FGIS 925 Rice Checktest Form

Reporting and Recordkeeping Requirements (US Grain Standards Act and Agricultural Marketing Act of 1946)

fgis-925.xls

Reporting and Recordkeeping Requirements - Private Sector

OMB: 0581-0309

⚠️ Notice: This form may be outdated. More recent filings and information on OMB 0581-0309 can be found here:

Document [xlsx]

Download: xlsx | pdf

Instructions

Overview

fgis-925Instructions

Sheet 1: fgis-925

| USDA-FGIS OMB No.: 0580-0013 |

|

|

||||||||||||||||||||||||||||||||||||||||||||||

| RICE CHECKTEST FORM | ||||||||||||||||||||||||||||||||||||||||||||||||

| DATE | FIELD OFFICE | LOCATION | TYPE OF RICE | |||||||||||||||||||||||||||||||||||||||||||||

| DOCKAGE TEST | TEST UNIT S/N | STANDARD S/N | ||||||||||||||||||||||||||||||||||||||||||||||

| MACHINE SETTING | SIEVES | MACHINE SETTING | SIEVES | |||||||||||||||||||||||||||||||||||||||||||||

| FEED | AIR | TOP | MIDDLE | BOTTOM | FEED | AIR | TOP | MIDDLE | BOTTOM | |||||||||||||||||||||||||||||||||||||||

| Sample | No. 1 | No. 2 | No. 3 | Avg. | No. 1 | No. 2 | No. 3 | Avg. | ||||||||||||||||||||||||||||||||||||||||

| Time thru Hopper | ||||||||||||||||||||||||||||||||||||||||||||||||

| Time Over Bottom Sieve | ||||||||||||||||||||||||||||||||||||||||||||||||

| Air Separation | g | g | g | g | g | g | g | g | ||||||||||||||||||||||||||||||||||||||||

| Over Top Sieve | g | g | g | g | g | g | g | g | ||||||||||||||||||||||||||||||||||||||||

| Over Middle Sieve | g | g | g | g | g | g | g | g | ||||||||||||||||||||||||||||||||||||||||

| Thru Bottom Sieve | g | g | g | g | g | g | g | g | ||||||||||||||||||||||||||||||||||||||||

| Total Dockage | % | % | % | % | % | % | % | % | ||||||||||||||||||||||||||||||||||||||||

| Test Unit Operator | Standard Operator | |||||||||||||||||||||||||||||||||||||||||||||||

| SHELLER TEST | TEST UNIT S/N | STANDARD S/N | ||||||||||||||||||||||||||||||||||||||||||||||

| Sample | No. 1 | No. 2 | No. 3 | Avg. | No. 1 | No. 2 | No. 3 | Avg. | ||||||||||||||||||||||||||||||||||||||||

| Weight to Sheller | ||||||||||||||||||||||||||||||||||||||||||||||||

| Time Thru Hopper | ||||||||||||||||||||||||||||||||||||||||||||||||

| Rice Hull Weight | g | g | g | g | g | g | g | g | ||||||||||||||||||||||||||||||||||||||||

| Brown Rice Weight | g | g | g | g | g | g | g | g | ||||||||||||||||||||||||||||||||||||||||

| Broken % (40 g portion) | g | g | g | g | g | g | g | g | ||||||||||||||||||||||||||||||||||||||||

| Paddy % (50 g portion) | % | % | % | % | % | % | % | % | ||||||||||||||||||||||||||||||||||||||||

| Test Unit Operator | Standard Operator | |||||||||||||||||||||||||||||||||||||||||||||||

| MILLER TEST | TEST UNIT S/N | STANDARD S/N | ||||||||||||||||||||||||||||||||||||||||||||||

| Sample | No. 1 | No. 2 | No. 3 | Avg. | No. 1 | No. 2 | No. 3 | Avg. | ||||||||||||||||||||||||||||||||||||||||

