OR Filled kettle ± 1.0 g of Standard counter weight. | |||||||||||||

| Form FGIS-927 (01/21) Previous editions are obsolete. Expires January 2024 | |||||||||||||||

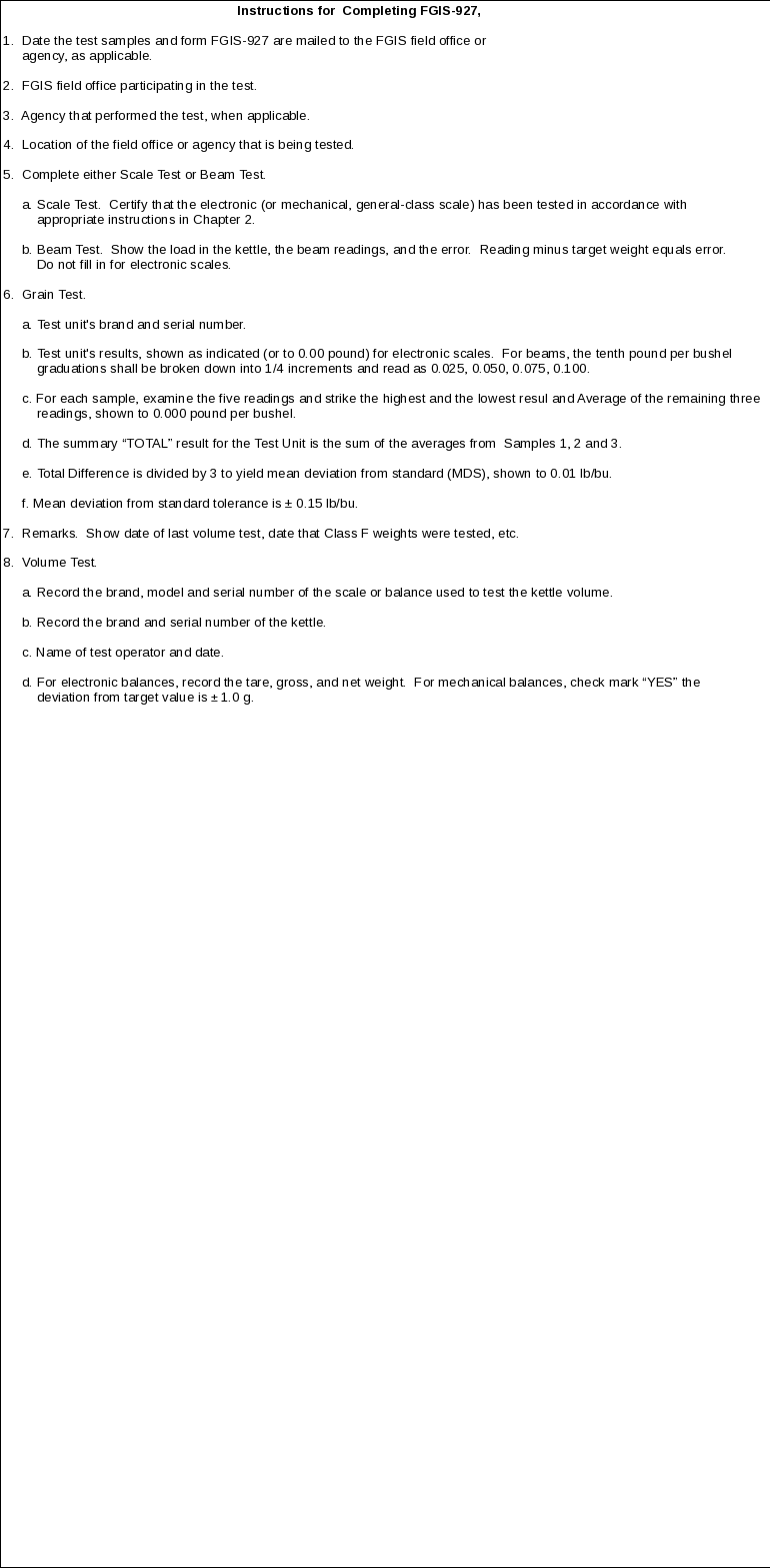

Sheet 3: Instructions

|

|||||||||||

| File Type | application/vnd.openxmlformats-officedocument.spreadsheetml.sheet |

| File Modified | 0000-00-00 |

| File Created | 0000-00-00 |

© 2026 OMB.report | Privacy Policy