| Weight to Miller | g | g | g | g | g | g | g | g | ||||||||||||||||||||||||||||||||||||||||

| Milling Time | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||||||||||||||||||||||||||||||||||||||||

| Brushing Time | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||||||||||||||||||||||||||||||||||||||||

| Weight from Miller | g | g | g | g | g | g | g | g | ||||||||||||||||||||||||||||||||||||||||

| Whole Kernel % | % | % | % | % | % | % | % | % | ||||||||||||||||||||||||||||||||||||||||

| Total Rice % | % | % | % | % | % | % | % | % | ||||||||||||||||||||||||||||||||||||||||

| Test Unit Operator | Standard Operator | |||||||||||||||||||||||||||||||||||||||||||||||

| CHECKTEST SUMMARY | TOTAL DOCKAGE |

SHELLER BROKENS |

SHELLER PADDY |

WEIGHT TO MILLER |

WHOLE KERNELS |

TOTAL RICE |

||||||||||||||||||||||||||||||||||||||||||

| Test Unit Avg. | % | % | % | g | % | % | ||||||||||||||||||||||||||||||||||||||||||

| Standard Avg. | % | % | % | g | % | % | ||||||||||||||||||||||||||||||||||||||||||

| Deviation (MDS) | #VALUE! | % | #VALUE! | % | #VALUE! | % | #VALUE! | % | #VALUE! | % | #VALUE! | % | ||||||||||||||||||||||||||||||||||||

| Allowable Tolerance | ± 0.5% | ± 3.0% | ± 3.0% | ± 1.0% | Brown ± 1.5% | Brown ± 1.0% | ||||||||||||||||||||||||||||||||||||||||||

| Rough ± 2.0% | Rough ± 1.5% | |||||||||||||||||||||||||||||||||||||||||||||||

| Within Tolerance | #VALUE! | #VALUE! | #VALUE! | #VALUE! | #VALUE! | #VALUE! | ||||||||||||||||||||||||||||||||||||||||||

| Out of Tolerance | #VALUE! | #VALUE! | #VALUE! | #VALUE! | #VALUE! | #VALUE! | ||||||||||||||||||||||||||||||||||||||||||

| SUMMARIZED BY | DATE | |||||||||||||||||||||||||||||||||||||||||||||||

| REVIEWERS RECOMMEN- DATION | Servicable | |||||||||||||||||||||||||||||||||||||||||||||||

| Retest | ||||||||||||||||||||||||||||||||||||||||||||||||

| Repair | ||||||||||||||||||||||||||||||||||||||||||||||||

| REVIEWED BY | DATE | |||||||||||||||||||||||||||||||||||||||||||||||

| Form FGIS-925 (7-04) Previous edition may be used. Expires January 2015 | ||||||||||||||||||||||||||||||||||||||||||||||||

Sheet 2: Instructions

|

|||||||||||||

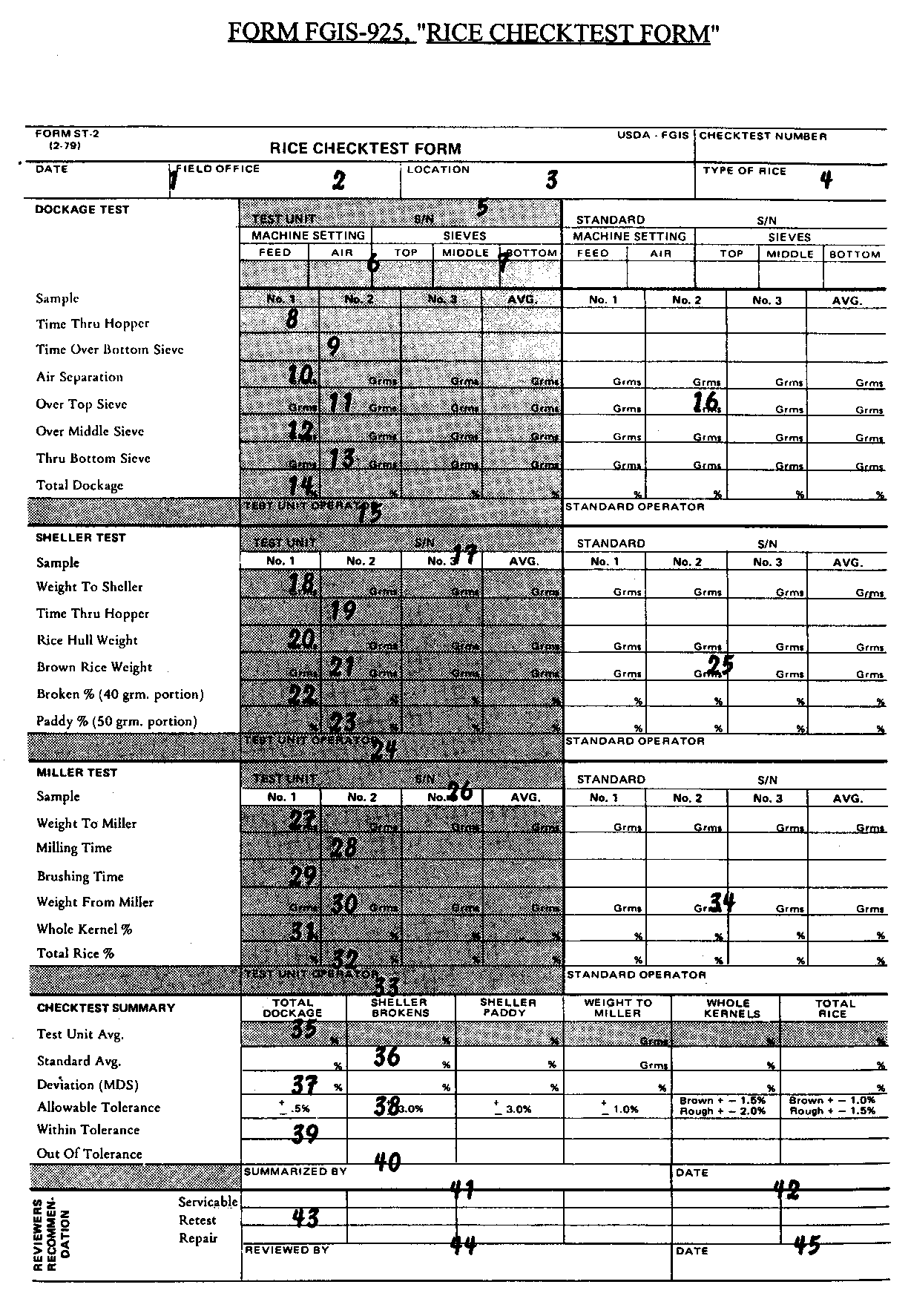

| INSTRUCTIONS FOR COMPLETING | |||||||||||||

| FORM FGIS-925, "RICE CHECKTEST FORM" | |||||||||||||

| l | Date the test samples and form FGIS-925 are mailed to the FGIS field office or agency, as applicable. | ||||||||||||

| 2 | FGIS field office or agency that performed the test, as applicable. | ||||||||||||

| 3 | Location of the field office or agency that performed the test, as applicable. | ||||||||||||

| 4 | LGRR for long grain or MGRR for medium grain. | ||||||||||||

| 5 | Test unit's serial number. | ||||||||||||

| 6 | For feed, show exact setting; for air, show exact setting. | ||||||||||||

| 7 | For long grain show, top - 28, middle - 25, bottom - 22; for medium grain show, top - 31, middle - --, bottom - 27. | ||||||||||||

| 8 | Time elapsed for each sample to clear the hopper, shown to the nearest whole second. | ||||||||||||

| 9 | Time elapsed for each sample to clear the bottom sieve, shown to the nearest whole second. | ||||||||||||

| 10 | Weight of the separation that is removed by air, shown to 0.01 gram. | ||||||||||||

| 11 | Weight of the separation that passes over the top sieve, shown to 0.01 gram. | ||||||||||||

| 12 | Weight of the separation that passes over the middle sieve, shown to 0.01 gram. | ||||||||||||

| 13 | Weight of the separation that passes through the bottom sieve, shown to 0.01 gram. | ||||||||||||

| 14 | Total dockage (air, over-the-top, over-the-middle, and | ||||||||||||

| through-the-bottom), shown to 0.01 percent. | |||||||||||||

| 15 | Name of the person who performed the test. | ||||||||||||

| 16 | Test information for the Standard dockage tester (see 8 - 15). | ||||||||||||

| 17 | Test unit's serial number. | ||||||||||||

| 18 | Weight of the sample prior to shelling, shown to the nearest gram. | ||||||||||||

| 19 | Time elapsed for each sample to clear the hopper, shown to the nearest whole second. | ||||||||||||

| 20 | Weight of the rice hulls removed from the sample, shown to the nearest gram. | ||||||||||||

| 21 | Weight of the rice sample (brown rice) after shelling, shown to the nearest gram. | ||||||||||||

| 22 | Percentage of broken kernels in a 40-gram portion of the brown rice, shown to 0.1 percent. | ||||||||||||

| 23 | Percentage of paddy kernels in a 50-gram portion of the brown rice, shown to 0.1 percent. | ||||||||||||

| 24 | Name of the person who performed the test. | ||||||||||||

| 25 | Test information for the Standard rice sheller (see 18 - 24). | ||||||||||||

| 26 | Test unit's serial number. | ||||||||||||

| 27 | Weight of the sample prior to milling, shown to the nearest gram. | ||||||||||||

| 28 | Time elapsed for sample to complete the milling run, shown to the nearest whole second. | ||||||||||||

| 29 | Time elapsed for sample to complete the brushing run, shown to the nearest whole second. | ||||||||||||

| 30 | Weight of the rice sample (milled rice) after milling, shown to the nearest gram. | ||||||||||||

| 31 | Percentage of whole kernels in the sample after milling, shown to 0.1 percent. | ||||||||||||

| 32 | Total percentage of rice in the sample after milling, shown to 0.1 percent. | ||||||||||||

| 33 | Name of the person who performed the test. | ||||||||||||

| 34 | Test information for the Standard rice miller (see 27 - 33). | ||||||||||||

| 35 | Test unit's average test results, shown to 0.1 percent. | ||||||||||||

| 36 | Standard unit's average test results, shown to 0.1 percent. | ||||||||||||

| 37 | Test unit's average minus Standard unit's average (see 35 and 36). Show any plus or minus deviation | ||||||||||||

| from the Standard, including the appropriate sign. | |||||||||||||

| 38 | Tolerances. | ||||||||||||

| 39 | Indicate the results that are within tolerance. | ||||||||||||

| 40 | Indicate the results that are not within tolerance. | ||||||||||||

| 41 | Name of the person who determined if the test results were in tolerance or not. | ||||||||||||

| 42 | Date the determination was made. | ||||||||||||

| 43 | Indicate the recommended action for each device tested; i.e., if the device was within tolerance and | ||||||||||||

| otherwise seems to be acceptable - mark “serviceable,” if the device fails the test or appears | |||||||||||||

| overly erratic - mark “retest,” if the device malfunctions - mark “repair.” | |||||||||||||

| 44 | If reviewed, name of the person who reviewed the accuracy of the final determination. | ||||||||||||

| 45 | Date of review. | ||||||||||||

| File Type | application/vnd.ms-excel |

| File Title | Rice Checktest Form |

| Subject | EqHB |

| Author | Phadyka |

| Last Modified By | ASGreenfield |

| File Modified | 2011-03-16 |

| File Created | 2003-05-06 |

© 2026 OMB.report | Privacy Policy